- Revision History

- Overview

- Feature Summary

-

- Functional Enhancements

-

- Drive Putaway Rules to Search for Locations with Same Item

- Support Overshipment and Undershipment Tolerances with Back Ordering

- Enhanced Purchase Order Based Receiving

- Scheduled Job to Verify Shipment

- Allow Receiving of QC Rejected LPNs and Return to Vendor

- New Parameter for Non-Multi-Field Barcodes

- Enhanced Configurability on Post-Pick Order Consolidation and Loading

- New Facility Parameter to Associate Blind ASNs

- Support for Legacy Company Parameter LEGACY_ACTUAL_WEIGHT_OVERRIDES_WT_VOL_CALC_IN_SHIPPING

- Backorder Processing Handling in WMS

- Allocation in Terms of Packs or Cases from Active Locations

-

- User Experience and Usability Enhancements

- Integration Enhancements

-

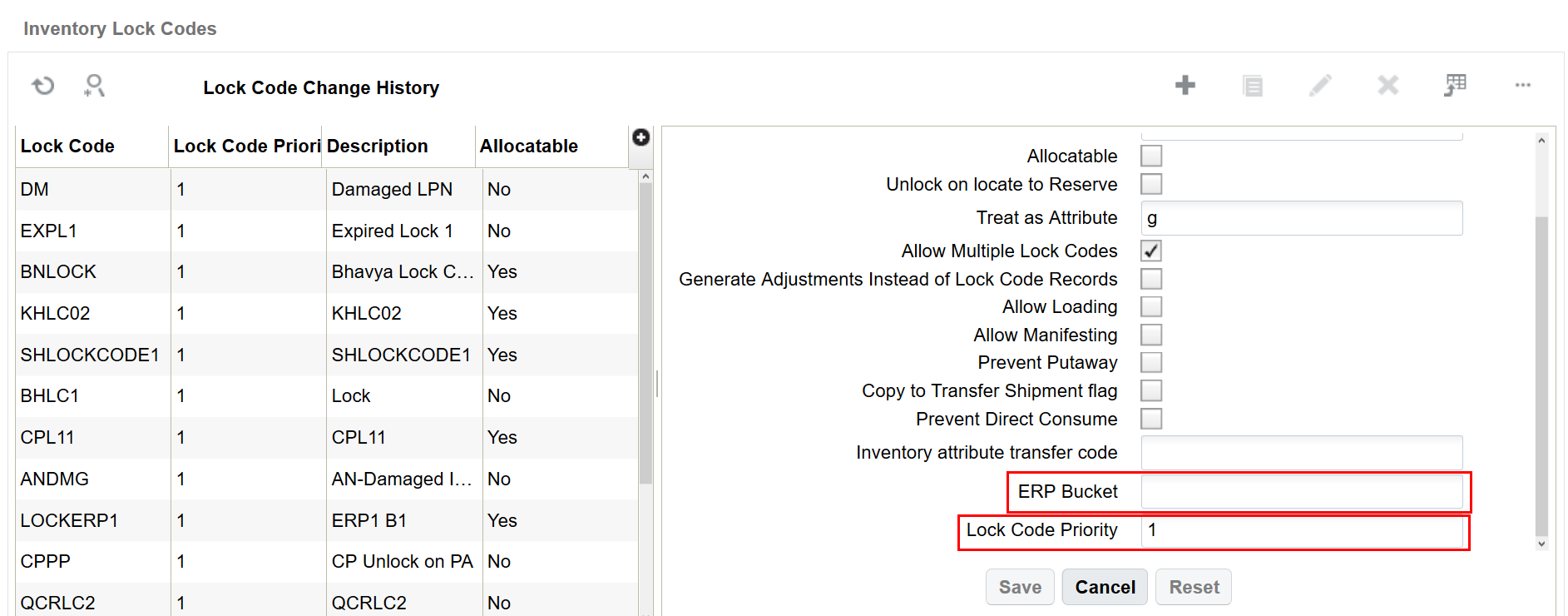

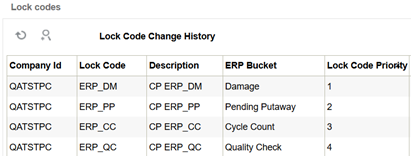

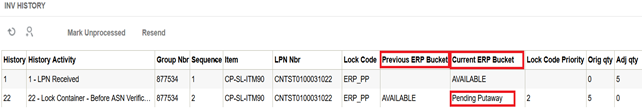

- WMS Cloud Lock Code to ERP Inventory Summary Alignment

- GET Available Warehouse Location for Putaway Using a REST API

- Additional Categories in Web Reports Gen 2

- Web Reports Optimization for Date/Time Functions

- Support ISO-8601 Format Date/Time Values

- Update Active Inventory for Serialized Product Using a REST API

- Update Location Counted to Be Counted Flag Using a REST API

- Locate LPN or Pallet to Location Using a REST API

- Update Orders with Ship Via and Shipment Number Using a REST API

- Expand Custom Fields in Inbound Shipment Interface and Inbound Shipment Verification Output

-

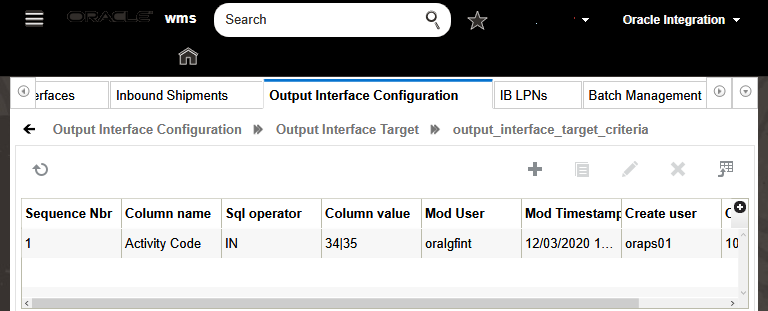

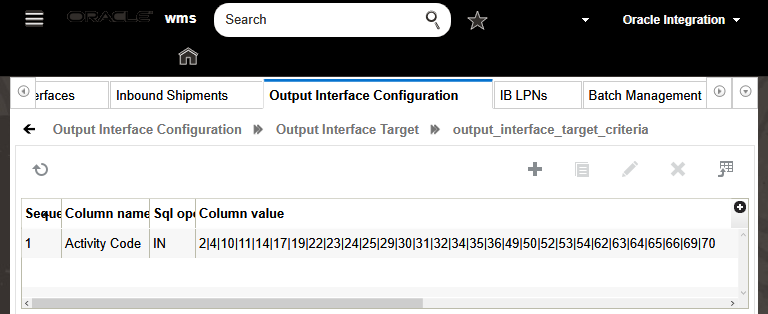

- Updates to WMS Cloud to SCM Cloud Integrator

-

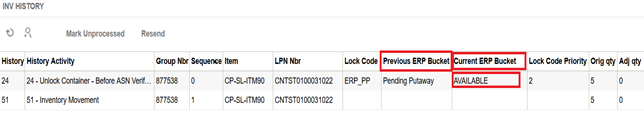

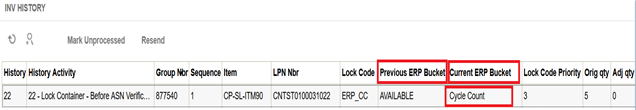

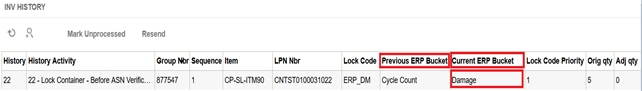

- Support for WMS Cloud Lock Code to ERP Inventory Summary Bucket Alignment on Purchase Order Receipt Confirmation and Inventory Transactions

- Support Shipping Tolerances for Sales Orders

- Communicate Backordering for Sales Orders

- Provide Transaction Reference on Purchase Order Receipt Confirmation, Inventory Transactions, and Sales Order Shipment Confirmation

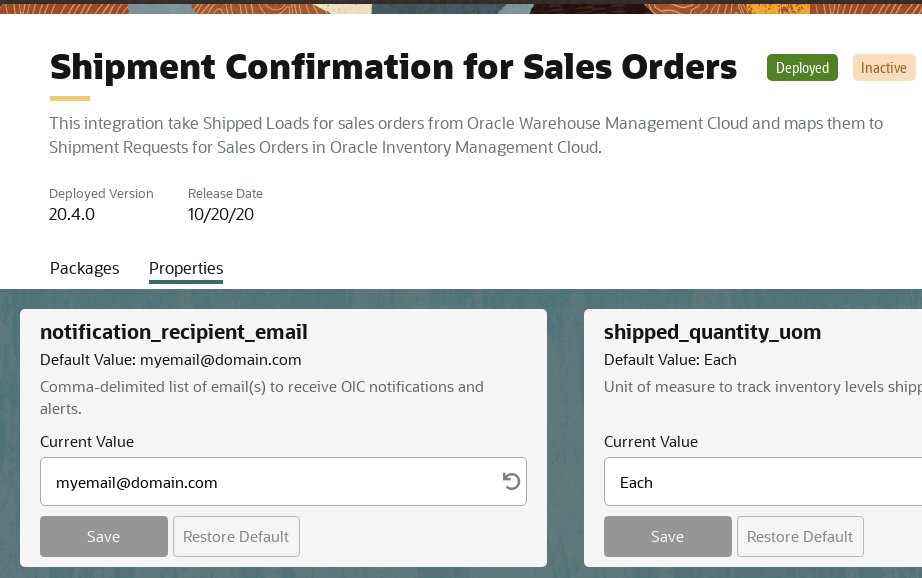

- Integration Properties Support in SCM Cloud Integrator

-

- Functional Enhancements

This document will continue to evolve as existing sections change and new information is added. All updates appear in the following table:

| Date | Product | Feature | Notes |

|---|---|---|---|

| 06 JUL 2021 | Functional Enhancements | Allow Receiving of QC Rejected LPNs and Return to Vendor | Updated document. Revised feature information. |

| 27 JAN 2021 | Functional Enhancements | Allow Receiving of QC Rejected LPNs and Return to Vendor | Updated document. Revised feature information. |

| 21 DEC 2020 | Functional Enhancements | WMS Cloud Lock Code to ERP Inventory Summary Alignment | Updated document. Revised feature information. |

| 11 DEC 2020 | Functional Enhancements | Allocation in terms of Packs or Cases from Active Location | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Integration Enhancements |

