This document will continue to evolve as existing sections change and new information is added. All updates are logged below, with the most recent updates at the top.

| Date |

What’s Changed |

Notes |

|---|---|---|

| 03 APR 2017 |

Initial Document Creation |

This guide outlines the information you need to know about new or improved functionality in Oracle Transportation & Global Trade Management Cloud Release 6.4.2. Each section includes a brief description of the feature, the steps you need to take to enable or begin using the feature, any tips or considerations that you should keep in mind, and the resources available to help you.

We welcome your comments and suggestions to improve the content. Please send us your feedback at otm-doc_us@oracle.com. Please indicate you are inquiring or providing feedback regarding the Oracle Transportation & Global Trade Management What’s New in Release 6.4.2.

Some of the new Release 6.4.2 features are automatically available to users after the upgrade and some require action from the user, the company administrator, or Oracle.

The table below offers a quick view of the actions required to enable each of the Release 6.4.2 features.

Oracle Transportation and Global Trade Management

This section of the What’s New captures the transportation and trade improvements that benefit both Oracle Transportation Management (OTM) and Global Trade Management (GTM).

This feature provides you with a complete UI look and feel update that includes changes to almost every aspect of the user experience including updates to screen colors, font sizes, button color, icons and menus.

Some of the improvements provided as part of this feature include:

- Updated look and feel of OTM/GTM using a new theme; themesalta.css. The new theme changes the following:

- colors, font, size, and contrast

- various icons have been redesigned and modernized including:

- SmartLink

- Edit

- Delete

- View

- Search

- Calendar

- Volume

- The f, n, l, v icons have been replaced by more intuitive Search, New, and View icons:

- Search icon has replaced the f and l buttons.

- If the field is populated and you click the magnifying glass to run a search, a ‘begins with’ search is run and the finder results are presented.

- If you click search for an empty field, the finder criteria screen is presented allowing you to run an empty search, or to populate criteria and then run your search.

- New icon has replaced the n icon.

- View icon has replaced the v icon.

Steps to Enable

There are no steps necessary to enable this feature.

Key Resources

- See the OTM Branding Guide for details related to the new theme changes.

- See the Basic Data Entry for Refreshed User Interface help topic for more details.

This feature provides a Logistics home page that has undergone a complete refresh. The new look includes a Springboard (main menu) and the Unified Global Header. The redesigned home page provides you with a clean, intuitive and more modern starting point for navigating through OTM/GTM.

Steps to Enable

There are no steps necessary to enable this feature.

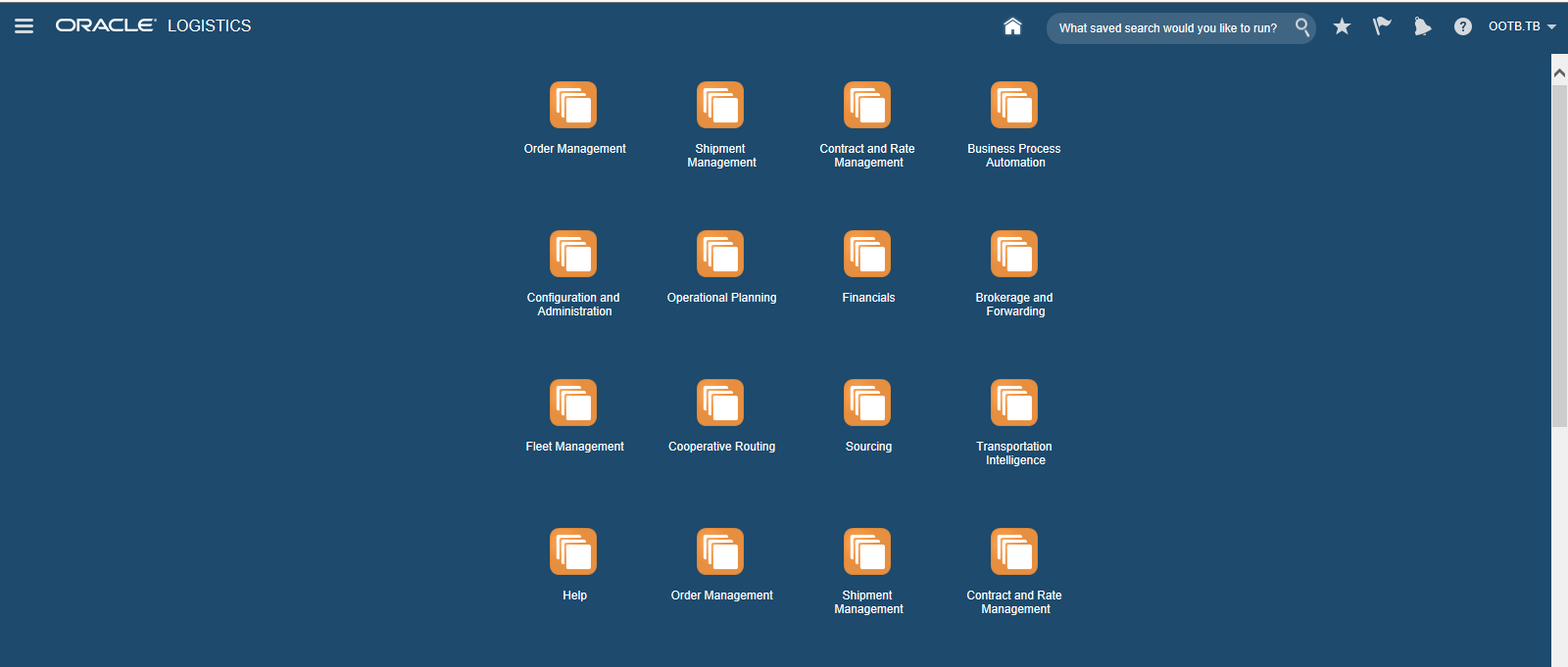

This feature provides you with a Unified Header that provides access to a set of core capabilities no matter where you are in the system.

![]()

The Unified Header provides access to the following capabilities:

- Navigator

- Provides you full menu access to all your OTM and GTM menu items.

- Home

- Returns you back to the Springboard.

- Global Search (Saved Queries)

- Enter the first three characters of an existing saved search (saved query) and you will be able to see a list of the saved search/query IDs that match the entered characters. You can click on a saved search/query link to see the query results.

- Favorites

- Allows you to view or manage your list of user favorites.

- Business Monitor

- Brings up your configured the business monitor.

- Notifications

- Provides access to the Message Center. If you have new unread messages, a red circle appears on the Notification icon. When the mouse pointer hovers over the icon, a tool tip displays the number new messages (# New Notifications). If you click the icon, you see a finder results page displaying all of your messages.

- Help

- Provides direct access to on-line Help.

- Settings and Actions

- Provides information on your user details, system details, troubleshooting, and administration. From the Settings and Actions pop-up, you can:

- Sign out of OTM/GTM

- View user details

- Change user roles

- View system details

- Configure explanations via the Tracking Mode and Tracking Level drop-down lists

- Turn on/off Tracking Diagnostics for a user's session

- Navigate to various troubleshooting and administrative areas of OTM/GTM

Steps to Enable

There are no steps necessary to enable this feature.

Tips and Considerations

In the message center - to control how often the number of new messages is refreshed, you can set the glog.ui.messageCenter.refresh property which sets the refresh rate of the Message Center (in seconds).

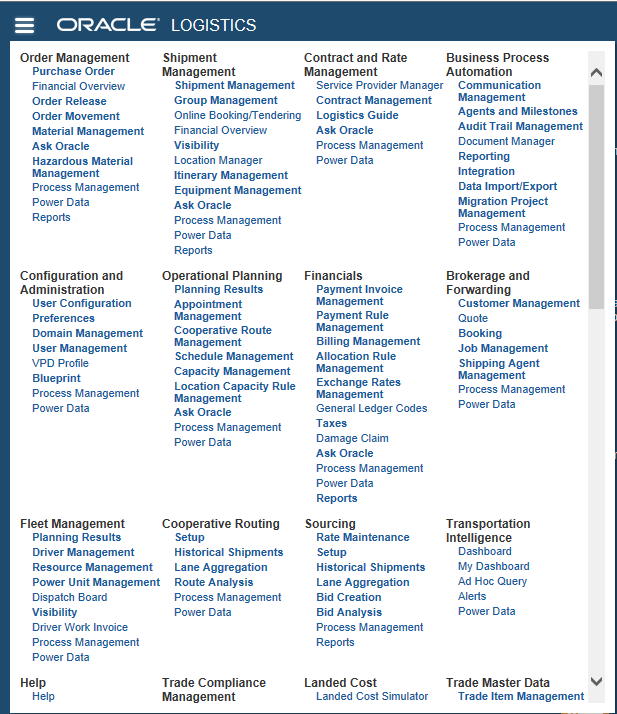

This feature provides two types of menu access - the Springboard and the Navigator. The Springboard provides access to a sub-set of the menu groups and links that you need quick and direct access to. The Navigator provides comprehensive access to all of your menu groups and links.

Steps to Enable

There are no steps necessary to enable this feature.

Tips and Considerations

For a single user, both the Springboard and the Navigator show the menus assigned to that user via user access. The Springboard and the Navigator cannot display different menus – however you can select which menu groups and links are displayed on the Springboard.

This feature provides a new icon based Springboard view that allows you to navigate quickly to and from those areas of the system that you use most often. By default, the Springboard displays all the components available in the system and adheres to the default multi-level menu structure provided in the system. The real benefit provided by the Springboard is the ability to configure the navigation options on the Springboard to allow you to go directly to the menu groups and links that you use most often.

The Springboard is ideally suited for:

- Providing you with visibility to your most frequently used areas of the system in one home view.

- Allowing you to go directly to the functionality required for completing a task and then return you directly to the home view without having to navigate through a multi-level menu structure.

The following options were added to the Menu Editor to support Springboard setup/configuration:

- The Show on Springboard option on the menu editor page allows you to make a group or link visible or hidden on the Springboard.

- The PUBLIC menus now include a variety of standard icons for menu groups and items. You can change these icons by selecting from one of the available Image IDs in the Menu editor. The icon only displays if the Show on Springboard option is selected.

- To preview a new icon in the menu editor, right-click on the menu item and select View Details.

- All menu items with the Show on Springboard option selected appear in the Menu editor with a yellow star on the folder.

- When migrating from a custom menu, you will see only two types of icons (an orange folder icon for groups and a blue document icon for menu links). To take advantage of the available icons that ship with OTM, you can create new menus based on the updated PUBLIC menus.

- To open a Springboard item in a new tab or window, right-click on the lowest level menu item (for example, Buy Shipments) and select "Open in new window". Depending on your browser settings, the page will either open in the new tab or a new window. This option is not available for some menu items. For those menu items you will see the message "New window not supported".

