- Revision History

- Overview

- Update Tasks

- Feature Summary

- Transportation and Global Trade Management

-

- Transportation and Global Trade Platform

- UI And Workbench

- Documents

- REST Services

- Analytics

- Technical Features

-

- XML Schema Validation - Update

- Restrict External ID (XID) Creation to Valid Characters

- Disable IntXmlService and IntGtmXmlService

- DBXML Maximum Export Size Restricted

- Use Nested GID in Agent DTA

- CSV Upload Refresh - Update

- Load Balance Topic Interface - Update

- Optimize Data Query Footprint - Update

- Process Manager - Run As User Role

- Performance Metric Collection

- OTM User to Oracle Identity Cloud Service Auto Creation

- External System Support for OAuth2.0

- Oracle Transportation Management (Base)

- Shipment Group

- Shipment

-

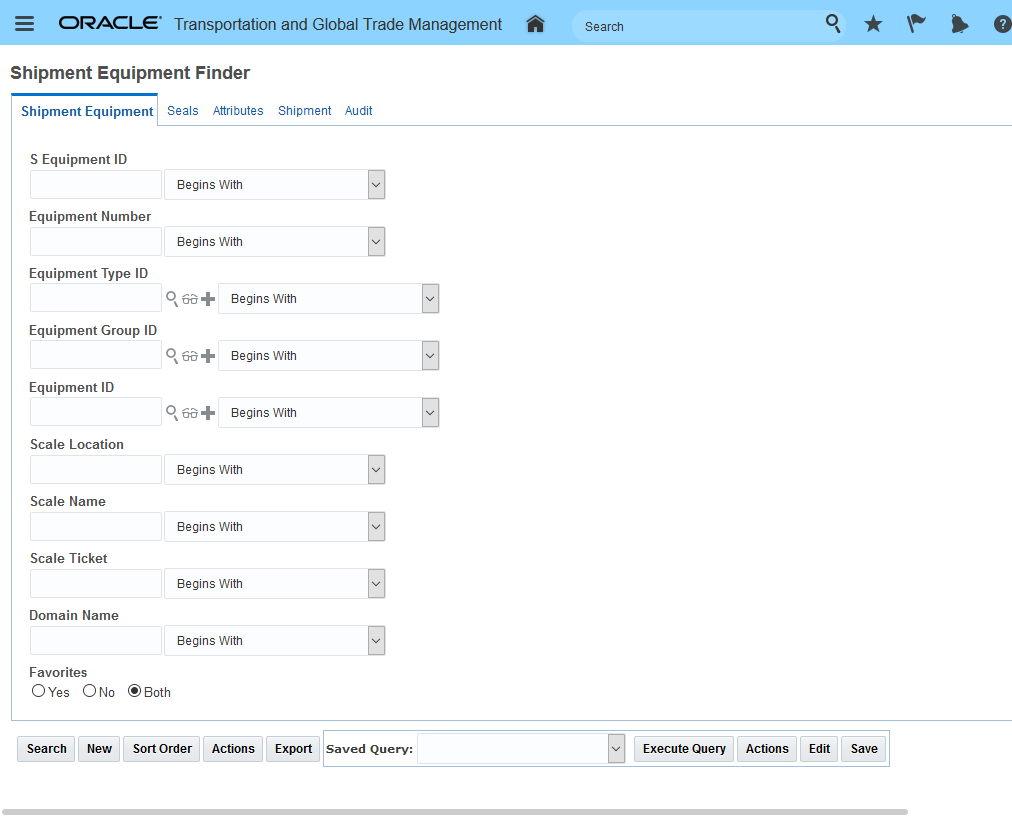

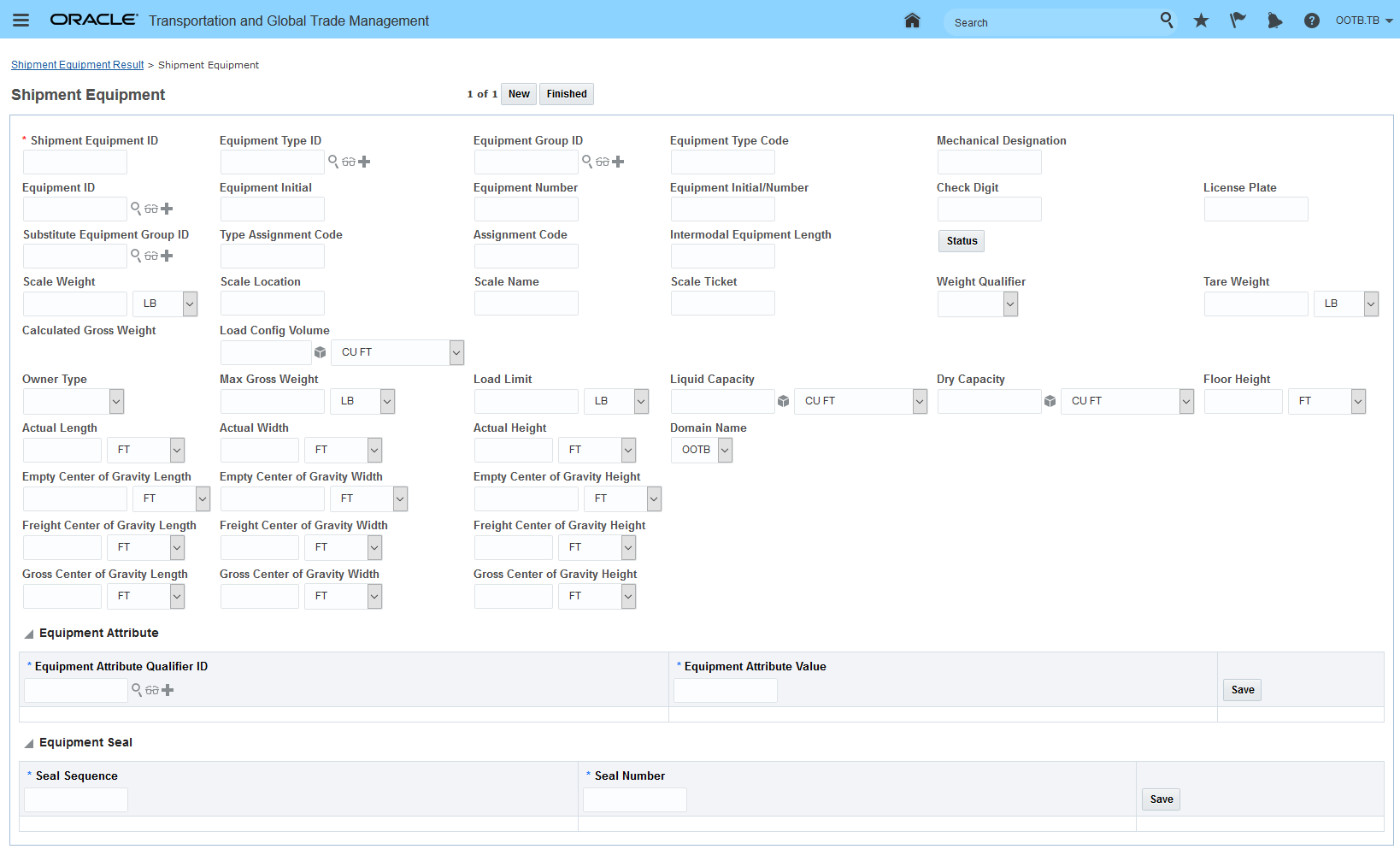

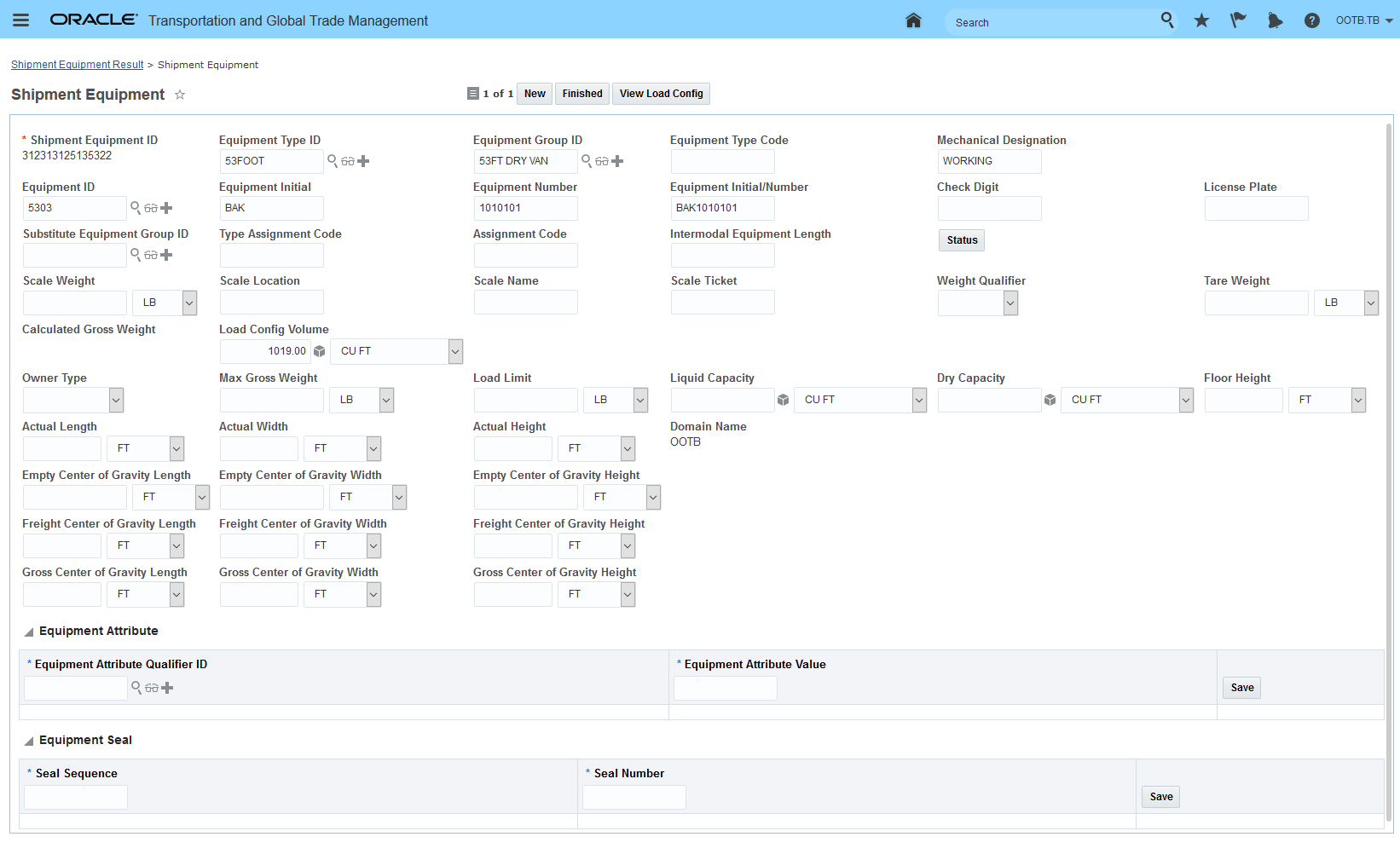

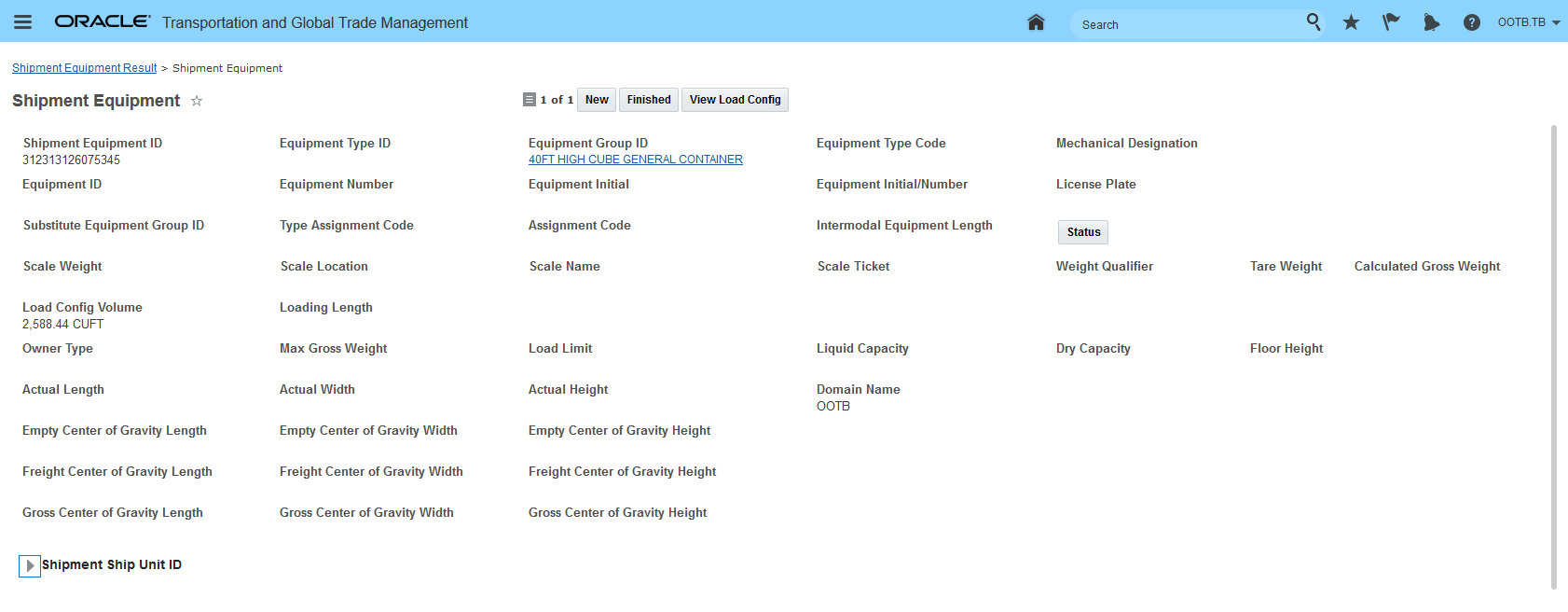

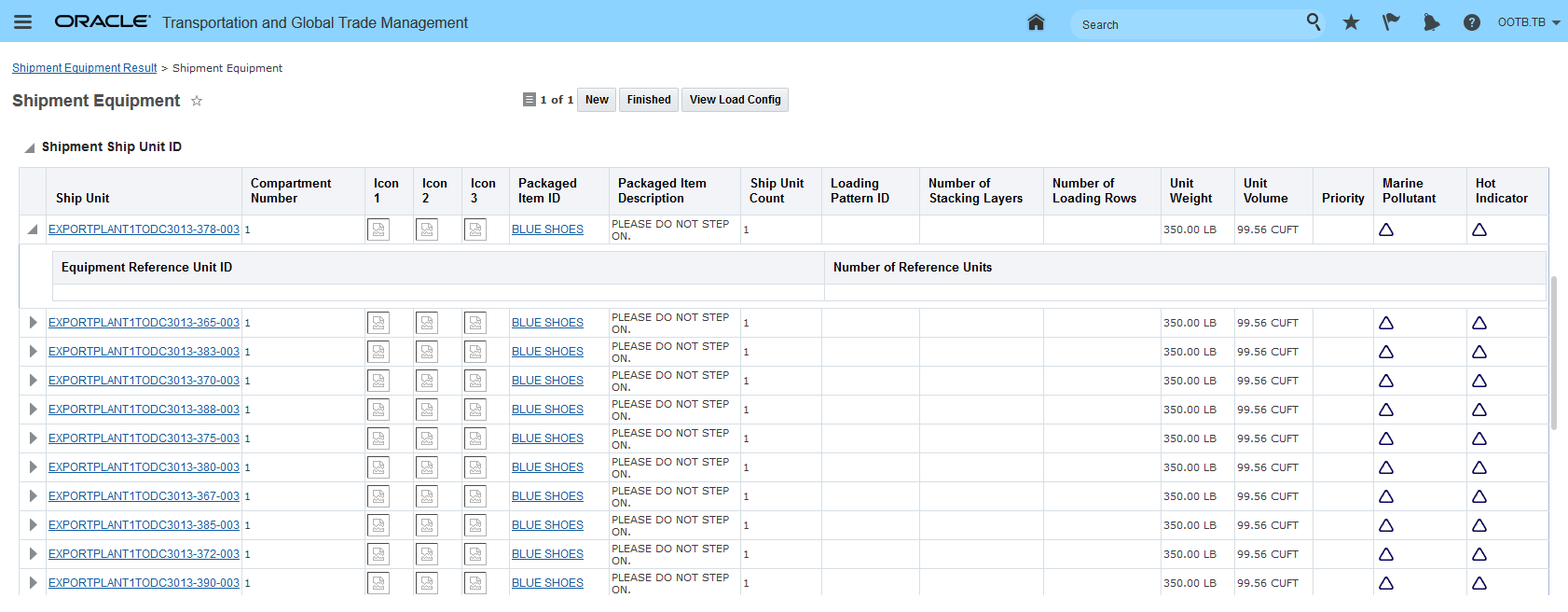

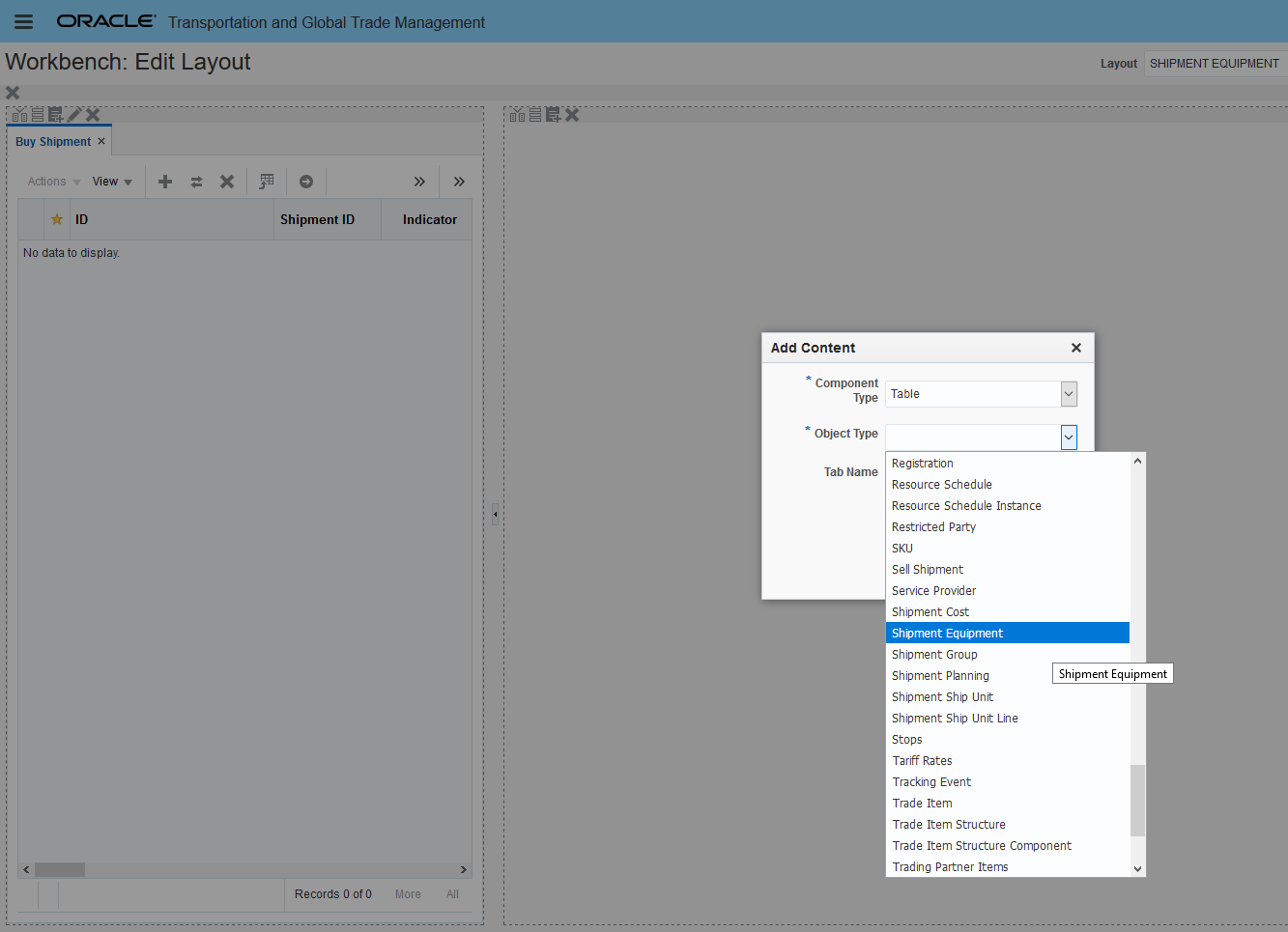