Backorder Processing Handling in WMS | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Functional Enhancements | Support for Legacy Company Parameter LEGACY_ACTUAL_WEIGHT_OVERRIDES_WT_VOL_CALC_IN_SHIPPING | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Updates to WMS Cloud to SCM Cloud Integrator |

Communicate Backordering for Sales Orders | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Updates to WMS Cloud to SCM Cloud Integrator |

Support Shipping Tolerances for Sales Orders | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Updates to WMS Cloud to SCM Cloud Integrator |

Support for WMS Cloud Lock Code to ERP Inventory Summary Bucket Alignment on Purchase Order Receipt Confirmation and Inventory Transactions | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | User Experience and Usability Enhancements | Link to WMS Cloud Application Pages Using Deep Links | Updated document. Revised feature information. |

| 11 DEC 2020 | Updates to WMS Cloud to SCM Cloud Integrator |

Integration Properties Support in SCM Cloud Integrator | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Updates to WMS Cloud to SCM Cloud Integrator |

Provide Transaction Reference on Purchase Order Receipt Confirmation, Inventory Transactions, and Sales Order Shipment Confirmation | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Functional Enhancements | Allow Receiving of QC Rejected LPNs and Return to Vendor | Updated document. Revised feature information. |

| 11 DEC 2020 | Integration Enhancements |

Web Reports Optimization for Date/Time Functions | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Functional Enhancements | Enhanced Purchase Order Based Receiving | Updated document. Revised feature information. |

| 11 DEC 2020 | Integration Enhancements | Update Orders with Ship Via and Shipment Number using a REST API | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Integration Enhancements | Additional Categories in Web Reports Gen 2 | Updated document. Delivered feature in update 20D. |

| 11 DEC 2020 | Integration Enhancements | WMS Cloud Lock Code to ERP Inventory Summary Alignment | Updated document. Revised feature information. |

| 09 OCT 2020 | Created initial document. |

This guide outlines the information you need to know about new or improved functionality in this update, and describes any tasks you might need to perform for the update. Each section includes a brief description of the feature, the steps you need to take to enable or begin using the feature, any tips or considerations that you should keep in mind, and the resources available to help you.

Give Us Feedback

We welcome your comments and suggestions to improve the content. Please send us your feedback at owms-cloud-comms_us@oracle.com.

Column Definitions:

Features Delivered Enabled

Report = New or modified, Oracle-delivered, ready to run reports.

UI or Process-Based: Small Scale = These UI or process-based features are typically comprised of minor field, validation, or program changes. Therefore, the potential impact to users is minimal.

UI or Process-Based: Larger Scale* = These UI or process-based features have more complex designs. Therefore, the potential impact to users is higher.

Features Delivered Disabled = Action is needed BEFORE these features can be used by END USERS. These features are delivered disabled and you choose if and when to enable them. For example, a) new or expanded BI subject areas need to first be incorporated into reports, b) Integration is required to utilize new web services, or c) features must be assigned to user roles before they can be accessed.

| Ready for Use by End Users Reports plus Small Scale UI or Process-Based new features will have minimal user impact after an update. Therefore, customer acceptance testing should focus on the Larger Scale UI or Process-Based* new features. |

Action is Needed BEFORE Use by End Users Not disruptive as action is required to make these features ready to use. As you selectively choose to leverage, you set your test and roll out timing. |

|||||

|---|---|---|---|---|---|---|

| Feature |

Report |

UI or |

UI or |

|

||

Support Overshipment and Undershipment Tolerances with Back Ordering |

||||||

Enhanced Configurability on Post-Pick Order Consolidation and Loading |

||||||

Support for Legacy Company Parameter LEGACY_ACTUAL_WEIGHT_OVERRIDES_WT_VOL_CALC_IN_SHIPPING |

||||||

Default Redwood Theme for WMS Application Pages and Mobile App |

||||||

GET Available Warehouse Location for Putaway Using a REST API |

||||||

Update Active Inventory for Serialized Product Using a REST API |

||||||

Update Orders with Ship Via and Shipment Number Using a REST API |

||||||

Expand Custom Fields in Inbound Shipment Interface and Inbound Shipment Verification Output |

||||||

Drive Putaway Rules to Search for Locations with Same Item

In 20D, a new flag “Search Location with matching SKU” is available in the Putaway Priority View UI. After you enable this flag on putaway method priority, the system directs you to the location that already has a matching SKU required to be putaway. This new mechanism helps to optimize the location with identical SKU’s instead of having the same SKU spread across the different locations. This also helps to achieve a smooth picking transaction and thereby reduces accessing any further location.

Let's say, you have an IBLPN with a single SKU or pallets having IBLPN single SKU during directed putaway, all the eligible locations (satisfying capacity check), and putaway method priority. The system now further narrows down and prompts the location that already has the SKU (Physical Inventory not In-transit) similar to the SKU targeted for putaway.

ADDITIONAL KEY POINTS:

- By default, this new flag is disabled on the Putaway Method Priority UI. Users need to check the flag explicitly to enable.

- This function is applicable to both Active & Reserve Locations.

- This new flag honors during Split Putaway to Active Location and Putaway Method Location Sequence/ Radial.

- On scanning an LPN, if there are multiple locations that have matching SKUs, then the system will apply putaway search mode to the eligible location (i.e locations that have matching SKUs).

NOTE: After scanning an IBLPN with multiple SKUs or pallets having an IB container containing multiple SKU, the system does not consider the Matching SKU criteria even though the flag on the Putaway method priority is enabled. If there are no locations with matching SKUs for the given putaway method priority, then the system will prompt location based on the putaway search mode from the respective putaway method priority.

Steps to Enable

- Go to PutawayPriorityView UI

- Click Create to create or Select the Putaway Type > Click edit icon.

- Check or un-check the Search Location with matching SKU checkbox to enable or disable the functionality.

- Click Save.

Key Resources

Support Overshipment and Undershipment Tolerances with Back Ordering

INTRODUCING SHIPPING TOLERANCE PERCENTAGE IN THE ORDER DETAIL UI AND INTERFACE

Previously, the system did not allow packing of more than the ordered quantity. Also, warehouses deal with a variety of items (such as produce or wires for example) where shipping an exact quantity or weight might not always be practical. To give users more flexibility in shipping item quantities, Shipping tolerance percentage is now available in Oracle WMS Cloud in 20D. You can now view and edit Shipping Tolerance Fields in the Order Header / Order Detail screen. You can also view Shipping Tolerance Fields in the Manual Wave and Order Detail screens.

You can also create/modify Shipping Tolerance Fields via:

- the Order Input Interface (through ORR, OHD, or ORD)

- the Order API

NOTE: The system will not allow tolerance% equal to 100% or more than 100% for the Minimum Shipping Tolerance% field.

WAVE ALLOCATION

In Order Type, if Partial allocated is enabled, the system will partially allocate the order. If the quantity allocated is within the tolerance threshold in the quantity to be allocated in the Order Detail, the order detail will be in a status of Allocated.

NOTE: During a wave, when the "Cancel Partially Unallocated" flag is enabled the system will not cancel the unallocated quantity from the order detail if the allocated quantity on the order detail is greater than or equal to minimum shipping tolerance% threshold value.

If allocated quantity is less than the minimum tolerance %, the order detail status will be partially allocated.

| Order | Order Quantity | Min % | Max % | Allocated Quantity | Order Detail Status |

|---|---|---|---|---|---|

| Order1 - Dtl1 | 100 | 10 | 10 | 92 | Allocated |

| Order2 - Dtl1 | 100 | 10 | 10 | 80 | Partly Allocated |

NOTE: Even though the max tolerance% is defined, the system will never over allocate during allocation from the wave.

HONORING TOLERANCE PERCENTAGE WHILE PACKING AGAINST ALLOCATED QUANTITY

In the following transactions, the system now allows you to pick more than the allocated quantity, when the respective allocated order is defined with a maximum shipping tolerance percentage as greater than zero. Oracle WMS Cloud also updates the respective order detail status based on the inventory picked honoring the shipping tolerance percentage.