Springboard

Steps to Enable

- No steps are required to enable the Springboard, the Springboard is on by default. There are, however, several steps (below) required for configuring the Springboard so that it provides the desired benefits for the user.

- From within the Menu Editor, you can configure the groups, links and icons that will appear in the Springboard when you create/add a new group or link to your menu.

- When creating a new menu element (group or link), you can make the group or link visible on the Springboard by checking the Show on Springboard option – the default is for the new menu element to be visible on the Springboard. To hide the element from the Springboard, deselect the Show on Springboard option

- Springboard icon ordering and positioning: The order of the icons shown on the Springboard is determined by the order in which the visible groups or links appear in the menu. The first group or link that is visible in the menu will occupy the upper left position in the Springboard; the next visible object will occupy the position to the right of the first. Each row in the Springboard contains four icons so the fifth group or link that is visible in your menu will occupy the first position in the second row of the Springboard.

- You can select an icon to display on the Springboard by selecting the desired Image ID icon. Note that a default icon will be displayed if you do not select an icon.

Tips and Considerations

Existing menu elements are not editable – configuring the menu options to show on the Springboard requires the creating of new menu elements.

This feature provides a new menu based navigation tool for navigating across the entire application. The Navigator, which is part of the new Unified Header, replaces the original application menu that occupied the left side panel in previous versions of OTM/GTM.

One of the big benefits of the Navigator is that it is closed by default which frees up valuable screen real estate. With the original menu, the user was constantly burdened with the arduous task of showing and hiding the menu to recover screen real estate. The Navigator is only displayed when you click on the icon to display it. Once you make your navigation selection the Navigator closes automatically.

The Navigator – like the menu from previous versions of OTM/GTM - relies on the menu configuration provided in the menu manager/menu editor. This means menu configurations from previous versions of OTM/GTM will work with the Navigator.

The Navigator represents the different menu hierarchies as follows:

- Options shown in bold black font represent groups that contain groups e.g., Order Management, Shipment Management, and Trade Master Data.

- Options shown in bold blue font under a group of groups represent a group e.g., Order Release, Equipment Management, and Trade Item Management.

- Options shown in blue font are direct links to managers, Power Data, etc.

Navigator

Steps to Enable

No steps are required to enable the Navigator. The Navigator is on by default and will follow your current menu configuration.

Key Resources

- See the UI Refresh TOI.

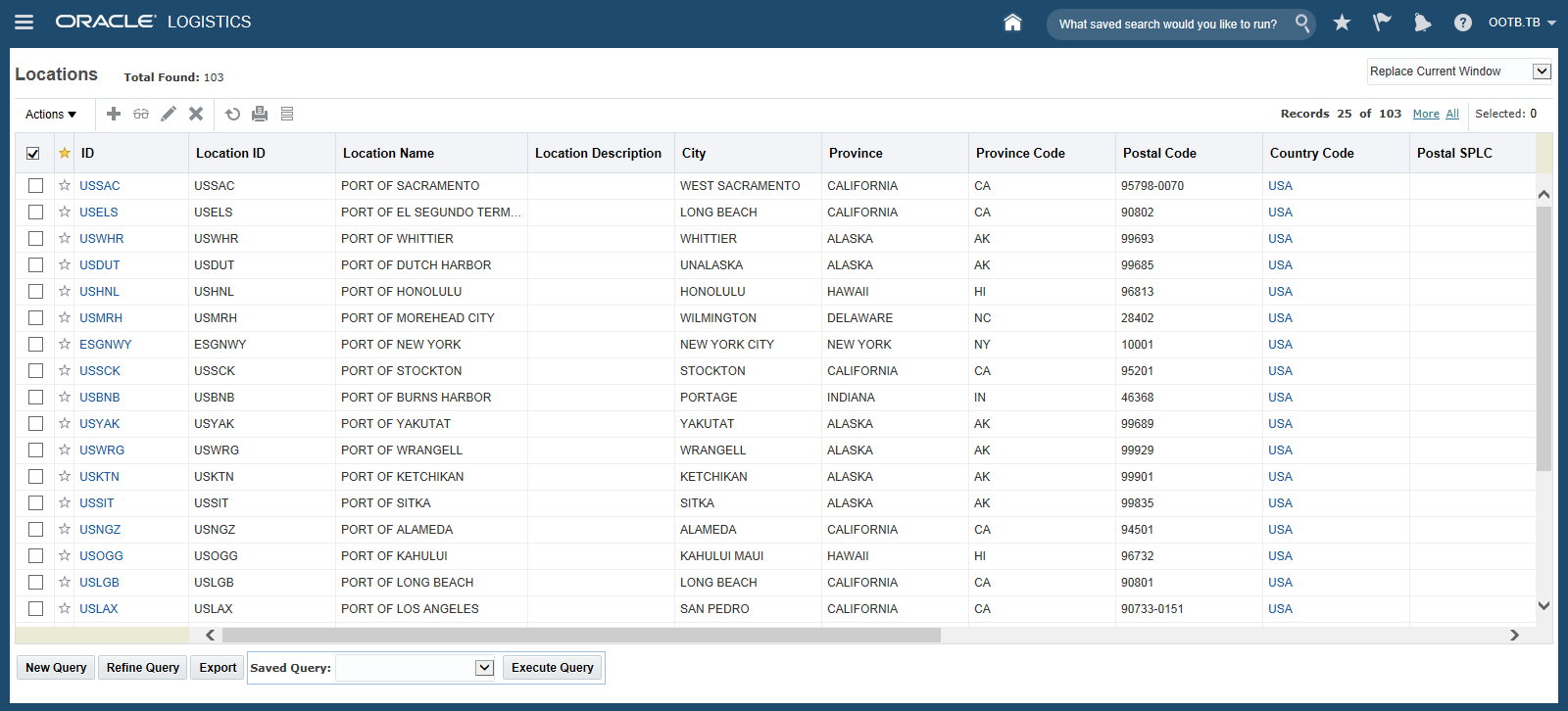

This feature provides a set of usability improvements for the finder result pages. The improvements will simplify your finder result navigation, sorting, and record counting. The changes also provide an updated location for the Actions menu related to the object as well as providing updated icons to represent the add, view, edit, and delete options you may wish to initiate against a select set of records.

Improvements:

- There is one results page instead of multiple pages. To view more records, click the More link. To view all available records, click the All link.

- The Record counter (X of Y records), lists the number of records that resulted from your search:

- X: the number of records that are displayed after a search and the number of additional records that will be displayed when you click the More link. You can configure this number using the glog.webserver.finder.page_size property.

- Y: the maximum number of records returned from a search. Click the All link to see all records returned for the query. You can configure this number using the glog.webserver.finder.limit property.

- Selected: displays the number of records selected.

- The Actions button has been moved to the tool bar just above the search results grid and has been replaced with an Actions drop-down list.

- The functional buttons (New, View, Edit, and Delete) have been moved to a tool bar just above the search results grid and replaced with icons.

Sample Refreshed Finder Results – Location Manager

Steps to Enable

There are no steps necessary to enable this feature.

This feature provides an improved and greatly simplified process for adding and removing Favorites. A new column titled Favorites has been added by default to all refreshed search results pages. The addition or removal of an entry from the Favorites list involves nothing more than marking or unmarking a record as a favorite.

You will find that most all pages have an Add to Favorites/Remove from Favorites star icon next to the object IDs. These pages include managers, power data, finder results, business object confirmation pages, etc. All you need to do is click the star icon to add or remove the object from the favorites list.

Steps to Enable

A yellow star indicates that a record is a favorite. A gray star indicates the record is not a favorite.

- Click the gray star to add that record as a user favorite – either in the edit screen or in the finder results screen.

- Click the yellow star to remove that record from user favorites – either in the edit screen or in the finder results screen

- From the User Favorites Page

- Click New Favorite.

- Choose a Table Name from the list.

- Enter an ID and click Save. The type of ID available changes depending upon which table name you selected. Repeat this step for additional records that you want as favorites.

- Click Save.

- Click Save Favorites on the User Preferences/Favorites page.

Key Resources

See the User Favorites, Search Results, Favorites from Unified Global Header, Screen Set Manager: General help topics for more details.

This feature provides a new PUBLIC menu, the ASK_ORACLE_MENU, that replaces the Ask Oracle tool bar. This new approach gathers all of the Ask Oracle capabilities together so that the process of granting access to these capabilities for you and your users is more standardized and greatly simplified.

The ASK_ORACLE_MENU menu contains all the existing Ask Oracle links:

- Rates

- Airports

- Ports

- Logistics Guide

- Logistics Guide Details

- Air Schedules

- Vessel Schedules

- Ground Schedules

- Currency

- Time Zones

- Container Optimization

- Distance/Time

- Routing Rules

- Restricted Party Screening

- Sanctioned Territory Screening

- Control Screening

- License Screening

Steps to Enable

By default, the new PUBLIC ASK_ORACLE_MENU is not part of your menu.

- Make a copy of the delivered PUBLIC ASK_ORACLE_MENU.

- Go to User Menu Layouts copy the PUBLIC ASK_ORACLE_MENU.

- Optionally, edit the copied version of the PUBLIC ASK_ORACLE_MENU in the Menu Editor so that it contains only the Ask Oracle links you are interested in.

- Go to Manage User Access and modify your assigned user menu so that it includes either the PUBLIC ASK_ORACLE_MENU or your copied version of the Ask Oracle Menu.

Reorganized Transmission XML Schema

Reorganized Transmission Schema

This feature provides a new transmission schema definition that consists of a set of smaller XSD schemas/files that contain a logical grouping of related objects and APIs.

Reorganizing the schema into a set of smaller files makes it easier for you to identify and load only the files you need to load for the interfaces you are developing. For example, if you are only working on Financial interfaces you will now only need to load the Financials schema versus loading the entire GLogXML schema.

Other benefits provided by the reorganized schema:

- You can take advantage of the capabilities provided by the newer cloud based integration tools like Oracle’s Integration Cloud Service (ICS).

- It is considerably easier for you to understand the messages and content of messages that can be sent to OTM/GTM.