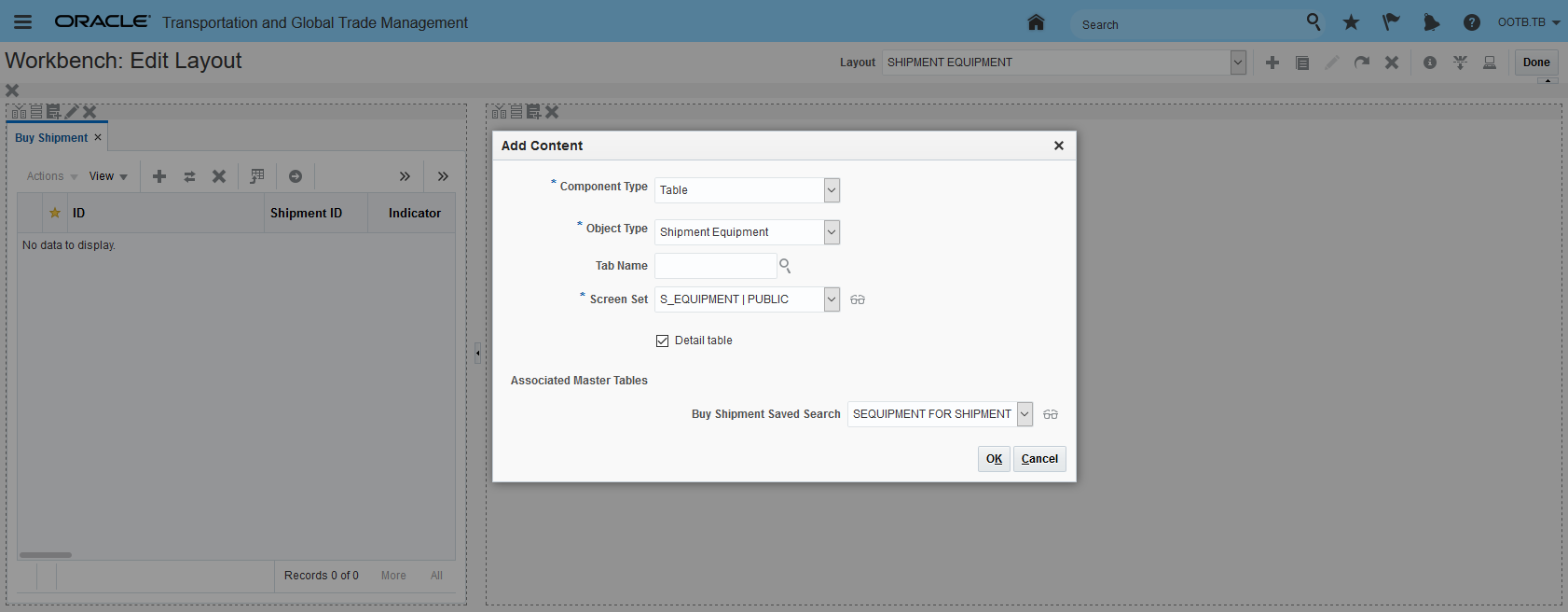

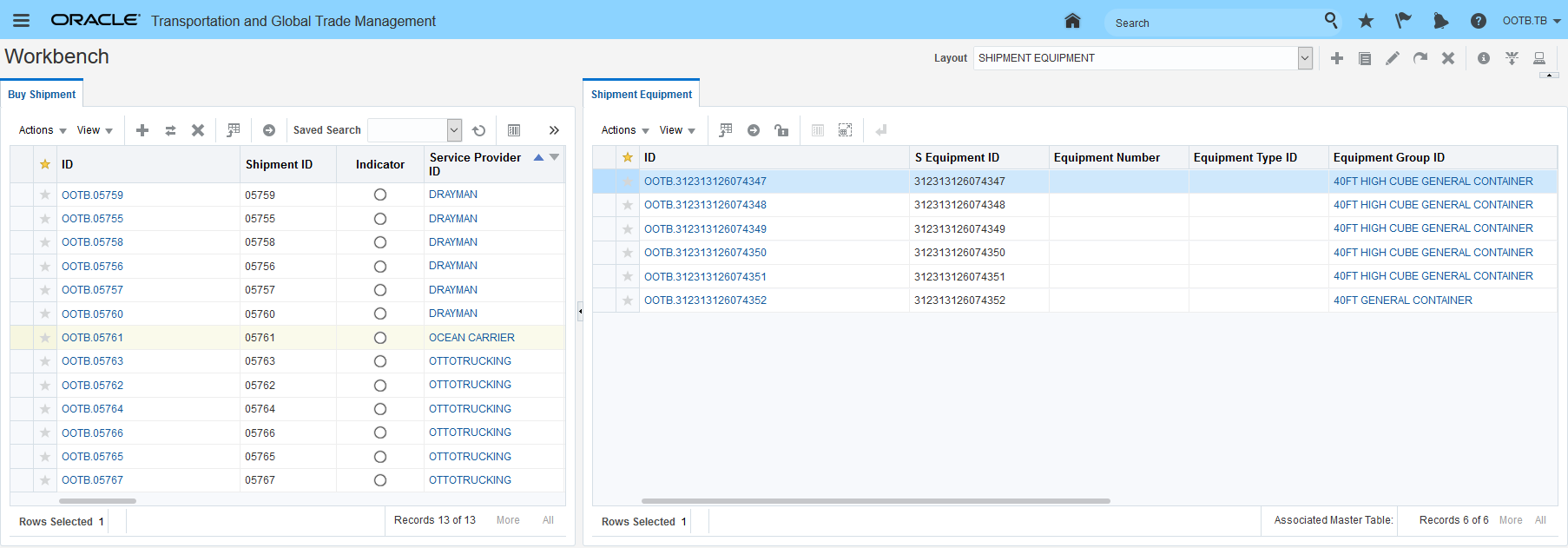

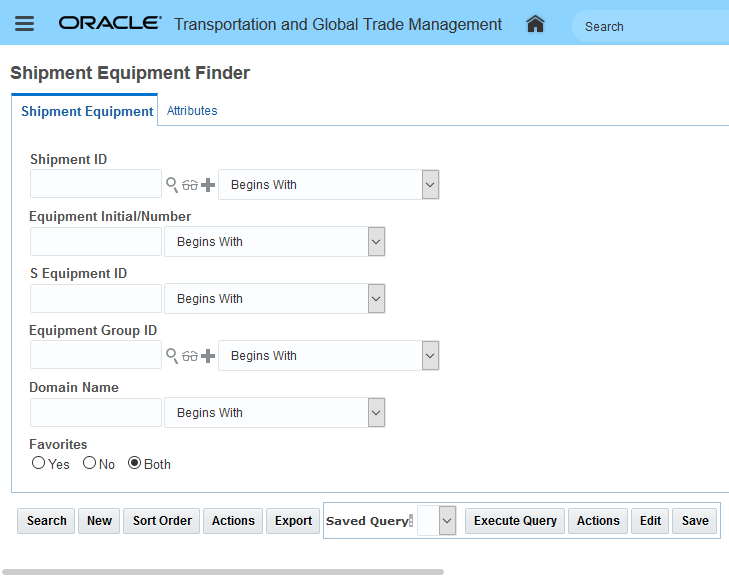

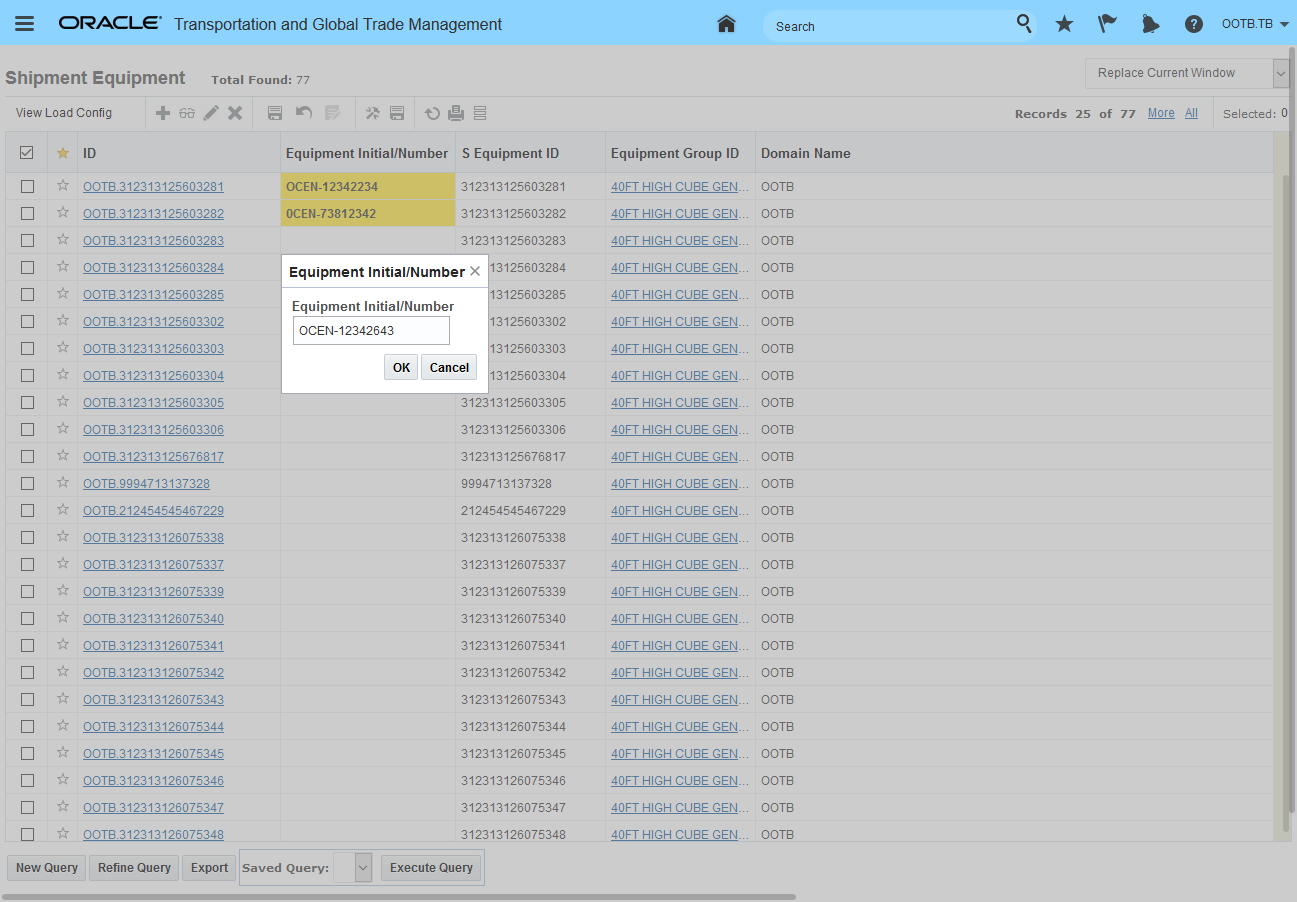

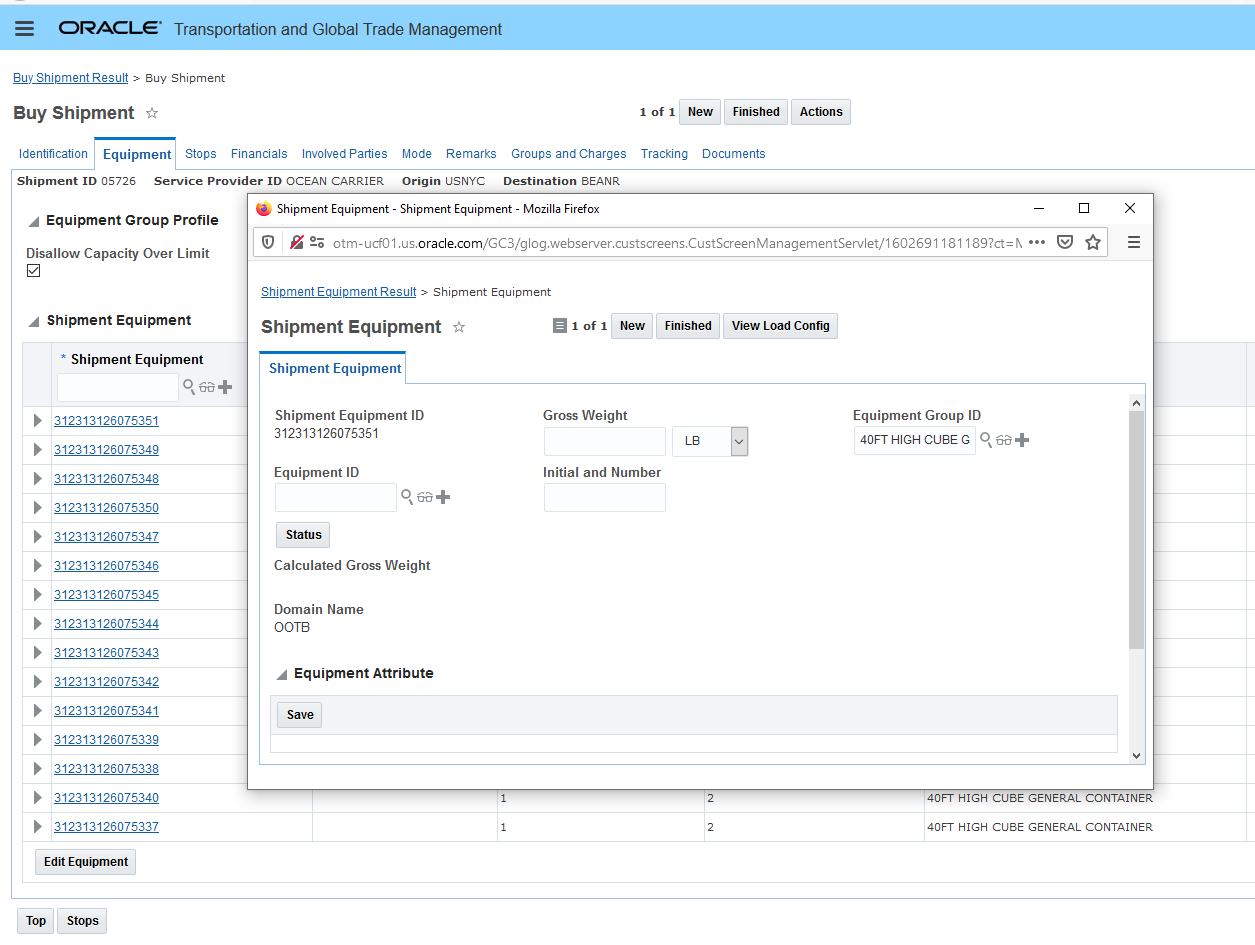

- Shipment Equipment Manager

- Manager Layout Enabled Action - Change Service Provider

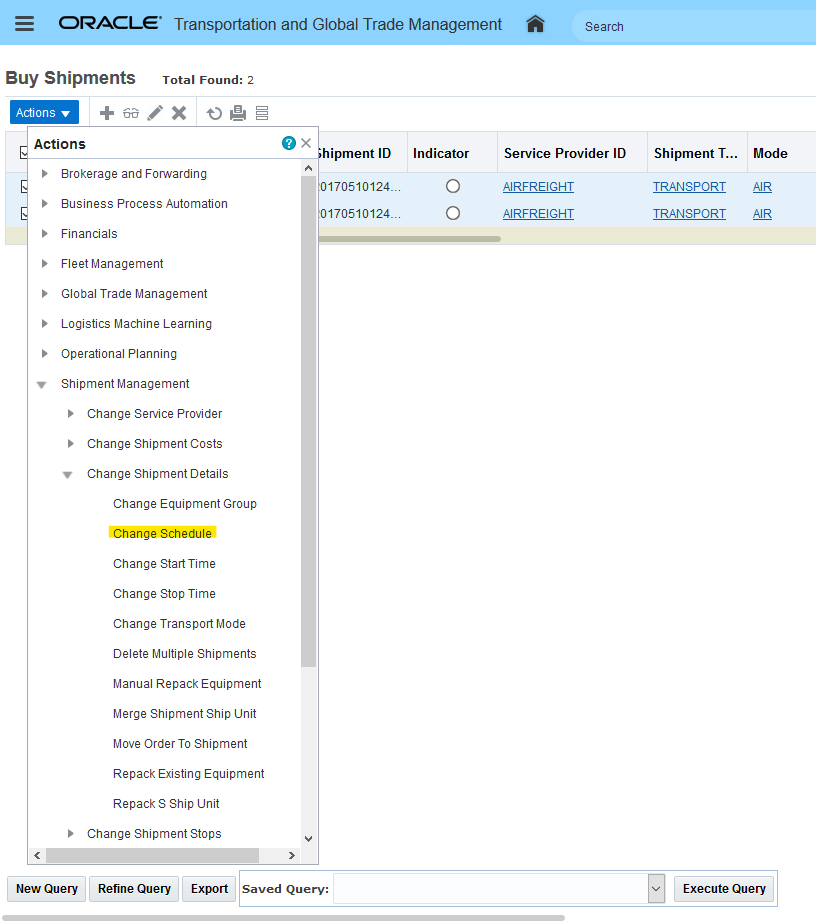

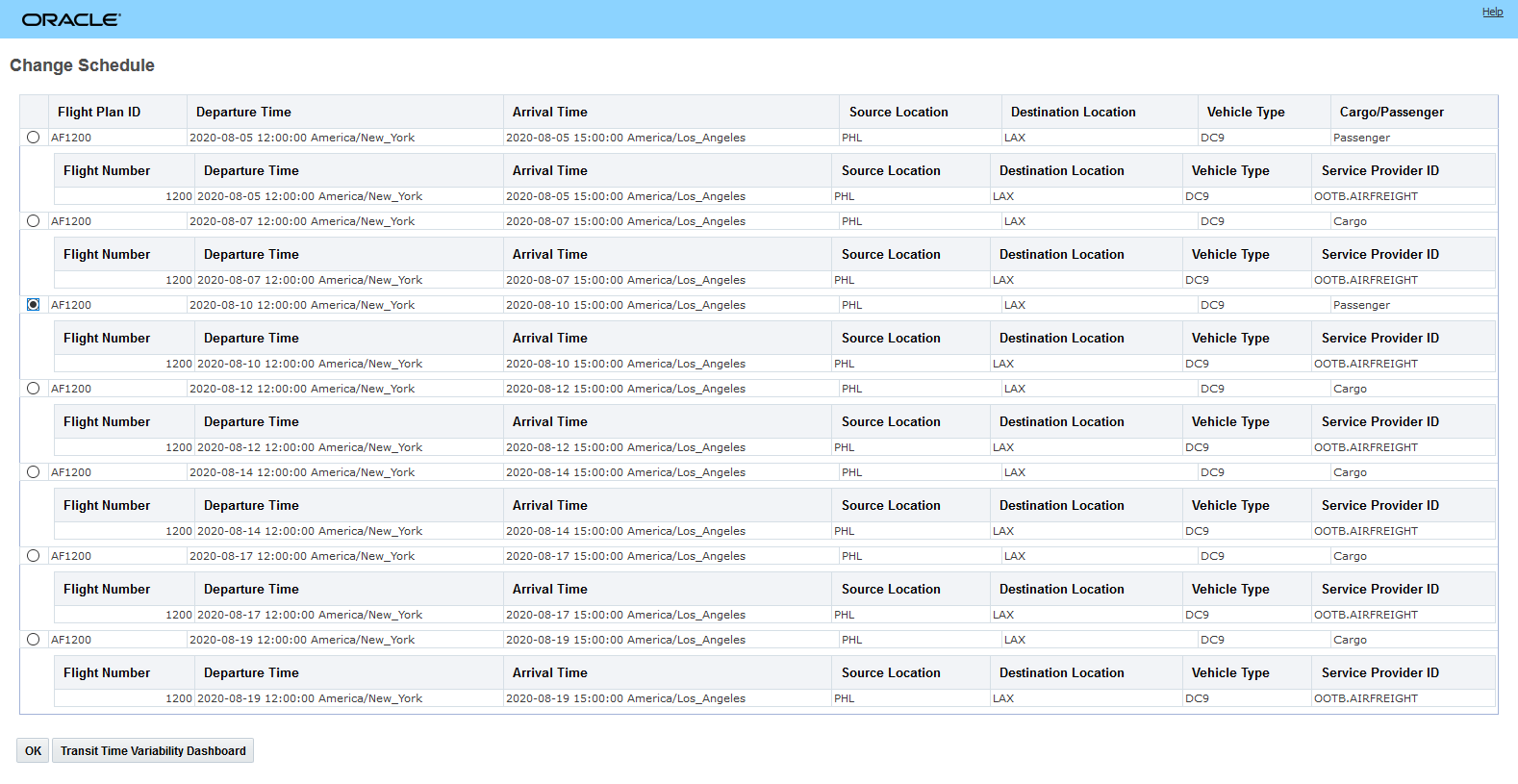

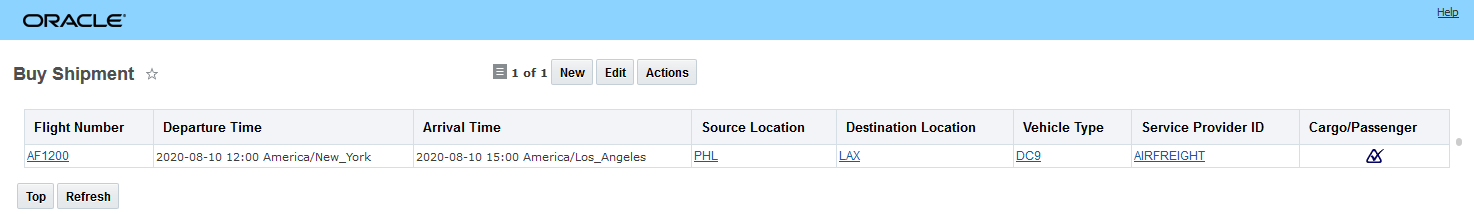

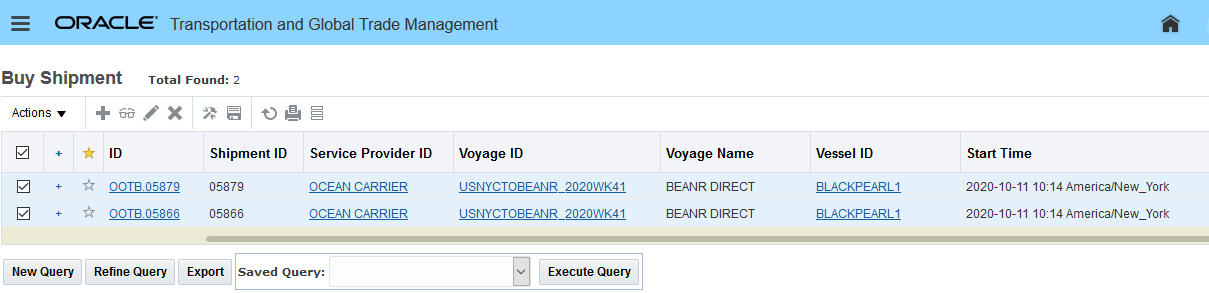

- Multi-Select for Change Schedule Action

- Additional User Defined Attribute Fields Added to Shipment and Shipment Stop