- RF Pack NC Active Order

- Pick {iblpn}

- Pick Cart

- Pick Confirm API

- Distribute OBLPN for Allocation mode "Distribution residuals OK"

NOTE: When distribution mode is Distribution residuals OK, LPNs allocated by the system may have more inventory than the allocated quantity. In this mode, you can pickup extra inventory available to over pack within the tolerance%.

You can now pick excess quantity against the allocated quantity and tolerance% is considered with respect to the allocated quantity:

Example 1: Let's say you have an order with 100 units with a max% of 10. If there are 2 allocations of 50 and 50, you can pick a max of 55 (subject to inventory availability) against each allocation.

While picking against allocated quantity if you pick in a single instance, then the overall max quantity that can be packed against an order detail may vary.

Example 2: Let's say you have an order with 100 units with max% of 10. If there is one allocation of 100 units against the order, you can pick up to 110 (subject to inventory availability) if the picking is done in a single instance.

But if you pick 60 in the fist instance, then the system asks you to pack the remaining 40. You can pick up to a max of 44 (subject to inventory availability.) In this case, the total packed quantity against the order detail will be 104.

ALLOW OVER PACKING

Oracle WMS Cloud now allows over packing based on the maximum shipping tolerance defined on the order detail during picking using the MHE API.

- When the maximum tolerance on the order detail is defined with greater than a zero value, then during MHE picking, the system calculates the maximum quantity that can be picked against the order detail by applying the maximum tolerance % on the allocated quantity against the respective allocation detail.

- When the maximum tolerance on the order detail is not defined or zero, then the system doesn’t allow over packing of inventory. Upon over packing, the error message "Only (Available Quantity) units available for packing" displays.

NOTE: Over Packing is allowed only when respective inventory is available (not allocated to any order) in the source location.

HONORING TOLERANCE PERCENTAGE DURING SUBSTITUTION

During the following RF Pack {oblpn}, the system now allows you to substitute inventory within the min/max threshold percentage, as long as the substituted LPN is allocated for an order that the original LPN can fulfill.

Example 1:

The Location has 2 LPNs:

| LPN | LPN Quantity | LPN Status | Order Allocated |

|---|---|---|---|

| LPN1 | 100 | Allocated | order 1 |

| LPN2 | 90 | Allocated | - |

User substitutes LPN1 with LPN2. Because LPN2 meets the tolerance limit and it is not allocated to an order, the user can substitute.

| Order | Order Quantity | Min % | Max % |

|---|---|---|---|

| order 1 | 100 | 10 | 10 |

Example 2:

The Location has 2 LPNs:

| LPN | LPN Quantity | LPN Status | Order Allocated |

|---|---|---|---|

| LPN1 | 100 | Allocated | order 1 |

| LPN2 | 90 | Allocated | order 2 |

| Order | Order Quantity | Min % | Max % |

|---|---|---|---|

| order 1 | 100 | 10 | 10 |

| order 2 | 100 | 10 | 10 |

The Location has 2 LPNs: User substitutes LPN1 with LPN2. Because LPN2 meets the tolerance limit for order 1 and LPN1 meets the tolerance limit for order 2, the allocation can be exchanged and the user is allowed to substitute.

Example 3:

| LPN | LPN Quantity | LPN Status | Order Allocated |

|---|---|---|---|

| LPN1 | 100 | Allocated | order 1 |

| LPN2 | 90 | Allocated | order 2 |

| Order | Order Quantity | Min % | Max % |

|---|---|---|---|

| order 1 | 100 | 10 | 10 |

| order 2 | 90 | 10 | 10 |

User tries to substitute LPN1 with LPN2. Even thought LPN 2 is within the percentage tolerance for Order 1, LPN 1 is NOT with in the percentage tolerance for order 2. Therefore, Substitution is not allowed.

DIRECT ALLOCATION WHEN LPN QUANTITY IS WITHIN THE SHIPPING TOLERANCE LIMIT OF THE ORDERED QUANTITY

Users can now allocate LPNs with a higher quantity than the ordered quantity. Also, allocating LPNs with a quantity within the shipping tolerance limit of the ordered quantity will mark the order detail as Allocated.

The following table is an example of the resulting Order Detail and LPN status during RF Direct Allocation based on the minimum and maximum shipping tolerance set:

| Ordered Qty | LPN Qty | Min ToI % | Max ToI % | Rem Ord Qty | Order Detail Status | LPN Status |

|---|---|---|---|---|---|---|

| 100 |

80 |

10 |

10 |

20 |

Partly Allocated |

Consumed |

| 100 |

90 |

10 |

10 |

10 |

Allocated |

Consumed |

| 100 |

90 |

0 |

10 |

10 |

Partly Allocated |

Consumed |

| 100 |

110 |

0 |

10 |

0 |

Allocated |

Consumed |

| 100 |

110 |

10 |

0 |

0 |

Allocated |

Consumed |

| 100 |

111 |

10 |

10 |

100 |

Error message- system should restrict |

Received |

PICK AND ALLOCATE WITH RESPECT TO THE SHIPPING TOLERANCE LIMIT

Users can now over pick quantity greater than the ordered quantity within the shipping tolerance limit applied. During Pick and Allocate, when LPNs with a higher quantity than the ordered quantity are packed based on the shipping tolerance%, the original allocated quantity will not be more than the original order quantity on the allocation record.

The following table is an example of the resulting Order Detail and Order Header status during RF Pick and Allocate based on the minimum and maximum shipping tolerance set:

| Ordered QTY | Allocated QTY | Packed Qty | Min ToI % | Max ToI % | Mode | Ord Detail Status | Ord Header Status |

|---|---|---|---|---|---|---|---|

| 100 |

100 |

50 |

10 |

10 |

System Directed |

Allocated |

In Packing |

| 100 |

100 |

90 |

10 |

10 |

System Directed |

Allocated |

Packed |

| 100 |

100 |

110 |

10 |

10 |

System Directed |

Allocated |

Packed |

| 100 |

50 |

50 |

10 |

10 |

User Directed |

Created |

Partly Allocated |

| 100 |

90 |

90 |

10 |

0 |

User Directed |

Allocated |

Packed |

| 100 |

90 |

90 |

0 |

10 |

User Directed |

Created |

Partly Allocated |

| 100 |

110 |

100 |

0 |

10 |

User Directed |

Allocated |

Packed |

COMPUTE ORDER DETAIL STATUS BY HONORING SHIPPING TOLERANCE PERCENTAGE ON THE ORDER

Previously, Oracle WMS Cloud computed Order Detail status based on the ordered, allocated and packed quantity for each order detail under it. With the introduction of shipping tolerance, the order detail status might get changed even if the allocated/packed quantity is more or less than the ordered detail quantity but within the tolerance. Now, the system computes the Order Detail status by honoring the shipping tolerance percentage defined on the respective order.

The following listed statuses are supported for order detail based on shipping tolerance percentages:

| Order Detail Status | Order Detail Data Condition |

|---|---|

| Created |

Allocated Quantity = 0 |

| Partly Allocated |

Allocated Quantity > 0 Allocated Quantity < Minimum Shipping Tolerance% threshold value |

| Allocated |

Allocated Quantity >= Minimum Shipping Tolerance% threshold value |

| In Picking |

Allocated Quantity >= Minimum Shipping Tolerance% threshold value and order detail has container which is in "In Picking" status |

| Picked |

Packed Quantity >= Minimum Shipping Tolerance% threshold value && If Any associated container status is Picked && there should not be any pending allocation against the order detail |

| In Packing |

Allocated Quantity >= Minimum Shipping Tolerance% threshold value & order detail has container which is in "In Packing" status |

| Packed |

Packed Quantity >= Minimum Shipping Tolerance% threshold value && If all the associated container status are packed && there should not be any pending allocation against the order detail |

| Loaded |

Loaded quantity against the order detail is > = Minimum Shipping Tolerance% threshold value && there should not be any pending inventory against the order detail |

| Shipped |

Shipped quantity against the order detail is > = Minimum Shipping Tolerance% threshold value && there should not be any pending inventory against the order detail |

CHANGES IN THE SHIPPED LOAD INTERFACE

Oracle WMS Cloud can now derive order detail status whenever the order detail is shipped. Order Quantity Consume is meant to be used by integration to consume quantity against the shipped quantity.The ability to derive the status on the order detail will help the end user to know about order status, so that user can plan further activity during shipping and manifest.

After loading all of an order’s packed OBLPNs, the user will perform shipping. If the shipped quantity is within the maximum/minimum shipping tolerance percentage defined on the order detail and the order detail doesn't have any pending allocation/picks, then the order detail status will be derived as "Shipped".

- Order detail status is shipped when shipping is performed via the RF or UI Ship Load transaction.

- Order header status is marked as shipped when all the order details against the order are shipped.

When inventory is shipped against the order detail, the order detail will be updated with:

- Shipped Quantity: Total inventory shipped against the order detail.

- Order Quantity to consume: Total order quantity to consume sent against the order detail.

NOTE: During Ship Load, the system generates the Outbound Load Export (SLS) file which has information associated with the order detail including:

- Maximum Shipping Tolerance%

- Minimum Shipping Tolerance%

- Order Quantity to Consume

DETERMINE BACK ORDER QUANTITY AS ORDER DETAILS ARE SHIPPED/CANCELLED

In the warehouse when orders are received, the warehouse tries to fulfill the order up to the ordered quantity. But sometimes, due to the unavailability of inventory, orders cannot be fulfilled completely. To handle these scenarios, Oracle WMS Cloud communicates to the host system how much quantity was not fulfilled, and based on that information, the host system creates back orders for further processing.