- It is now considerably easier to understand and identify the interfaces that are inbound, outbound or both inbound and outbound interfaces

List of XSD Schema files

| Schema Name |

Description |

|---|---|

| Transmission.xsd |

Definitions for all Primary Documents. |

| TransmissionCommon.xsd |

Definitions for types shared across interfaces. |

| Transaction.xsd |

This is a convenient schema which imports all other Transaction definition schemas. |

| GTM.xsd |

Transaction interfaces for GTM application functionality. |

| LocationContact.xsd |

Transaction interfaces for Location and Contact business objects and other related common types used in other interfaces e.g. Involved Party. |

| ShipUnit.xsd |

Transaction interfaces for Ship Units common to Orders, Shipments etc. |

| Item.xsd |

Transaction interfaces for Item and Package related business objects. |

| Document.xsd |

Transaction interfaces for Document Content for Content Management Systems. |

| Configuration.xsd |

Low level transaction interfaces e.g. User management. |

| Shipment.xsd |

Transaction interfaces for Shipment related business objects including Planned, Actual and Tendered shipments. |

| Order.xsd |

Transaction interfaces for Purchase Orders and Order Release business objects. |

| Planning.xsd |

Transaction interfaces related to planning of Orders onto Shipments. |

| Finance.xsd |

Transaction interfaces related Invoices, Payments etc. |

| Rate.xsd |

Transaction interfaces related to Rating structures used for cost calculations. |

| Job.xsd |

Transaction interfaces for Brokerage and Forwarding. |

| GenericTransaction.xsd |

Miscellaneous transaction interfaces that can apply to many business object types e.g. for object status updates. |

Starting in version 6.4.2 a new namespace URL will be used to identify XML messages which are valid according to the new set of schema files listed in the preceding table.

The following table lists the namespace URLs and associated physical file name for each new schema defined in version 6.4.2:

| XSD Schema File |

Namespace |

| Transmission.xsd and all other non-GTM schemas |

http://xmlns.oracle.com/apps/otm/transmission/v6.4 |

| GTM.xsd |

http://xmlns.oracle.com/apps/gtm/transmission/v6.4 |

To support backward compatibility, the version 6.4.1 GLogXML and GLogXML-GTM schemas will continue to be distributed with version 6.4.2 but will only describe XML messages for versions up to but not including, version 6.4.2.

All future 6.4.x versions of OTM and GTM will use the namespace URL introduced in version 6.4.2, namely “http://xmlns.oracle.com/apps/otm/transmission/v6.4”.

Steps to Enable

- To take advantage of the new schema, the new namespace URL must be used to identify XML messages which are valid according to the new set of schema files.

- There are no changes required if you plan to only use message formats from prior versions and do not intended to take advantage of any of the new 6.4.2 capabilities.

Key Resources

- See the 6.4.2 Integration Guide.

Tips and Considerations

All message formats currently accepted by versions prior to version 6.4.2 will continue to be accepted in version 6.4.2.

The new 6.4.2 messages must be used to take advantage of new features introduced in 6.4.2.

Integration Cloud Service Logistics Adapter

Integration Cloud Service Logistics Adapter

This feature provides a new Logistics adapter (for OTM/GTM) that expands the portfolio of available adapters available with Oracle’s Platform as a Service (PaaS) Integration Cloud Service (ICS) offering. ICS is a powerful and intuitive cloud based integration tool that allows you to design and deploy cloud to cloud (and on-premise to cloud) integrations quickly and securely.

The Logistics adapter (for OTM/GTM) simplifies the ICS Connection to a specific Logistics Cloud (OTM/GTM) instance and exposes the OTM/GTM schema for integration flow mapping/development in an easy to use visual designer environment.

Steps to Enable

License and configure Integration Cloud Service (ICS) to work with your OTM/GTM instance.

Key Resources

For more information on Integration Cloud Service, refer to https://cloud.oracle.com/integration.

This feature provides the ability to edit the content of an existing workbench layout. In previous versions, the edit content option was limited to removing content. This feature allows you to make changes to the previously defined content including changes to the object type, the tab name, and the screen set used.

Steps to Enable

There are no steps necessary to enable this feature.

Removed Restriction on Number of Workbench Layouts

This feature provides the ability to create an unlimited number of workbench layouts. Previously, there was a limit on the number of workbench layouts you could define. This limitation has been removed.

Steps to Enable

There are no steps necessary to enable this feature.

This feature provides you with the ability to copy an existing workbench layout. All panels, regions, screen sets, saved searches, etc. are copied to the new layout.

Steps to Enable

- The Copy action requires that you provide a new name for the copied layout.

- Copy options:

- You have the option to provide a new description for the new layout.

- You also have the option to select a different logic configuration to use with the new layout.

The default is for the copy actions to retain the existing description and logic configuration.

User Access/Domain Grants for Workbench Layouts

This feature provides the ability to grant or restrict access to workbench layouts using domain grants and VPD. With this new capability you can control which workbench layouts are available to which users. You can also control the user’s ability to edit the workbench layouts and layout content that they have access to.

Steps to Enable

There are no steps necessary to enable this feature.

This feature provides you with the ability to perform inline editing of records without having to open and edit each record individually.

Depending on your configuration, you will see the icons related to the new inline editing capabilities. The new icons are for Inline Edit, Revert and Save. All fields that you have defined as editable on the Screen Set manager - Results tab can be modified using the inline editing capabilities directly on the search results section page.

- When you click the Inline Edit icon (

), if a field is editable, you see an editable field replace the read only version. If editable, many fields in the results grid are available for editing. You can edit multiple fields in the grid.

), if a field is editable, you see an editable field replace the read only version. If editable, many fields in the results grid are available for editing. You can edit multiple fields in the grid. - If you want to discard all changes, click the Revert icon (

). Note that the values cannot be reverted once the data has been saved.

). Note that the values cannot be reverted once the data has been saved. - Edit a value and click the Save icon (

) to save the value to the database. In the Save Results pop-up, a green check mark indicates successfully saved records and a red check mark indicates records that were not saved.

) to save the value to the database. In the Save Results pop-up, a green check mark indicates successfully saved records and a red check mark indicates records that were not saved.

Steps to Enable

For the object you wish to configure Inline editing for:

- Go to the Screen Set Manager - Results tab

- For each of the fields you would like to have available for Inline editing, click the More button. Then under Edit Options, select Editable Save.

- When all desired fields have been set to Editable, click Finish.

Tips and Considerations

You cannot edit the following fields using inline editing:

- Fields with links such as IDs

- Any fields that are primary keys

- Date fields

- Date/time fields

Although you can select the Editable option in the Screen Set Manager for these types of fields, they are not editable inline for the enhanced UI.

In addition, not all search results pages are compatible with the Inline Editing functionality.

Additional OTM Objects Supported in the Workbench

This feature provides an enhanced workbench that is now able to support most of OTM’s key objects. With these added objects, the workbench should become the first place you go to configure any work environment that involves relating multiple objects together in one view. For example: relating a shipment to the shipment stops and the orders on the shipment; relating a shipment to the related invoice and invoice lines.

New OTM objects available for adding as a table include:

- Appointment

- Bill

- Bulk Continuous Move Result

- Bulk Plan

- Capacity Limit

- Charter Voyage

- Consol

- Demurrage Transaction

- Driver Type

- Equipment

- Equipment Group

- Equipment Type

- Fleet Resource Assignment Results

- Invoice

- Invoice Line Item

- Item

- Itinerary

- Itinerary Leg

- Job

- Location

- Location Asset Inventory

- Network

- Network Detail

- Network Leg

- Order Base

- Order Release Ship Unit

- Order Release Ship Unit Line

- Power Unit

- Power Unit Type

- Rate Offering

- Rate Record

- Resource Schedule

- Resource Schedule Instance

- Sell Shipment

- Service Provider

- Shipment Equipment

- Shipment Group

- Shipment Ship Unit

- Shipment Ship Unit Line

- Tracking Events

- Voucher

- Work Assignment

- Work Invoice

New OTM objects available for adding to a map:

- Location

- Network

Steps to Enable

There are no steps necessary to enable this feature.

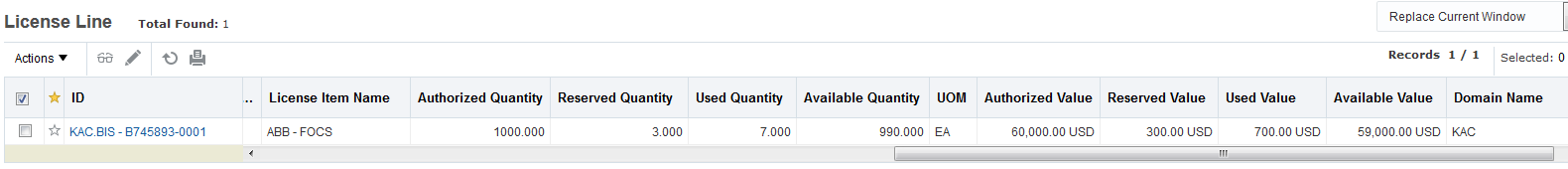

Additional GTM Objects Supported in the Workbench

This feature provides the ability to use the workbench capabilities with all of GTM’s key objects. With this feature, the workbench becomes the ideal place to configure any work environment that involves relating multiple objects together in one view.

- Document

- License

- License Line

- Party

- Product Classification Type

- Registration

- Restricted Party Screening Workbench

- Trade Item

- Trade Item Structure

- Trade Transaction

- Trade Transaction Line

- Declaration

- Declaration Line

- Declaration Message

Steps to Enable

There are no steps necessary to enable this feature.

Master-detail Saved Queries for Workbench - OTM

This feature provides a set of preconfigured PUBLIC saved queries that simplify the setup of basic master - detail table relationships in your OTM workbench designs.

The saved queries provided include:

- BILLS FOR SELL SHIPMENT

- BUY SHIPMENTS FOR ORDER RELEASE

- BUY SHIPMENTS FOR SELL SHIPMENT

- DETAILS FOR NETWORK

- EQUIPMENT FOR SHIPMENT

- INVOICES FOR SERVICE PROVIDER

- INVOICES FOR SHIPMENT

- LEGS FOR ITINERARY

- LEGS FOR NETWORK

- LINE ITEMS FOR INVOICE

- LINES FOR ORDER BASE

- LINES FOR S SHIP UNIT

- ORDER MOVEMENTS FOR ORDER RELEASE

- ORDER RELEASES FOR ORDER BASE

- ORDER RELEASES FOR SELL SHIPMENT

- ORDER RELEASES FOR SHIPMENT

- RATE OFFERINGS FOR SERVICE PROVIDER

- RATE RECORDS FOR RATE OFFERING

- SELL SHIPMENTS FOR BUY SHIPMENT

- SELL SHIPMENTS FOR ORDER RELEASE

- SHIP UNIT LINES FOR ORDER RELEASE

- SHIP UNITS FOR ORDER RELEASE

- SHIP UNITS FOR SHIPMENT

- SHIPMENTS FOR DRIVER

- SHIPMENTS FOR SHIPMENT GROUP

- STOPS FOR SHIPMENT

- TRACKING EVENTS FOR SHIPMENT

- VOUCHERS FOR INVOICE

- VOUCHERS FOR SERVICE PROVIDER

- WORK INVOICE FOR DRIVER

There are no steps necessary to enable this feature.