- Manager Layout - Remove Booking Information Section from Shipment

- Manager Layout Enabled Action - Merge Shipments

- Shipment Manager - License Plate Field Added to Screen Set

- Booking And Tendering

- Usability Improvements

- External Distance Engine and Map Enhancements

- Staged Integrations

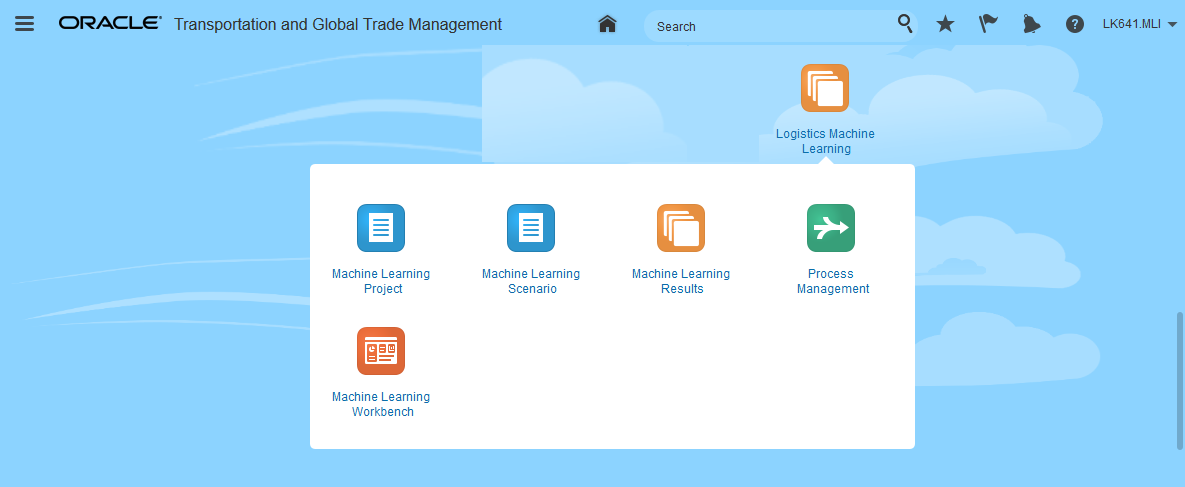

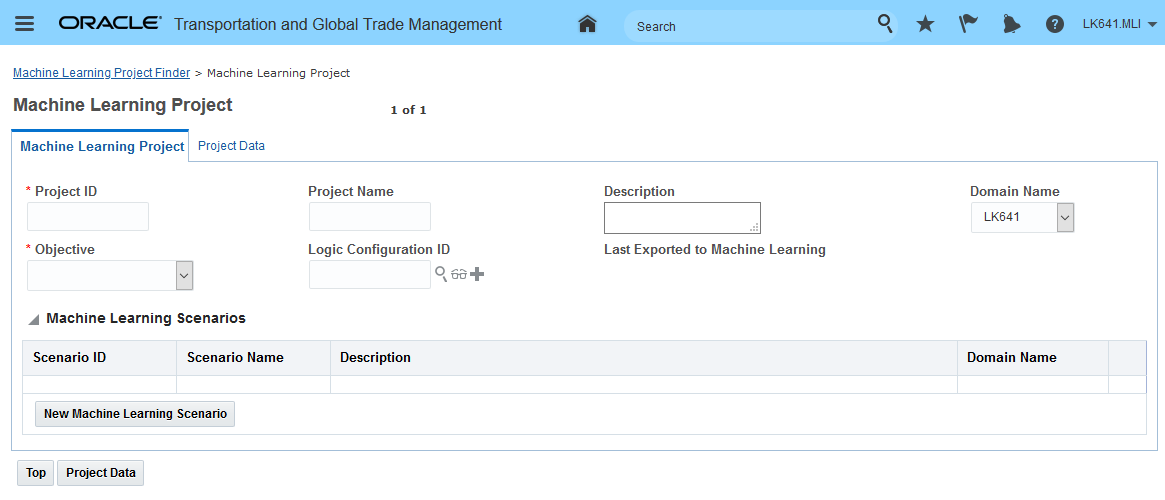

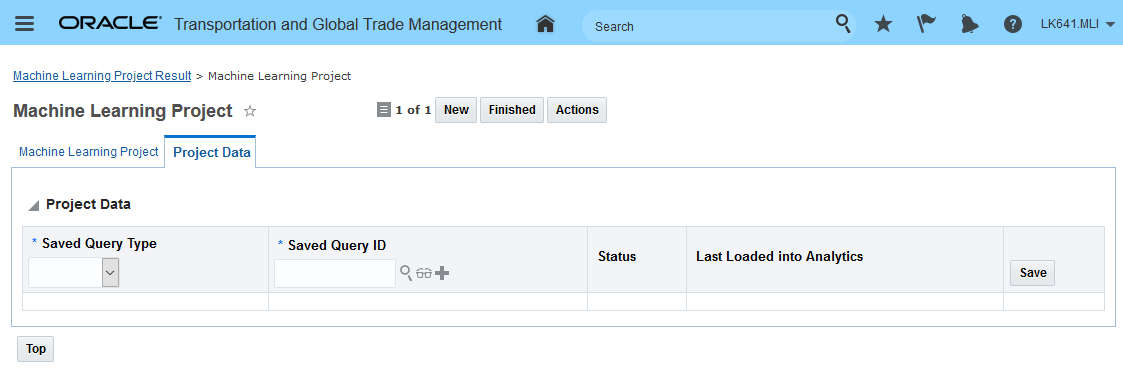

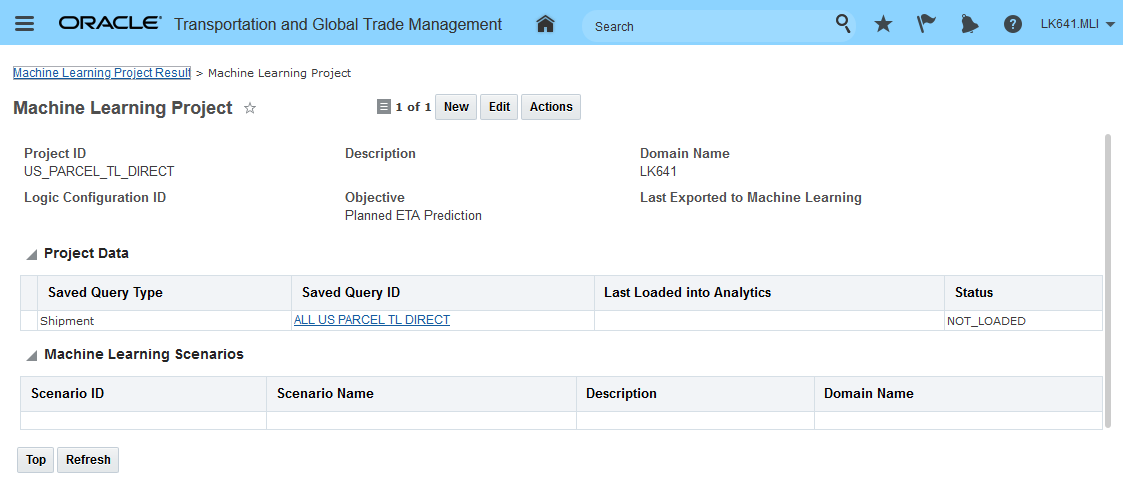

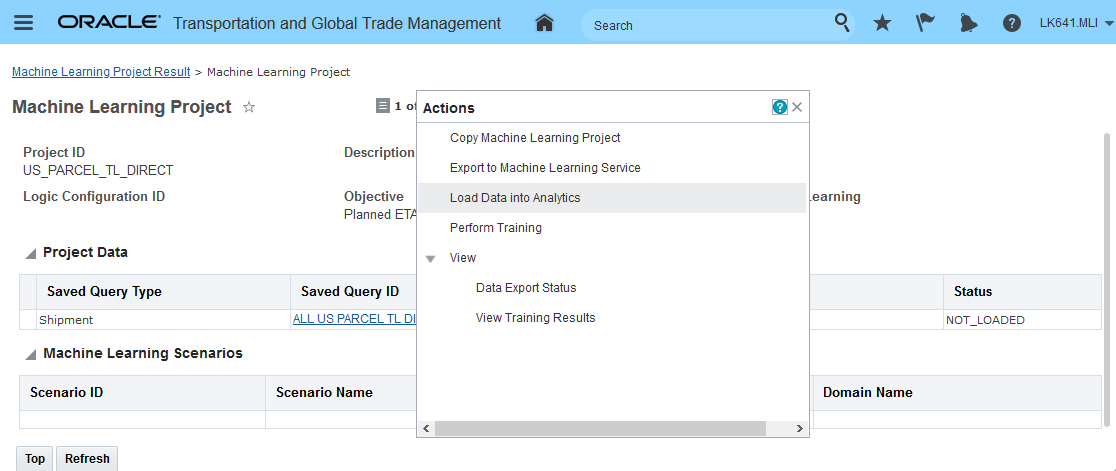