The system will now determine the Back Order quantity when an order detail is Shipped. It will then populate the back order quantity on the reference field for Order Detail Status change Inventory History Transaction (IHT) (ref value 4.)

When the system cancels the Order Detail, Back Order Quantity against the Order detail is now computed and displays in the Ref Code 4 (Back Order Quantity) of the Order Detail Status change Inventory History Transaction (IHT- 85). When order detail is cancelled, Back Order Quantity will be equal to the Original Order Quantity.

The following are the some of trigger points associated when the order detail is cancelled:

- Wave (when Cancel Fully Unallocated flag is enabled)

- IB Shipment UI ("Unallocated order details to cancel on ASN verify" mode on the IB Shipment Type)

- Interface

- Order Interface

The following RF Transactions are triggered (when allocated inventory against the order detail is shorted and the Only deallocate on short flag is disabled on the Order Type)

- RF Pack NC Active Order

- Modify Cancel {oblpn}

- Pick {iblpn}

- Distribute {oblpn}

- Pack {oblpn}

- Pick Cart

- Outbound Audit

- Repack OBLPN

- RF Move LPN

The following APIs are triggered (when allocated inventory against the order detail is shorted and the Deallocate on Short flag is disabled on the Order Type)

- Pick_Confirm API

- Legacy Pick_Confirm API

PROCESSING BACK ORDER IN ORACLE WMS CLOUD

When an order is not fulfilled, the Oracle Inventory Fusion Management Cloud sends the backorder back with the same order number to Oracle WMS Cloud. To address this instance, the Oracle WMS Cloud is enhanced to suffix the original order number in the order interface. This suffixed order number interface payload is processed to the external system. However, when the Oracle Inventory Fusion Management Cloud system downloads the payload, the generated payload will carry the original order number WITHOUT the suffix.

The system calculates the back order quantity against each order detail only when the respective order's order type has the Require Back Order flag set to true in conjunction with Deallocate on Short flag set to false on the Order Type UI.

NOTE: Adding a suffix for an order number is applicable for Oracle Inventory Fusion Management Cloud only. Other ERP systems are recommended to send a new order number to process the backorder and avoid sending the same order numbers. For more information, refer to the Back Order Processing Handling feature.

Steps to Enable

In order for the system to derive back order quantity, you must enable the Require Back Order flag from the Order Type UI.

Key Resources

Enhanced Purchase Order Based Receiving

PURCHASE ORDER AND PO SEQUENCE PROMPT

Prior to 20D, Purchase Order (PO)-based receiving updates were happening for a single detail even if a PO had multiple details, leading to reconciliation issues. In order to support reconciliation of Purchase Order (PO) lines under receipt, a new RF Parameter (prompt_po-seq-line) is now available in RF Receive (LPN) Shipment (rf.inbound.cwrfrecvlpnshpmt) and RF Receive Load (rf.inbound.cwrfrecvlpnload) modules which supports prompting for the PO sequence number or the PO line schedule number based on the configuration.

PARAMETER DETAILS

The prompt_po-seq-line parameter has the following options under the drop-down:

- PO Sequence

- PO line schedule

NOTE: The default value of the prompt_po-seq-line parameter is Blank. When the parameter is set to Blank, the system exhibits the existing behavior and should not prompt for the PO sequence or line schedule number.

Companies using Oracle WMS Cloud together with Oracle SCM Cloud should set the parameter "prompt_po-seq-link" screen parameter to be "PO Line Schedule."

This parameter can be used in the following flows:

- PO Based Receiving

- RF Receiving Flow

- RF Receive by Load

The following table provides details about the parameter behavior for these flows when the prompt_po-seq-line parameter is set to PO Sequence or PO line schedule:

| Flow | prompt_po-seq-line set to: Purchase Order (PO) Sequence | prompt_po-seq-line set to: Purchase Order (PO) Line Schedule |

|---|---|---|

| PO Based Receiving |

|

|

| RF Receive Shipment |

|

|

| RF Receive by Load |

|

|

QUANTITY DISTRIBUTION FOR PO AND SHIPMENT BASED RECIPT

Prior to 20D, if a purchase order had multiple lines for the same SKU, Purchase Order (PO)-based receiving updates were happening for a single detail even if a PO had multiple details, leading to reconciliation issues. Oracle WMS Cloud has been updated so that when the prompt_po-seq-line screen parameter is set to blank, the system evenly distributes the received SKU quantity across multiple Purchase Orders or purchase order lines, which resolves purchase order line reconciliation issues. Quantity distribution is only supported for IB shipments details carrying multiple purchase orders for the same SKU or a purchase order with multiple lines for the same SKU.

The following table provides details about the system behavior for these flows when the prompt_po-seq-line parameter is set to blank:

| Flow | Behavior |

|---|---|

| PO Based Receiving |

|

| RF Receive Shipment (Shipment is carrying multiple PO numbers or PO details of the same SKU) |

|

| RF Receive Load (Shipment is carrying multiple PO numbers or PO details of the same SKU) |

|

PREVENT CONSUMING ENTIRE PURCHASE ORDER DURING PO-BASED RECEIVING

Prior to 20D, during PO based receiving the entire PO was getting converted to a shipment right after scanning the PO number. As a result, the host system could not reduce the purchase order quantity or delete a PO line (a shipment against the purchase order quantity was already being created.) A new screen parameter prevent-entire-po-to-asn-conversion-flg, in the RF Receive Shipment (rf.inbound.cwrfrecvlpnshpmt) module allows you to restrict the system from converting the entire PO to a shipment right after the PO scan during PO based receiving. The screen parameter receiving mode should be set to PO based receiving.

PARAMETER DETAILS

The prevent-entire-po-to-asn-conversion-flg parameter has the following options under the drop-down:

- No (default behavior)

- Yes

When the prevent-entire-po-to-asn-conversion-flg is set to Blank or No,

- The system converts the entire PO to an ASN during PO based receiving. However, the system converts the entire PO to an ASN only after you scan or skip the trailer scan during PO based receiving.

- In case multiple shipments are created prior to PO based receiving, the system will throw the following error message right after the PO scan.

“Cannot receive PO linked to Multiple ASNs”

- Vendor QC will be supported for this mode and the quality check will happen based on the shipped quantity and the vendor QC configuration.

- Users will not be able to reduce the purchase order quantity once the entire PO is converted to a shipment during PO based receiving.

When the prevent-entire-po-to-asn-conversion-flg is set to Yes:

During PO Based Receiving, the system can now create the ASN details based on the PO quantity a user is receiving from PO-based receiving mode, so that the whole PO does not get converted to an ASN and its respective details. This allows purchase orders that have been partially received to be updated. For example, supply chain planning may send a recommended change for a purchase order when the supplier was not able to ship the full expected quantity.

NOTE: The purchase order quantity can’t be updated for less than the received quantity.

- The system now prevents consuming the entire PO to the respective IB shipment details when you scan a PO in PO-based receiving mode. After scanning the PO number, the system creates only the IB shipment header based on the PO and the trailer number combination (if no IB shipment with status less than Verification in progress is found for the same PO and trailer number combination.)

- After you scan the trailer number, if no open ASN is found, then the system creates a new ASN associating the trailer number to proceed with PO based receiving. The ASN header won't be created until you scan or skip the trailer number.

- You can press the Ctrl-E hot key to end receiving on the PO based receiving transaction and the shipment details created will have 0 as the shipped quantity if no prior shipment is created for the PO from the UI or the interface.

- Vendor QC is not supported in this mode of PO based receiving as the shipped quantity for the shipments created during this mode of PO based receiving will be 0.

- The shipment verification files generated upon ASN verification of the ASNs created during PO-based receiving will also have a shipped quantity as 0.

- The system will create a new trailer number record if you scan a trailer number which is not present in the system and the system latches the trailer number to a Shipment with ‘In transit’ status and which does not have a trailer number populated. If no eligible shipment is found for the PO trailer combination, the system then creates a new Shipment with the PO trailer combination.

- Users can receive the remaining PO order in different trailers. The system creates a new Shipment with 0 as shipped quantity with the PO and trailer combination and allow users to receive the outstanding PO quantity against the shipment.

- In case the system finds multiple shipments created prior to PO based receiving, and if it cannot identify the shipment even after you scan the trailer number, the system will throw the following error message:

“PO linked to Multiple ASNs created prior to receipt, cannot perform PO based receipt”

However, the system will allow you to proceed with PO based receiving if multiple shipments are created with 0 as shipped quantity in this mode of PO based receiving. The shipments will be identified and picked based on the PO trailer combination.