Master-detail Saved Queries for Workbench - GTM

This feature provides a set of preconfigured PUBLIC saved queries that simplify the setup of the basic master - detail table relationships in your GTM workbench designs.

The saved queries provided include:

- DECLARATION LINES FOR DECLARATION

- DECLARATION MESSAGES FOR DECLARATION

- DOCUMENTS FOR DECLARATION

- DOCUMENTS FOR TRADE ITEM

- DOCUMENTS FOR TRANSACTION

- ITEMS FOR LICENSE LINE

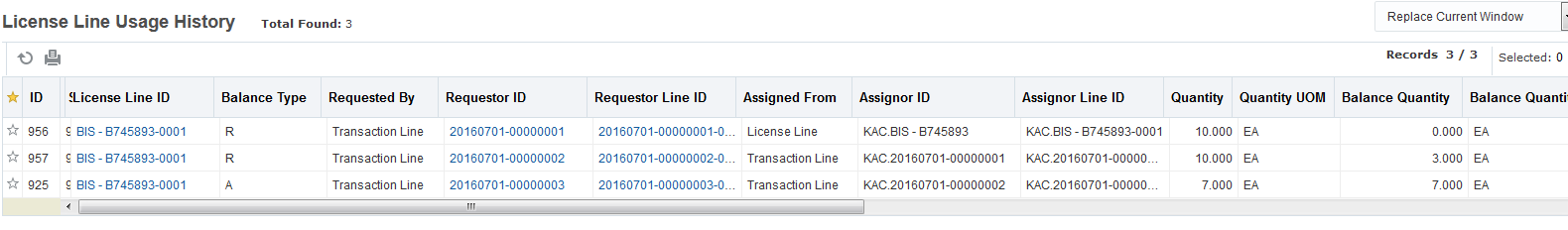

- LICENSE LINES FOR DECLARATION LINE

- LICENSE LINES FOR LICENSE

- LICENSE LINES FOR TRANSACTION LINE

- LICENSES FOR DECLARATION LINE

- LICENSES FOR LICENSE

- LICENSES FOR REGISTRATION

- LICENSES FOR TRANSACTION LINE

- PARTIES FOR DECLARATION

- PARTIES FOR DECLARATION LINE

- PARTIES FOR LICENSE

- PARTIES FOR REGISTRATION

- PARTIES FOR TRADE ITEM

- PARTIES FOR TRADE ITEM STRUCTURE

- PARTIES FOR TRANSACTION

- PARTIES FOR TRANSACTION LINE

- PRODUCT CLASSIFICATIONS FOR TRADE ITEM

- REGISTRATIONS FOR LICENSE

- REGISTRATIONS FOR PARTY

- REGISTRATIONS FOR REGISTRATION

- TRADE ITEMS FOR REGISTRATION

- TRANSACTION LINES FOR TRANSACTION

Steps to Enable

There are no steps necessary to enable this feature.

This feature improves the way that credential information is stored by now storing that information in Oracle Wallet. This change ensures that secure data, such as passwords, are placed into an encrypted store, and not visible to an end user.

The credentials supported by the Oracle Wallet include:

- Creating database connections

- Sending integrations to downstream systems

- Invoking external distance or rating engines

- Running reports on a BI Publisher server

- Storing documents in a Content Management System

Steps to Enable

There are no steps necessary to enable this feature.

Key Resources

For more information see The Security Guide, Migration Guide, and Administration Guide.

Oracle Transportation Management

Oracle Transportation Management (OTM) delivers robust transportation planning and execution capabilities to shippers and third party logistics providers. It integrates and streamlines transportation planning, execution, freight payment, and business process automation on a single application across all modes of transportation, from full truckload to complex multi-leg air, ocean, and rail shipments.

Oracle Transportation Management lowers transportation costs, improves customer service and asset utilization, and provides flexible, global fulfillment options.

Oracle Transportation Management (Base Product)

Order Management UIs and APIs to enter & manage orders in OTM Rate Management Rating engine Shipment Management Shipment creation (manual and agent based shipment creation) Booking & tendering (includes spot bids & broadcast tenders) Carrier communications Supply Chain Event Management Order & shipment events & visibility Business Process Automation Workflow agents & monitor profiles Document management Operational reporting.

Rate Inquiry Ports of Load - Ports of Discharge Constraint

This feature provides the ability to specify the Ports of Load and/or Ports of Discharge that should be considered when running your rate query. By specifying the Ports of Load and/or Ports of Discharge, the number of options considered can be greatly reduced. The reduction in options considered and the options returned simplifies your review process and has the added benefit of improving the run-time associated with generating the set of options.

Steps to Enable

There are no steps necessary to enable this feature.

This feature provides a set of automation agent usability enhancements.

- The description of your automation agent description can now be up to 4000 characters in length.

- The Direct SQL Update SQL length has been extended to 2000 characters.

- You can now track the user, time and optionally the reason for changes made to your automation agents. Now whenever you modify an agent, a record is added to the AGENT_CHANGE_LOG table. This table holds the user, time and optional reason for the change.

Steps to Enable

You can see an agent's change log by clicking on the Change Log button on the agent edit screen, or by opening the Change Log section of the agent view screen.

Tips and Considerations

The agent log is automatically removed if the agent is removed.

This feature provides a redesigned NMFC Class Table that now includes a new column called NMFC Class Code. This new column – and the seeded values – will now be transmitted to all External Rating Engines (e.g., SMC³’s RateWare® XL LTL Rating Engine) that depend on a properly formatted National Motor Freight Classification code for LTL freight rating.

Previous NMFC Class Codes values sent for rating:

50.0, 55.0, 60.0, 65.0, 70.0, 77.5, 85.0, 92.5, 100.0, 110.0, 125.0, 150.0, 175.0, 200.0, 250.0, 300.0, 400.0, 500.0

New NMFC Class Code values sent for rating:

50, 55, 60, 65, 70, 77.5, 85, 92.5, 100, 110, 125, 150, 175, 200, 250, 300, 400, 500

Steps to Enable

No steps are required to take advantage of the new NMFC Class Code field. The new mapping is handled as part of the migration.

Additional Details on Order Release Line Allocation Entity

This feature provides Order Release Line allocation details that now capture references to the shipment cost and/or invoice line item for better visibility and reporting purposes.

Steps to Enable

There are no steps necessary to enable this feature.

RateWare® XL Stop Alternation Support

This feature provides the ability to select the weight break to send to the RateWare® XL LTL Rating Engine to use for stop alternation. Selecting the Stop Alternation Break from the available drop-down list instructs RateWare® XL to not alternate to the next higher weight band if one is available.

Steps to Enable

- A new drop-down has been added to SMC Discount Section called Stop Alternation Break; the value selected here specifies the weight band where deficit rating should stop.

- If no value is specified in this drop-down, then the weight band which contains 99.99 (if any has been specified) is taken as the weight break where deficit rating should stop.

Tips and Considerations

The 99.99 default allows you to migrate from your old on-premise Rateware setup to the new RateWare® XL LTL Rating Engine option without requiring you to change your setup.

In the original Rateware on-premise application Stop Alternation was invoked when the weight break value of 99.99 was setup in OTM and sent to Rateware.

This feature adds the Shipment Group object to an extensive list of objects supported by OTM’s Tracking Event functionality. With this functionality, you can now create, view and manage tracking events related to your shipment groups.

For many implementations, the virtual Shipment Group is used to model real-world objects such as the ocean carrier booking request, the House Bill of Lading, the Shipper's Letter of Instruction, as well as the carrier manifest.

Steps to Enable

- You can add the tracking event information for shipment groups using the methods below:

- By using the web action on the shipment group Add Tracking Event.

- By directly entering the tracking event information related to the shipment group in the Shipment Group tab of the Tracking Event Manager.

- By sending in an inbound tracking event transmission with information related to shipment group.

- To link a tracking event to a shipment group, you can use the agent action Match Shipment Group. There are different matching methods provided for this:

- By Shipment Group

- By Shipment

- By Order Release

- By Order Release Line

- By Equipment

- Once the tracking event has been linked to a shipment group, you can use the following Data Type Associations to perform different actions on the objects related to the shipment group:

- TRACKING EVENT TO SHIPMENT GROUP

- TRACKING EVENT TO SHIP GROUP RELATED ORDERS

- TRACKING EVENT TO SHIP GROUP RELATED SHIPMENT

- Actions performed against related objects include:

- Recalculate Secondary Charge on shipment group

- Set External Status

- Recalculate Shipment

Secondary Charge Rule with Accessorial Code in Result

This feature provides the ability to assign an accessorial profile or a special service profile to the contracts for secondary charge section of your secondary charge rule definitions. When a secondary charge rule with either an accessorial profile or a special service profile is selected, OTM will copy the accessorials from the accessorial profile or the special services from the special service profile to the generated secondary charge shipments. OTM will then use the copied accessorial or specials services when the shipment is rated.

Steps to Enable

- Create the required accessorial profile and/or special service profile.

- Assign the accessorial profile and/or special service profile in the contracts for secondary charge section of your secondary charge rule.

- Save the entries in the contracts for secondary charge grid.

- Select finish to save the secondary charge rule.

- Execute the Build Secondary Charge Shipments action, if the selected secondary charge rule has an accessorial profile or a special service profile assigned, OTM will copy the accessorials and/or special services to the generated secondary charge shipments.

Tips and Considerations

In certain cases, services which need to be performed cannot be captured at the time of booking i.e. creating the order release; such services are discovered at the time of execution. For these additional services, the local office will have to setup a secondary charge rule with accessorial and special service profiles.

Ability to Configure Rates Based on Flex Fields

This feature provides the ability to rate shipments using flex field attributes related to different objects.

The flex field attributes related objects include the following objects:

- Shipment

- Equipment

- Ship Unit

- Shipment Stop

- Job

- Order Release

The Flex Field Rate Basis Items (RBIs) are grouped as:

- String

- Number

- Date

- Currency

Provided the following RBIs (Object and Type):

- <Object> Flex Field Qualifier

- Used as a conditional RBI to narrow down the flex field with which you want to work.

- <Object> <Type> Flex Field Value

- Used as conditional RBI, which returns the value of the String Flex Fields of the object used for rating.

- <Object> <Type> Field Value as Number

- Used as both conditional and charge RBI. This returns the double value of the string flex fields.

- <Object> <Type> Field Value as Weight

- Used as both conditional and charge RBI. This returns the double value of the string flex fields.