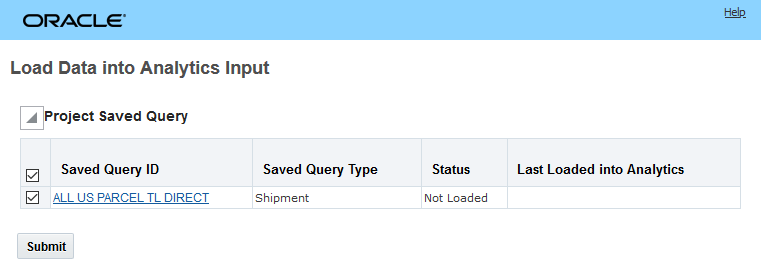

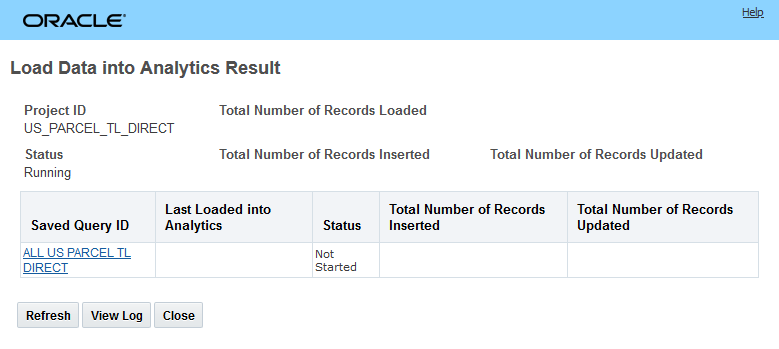

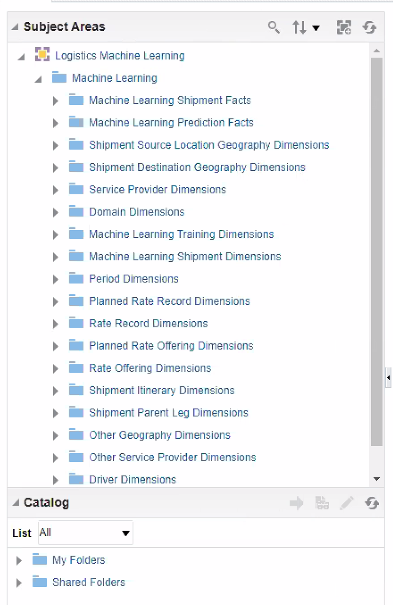

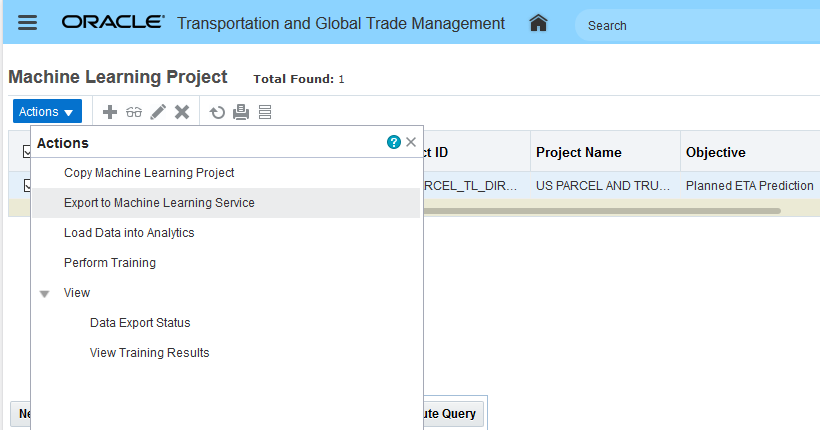

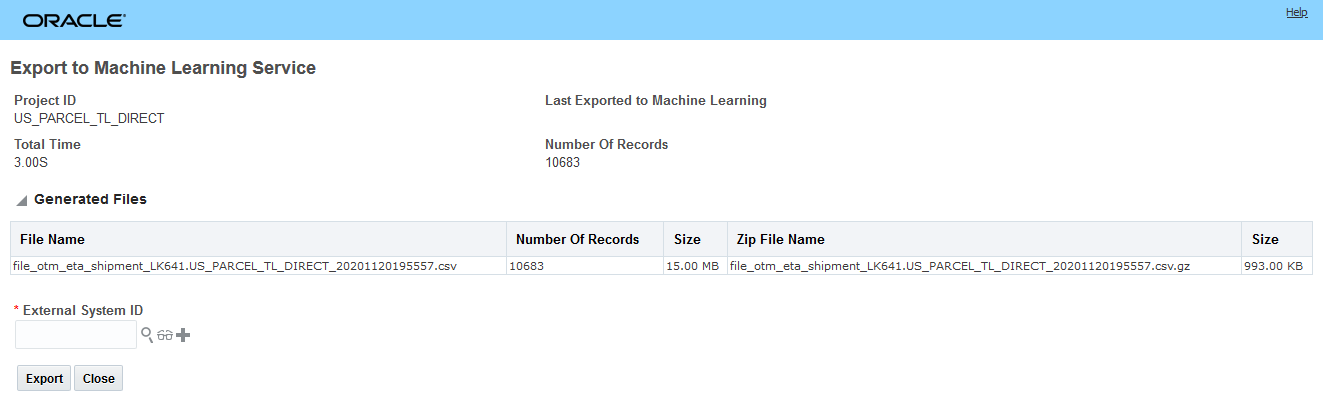

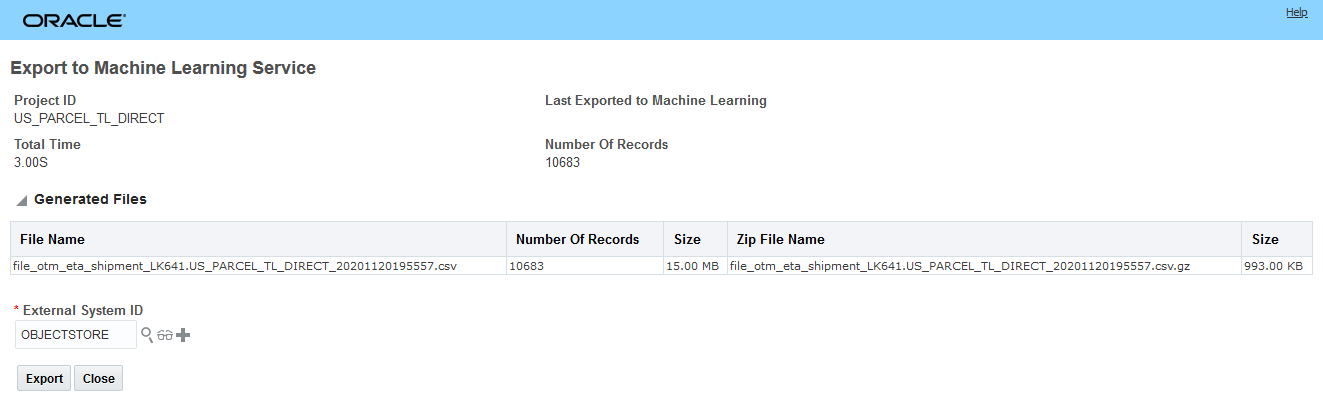

- Logistics Machine Learning

- Transportation Operational Planning

-

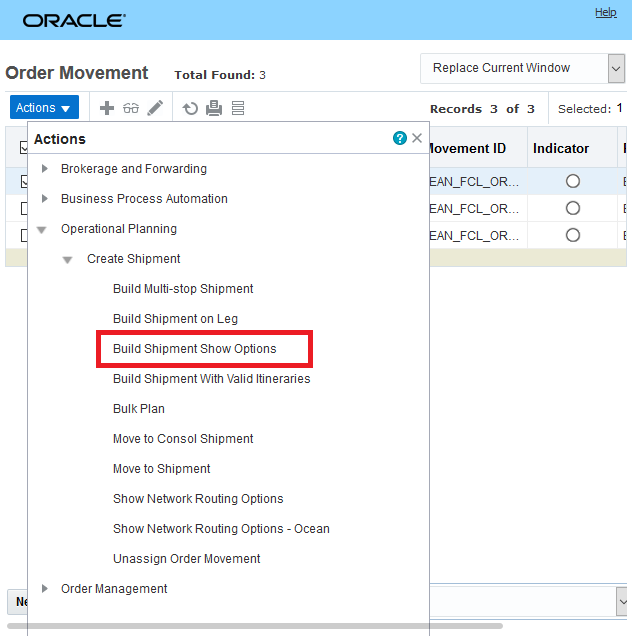

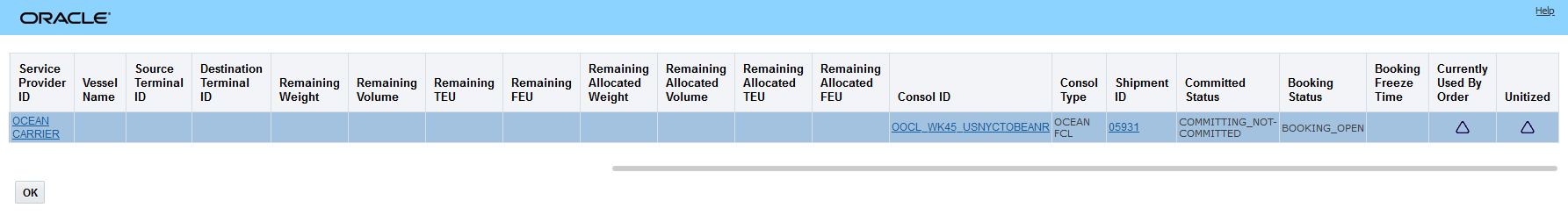

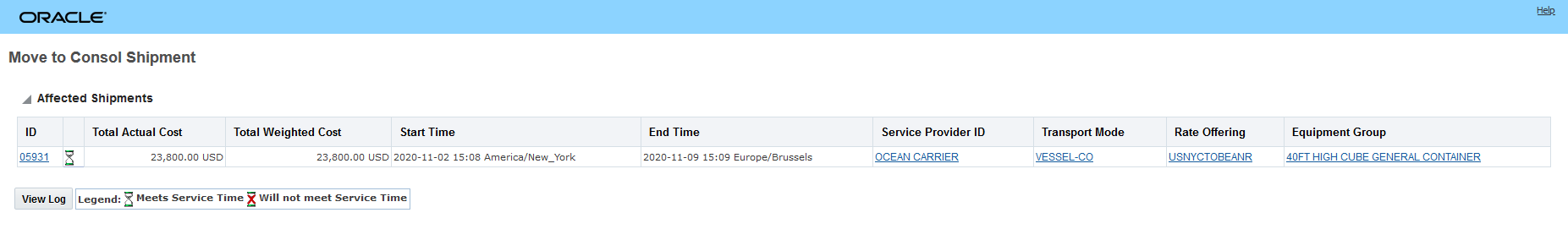

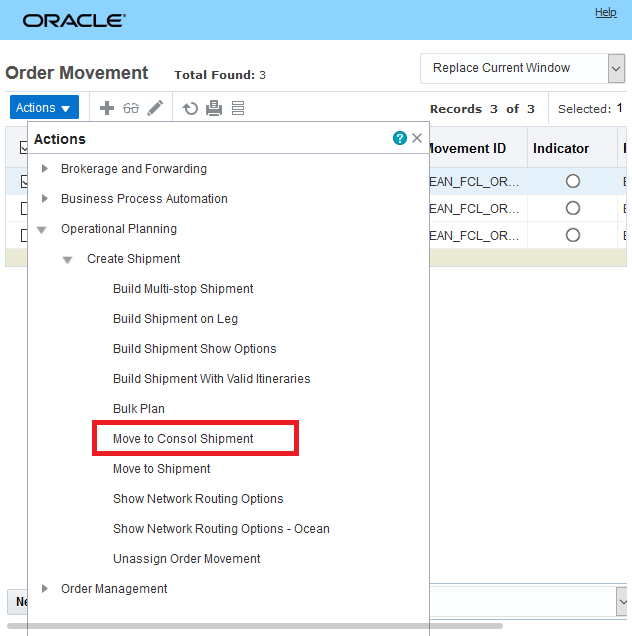

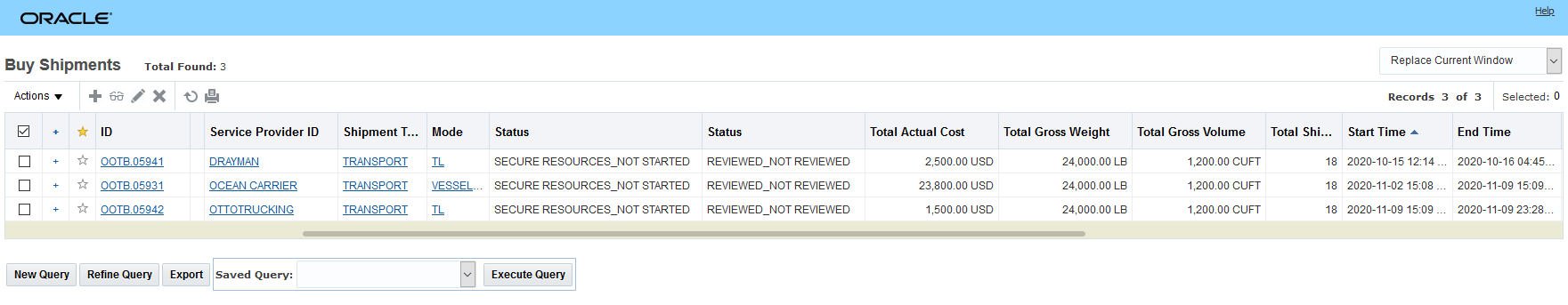