BEHAVIOR FOR PO BASED RECEIVING BASED ON FLAG

| Transaction | prevent-entire-po-to-asn-conversion-flg = Blank /NO |

prevent-entire-po-to-asn-conversion-flg = Yes |

|---|---|---|

| Entire PO gets converted to shipment |

YES | NO |

| Shipped qty is more than zero |

YES |

NO |

| PO order qty can be reduced after users starts receiving partially |

NO |

YES |

| PO Seq /Line prompt is supported |

YES |

YES |

| Attribute Prompt is based on shipment dtl |

YES |

NO |

| Vendor QC is supported |

YES |

NO (based on PO details -if PO has Attribute) |

| Shipment is created/Identified After trailer scan |

YES |

YES (Only if shipment is created Prior to PO receiving) |

| verification file has 0 as Shipped qty |

NO |

YES |

| Allow PO recv when Multiple Shipments are found |

NO |

YES (If system can identify shipments after trailer scan) |

| Additional PO qty or PO details gets latched to the same ASN |

YES |

NO |

INTRODUCTION OF NEW MESSAGES

| Parameter status | Use case | Error message |

|---|---|---|

| prevent-entire-po-to-asn-conversion-flg= Yes |

Multiple IB shipments are found with more than 0 as shipped qty in less than verification in progress |

PO linked to Multiple ASNs created prior to receipt, cannot perform PO based receipt |

| prevent-entire-po-to-asn-conversion-flg= Yes |

Shipment is attached to an appointment and the scanned trailer does not match with the shipment |

Trailer and shipment do not match |

Marking the Reference Purchase Order column as '*' when an LPN is Received With Multiple POs

Prior to 20D, when you receive an IBLPN from RF Recv Shipment or RF Recv load or from the IB Shipment header or detail UI, with multiple purchase orders, the IB container UI gets populated with only one PO number on the REF PO column. With the 20 D enhancement, the system now will mark the REF PO number column on the IB container UI as "*" for the IBLPNs received with multiple purchase orders. This will indicate that the LPN is carrying multiple purchase orders.

NOTE: The IHT-1 LPN received inventory history will continue to get split based on the PO numbers getting received in the IBLPN. Additionally, The REF PO number column on the IB container UI will show the PO number if the IBLPN is being received with only a single purchase order.

Steps to Enable

- To prompt for PO-sequence number or the PO-line schedule number during Inbound Receiving, from the prompt_po-seq-line parameter drop-down, select the PO Sequence or PO line schedule option.

- In order to evenly distribute SKU quantity received across multiple Purchase Order or IB Shipment details, set the prompt_po-seq-line parameter to blank.

Key Resources

Scheduled Job to Verify Shipment

A new scheduled job type Auto Verify IB Shipment will mark shipments that are received and due for verification for a specified duration (or 72 hours from the last LPN received time) as verified depending on the configuration of the scheduled job. Auto Verify IB Shipment will not only mark shipments as verified, it will also generate the shipment verification output file. This feature is beneficial because users now don't have to verify the shipment, if they are not interested in tracking the shipment.

The following table describes the Auto Verify IB Shipment job type parameters:

| Field Name | Description |

|---|---|

| Username |

|

| Shipment Type |

|

| Time since last receipt (hrs) |

NOTE: When configuring lesser values, make sure to provide the right shipment type and time since last shipment, otherwise the system could update the status while receiving is still in process. |

NOTE: Shipments with Receiving Started and Receiving Complete status are eligible for verification. Also, shipments will not be verified if they have QC pending LPNs even if the shipments match the job parameter criteria for auto-verify through the scheduler.

Steps to Enable

To mark shipments that are received and due for verification, go to the Scheduled Jobs UI, and create a Scheduled Job with Job Type Auto Verify IB Shipment.

Key Resources

Allow Receiving of QC Rejected LPNs and Return to Vendor

Generally, inventory is subjected to Quality Check (QC) at the dock station. During QC, when inventories are rejected, the system marks these IB containers to Cancelled status and are physically left behind at the QC location. This may create certain difficulties for the warehouse users to differentiate between the actual containers received to put away and the QC rejected container.

In 20D, Oracle WMS Cloud has taken an efficient approach in handling such inventories, where operations can now allow the QC rejected containers inside four walls of the warehouse, track and monitor, and ship out to the faulty or defect inventories to the respective vendors.

ALLOW QC REJECTED INVENTORY INTO THE WAREHOUSE

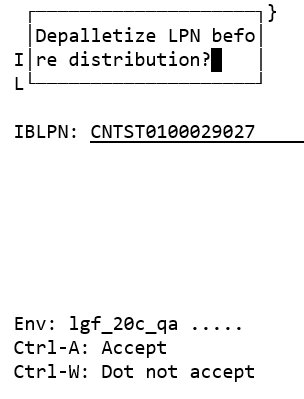

New parameters are added in the RF QC Complete (rf.inbound.cwrfqccomplete) module that prompts users to provide a lock code (un-allocatable) on completing for the RF QC Complete transaction. On applying the lock code, the QC rejected status remains in Rejected status but the LPN status now moves to Received, thus allowing rejected inventories to be brought inside the warehouse.

The benefit of applying lock code is to avoid QC rejected inventories to be merged with the mainstream inventories during any movement of inventory.

NOTE: All the lock code prompts that are displayed are based upon the parameter configuration only on LPN that is QC rejected and do not prompt any lock code if the LPN is QC accepted.

- rejected-inventory-handling

Selections Description Blank (default)

Does not track any QC rejected inventory and the system falls back to existing behavior where LPNs are marked to Cancelled status upon QC rejection.

Lock rejected inventory

Prompts for lock code during the RF QC complete transaction to apply an un-allocatable lock code for the rejected LPNs.

- rejected-lock-code

Parameter Choice Description Blank (default)

Prompt for the lock code if the Rejected inventory handling is set to Lock rejected inventory.

NOTE: The system will not Prompt for the lock code if the Rejected inventory handling is set to Blank.

Text Field Users can explicitly define the parameter to set the lock code.

NOTE: If the rejected-lock-code has defaulted with a valid and un-allocatable lock code, then the system will not Prompt for the lock code. The LPNs will be marked as Received and QC status as QC rejected.

The following table depicts the behavior of the parameter:

| QC Status | Rejected Inventory Handling | Rejected Inv LC | LPN Status | LPN Lock Code |

|---|---|---|---|---|

| QC rejected |

Blank |

Blank |

Canceled |

N/A |

| QC rejected |

Lock rejected inventory |

Blank |

Received |

Users need to provide an un-allocatable lock code (if not defaulted) when prompted. |

| QC rejected |

Blank |

Lock code provided |

Canceled |

The lock code is not honored. |

| QC rejected |

Lock rejected inventory |

Lock code provided |

Received |

Lock code defaults and the system does not show any prompt to users. |

- When the parameter rejected-lock-code is set to Blank and if the Rejected inventory handling is set to Lock rejected inventory, then the system prompts users for the lock code. The system displays un-allocatable lock codes available in the system during the QC complete transacting for users to select a lock code from the list.

- If the Rejected inventory handling is set to Lock rejected inventory and the rejected lock code screen parameter is configured with an un-allocatable lock code, the system will default the lock code from the rejected lock code screen parameter upon QC rejection and will not prompt for lock code.

NOTE: If the lock code is provided in the rejected lock code text field, the system will not prompt for lock code in RF.

- If the defaulted lock code is invalid, the system displays the following message, “Invalid lock code for facility or company" (Message code 2013). Upon accepting the message, the un-allocatable lock codes are displayed for users to choose from.

- The system updates the shipment and associated PO quantity (if any) considering the QC rejected inventories.

IMPORTANT NOTE: If an un-allocatable lock code is removed from the QC rejected LPN, then the rejected inventories will be at risk of getting allocated and picked by the wave or non-wave transactions.

- A new error message "Cannot QC reject with an allocatable lock code" is introduced and displayed when the user applies an allocatable lock code on the QC rejected LPN or configured from the rejected lock code parameter, and is by default enabled for all respective facilities.

- A new column “Lock Code” is added in the Verification History view UI screen to displays the un-allocatable lock code applied on the QC rejected LPNs from the RF QC Complete transaction.

APPLY LOCK CODE VIA IB CONTAINER AND IB SHIPMENT UI

A new pop-up window is introduced and displayed in the IB Container (IbContainerView) and IB Shipment (IBShipmentView) UI when users click the Reject button on the respective UI. This pop-up window lists only an un-allocatable lock code for users to select from the drop-down. On applying the lock code, the QC rejected LPN status moves to Received and thus allowing users to bring the LPN within the four walls.

NOTE: Applying a lock code upon rejecting an LPN is not mandatory. However, if users do not select a lock code, the system retains the original behavior where the LPN status moves to Cancelled upon performing QC reject.

- Users can select multiple records for the Quality Check from the IB Container (IbContainerView) and IB Shipment header (IBShipmentView) UI. The applied lock code will be applicable to all the selected LPNs subjected to QC.

- When multiple QC rejected LPNs are pending, and the user proceeds to apply an un-allocatable lock code to reject the LPNs, the system will only process those LPNs which do not have the same lock code. Thus, marks such LPN as Received with QC status as QC rejected. But, for some LPNs which already has the same lock code, the system displays an error “Successfully completed:<LPN> Some of the LPNs are not rejected with lock code as the same lock is already applied to them <LPN>”, and retains the same LPN status and do not get QC rejected.

ORDER CREATION FOR QC REJECTED LPNS

You can now create an order manually to ship out rejected inventories from designated locations.

A new “Lock Code for QC Reject Allocation” text field is introduced in the Order Type UI where:

- You can define both allocatable and un-allocatable lock codes that allow IBLPNs to be allocated and shipped to the vendors via RF Direct Allocation and RF Pick and Allocate transactions.