- <Object> <Type> Field Value as Volume

- Used as both conditional and charge RBI. This returns the double value of the string flex fields.

- <Object> <Type> Field Value as Volume

- Used as both conditional and charge RBI. This returns the double value of the string flex fields.

- <Object> <Type> Field Value as Duration

- Used as both conditional and charge RBI. This returns the double value of the string flex fields.

- <Object> <Type> Field Value as Date

- Used as both conditional and charge RBI. This returns the double value of the string flex fields.

- <Object> <Type> Field Value as Distance

- Used as both conditional and charge RBI. This returns the double value of the string flex fields.

For String type flex fields, all the above RBIs are applicable.

For Number type flex fields, except for Field Value as Number, all others are applicable.

For Date type flex fields, only Field Qualifier and Flex Field Value are applicable.

For Currency type flex fields, only the Flex Field Qualifier and Flex Field Value are applicable.

Steps to Enable

- Select the Flex Field to use as either a condition or charge on your rate record.

- Enter the desired criteria i.e., dates for date fields, days, hours, minutes for duration fields, numeric values for weight or volume fields, numeric values for text flex fields holding numeric values etc.

- Save the rate record.

Tips and Considerations

When you want to use a specific flex field as a condition or as a chargeable RBI, you must specify the flex field using a flex field qualifier RBI from the Basis drop-down list in the Conditions section. This will narrow down flex fields to a specific flex field you wanted to work. If the flex field qualifier is not specified and one of the flex field RBIs is used for rating, then the rating engine rates the shipment with all the flex fields corresponding to the object.

Spatial Integration to Support Postal Code Searches

This feature provides the ability to use Oracle Spatial for Postal Code to Postal Code level distance and time lookups. You can now provide just the Country Code and Postal Code for address validation and distance queries.

Previously Street Address, Country Code and Postal Code were mandatory for the address type POSTAL_CODE for the Oracle Spatial Engine to find distance, time, and geocode addresses. Now you can provide Country Code and Postal Code for address validation and distance queries.

Steps to Enable

There are no steps necessary to enable this feature.

PC*MILER Web Service Upgraded to Use Windows Communication Foundation (WCF)

This feature provides an upgraded PC*MILER Web Services integration using Windows Communication Foundation (WCF). The upgrade to WCS from Active Server Methods (Microsoft filename extension) ASMX was necessitated by Microsoft’s deprecation of ASMX.

The glog.ExternalDistanceEngine.PCMilerWS.useWCFEngine property has been added to the glog.appserver.properties file. This property tells OTM which web services implementation (WCF or ASMX) to use. The default is true, meaning use the WCF web services implementation.

New WCF credentials properties that have been provided include:

glog.ExternalDistanceEngine.PCMilerWS.AuthorizationKey

glog.ExternalDistanceEngine.PCMilerWS.useWCFEngine

Steps to Enable

There are no steps necessary to enable this feature.

PC*MILER Address Validation Match List Option

This feature provides the ability to configure your PC*MILER Web Services external distance engine to return a list of possible matches versus just receiving one match option when you run the Address Validation action using PC*MILER Web Services.

Steps to Enable

- Create a new External Distance entry by copying one of the existing PC*Miler web service External Distance entries.

- Enter a new External Distance ID

- Add a new parameter entry in the parameter grid.

- The parameter should be "GEOLIST_PROPERTY"

- The value should be "Yes"

- The country code should be "*".

- Click "Save" to save the parameter entry

- Click "Finished" to save the New External Distance Engine.

- The newly created External Distance Engine will be available for use for Validating Location Address. The new parameter provides a list of matched responses versus a single response.

PC*MILER Version Provided in Web Service Call

This feature provides the ability to specify the PC*MILER data version to use in the PC*MILER Web Service call. If no version is specified, the latest version is used by default.

Steps to Enable

- When configuring the PC*MILER Web Service to be used as either an external distance engine or external service engine, you can now specify the version to use by adding a parameter called DATA_VERSION. The value provided for this parameter should be the version which you want to use.

- You can also configure this at the application level with the property "glog.ExternalDistanceEngine.PCMilerWS.DataVersion". The value should be the version.

Tips and Considerations

If no version is specified, the latest version is used by default.

PC*MILER Web Services Staged External Service Engine Configurations

This feature provides a set of default external service engine (ESE) configurations to use with PC*MILER Web Service.

Default external services provided include:

- Lat/Long to Lat/Long (Practical)

- Address to Address (Practical)

- Postal to Postal (Default, Practical and Shortest)

- City to City (Default, Practical and Shortest)

Steps to Enable

There are no steps necessary to enable this feature.

This feature extends OTM’s PC*MILER|Rail integration options to include PC*MILER’s new PC*MILER|Rail Web Services offering. The new Web Service offering provides all the benefits of the on-premise version including: rail routing, distance calculation, but without the traditional on-premise management and costs.

Steps to Enable

- Obtain a license for PC*MILER|Rail. A license is required to use the PC*MILER|Rail Web Services offering.

- Contact an Enterprise Solutions Account Executive at 800.377.6453 or email sales@alk.com for more information.

- Set up authorization credentials. Once you have the necessary authorization credentials from PC*MILER, set the ExternalDistanceEngine properties in the glog.properties file. For PC*MILER RAIL Web Services, the web services authentication credentials are handled through the properties below:

- glog.ExternalDistanceEngine.PCMilerRailWS.AuthorizationKey

- glog.ExternalDistanceEngine.PCMilerRailWS.WbserviceWSDLUrl

- Configure a new Rate Distance for PC*MILER|Rail:

- Create and configure a new External Distance Engine where the javaclass 'glog.business.rate.ratedistance.external.PCMilerRailEngineWS' and the other required parameters like 'ROUTE_TYPE', 'SOURCE_ADDRESS_TYPE', DEST_ADDRESS_TYPE' are provided

- You can use the pre-seeded External Distance ID “PCMILER_RAIL_PRACTICAL_WS”

- Assign the Rate Distance to a Rate Offering.

or

Key Resources

- For additional information http://www.pcmiler.com/Media/pdfs/PCM29-FeatureSheet_Rail22.pdf

Generate Excel Reports Using Excel Format Template

This feature provides you with four additional Excel format options that you can use to generate reports. The set of available Excel formats now include: .html, .mhtml, .xlsx, and .xls.

You now have the following format options:

- Excel (.html) – select for reports with RTF format template. The generated output is html, which is enhanced with the .xls extension.

- Excel (.mhtml) – select for reports with RTF format template. The generated output is mhtml, which is enhanced with the .xls extension.

- Excel (.xlsx) – select for reports with RTF format template. This file will be with the .xlsx extension. This format provides binary content unlike the above two.

- Excel (.xls) – select for reports with Excel format template. This file will be with .xls extension. This format also provides binary content.

Steps to Enable

There are no steps necessary to enable this feature.

Charge Basis Added to Rate Cost View Screen

This feature enables you to view both the details of the rate cost lines and the details of the rate unit break profile when you view a rate record. Links to the details are found in the rate cost section of the rate record view page.

Steps to Enable

There are no steps necessary to enable this feature.

Provide Lat_Long Cache for Logic Configuration Rate Service ID

This feature provides the ability to cache latitude longitude based distance lookups provided from an external distance engine (EDE) and then use those cached distances for the calculations done inside of bulk planning. Using the cached distance setup inside of bulk planning’s multistop logic can improve solution quality without a significant increase in run-time.

Steps to Enable

- For the external distance engine providing distance based on latitude and longitude, the source and destination address type values should be set to “LAT_LONG”.

- The Cache Control Type should be set to ‘Cache by Address Lookup and Save'.

- To use the cache distances in planning the MULTISTOP RATE DISTANCE ID in the Multistop Logic Config should be set to point to the Rate Distance ID of the rate distance setup using the cached distance from the External Distance Engine.

Certify EBS Accounts Payable Integration Via SOA 12c

This feature provides an updated OTM - EBS Accounts Payable integration that is now supported with Oracle SOA 12c.

Steps to Enable

There are no steps necessary to enable this feature.

Sequencing Factor for Accessorial Rating

This feature enables you to control the sequence in which accessorials are costed by rating engine. Previously, accessorials were rated in alphabetical order based on the object where the requirement for the accessorial originated, i.e. shipment accessorials first, then ship unit, then location, then order base, then order base ship unit, then item and finally the global accessorials. With this enhancement OTM consolidates all of the identified accessorials across all the objects and then sequences them for rating using the sequencing factor values provided on the accessorials.

Steps to Enable

- To explicitly control the sequencing of the accessorials in rating, you must review your list of accessorials and determine the desired sequencing across all of your accessorials.

- For each accessorial, enter the appropriate Sequencing Factor. The Sequencing Factor value is used to control the order in which accessorials are rated.

- For example, to calculate Out of Route Miles charges first and then a Fuel Surcharge, and Discount; enter the sequencing factor value as 1 for the Out of Route Miles charges, 2 for Fuel Surcharge, and 3 for Discount.

Agent Action to Copy Flex Fields Between Objects

This agent action allows you to copy flex field attributes based on the associated objects for which the agent is triggered. If there are multiple related objects, the flex fields are copied to each one.

This agent action is available on the following agent types:

- CLAIM

- CONSOL

- GTM TRANSACTION

- GTM TRANSACTION LINE

- INVOICE

- ITEM

- JOB

- LOCATION

- ORDER BASE

- ORDER BASE LINE

- ORDER BASE SHIP UNIT

- ORDER MOVEMENT

- ORDER RELEASE

- ORDER RELEASE LINE

- ROUTE INSTANCE

- ROUTE INSTANCE LEG

- SELL SIDE SHIPMENT

- SHIPMENT

- SHIPMENT GROUP

- TRACKING EVENT

- VOUCHER

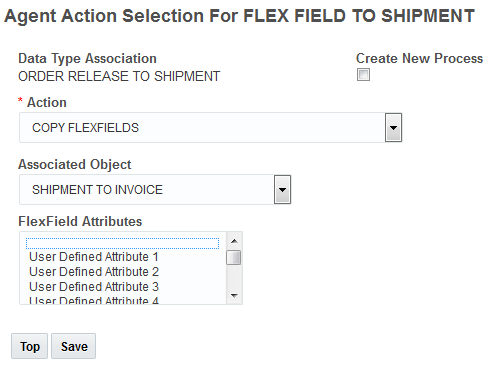

Agent Action for COPY FLEXFIELDS

Steps to Enable

- Create an automated agent for one of the agent types that support this agent action.

- Select a data type association (DTA) where the COPY FLEXFIELDS agent action is supported.

- Select the COPY FLEXFIELDS agent action.