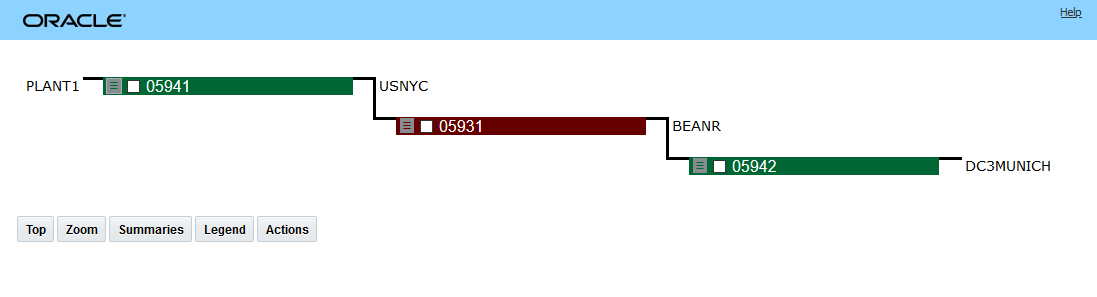

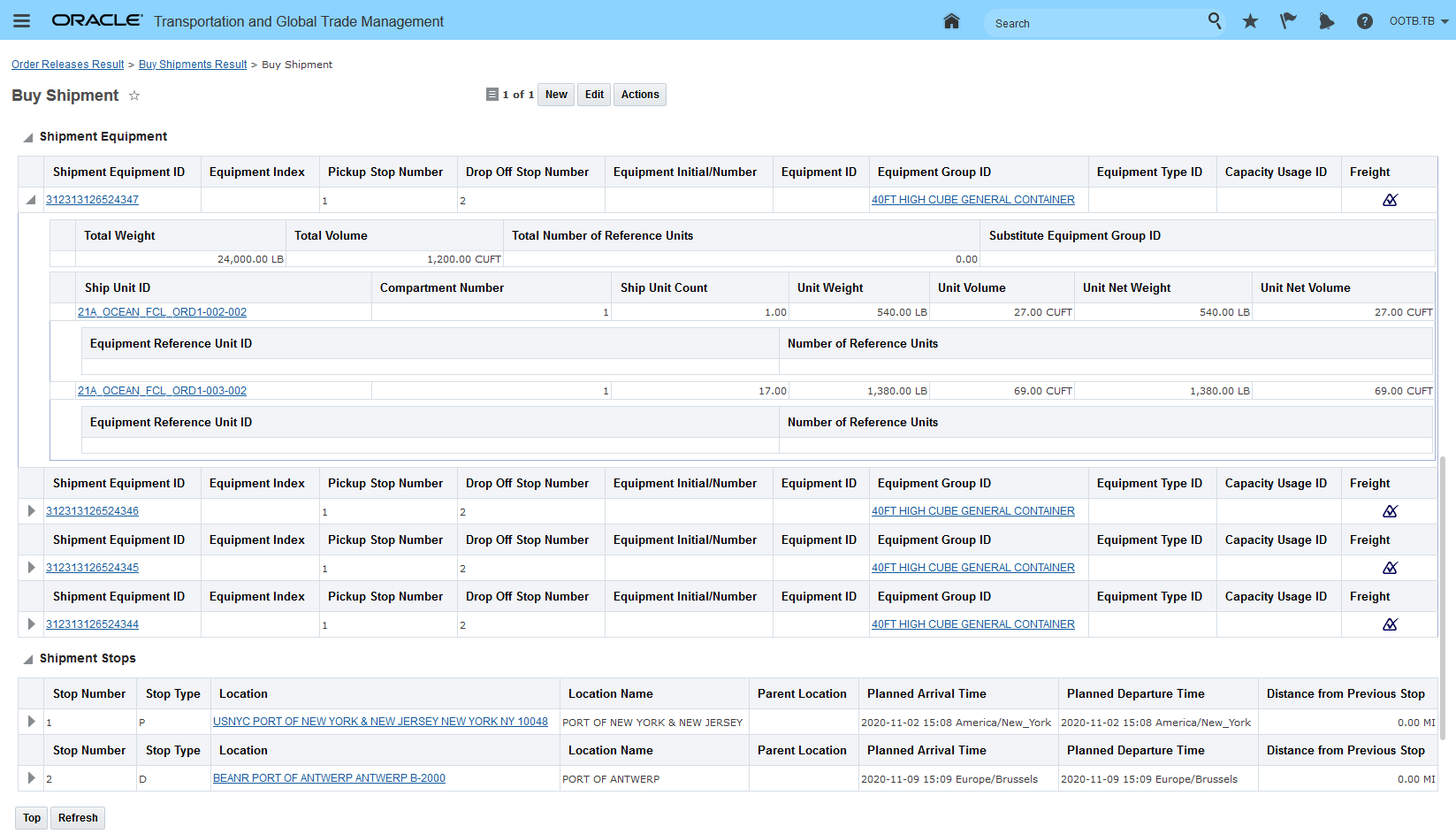

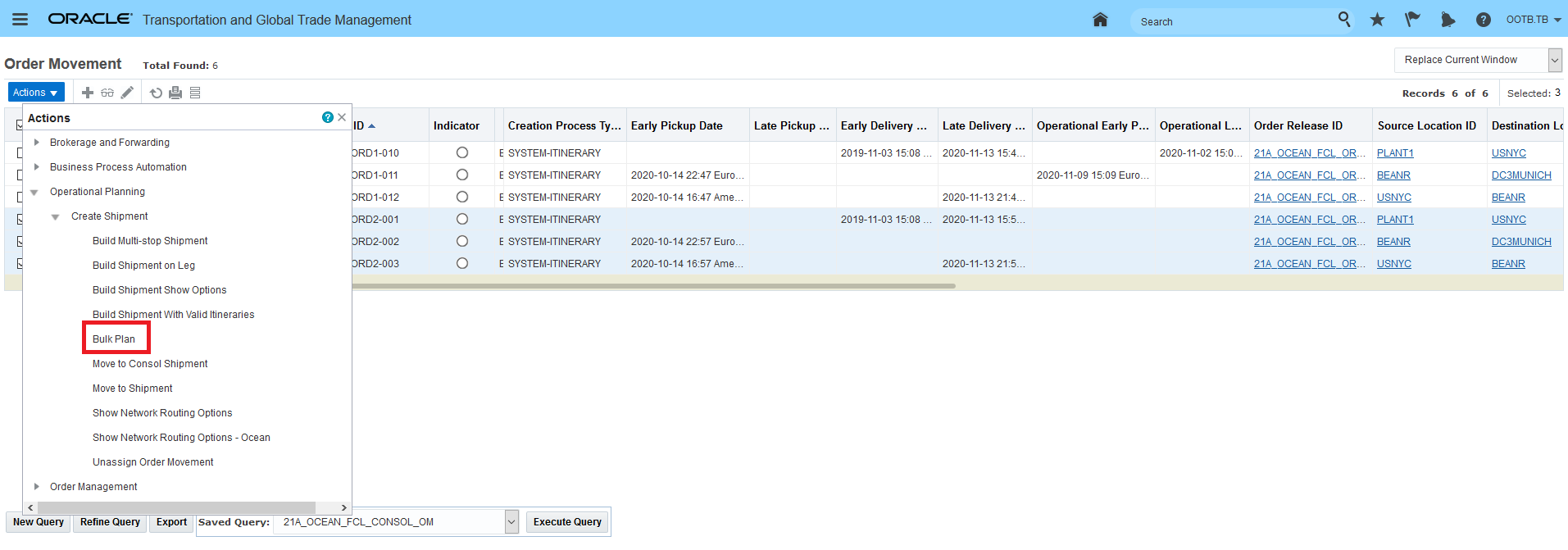

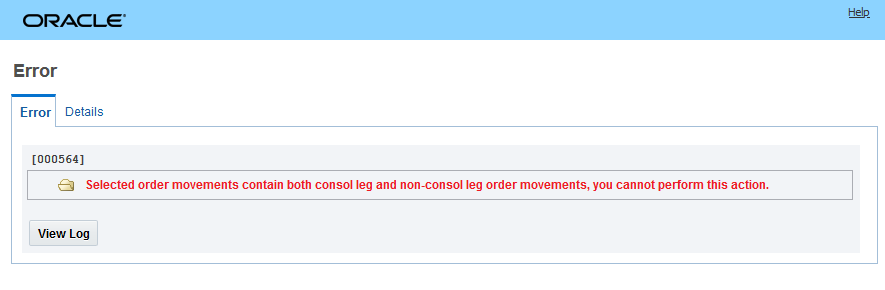

- Consol Shipments - Build Shipment Actions Bulk Planning for Order Movement

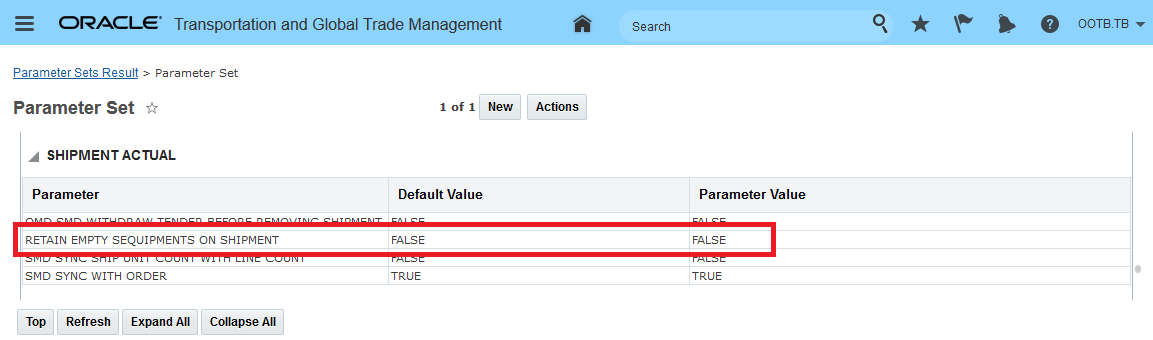

- Parameter to Control Retain or Delete for Empty Shipment Equipment

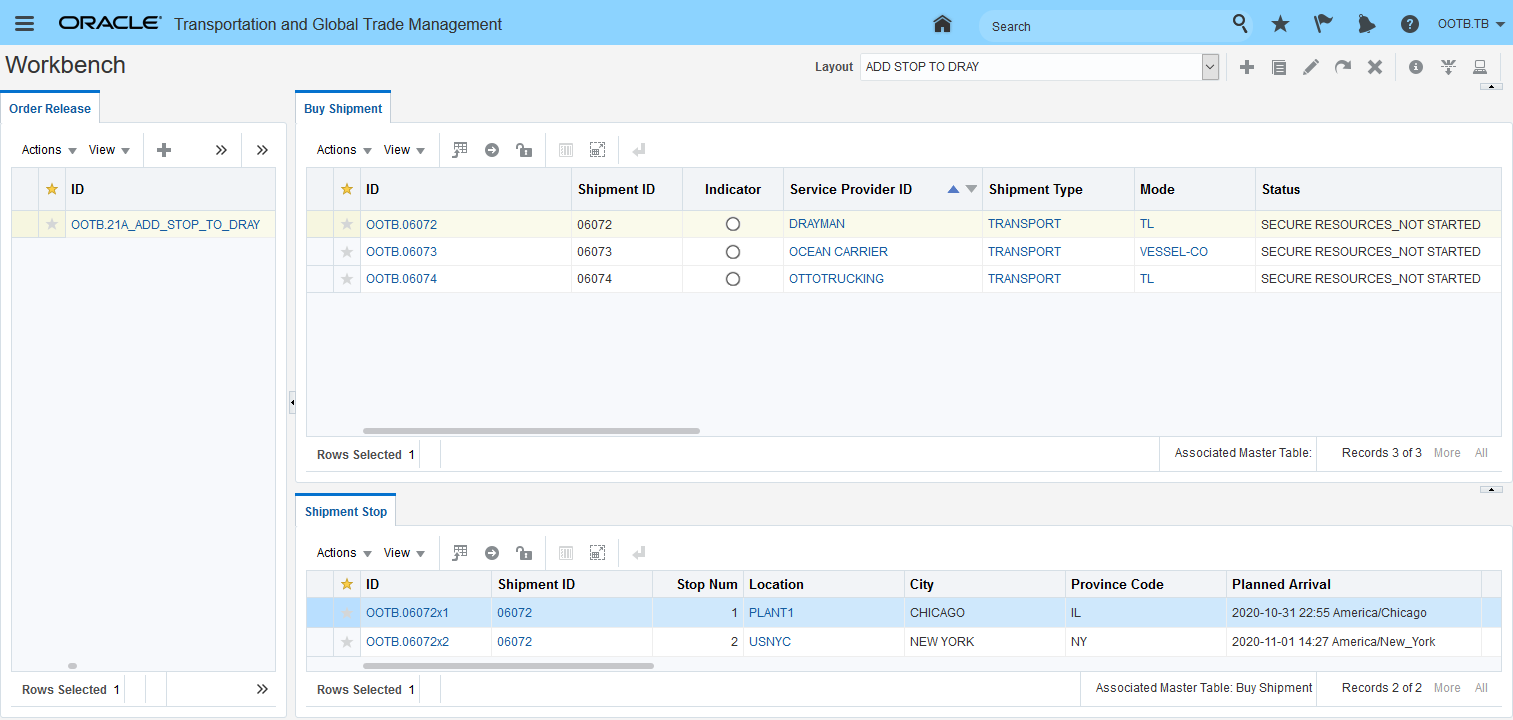

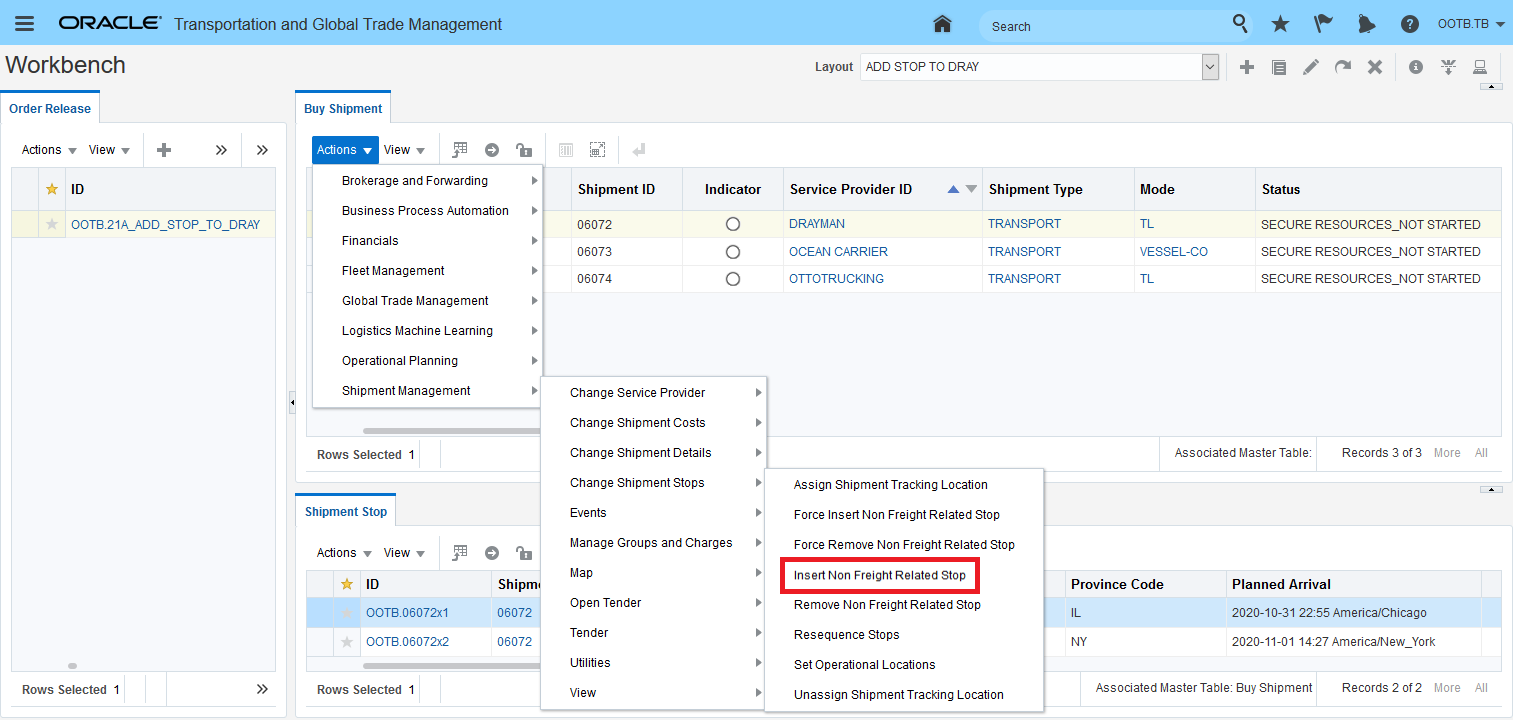

- Run Insert Non Freight Related Stop for Non-Fleet Service Providers - Add Container Yard Stop