- When you define the lock code in the “Lock Code for QC Reject Allocation”, the system tries to match the lock code on the IBLPN against the lock code on the order type. If the lock code on the IBLPN matches with the order type lock code, only then the QC rejected IBLPN is allocated.

- Supports configuring one or more valid lock codes separated by a comma only. The system will display an error if any other characters are used to add more than one lock code.

- The system erases any leading and trailing spaces between two consecutive commas provided in the “Lock Code for QC Reject Allocation” field when saving the record.

The following table depicts the allocation of IBLPNs via RF Direct Allocation and RF Pick and Allocate:

| IBLPN |

Lock Code | Lock Code Type | Lock Code for Order type | Description |

|---|---|---|---|---|

| LPN01 | LC01 |

Allocatable |

Not required. Do not provide any lock code. |

|

| LPN01 |

LC01 |

Allocatable |

LC02 (un-allocatable) |

Users will be prompted "Lock code mismatch". |

| LPN01 |

LC02 (un-allocatable) |

Users will be prompted "Lock code mismatch". |

||

| LPN01 |

LC02 |

Un-allocatable |

LC02, LC03 (both un-allocatable) |

IBLPN gets allocated. |

| LPN01 |

LC02, LC03 |

Un-allocatable |

LC02, LC03 (both un-allocatable) |

IBLPN gets allocated, if you are using lock code priority, then LC02 should have lesser priority than LC03. |

ALLOCATING FOR QC REJECTED LPNS

Oracle WMS Cloud also allows you to ship out of QC rejected LPN to vendors via RF Pick and Allocate and RF Direct Allocation transactions.

NOTE: The allocation of QC Rejected inventory is supported only through User directed mode in the RF Pick and allocate transaction.

- Allocation for QC rejected inventories is supported only if the LPNs are in Reserve/Drop locations, LPNS that are not located are in Received status, and LPNs that have matching Allocatable/ un-allocatable lock code defined in the Lock Code for QC Reject Allocation on Order type UI.

- If the scanned LPN has multiple un-allocatable lock codes, but only one of them matches with the Lock Code for QC Reject Allocation in the Order Type, then the lock code with higher priority will take precedence.

- In case a QC rejected LPN has two un-allocatable lock codes and the matching lock code defined on the order type has a higher priority than the other un-allocatable lock code present on the LPN, the system successfully performs allocation of the rejected LPN.

- In case a QC rejected LPN has two un-allocatable lock codes and the matching lock code defined on the order type has a lower priority than the other un-allocatable lock code present on the LPN, the system displays the newly introduced error message “Scanned LPN has another un-allocatable lock code with a higher priority" and does not perform allocation of the rejected LPN.

- During the Pick and Allocate transaction to allocate a QC Rejected LPN, when the user scans the active location, the system displays a newly introduced error “Order Type has lock code for QC Reject. <%> location is not supported for allocation.”

- If the allocated Order Type does not have 'Lock Code for QC Reject Allocation' configured and upon scanning a reserve location and IBLPN with an un-allocatable lock code, then the system displays an error “Scanned LPN has un allocatable lock.”

RESTRICT RF SPLIT IBLPN AND RF IB SORT DURING QC COMPLETE TRANSACTION

Users can now split, and sort similar QC rejected inventory via the RF Split IBLPN (rf.inbound.cwrfsplitcntr) transaction and thus restricting splitting of QC rejected inventory into non-rejected LPN when performing the split transaction.

When performing RF Split IBLPN (rf.inbound.cwrfsplitcntr), the system behaves in the following manner:

| Source LPN | Destination LPN | Behavior |

|---|---|---|

| QC rejected inventory |

With New LPN |

Inventory is split from the source LPN and moved to the destination LPN and therefore, the lock code and QC status will be transferred to the destination LPN. |

| QC rejected inventory |

An existing QC rejected LPN |

Allows the inventory to be split for source and destination LPN having the same or different lock code. NOTE: When the Required Validation parameter is set to All, and if the source LPN has an un-allocatable lock code present, the same lock code should be matched with the destination LPN as well. Otherwise, the system will say Lock code mismatch. Users can perform RF split transactions when the source and destination IBLPN has different lock codes and the Required Validation parameter is set to None. |

| QC rejected inventory |

Existing LPN without any reject inventory |

Displays a newly introduced error “QC Reject inventory cannot be mixed with non-reject inventory' should be displayed” message. |

| Existing LPN without any reject inventory | QC Reject LPN | Displays a newly introduced error “QC Reject inventory cannot be mixed with non-reject inventory' should be displayed” message. |

When performing RF IB Sort (rf.inbound.cwrfibsortlpn) transaction, the system behaves in the following manner:

| Source LPN | Destination LPN | Behavior |

|---|---|---|

| QC rejected inventory |

With New LPN |

Upon merging, inventory is fetched from the source LPN and moved to the destination LPN, and therefore, the lock code and QC status will be transferred to the destination LPN. |

| QC rejected inventory |

An existing QC rejected LPN |

Allows the inventory to be merge from source and destination LPN having the same or different lock code. |

| QC rejected inventory |

Existing LPN without any reject inventory |

Displays a newly introduced error “QC Reject inventory cannot be mixed with non-reject inventory' should be displayed” message. |

| Existing LPN without any reject inventory | QC Reject LPN | Displays a newly introduced error “QC Reject inventory cannot be mixed with non-reject inventory' should be displayed” message. |

NOTE: It is recommended that user users Container QC status as the sort criteria to sort the QC rejected IBLPNs. Otherwise, users are required to scan a different sort zone to sort the QC rejected LPNs if the sorting zone already has mainstream inventories. We will introduce skip location functionality or allow users to scan a different location within the sort zone at a later version release.

RESTRICT CREATING LPNS FROM ACTIVE LOCATION

When LPNs are created from active using the RF Create LPN module, WMS allows an existing IBLPN to be used, as long as the shipment associated with the IBLPN is verified. A new error “Invalid LPN status, LPN is QC rejected” is introduced in this module which is encountered when users scan an existing IBLPN that is QC Rejected and is in Received status.

NOTES:

- The new error is applicable only when LPNs are created with inventory out of an active location. This is because the WMS does not allow existing IBLPNs to be used by RF Create LPN if inventory is not from active location.

- The new error is applicable only for LPNs that are associated with a shipment that is verified. This is because WMS does not allow existing IBLPNs to be used by RF Create LPN if the associated shipment is not verified.

RESTRICT QC REJECTED LPNS DURING PALLETIZATION

Enhancements are made to prevent the combining of rejected inventory with regular inventory on the pallet. A newly introduced error “Pallet cannot have a mix of QC rejected and non-rejected inventory” message is displayed under the following conditions:

RF Palletization (rf.inbound.cwrfpalletizeplt) transaction:

- When the user scans an existing pallet during palletization containing QC rejected LPNs, and user scans a regular LPN.

RF putaway (rf.inbound.cwrfputaway) transaction:

- When the prompt-dest-pallet parameter is set to yes and the user scans a QC rejected LPN for putaway and pallet contains good LPN.

- When the prompt-dest-pallet parameter is set to yes and the user scans a regular LPN for putaway and pallet contains QC rejected LPN.

RF Locate LPN/pallet (rf.inbound.cwrflocatelpnpallet) transaction:

- When the prompt-dest-pallet parameter is set to yes and the user scans a QC rejected LPN to locate and pallet contains good LPN.

- When the prompt-dest-pallet parameter is set to yes and the user scans a regular LPN to locate and pallet contains QC rejected LPN.

Palletize via API:

- When performing palletization form the API where the user provides a QC rejected LPN and the destination pallet has a regular LPN.

- When performing palletization form the API where the user provides a regular LPN and the destination pallet has a QC rejected LPN.

This enhancement also focuses on improving screen flow during various transactions for QC rejected inventories.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

RECOMMENDATIONS:

- Users are advised not to remove the un-allocatable lock codes from the QC rejected inventories. If the un-allocatable lock codes are removed from the QC rejected yet LPNs are received, the system will consider the rejected LPNs as mainstream inventories and can be allocated through the wave or non-wave transactions.

- Users must ensure not to putaway QC rejected LPN's to an Active location. Currently, the system has no restriction to prevent the putaway of QC rejected LPNs to an Active location and can only be controlled by enabling the Prevent Putaway flag on the lock code applied.

- It is recommended to disable the Unlock on locating to Reserve flag so that the un-allocatable lock code is not removed from the QC rejected LPNs upon locating to a reserve location.

Key Resources

New Parameter for Non-Multi-Field Barcodes

Prior to update 20D, the barcode type “Count” only applied in Multi-Field Barcode (MFB) scenarios, and only when the Multi-Field Barcode was scanned in a non-quantity barcode field. Now with update 20D, you can use the Count barcode type for both MFB scenarios, and non-MFB scenarios. A new Company parameter “ENABLE_NON_MFB_COUNT_BARCODES” has been added to control this behavior. The default is No, but If set to Yes, it will allow:

- The count barcode type to be used in a non-MFB scenarios.

- Single barcodes for count (ie quantity) to be scanned into the quantity field.

- To validate against the barcode type rules as defined for the count type.

- All quantity entry fields will recognize this barcode type.