- Select the related target object to which flex fields are copied by selecting the appropriate Associated Object.

- For the FlexField Attributes, select one or multiple flex field attributes which you would like to have copied to the associated object.

- If no flex field attributes are selected, all the attributes for the flex fields are copied.

- Save the Agent Action Selection.

- Click Finished to save the defined agent.

Tips and Considerations

If the selected flex field attributes are not present in either of the associated objects, the agent action will fail.

This feature provides a new agent action NOTIFY CONTACT that can be used to notify a contact in case any agent for Shipment Ship Unit and Shipment Ship Unit Line fails.

- Create an automated agent for Shipment Ship Unit or Shipment Ship Unit Line

- Action: Select the NOTIFY CONTACT agent action.

- Contact : Select the contact to notify.

- Communication Method: Select the method for contacting the specified contact.

- Subject: Select the subject line for the communication.

- Stylesheet Profile: Select the stylesheet profile for the message.

- Save the Agent Action Selection.

- Save the defined agent by clicking Finished .

Rate Basis Item for Shipment Total Rest Time

This feature provides a new rate basis item (RBI) that allows you to establish a time based rate that is based on a shipment’s total rest time. This Shipment Total Rest Time RBI allows you to enter a rate and calculate a cost for just the rest time portion of a shipment’s time related activities.

The total rest time for a shipment is calculated by accumulating the information from all the stops. This includes rest time from all the Hour of Service (HOS) rules which includes rest breaks, lunch hours, and overnight layovers between stops.

Steps to Enable

- Create a new rate record and add a new rate cost.

- Under the charge section, select the Basis Shipment Total Rest Time.

- Enter the rate.

- Enter the per unit days, hours, minutes.

- Save the rate cost entry.

- Save the rate record by clicking Finished.

Rate Basis Items for External Rating Engine

This feature allows you to send additional elements to an external rating engine 1) SHIPMENT.ITINERARY 2) SHIPMENT.RATE_RECORD 3) SHIPMENT.RATE_OFFERING to support a very unique external rating requirement related to multi-leg itineraries.

Steps to Enable

There are no steps necessary to enable this feature.

Tips and Considerations

These Rate Basis Items (RBIs) SHIPMENT.ITINERARY , SHIPMENT.RATE_RECORD , SHIPMENT.RATE_OFFERING are not part of OTM’s internal rating engine logic and are only provided for a unique external rating scenario.

Rate Basis Items for Order Ship Unit Line Length, Weight and Height

This feature provides three new Ship Unit Line level Rate Basis Items (RBIs) that can be used to support dimension rating requirements with the generic web service rating engine. The added RBIs are: Ship Unit Line Length, Ship Unit Line Width, and Ship Unit Line Height.

Steps to Enable

- Create a new rate record and add a new rate cost

- Under the charge section, one of the new RBIs as the Basis.

- For Amoun,t enter the rate for the selected Basis

- Enter the per unit amount and select the unit of measure

- Save the rate cost entry

- Save the rate record by hitting Finished

SQL Servlet Show Execution Plan

This feature provides an easy to use check box “Show Execution Plan” that can be checked when you provide a SQL statement. When you select this check box, you will be able to view the execution plan chosen by the Oracle optimizer for executing the query. The execution plan information can be extremely useful for troubleshooting a poorly performing query.

Steps to Enable

- A new check box called "Show Execution Plan" has been provided to show the execution plan.

- When you provide a SQL statement and select the “Show Execution Plan” check box, you will be able to view the execution plan chosen by the Oracle optimizer for executing the query.

This feature provides the ability to upload, modify, and delete documents using SharePoint 2013 as a content management system.

Steps to Enable

There are no steps necessary to enable this feature.

Cloud Document Service Integration

This feature provides the ability to use Oracle’s Platform as a Service (PaaS) document management offering Oracle Document Cloud (ODC) to upload, modify, and delete documents.

Oracle Documents Cloud Service is an enterprise-level collaboration platform that connects people and information. With Oracle Documents Cloud Service, you can use a web browser, your tablet, or your phone to access your files, wherever you are, and share files with other people.

Steps to Enable

You can configure a content management system with URL, username, and password to connect to the Oracle Document Cloud server. After authentication credentials are verified, you can perform, upload, edit, and delete operations for documents into the Oracle Document cloud server from OTM.

Key Resources

For more information about Oracle Document Cloud see https://cloud.oracle.com/en_US/documents

Rate Factor Logic Re-write in Java

This feature provides a completely re-architected and more efficient rate factor processing logic.

Some of the improvements provided by this re-architected solution include:

- The new rate factor logic only processes the rate factors when they are needed.

- The need for the generation of rate factors is now based on the start date of the shipment being considered and the effective and expiration dates of your rate factors.

- Previously, rate factors were processed and the values were stored in the database without any reference to the demand for the rate factor data.

Steps to Enable

There are no steps necessary to enable this feature.

Online Booking and Tendering Screens Additional Shipment Attributes Available

This feature allows you to now configure your online booking and tendering screens to display many more shipment attributes directly on your booking and tender screens. Additionally, the user-defined image path icons can now be configured.

Steps to Enable

- Copy the public Manager Layout for the online booking and tendering screen

- Modify the copied version of the online booking and tendering manager layout adding and modifying to layout to include the desired changes

- Save the modified layout

- Add the modified layout to the appropriate menus

Online Booking and Tendering Screens Actions for Reports and Documents

You can now configure your online booking and tendering screens to:

- Display actions for shipment reports

- View attached documents.

Steps to Enable

There are no steps necessary to enable this feature.

Online Booking/Tendering Screen Improved Performance Properties

This feature provides a set of configuration capabilities that can be used to improve the editing and viewing performance of the Online Booking/Tendering UI. You can now exclude portions of the XML to improve the editing/viewing performance experience in the Online Booking/Tender screen. You can also configure a set of UI performance properties to improve the performance and the viewing experience when a large number of related objects (order release, order release line, ship unit) need to be loaded into the Online Booking/Tendering UI.

Steps to Enable

- Online Booking/Tendering Profile ID is an Out XML Profile ID that helps to exclude specific portions of outbound tender offer XML while you edit/view a tender transaction.

- Online Booking/Tendering Profile ID is considered only when the glog.tender.UseOBTProfileID property is TRUE. The default is FALSE.

- The Default Online Booking/Tendering Profile ID is GLOG_OBT_XML.

- Note: To use Online Booking/Tendering Profile ID, you must select MAX as Default Mode on Out XML Profiles.

- There are a set of new properties available that you can use to improve the UI loading and viewing experience when there are – potentially - a large number of related objects that need to be loaded into the UI.

- glog.tender.UseOBTProfileID.limit.OrderRelease - Use this parameter to speed up the loading of the tender UI. When the order release count associated with a shipment exceeds the set value, the View Order Information button appears. Click this button, to view the order release information in a pop up window. Default: 100

- glog.tender.UseOBTProfileID.limit.ReleaseLine - Use this parameter to speed up the loading of the tender UI. When the sum of order release lines of all order releases exceeds the set value, the View Order Information button appears. Click this button, to view the order release information in a pop up window. Default: 100

- glog.tender.UseOBTProfileID.limit.ShipUnit - Use this parameter to speed up the loading of the tender UI. When the ship unit count of a shipment exceeds the set value, the View ShipUnits button appears in the Stops tab on the Online Booking and Tendering page. Click this button to view the ship unit information in a pop up window. Also, the View Items button appears in the Order Information tab. Click this button, to view the order item information. Default: 100