- Merge Shipment Action - Enhanced

- Support Split by Equipment for Reuse Equipment Shipment Legs

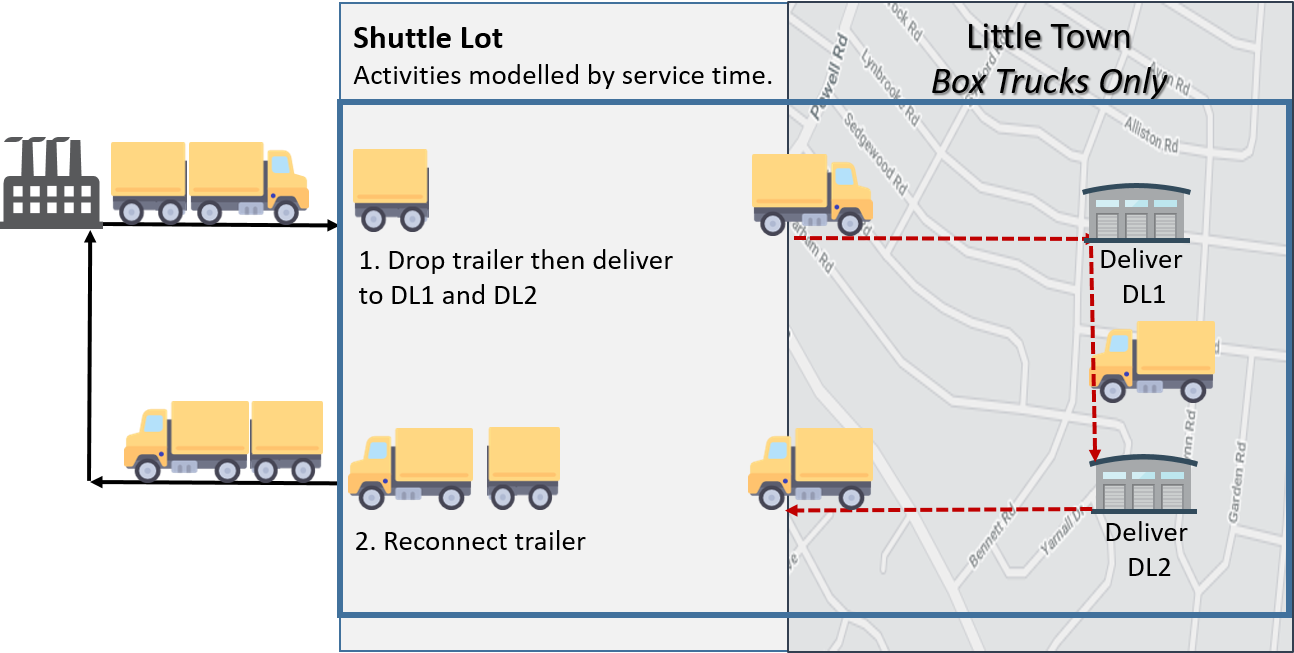

- Multi-Stop - Shuttle Lot Activity Time Enhancement

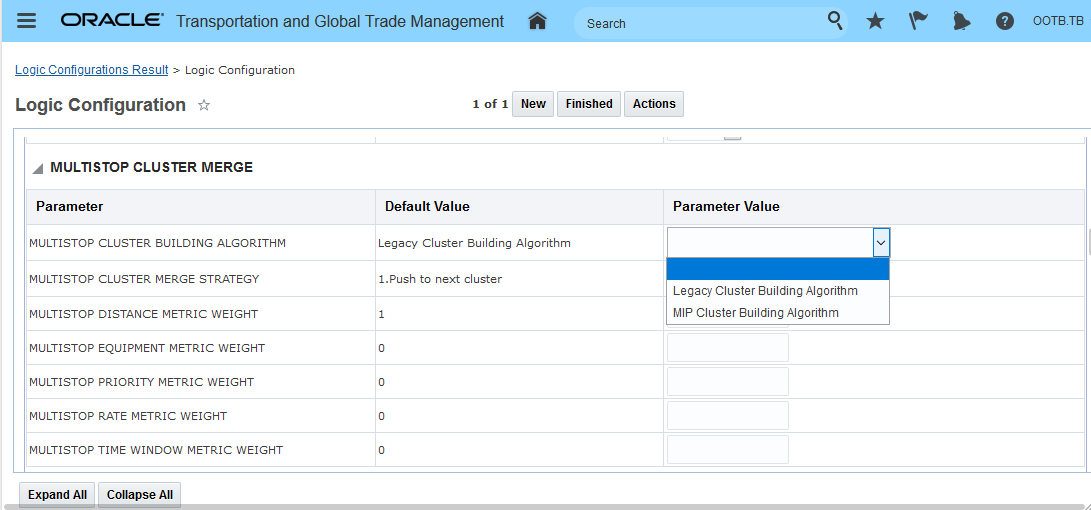

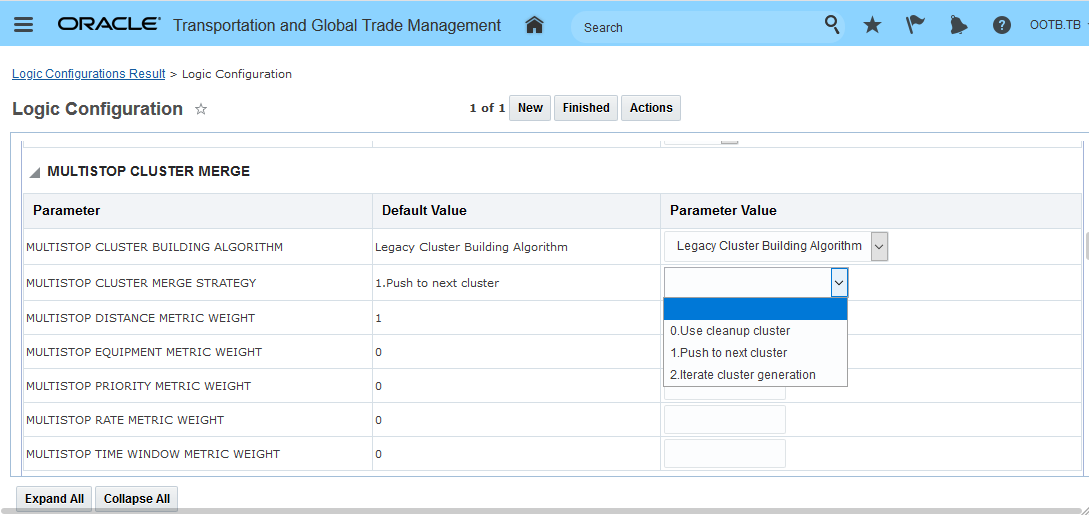

- Multi-Stop - Cluster Merge Enhancements

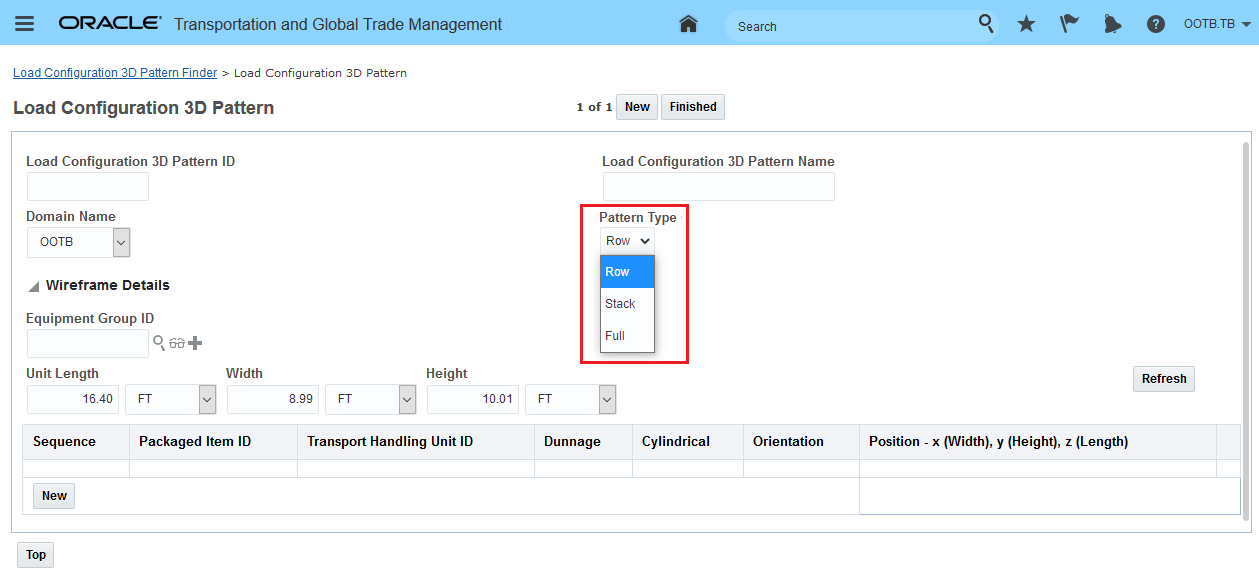

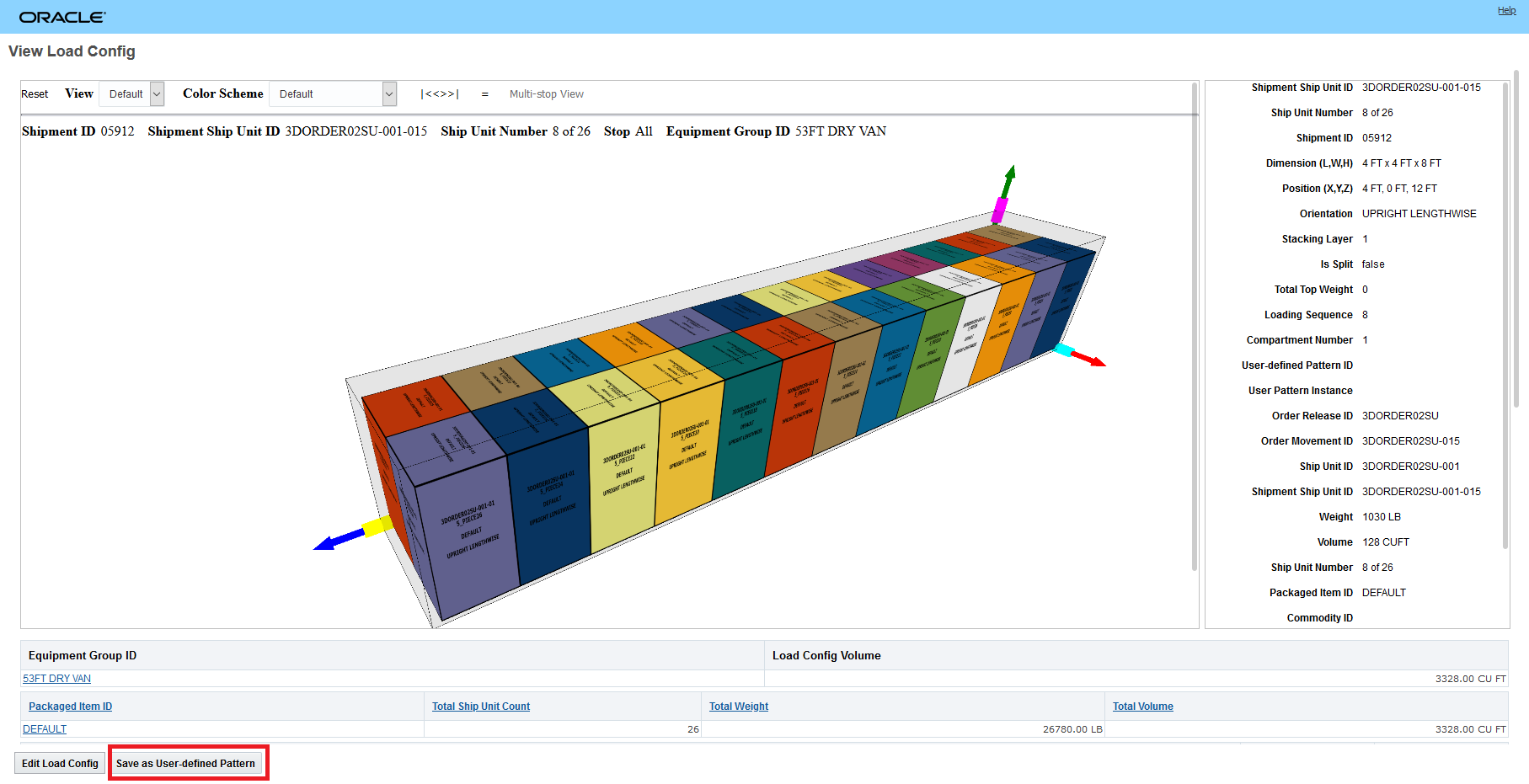

- Load Configuration 3D Pattern/User Defined Pattern Enhancement

- Edit Load Config Additional Packing Constraints

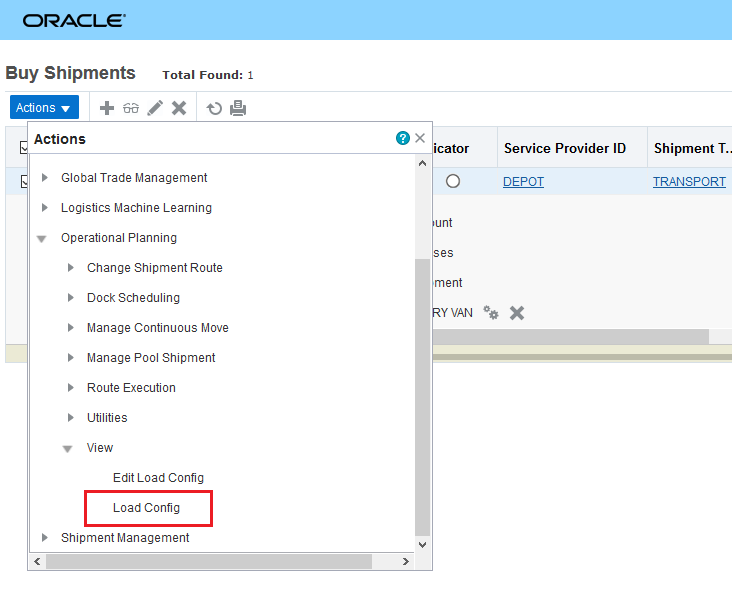

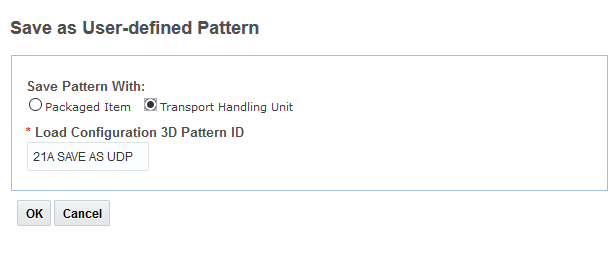

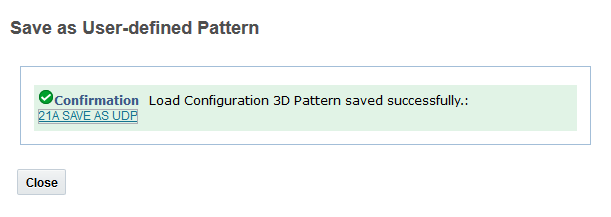

- Save As User-Defined Pattern

-

- Freight Payment, Billing, and Claims

- Oracle Fleet Management

- Logistics Digital Assistant

- Global Trade Management (Base)

-

- Improvements to Propagating Information from OTM Objects to GTM Objects

- Order Release to Transaction Data Configuration Using New Date and Number Attributes