- The "numeric" flag on the barcode type detail should be ignored for Count and the behavior should be as if it was enabled.

- Any non-numeric (ie except numbers, decimal point) values other than the prefix will result in an error message.

NOTE: The quantity entry field currently accepts non-numeric characters and ignores them silently. This behavior will continue when the new parameter is disabled

3PL CONSIDERATIONS

Oracle WMS Cloud only looks up this value for the users default company. If a user at the parent company level logs in and starts receiving a shipment for a child company, the parameter value that gets used is the one for the user's default company which is the parent company. If a user that belongs to a child company logs in, the parameter at that level is what applies.

Steps to Enable

You don't need to do anything to enable this feature.

Enhanced Configurability on Post-Pick Order Consolidation and Loading

In order to streamline throughput in the warehouse, Oracle WMS Cloud has added a new feature to manage and control Outbound LPN movements after picking/packing using Outbound LPN/Pallet Putaway.

This makes your time to market faster and reduces user clicks and screen time – ultimately reducing bottlenecks within the warehouse.

CONFIGURATION

New Transaction - RF Module OBLPN Directed Putaway

Outbound LPN/Pallet Putaway is a new module (rf.outbound.cwrfputawayoblpn) that will be used for pushing picked or packed OBLPN's to relevant locations or to call other transactions like Loading or Dynamic Staging.

NOTE: The Outbound LPN/Pallet Putaway transaction can be called standalone or through tasking.

- Users should be able to scan single or multiple LPNs or a Pallet. If they are scanning multiple LPNs a counter will also be displayed.

- When scanning, OBLPN status must be "Picked or Packed”.

- When scanning, a Pallet status must be "In-use”.

- If user scans an LPN on the Pallet, the following message will appear -- "LPN will be depalletized, proceed further".

- We do not support multiple pallet scan with this transaction.

SCREEN PARAMETERS FOR THE NEW DISPATCH MODULE

putaway-type-determination-rule

This is a free form text box where you can add the rule name you configured in OBLPN Putaway type determination UI. Rule name provided will determine the putaway type by going through the individual rule sequences.

determine-patype-for-each-lpn

If _determine-patype-for-each-lpn is set to "No":

- Then when users scan multiple LPNs, the putaway type is not going to be calculated for each LPN. Instead the system is only going to calculate the putaway type according to the rules and inventory. Incompatible putaway types will not come into play as there will only be one putaway type determined for all LPNs on a pallet or all the LPNs scanned or passed through tasking mode.

If _determine-patype-for-each-lpn is set to "Yes":

- System will calculate the putaway type for each LPN scanned.

- If a common putaway type is determined for all LPNs on the pallet or all individual OB LPNs scanned in OBLPN Putaway or all LPNs passed through tasking mode. User will be prompt with the action configured in OBLPN Putaway Action UI.

- If Putaway types determined for all LPNs on the pallet or all LPNs passed through tasking is different and are incompatible then message will be displayed "Putaway types are different and not compatible for proceeding with next action," and user will be prompted with a drop location.

- If Putaway Type determined is not same(heterogeneous) and OBLPN Putaway is invoked Standalone. Putaway type determination to happen after each LPN scan, and if putaway type determined for next LPN scanned is not compatible with previously scanned LPNs display error message "Putaway type determined for %LPN% is not compatible with previously scanned LPNs, scan different LPN".

default-drop-location

This is a free form text box, which will allow users to configure the drop location.

NOTE: Drop Location configured should not be part of Inbound Sort Zone or Outbound Sort Zone.

Recalculate Putaway type

- If screen parameter recalculate Putaway type is set to "Yes", putaway type will be determined even though container has putaway type.

- If screen parameter recalculate Putaway type is set to "No", putaway type will not be determined if container has putaway type. Putaway type determination will be invoked only if container does not have Putaway type.

- If Pallet is subjected for Putaway type determination, and recalculate Putaway type is set to "Yes" Putaway type will be computed for each LPN on the Pallet, even though putaway type is populated on the LPN's.

- If Pallet is subjected for Putaway type determination, and recalculate Putaway type is set to "No" Putaway type will not be computed if all outbound LPN's have Putaway type populated. Determine Putaway type only for those LPN's which do not have PA type.

NOTE: Putaway type determination is based on the configuration of determine-patype-for-each-lpn screen parameter. The configuration of this parameter is very important as it drives the whole logic of how the putaway type is determined.

DETERMINING PUTAWAY TYPE

New UI - OBLPN Putaway Type Determination

OBLPN Dispatch assigns an OBLPN Putaway Type to OBLPNs or Pallet according to the rules configured in the new OBLPN Putaway Type Determination UI. The New RF OBLPN Direct Putaway will look into the rules and the selection criteria that the user has set up in the new UI – OBLPN Putaway Type Determination, and if the selection criteria matches the inventory in the OBLPN, it will assign the Putaway type configured in that rule. In the New OBLPN Putaway type Determination UI you can configure the rule name. This rule name is configured in the screen parameter "putaway-type-determination-rule" of the RF OBLPN Direct Putaway.

Putaway Type Determination Sequence

- In the OBLPN Putaway Type Determination UI, the user must configure a putaway-type-determination-rule. Each rule can have a set of Putaway type determination sequences that can be configured in the detail screen. The system will assign a putaway type by looking at the sequence and its corresponding selection criteria. If selection criteria configured matches against the container's attributes, then the system will assign the putaway type configured on that particular sequence. If selection criteria is not configured then Putaway type will be assigned as per that sequence.

- If LPN which is subjected for Putaway type determination contains multiple SKUs and if the underlying selection rule has item/item facility attributes used in the rule, then any one of the item's attributes can be considered, and if one matches the selection criteria then system will assign that putaway type.

- If LPN which is subjected for Putaway type determination contains multiple orders and if the underlying selection rule has order header attributes used in the rule, then any one of the order header's attributes can be considered.

- If LPN which is subjected for Putaway type determination contains multiple order details and if the underlying selection rule has order detail attributes used in the rule, then any one of the order details attributes can be considered.

- If LPN which is subjected for Putaway type determination contains multiple allocations and if the underlying selection rule has allocation attributes used in the rule, then any one of the allocation's attributes can be considered.

- If selection criteria does not pass based on the containers contents (items, orders, allocation), then proceed with next sequence.

- If Putaway type is not determined then a drop location will be prompted. If Putaway type determination fails for one or more LPN then the system will display the message "Putaway type determination failed for some of the LPN's, locate to drop location".

Selection Criteria

Selection Criteria can be assigned for each Putaway Type Determination Sequence. Selection criteria has fields from tables such as Container, Order, Allocation, and more. We have also added a list of additional functions. These new functions can be useful to assign a Putaway Type.

| Complex Function | Comments |

|---|---|

| Has All LPNs on Single Load. |

If all OBLPNs are assigned to same Load, then Loading Module could be called. If all OBLPNs are assigned to same Load, then operator can directly perform Loading. Typically useful when LPNs are called in tasking mode or while picking a Pallet or while picking multiple LPNs in standalone mode and Putaway type is not determined by LPN. LPNs without a load number are not evaluated. |

| Total Weight by LPN |

Will yield the summation of OBLPNs' weight on all the participating LPNs. Actual weight determined can be different than estimated weight. This function could be used in operations after capturing the actual weight. Typically useful when LPNs are called in tasking mode or while picking a Pallet or while picking multiple LPNs in standalone mode and Putaway type is not determined by LPN. |

| Total Volume by inventory |

Sum (curr_qty * unit_volume) across all inventory lines. |

| Has All_LPNs on Single Stop |

If all OBLPNs are assigned to the same Stop, then Loading Module could be called. If all OBLPNs are assigned to same Stop, then operator can directly perform Loading. Typically useful when LPNs are called in tasking mode or while picking a Pallet or while picking multiple LPNs in standalone mode and Putaway type is not determined by LPN. LPNs without a load stop are not evaluated. |

| Has All LPNs on Active Stop |

If all OBLPNs are assigned to the Active Stop (the first non-closed stop on the specified load), then Loading Module could be called. If all OBLPNs are assigned to the Active Stop, then operator can directly perform Loading. Typically useful when LPNs are called in tasking mode or while picking a Pallet or while picking multiple LPNs in standalone mode and Putaway type is not determined by LPN. LPNs without a load stop are not evaluated. |

| Has complete orders |

All underline orders must be present in the task, pallet or scan OBLPN, and they must be completely packed. |

| Has complete pick orders |

All underline orders in the task pallet or scanned OBLPN , and they must be completely in pick status for final packing to be started using RF Repack. |

| Has mix destination facilities |

Checks the selected inventory orders' DESTINATION facility, if there's more than one, true. |

| Has mix order type |

Checks orders' type, if there's more than one, true. |

| Has mixed shipto |

checks orders' SHIP TO facility, if there's more than one, true. |

| Is multi sku |

Returns true if there is more than one type of item in the selected inventory. |

| Number of orders |

Counts all the orders in the selected inventory. |

| Total weight by inventory |

Sum (curr_qty * unit_weight) across all inventory lines. |

| Inventory exceeds LPN type capacity |

Checks to see inventory uses any LPN types. If it does, it tests if LPN total volume or weight exceeds the LPN types capacity. It returns true if ANY of the LPNs exceed it's LPN type capacity. |

New OBLPN Putaway Action UI

Once your Putaway Type has been determined as per the configuration rules above, you may configure activity based on the determined Putaway type in a new web UI screen. The OBLPN Putaway Action configuration will decide if the LPNs or Pallet will be either “Locate,” “Stage,” or “Load.” This is going to save you time and you will not need to exit one transaction before logging in to the next transaction. This is crucial for warehouses that only have a single user who performs multiple steps from pick to load.