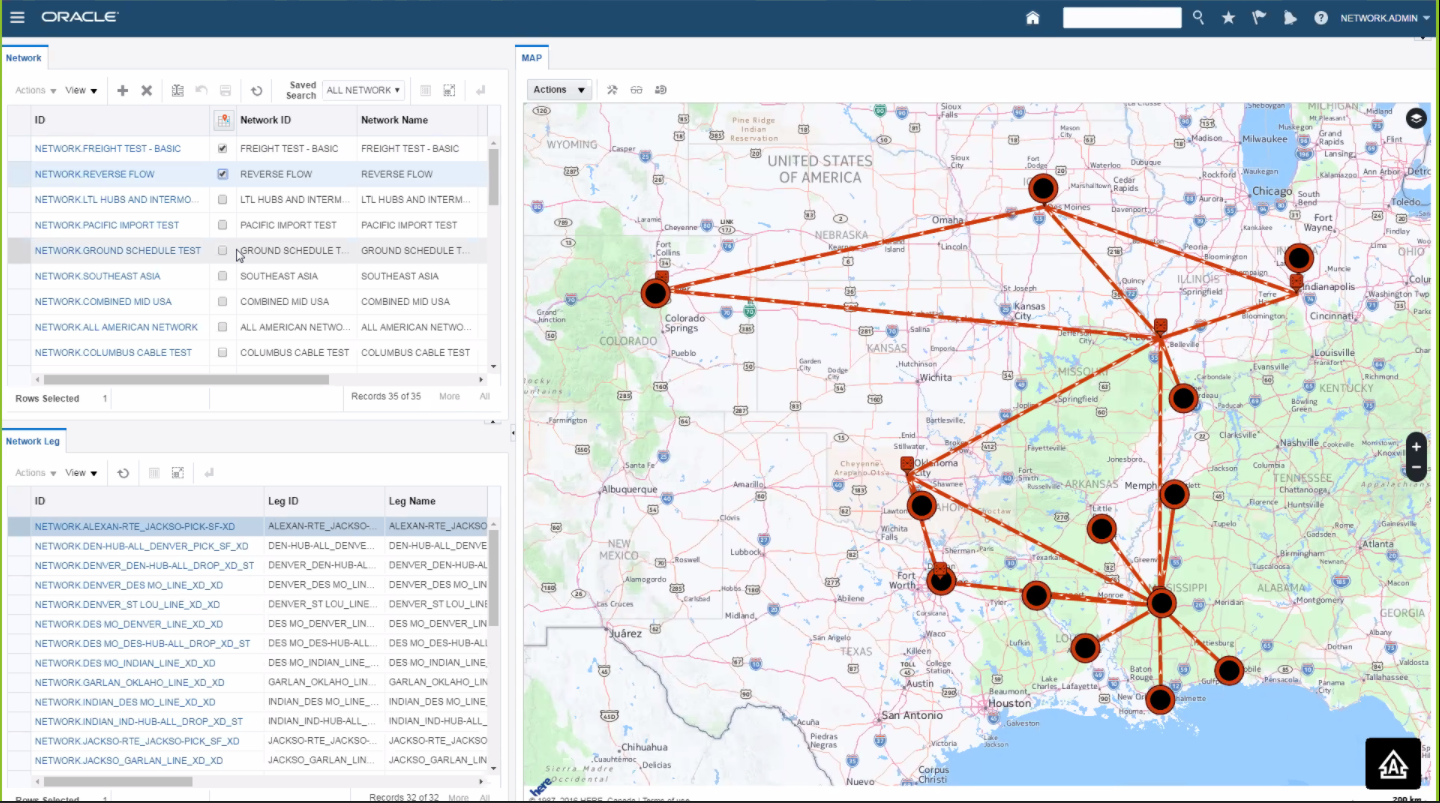

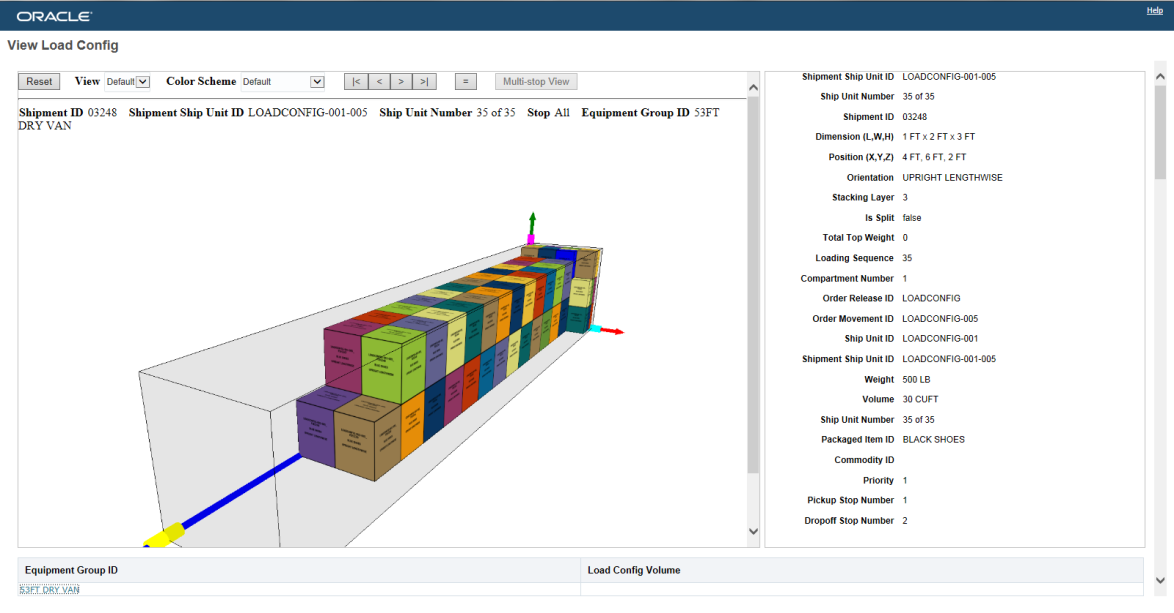

This feature provides a set of workbench Map enhancements that improve the usability and extend the capabilities available for your workbenches that include a map.

Location, Network and Network Details Added to Map

The available objects that can be shown on the map within the workbench has been enhanced to include Locations and Networks (Network, Network Details)

Workbench with Mapped Network, Network Details

Capabilities provided as part of this feature include the following:

- Added the following objects to a workbench map:

- Location

- Network, Network Details

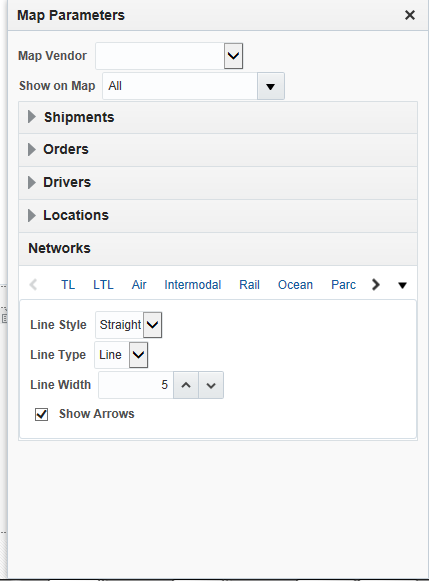

- New Grouping Logic Configuration parameters for network map logic added to the Logic Configuration – Workbench. These parameters allow you to set the Line Style, Line Type, Line Width and whether to Show Arrows for network, network details on a by mode basis.

- Mode options include: Default –no matching mode, Air, TL, Intermodal, Ocean, Parcel, Rail.

Map Parameters

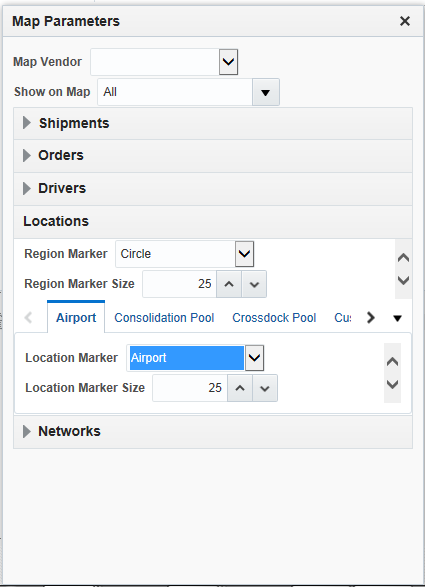

- New Grouping Logic Configuration parameters for location map logic added to the Logic Configuration – Workbench. These parameters allow you to set the Location Marker to use and the Location Marker Size to use by location role.

- Roles supported include Default –role not covered, Airport, Consolidation Pool, Crossdock Pool, Customer, Deconsolidation Pool, Equipment Pool, Port, Rail Junction, Rail Ramp, Rail Station, ShipFrom/ShipTo.

- You can also set the Region Location Marker and Region Location Marker size.

Map Parameters Markers

- New map hover text details for the newly supported objects – Locations, Network and Network details.

Steps to Enable

There are no steps necessary to enable this feature.

Map Vendor Added Oracle Elocation

You can now select ORACLE ELOCATION (Oracle Maps Cloud Service formerly known as eLocation and Spatial maps) as your map vendor when setting the Map Parameters to use for the map content in your workbench. As with the other supported map vendors, you can set the properties to use with the ORACLE ELOCATION map option.

Capabilities provided as part of this feature include the following:

- You can now configure workbench maps to use Oracle eLocation.

- Added properties to configure eLocation for maps

- Added ORACLE ELOCATION as a map vendor in Map Parameters.

Steps to Enable

There are no steps necessary to enable this feature.

You can now show driving directions for a mapped shipment. This feature is supported for HERE, ALK, and Oracle eLocation.

Steps to Enable

There are no steps necessary to enable this feature.

Workbench Maps: ALK Geographic Region Configuration

You can now set the ALK MAP GEOGRAPHIC REGION parameter in the workbench logic configuration to identify the region that will invoke street level mapping of shipments when using ALK maps.

The different regions available are:

- Africa

- Asia

- Australia

- Europe

- Middle East

- North America

- South America

Steps to Enable

- Create a Workbench Logic Configuration for your workbench layout.

- Set the ALK MAP GEOGRAPHIC REGION parameter to the region where you would like to support street level shipment routing.

- Save the Workbench Logic Configuration.

- Create a new workbench using the newly created Workbench Logic Configuration.

Tips and Considerations

Street level mapping of shipments across multiple regions is not possible in the same layout since you can only specify one region at a time. To support multiple regions you can create two layouts using two different workbench logic configurations with two different region settings for the ALK MAP GEOGRAPHIC REGION parameter. You cannot use a line style of "street" to view street level routing in the same workbench layout. The workaround is to use line style of "Arc" or "Straight".

This feature provides a new set of easy to use drag-and-drop actions. These drag-and-drop actions are only available when using HERE as the selected map vendor for your layout.

The available drag-and-drop actions include:

- Move Order Releases to a Shipment

- Move Shipment Stop to Shipment (move order releases on a shipment stop from one shipment to another shipment)

Steps to Enable

There are no steps necessary to enable this feature beyond the requirement to select HERE maps as the map vendor for your layout.

Additional Markers for Use with All Objects on Maps

This feature provides a new set of visually pleasing markers that are used to view different objects on the map.

New markers are provided for the following objects:

- Airport

- Port

- Rail

- Crossdock Pool

- Equipment

- Consolidation Pool

- Deconsolidation Pool

Steps to Enable

There are no steps necessary to enable this feature.

This feature changes the default setting for the map vendor in the PUBLIC WORKBENCH DEFAULT logic configuration. Now, by default, there is no default value for the MAP VENDOR parameter in the WORKBENCH DEFAULT logic configuration. If you are using the PUBLIC (default) WORKBENCH DEFAULT logic configuration, you must now either manually select a map vendor from the map parameters pop-up or create a new WORKBENCH logic configuration with your selected map vendor of choice specified in the MAP VENDOR parameter.

Steps to Enable

There are no steps necessary to enable this feature.

Edit Shipment Agent Works on Ship Units that Contain Lines from Multiple Orders

This feature provides an OMD Edit Shipment agent action that now works for shipments with repacked shipment ship units that originate from multiple orders.

Steps to Enable

There are no steps necessary to enable this feature.

This feature provides an improved OMD propagator that can be configured as a pre-persist agent with the following functions:

- Add, delete, and modify a ship unit and propagate changes to shipments

- Delete order release lines and modify order release lines in a one-to-one relationship

- Set the shipment status to SHIPMENT MODIFIED_MODIFIED

Steps to Enable

There are no steps necessary to enable this feature.

Build Ship Units with Maximum Number of Different Items

This feature provides the ability to limit the number of packaged items to ship and the number of types of items to ship when creating a rainbow pallet. The limits can be set just for a transport handling unit or for a transport handling unit at a specific (delivery) location.

Steps to Enable

- Defining a Packaging Reference Unit:

- Enter a unique identifier in the Packaging Reference Unit ID field.

- Enter the unit's name in the Name field.

- Enter a description in the Description field.

- Select the Grouping Rule. This determines how to group items when consuming this packaging reference unit's capacity.

- A packaging reference unit with the SAME grouping rule can be attached to both a transport handling unit or a transport handling unit at a certain location, to limit the number of different types of package items allowed on that transport handling unit, or that transport handling unit going into that location. "Same" items are items with the same packaged item ID.

- A packaging reference unit with the LIKE grouping rule can be attached to both a transport handling unit or a transport handling unit at a certain location Doing so limits the number of LIKE items allowed on that transport handling unit, or transport handling unit when going into that location. "Like" items are items with the same packaged item type and the same packaging unit or if there is no packaging unit defined.

- Click Finished.

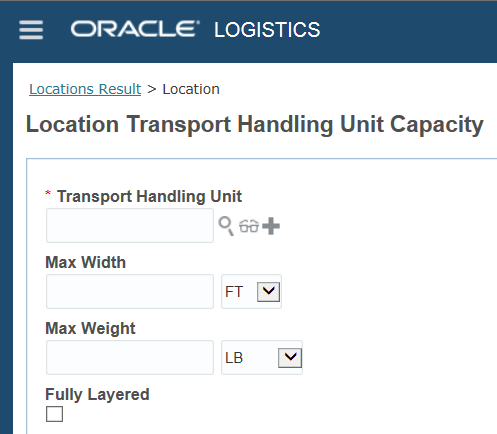

- Go to the delivery location where you want to define your packaging reference unit count and total packaging unit reference counts. Go to the Location Role Profile then create a new Location Transport Handling Unit Capacity entry.

- Enter the transport handling unit you want to define limits for in the Transport Handling Unit field.

- Enter the Packaging Reference Unit ID that you defined above

- Enter the desired Limit Packaging Reference Unit Count. This represents the number of package references units that can fill the usable space in the location. The area of a location may suggest more packaging reference units can fit, but due to the actual dimensions of the packaged reference units, a lower limit may be reached.

- Enter the desired Total Packaging Reference Unit Count. This total represents, by volume, the amount of packaging reference units that can fill the space. It does not take into account the actual shape and dimensions of the packaging reference unit, but rather how many packaging reference units can fit in the space based on the volume of each packaging reference unit.

- Click Save for each Capacity in Package Reference Units entry you define.

- Click Save to save the Location Transport Handling Unit Capacity entry

- Click Save to save the Location Role Profile

- Click Finished to save the location record

ERU Information Added to Shipment Manager Equipment Tab

This feature provides visibility to the Equipment Reference Unit ID and the Total Number of Equipment Reference Units on the Shipment Manager Equipment Tab.

Expand any shipment equipment to see the Equipment Reference Unit ID and Total Number of Reference Units for the equipment.

Steps to Enable

There are no steps necessary to enable this feature.

Ship Unit Build Properties Moved to Parameters

This feature provides a new ship unit logic configuration SUBLD LOGIC PARAMETER CONFIG which contains three parameters that were previously managed as properties.

The new SUBLD LOGIC PARAMETER CONFIG ID logic config can be found in the SHIP UNIT BUILDING group in the parameter set. The default values are provided in the SUBLD LOGIC PARAMETER DEFAULT logic config.

SUBLD Logic Parameters

- ESTIMATE SHIP UNIT HEIGHT - This parameter is used for ship unit height calculation. It controls if OTM will estimate the ship unit height using ship unit net volume or not. When In/On/Max for THU is On and ship unit height cannot be calculated due to lack of TiHi to use. The default is FALSE.

- Replaces property glog.business.order.estimateShipUnitHeight

- SHIP UNIT AS REPACK OPTION - When true, OTM will consider the order's ship units as an option during repack. The default is FALSE.

Note: Since OTM can only pack lines, this could be a misleading solution and it’s use is discouraged. - Replaces property glog.business.equipment.shipUnitAsRepackOption

- SHIP UNIT HEIGHT ADJ PERCENTAGE - This parameter is used for ship unit height calculation. It defines the adjustment factor for the estimated height. Default value is 20 meaning 20%. If the estimated height is H, then OTM will inflate to H * (1 + 20%).20.00 20.00.

- Replaces property glog.business.order.shipUnitHeightAdjPercentage

There are no steps necessary to enable this feature.

Control Repack Processing by Modes

This feature simplifies how you set the modes to consider for repack by providing an Allow Repack check box directly on the Transport Mode screen. This check box determines whether to consider the transport mode for repacking. Previously, this functionality was controlled by the property “glog.business.equipment.repackOnlyCostConsideredModes”.

Steps to Enable

- By default transport modes the Allow Repack check box is checked and the selected mode will be considered during repack.

- When the “Allow Repack” check box is checked, you can also specify if cost should be considered during repack by checking the “Consider Cost During SSU Repack” check box. By default, the “Consider Cost During SSU Repack” check box is not checked.

- To no longer have a particular transport mode considered for repack the “Allow Repack” on the transport mode should not be checked.

Order Configuration UI to Show Ship Unit Configuration for All Order Types

This feature provides order configuration UI that will be displayed for line-based order configurations.

Steps to Enable

There are no steps necessary to enable this feature.

Earliest Estimated Pickup Date Added to Order Release

This feature provides visibility to the earliest estimated pickup date for an order. The Earliest Estimated Pickup Date is read only and displays the earliest departure time for all of the first leg shipments that an order release is on. The time is displayed in the time zone of the source location.

Steps to Enable

- Added a parameter RECALC ORDER EARLIEST EST PICKUP DATES. When set to TRUE, the order release Earliest Estimated Pickup Date will be recalculated.

- Added a property glog.workflow.topic.OrderEarliestEstPickupDateSync.suppresslifetime. When true, a change to the Earliest Estimated Pickup Date does not trigger the Order Release MOD lifetime event or custom event.

- Added Earliest Ship Date to Order Release - Agent Action.

Order Release Delivered Status Types and Values

This feature provides a new order status type and a list of related values that can provide information about an orders delivery status. The new Order Delivered status is set according to the status of the related last leg buy shipment that the order is on. This status provides a way to understand if the order is still enroute, if some of the order has been delivered or if all the shipments involved in the final delivery leg for this order have been completed.

Capabilities

- Added a new agent action: SET ORDER DELIVERED STATUS.

- Added an order release status type “ORDER DELIVERED”, with the following values:

- ORDER DELIVERED_NOT STARTED: None of the shipments are ENROUTE-COMPLETED.

- ORDER DELIVERED_PARTIAL: At least one but not all of the shipments are ENROUTE-COMPLETED.

- ORDER DELIVERED_COMPLETE: All shipments are ENROUTE-COMPLETED.

Steps to Enable

- Create a new automation agent with the Agent Type of Order Release

- Set the desired conditions for changing the Order Delivered Status.

For example, you can decide to trigger this agent action when the shipment status is set to ENROUTE-COMPLETED. - Add the Action SET ORDER DELIVERED STATUS

- Click Save to save the action

- Click Finished to save the agent

Allow Source Location on Ready to Ship to Be Blank

This feature provides the ability to have the Source Location on the Ready to Ship screen to be blank. By allowing for the Source Location to be blank, you now have a more visible cue that the Source Location must be provided. Previously, the Source Location field was always populated with a Source Location since the data model requires that this field be populated. Populating the Source Location field by default allowed users to easily skip the step of updating this field with the correct source location.

Steps to Enable

- Source Location on the Ready to Ship action can default to blank by setting the glog.webserver.rts.defaultShipFromAsBlank property to true.

Order Base Line Releasing Improved

This feature provides a new action “Order Base Line Packing” that allows you to specify the packing information for order base lines coming from multiple order bases. The result of running this action will be one order release with multiple ship units that contain ship unit lines from multiple order base lines.

Steps to Enable

There are no steps necessary to enable this feature.

Tips and Considerations

This action only works for order configurations where the Releasing Logic is set to “One Ship Unit for All Lines”. A new public Order Configuration called “Instructed Prepack” with the Releasing Logic set to “One Ship Unit for All Lines” has been provided for you to use. It is recommended that you use this order configuration if you are using the new Order Base Line Packing action and Simple Ready to Ship.

Build Single Product Pallets with a Full Layer

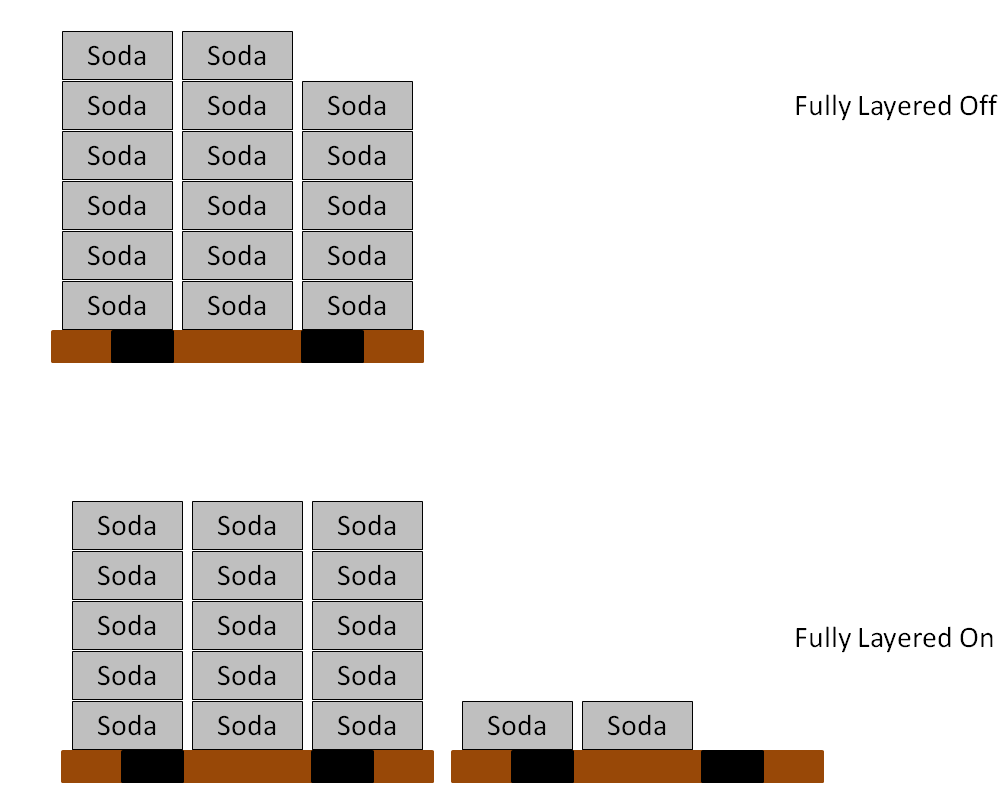

This feature provides a Fully Layered check box on your Location's Location Transport Handling Unit Capacity grid that allows you to specify, by transport handling unit (THU), whether the ship unit built onto the specified THU - involving only one type of item - will be built fully-layered; i.e, no partial layers.

For example, you are packing 17 cartons of soda onto a given PALLET (THU) and the TiHi specified is 6 x 3. Normally, you would pack all 17 cartons onto one pallet with 5 full layers and one partial layer of 2 cartons. However, if you only allow full layers, checking the Fully Layered check box for this THU for this location will instruct OTM to pack 15 cartons on 1 pallet in 5 full layers of 3 each and then start another pallet with the remaining 2 cartons.