DISPATCH ACTIONS

OBLPN Putaway Action - Locate

After Putaway type is determined, the system will check the configuration for that putaway type. If the action is to Locate, the following will happen:

- If resultant action has destination location barcode configured, user will be prompted with location and will have to confirm location.

- If the resultant action has destination location type and destination zone configured, then user will be suggested a Task Zone and user will be free to put the OBLPN or Pallet in a location with that task zone.

- WMS activity records needs to be written as configured.

Let's say you have LPNs in a pallet with different putaway types and those putaway types have an OBLPN Putaway Type equal to Locate. However, those putaways are all set up to be located in different locations. The system will prompt you to depallatize the pallet, and to scan each LPN, so that they are located in the correct location.

NOTE: Customers will have to configure task zones for the locations like drop/packing station/Staging/Pack and Hold.

OBLPN Putaway Action - Stage

Currently, pickers have to drop picked LPNs in a drop location and the next operator has to pick the LPNs for staging. For small warehouses where staging locations are nearby, it will be beneficial to call a dynamic staging transaction right after picking is completed. Without this feature, users will have to come out of tasking and invoke the transaction standalone which can result in productivity issues.

With this new feature, customers will be able to configure staging transaction to be called upon completion of picking and users will be prompted for performing dynamic staging or invoke staging transaction for the LPN's or Pallets post packing based on Putaway type determination.

Please note that if Dynamic staging transaction is being called from Outbound LPN Putaway Module, the transaction will allow you to scan more than one LPN, and the system will ask the user to scan each LPN to be staged one by one.

OBLPN Putaway Action - Load

To facilitate loading, users are now able to load LPNs or single pallet right after picking. Now, you will be able to call Loading upon completion of picking, so the same user can be prompted to do the loading of the LPNs or Pallet packed using the new RF OBLPN Putaway Directed transaction. If user has configured loading as the putaway action, users will be able to easily load into the truck. Some examples of validations included:

- Prevent loading onto inactive stop

- Prevent loading if LPNs are assigned to multiple loads

- Prevent loading if some LPNs are NOT assigned to a load

- Prevent loading if order is blocked for shipping

The system will prompt for a message to perform Loading. Loading is completed by scanning a dock door/trailer/load number. You will not be Prompted to rescan the LPN or Pallet, after scanning in OBLPN/Pallet Putaway. To speed up the process, you will be prompted to either scan a dock number (if dock is assigned via appointment) or trailer number/load number.

NOTE: Users are only allowed to scan OBLPNs that have been passed thru OBLPN Directed Putaway transaction. If users scan an OBLPN which is not passed from OBLPN Directed Putaway transaction the system will display error message "Scanned LPN/Pallet not part of OBLPN Putaway".

LOCATE

If system is not able to determine a putaway type, then users will be prompted to scan a location or to confirm a location if default is set up in transaction. This location must be a “Drop” Location, and the type of the location should be ‘drop’ for the logged facility. Drop Location configured should not be part of Inbound Sort Zone or Outbound Sort Zone.

Once users confirm the location, if dealing with LPNs alone, the current location of the LPNs is updated. If dealing with pallets, ensure current location of the pallet is updated to the drop location scanned.

Change in Task Type detail UI to make System Call New Transaction

The following Allocation types have a new entry to task type detail screen. This new entry is Putaway OBLPN, and users will be able to add the new RF OBLPN Directed Putaway screen. The entry is not mandatory.

- Full LPN/FULL-LPN-PALLET or FULL-CONTAINER (Post full LPN picking)

- LPN Cases/LPNCases (Post Non cubed Active Picking)

- LPN Packs/LPNPacks (Post Non Cubed Active Picking)

- LPN Units/LPNUNITS (Post Non Cubed Active Picking)

- Full LPN/PLTMV_AUTOPK (Post Pack OBLPN, with Pallet being pulled)

- Active Pick/NC-ACTIVE-PICK (Post Non Cubed Active Picking)

Multiple Types/PICK_CART (Post Pick Cart)

In tasking flow, you can either get task zone movements (and then you can use oblpn putaway standalone) or you can get oblpn_putaway built in, but you cannot configure both.

OBLPN Inquiry and Item inventory by LPN Screens – Now Displays Putaway Type

- Putaway type column is exposed in Outbound LPN Inquiry.

- Putaway type column is exposed in Item Inventory by LPN.

- Not by default.

- You can search by putaway type.

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

New Facility Parameter to Associate Blind ASNs

The ability to associate a shipment type for blind shipments is now available in 20D. A new facility parameter SHIPMENT_TYPE_FOR_BLIND_IBSHIPMENT allows you to associate a Shipment Type to a blind ASN and also harness additional flags on the shipment type during receipt like the "allow receipt of expired inventory" flag.

The SHIPMENT_TYPE_FOR_BLIND_IBSHIPMENT parameter includes the following details:

- By default the Parameter Value is <Blank>.

- The parameter should be configured with a valid 'Shipment Type' configured in the system.

- When SHIPMENT_TYPE_FOR_BLIND_IBSHIPMENT is <blank>, during RF Recv Shipment (Blind ASN Receiving) - blind ASNs are created without a Shipment Type.

When SHIPMENT_TYPE_FOR_BLIND_IBSHIPMENT is configured with a valid value (Shipment Type configured in the logged in company), during Blind ASN Receiving:

- After receiving the first LPN, when the system displays the LPN prompt screen, the system displays the configured Shipment Type in the "Shipment Type" field.

- Blind ASNs are created with the configured Shipment Type.

- When a blind shipment is defined with a shipment type, the ASN should honor the Allow Expired Inventory field.

Steps to Enable

To facilitate auto-verification of blind ASNs, configure facility parameter SHIPMENT_TYPE_FOR_BLIND_IBSHIPMENT with a valid shipment type.

Key Resources

Support for Legacy Company Parameter LEGACY_ACTUAL_WEIGHT_OVERRIDES_WT_VOL_CALC_IN_SHIPPING

As part of 20D, a new company parameter LEGACY_ACTUAL_WEIGHT_OVERRIDES_WT_VOL_CALC_IN_SHIPPING is introduced in the system to re-compute the weight/volume for the OBLPN based on the Item's unit weight and quantity on the OBLPN when the OBLPN gets loaded and shipped. This company parameter is set to No, by default.

If the parameter is set to YES, the system does not re-compute the weight/volume on the OBLPN and OBLOAD and will retain the actual weight/volume captured either via UI/RF or API.

NOTE: If the actual weight and volume are recorded post packing and if the actual weight does not change, then it's recommended to set the parameter to Yes so that the actual weight recorded is not overwritten.

After performing Picking, the actual weight/volume/dimensions of the LPN can be recorded. Even though the actual weight and volume are recorded upon performing ship load, the OBLPN’s weight and volume were previously recomputed. As part of this change, the application will provide the ability to retain the actual weight and volume of the OBLPN recorded during ship load.

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

Backorder Processing Handling in WMS

The system allows the processing of orders with the same order number only when the "Require Back Order Flag" on the order's order type is enabled and the existing order with the same order number is in Shipped or Canceled status.

Users can process the order from:

- Order Interface

- Init stage API for order

- Order UI

NOTE: IF the "Require Back Order Flag" on the order's order type is disabled and the existing order with the same order number is in Shipped/Canceled status, then the system displays an error message.

A new column "Original Ord Number (original_order_ndr)" is introduced on the Order header. By default, the value in the column is set to Blank.

During backorder processing, the existing order present in the system with the same order number is renamed with timestamp suffix (YYYYMMDDHHMMSS) and the renamed order number is displayed in the order number field in the Order UI. On renaming the order number during backorder processing, the original order number (before renaming) is stored in the Original Order Number column in the Order Header UI. The Original Order Number column is also displayed in the Order Header category in Web Reports.

The system considers the order number from the Original Order Number column present on the order. If the value is blank, then the order number is considered from the Order Number column of the respective order for the following interfaces:

- Inventory History (IHT)

- Shipped Load (SLS)

- Order Outbound Load Export (PLS)

- Pallet Shipping Info (PLO)

- OBLPN Shipping Info (OLO)

- Container Outbound Load Export (LLS)

When Oracle Inventory Management Cloud sends an unfulfilled order back with the same order number to Oracle WMS Cloud, the system was not processed because of an already existing order number present in the system whose order status was greater than created.

Back Order Processing has been enhanced so that you can now process back orders with the same order number even if an earlier order with the same number is in Shipped/Cancelled status.

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

Allocation in Terms of Packs or Cases from Active Locations

In 20D, Oracle WMS Cloud is enhanced to support Picking allocations from the Wave in terms of Packs or Cases from active locations. Now, users who track inventory in terms of item’s standard pack or item’s standard case quantity can use the feature for allocating in terms of packs or cases from active.

Highlights of the enhancements include:

PICKING WAVE ALLOCATION