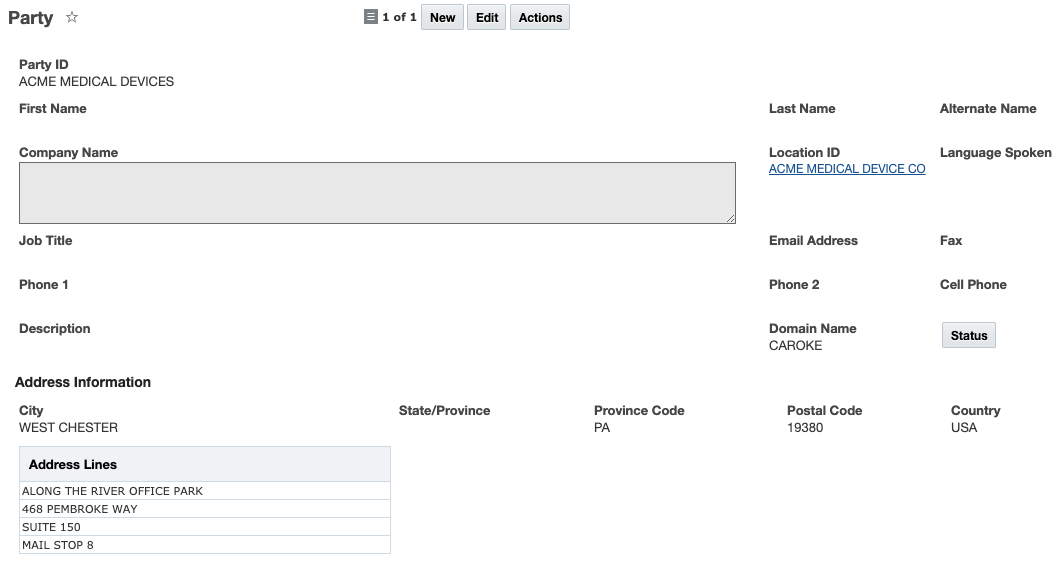

- Display All Address Lines on Party

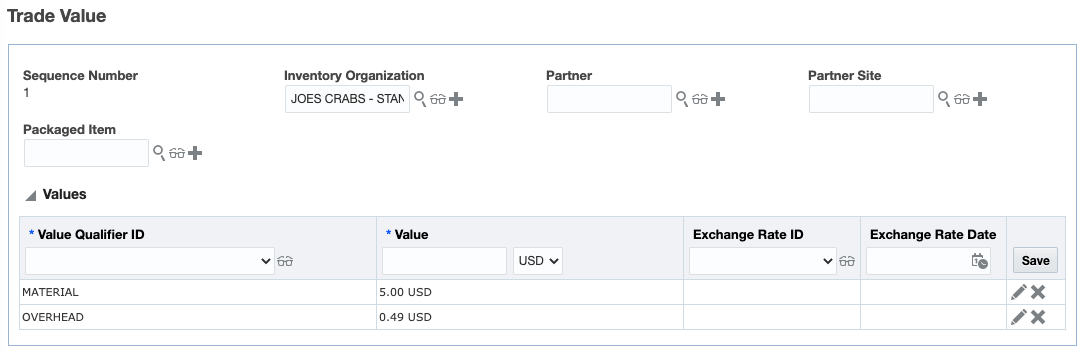

- Support for Trade Values on Item

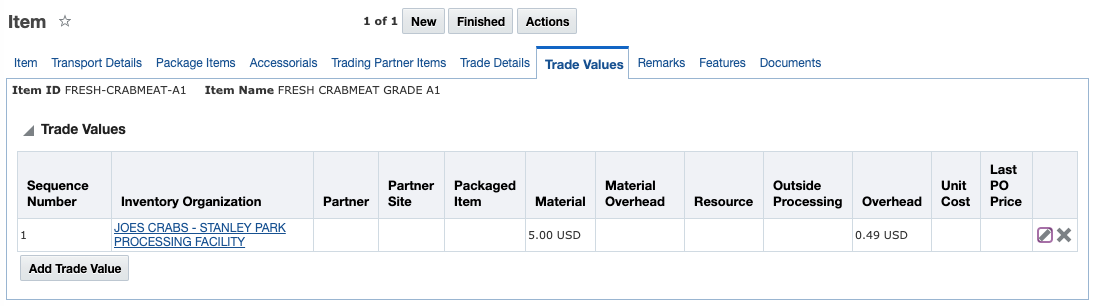

- View Additional Details About Trading Partner on Item

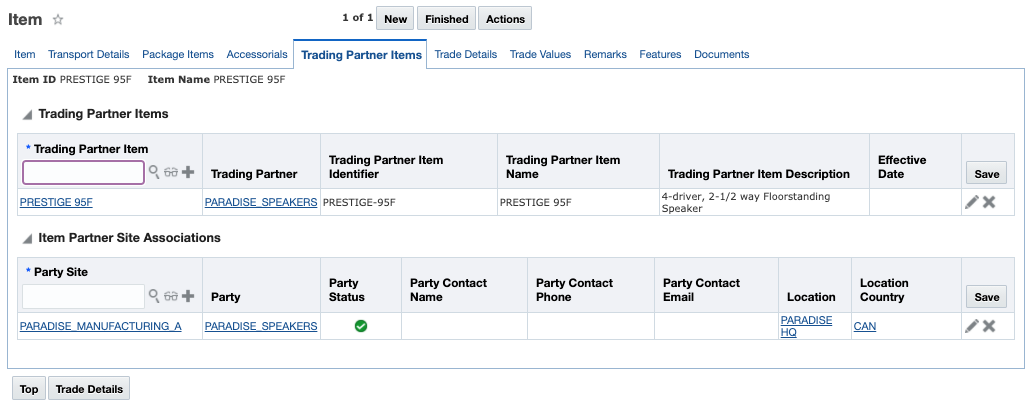

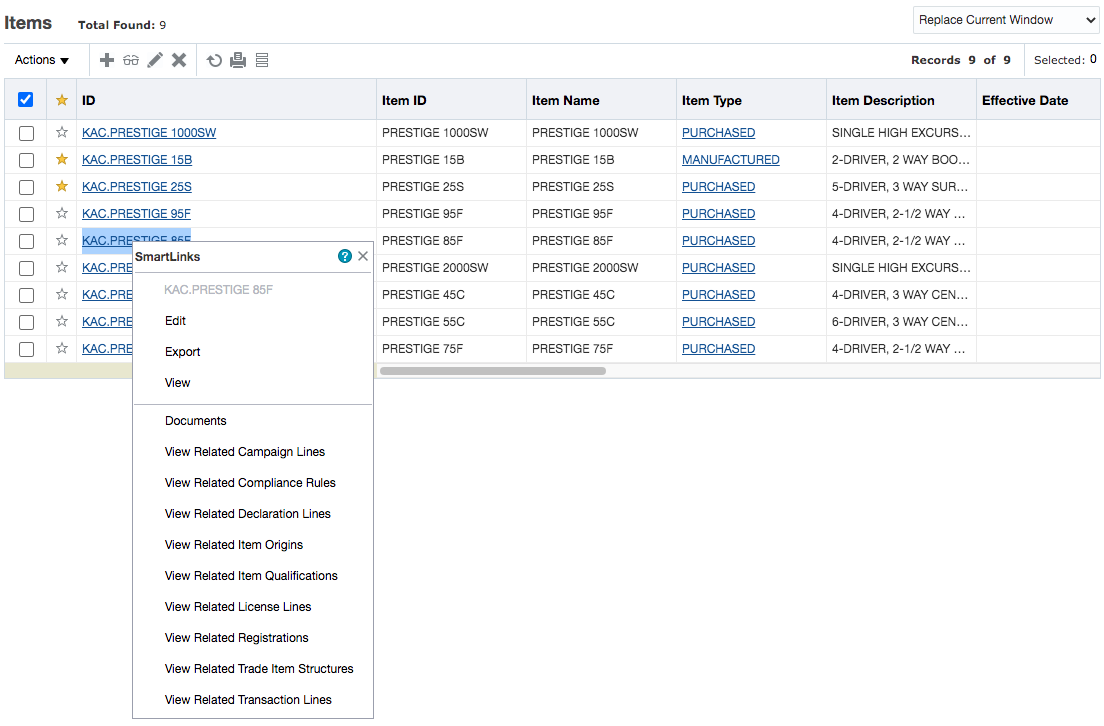

- Additional SmartLinks on Item-Related Objects

- Visibility To Item Information On Item Origin

- Identify the Campaign Purpose in Logic Configuration

- Solicit Information for an Item Using Campaign Management

- Solicit Information for an Item Origin Using Campaign Management

- Partner Item to Campaign Data Configuration Using New Date and Number Attributes

- Campaign Line to Item Data Configuration Using New Date and Number Attributes

- New Attribute Fields Added to Various Objects

- Additional Pseudo-Fields Available Across Various Objects

- Transaction Line Attribute Flex Fields Sent in Outbound XML

- Update Various GTM Integration Elements to Be Optional

- New Resources Added to REST APIs

- Use GTM General Parameter Set

- Allow Declaration Grouping Criteria Changes

-

- Trade Agreements

- Trade Compliance

- Customs Management

- Global Trade Intelligence (GTI)

- Transportation and Global Trade Platform

- Upcoming Changes

This document will continue to evolve as existing sections change and new information is added. All updates appear in the following table:

| Date | Product | Feature | Notes |

|---|---|---|---|

| 25 MAR 2022 | Transportation and Global Trade Platform |

Updated document. Revised opt in information. | |

| 17 DEC 2021 | Transportation and Global Trade Platform |

Updated document. Revised opt in information. | |

| 25 JUN 2021 | Transportation Operational Planning | Merge Shipment Action - Enhanced | Updated document. Revised feature information. |

| 15 JUN 2021 | Technical Features | Use Nested GID in Agent DTA | Updated document. Revised feature and opt in information. |

| 12 MAR 2021 | Trade Agreements | Rules of Origin - Data Download and Objects | Updated document. Revised feature information. |

| 24 FEB 2021 | Transportation and Global Trade Platform |

Manager Layout Enabled - Contact Manager |

Removed feature from update 21A. |

| 19 FEB 2021 | Transportation and Global Trade Platform |

Disable IntXmlService and IntGtmXmlService | Updated Document. Revised feature information. |

| 17 FEB 2021 | Transportation and Global Trade Platform | REST - New Query String Parameters to Hide/Show Primary Key Fields in REST Payload | Updated document. Delivered feature in update 21A. |

| 05 FEB 2021 | Oracle Transportation Management (Base) | Updated document. Delivered feature in update 21A. |

|

| 05 FEB 2021 |

Oracle Fleet Management | Work Assignment - First Shipment Selected Planning Parameter |

Updated document. Delivered feature in update 21A. |

| 18 DEC 2020 | Created initial document. |

This guide outlines the information you need to know about new or improved functionality in Oracle Transportation & Global Trade Management Cloud Update 21A. Each section includes a brief description of the feature, the steps you need to take to enable or begin using the feature, any tips or considerations that you should keep in mind, and the resources available to help you.

GIVE US FEEDBACK

We welcome your comments and suggestions to improve the content. Please send us your feedback to otm-doc_us@oracle.com. Please indicate you are inquiring or providing feedback regarding the Oracle Transportation & Global Trade Management What’s New in Update 21A.

This section gives you information to help you plan, deploy, and validate your update. We make frequent additions to this document, so don’t forget to check back and get the latest information before your update starts.

Review the Release Notes.

- The release notes include fixes, special instructions, and resolutions related to the Oracle Transportation and Global Trade Management Cloud.

- Release Notes can be found here:

- https://support.oracle.com/epmos/faces/DocumentDisplay?id=2620583.1

Use the following resources to prepare for and validate your Oracle Engagement Cloud update.

On My Oracle Support Read:

- Doc ID 2095509.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Environment Refresh Policy

- Doc ID 2095528.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Quarterly Update Planning

- Doc ID 2096782.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Quarterly Update Planning FAQs

- Doc ID 2195580.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Get Started with Your Implementation

- Doc ID 2508854.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Quarterly Updates - Preparation and Testing Recommendations

Column Definitions:

Features Delivered Enabled

Report = New or modified, Oracle-delivered, ready to run reports.

UI or Process-Based: Small Scale = These UI or process-based features are typically comprised of minor field, validation, or program changes. Therefore, the potential impact to users is minimal.

UI or Process-Based: Larger Scale* = These UI or process-based features have more complex designs. Therefore, the potential impact to users is higher.

Features Delivered Disabled = Action is needed BEFORE these features can be used by END USERS. These features are delivered disabled and you choose if and when to enable them. For example, a) new or expanded BI subject areas need to first be incorporated into reports, b) Integration is required to utilize new web services, or c) features must be assigned to user roles before they can be accessed.

Transportation and Global Trade Management

Transportation and Global Trade Platform

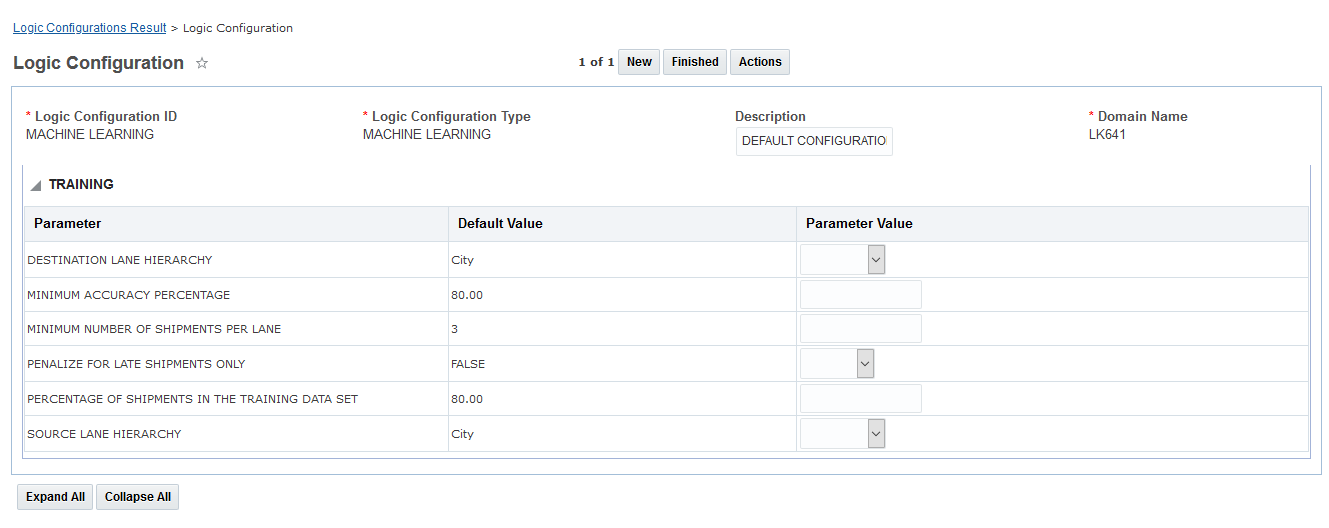

UI Configuration Logic Configuration

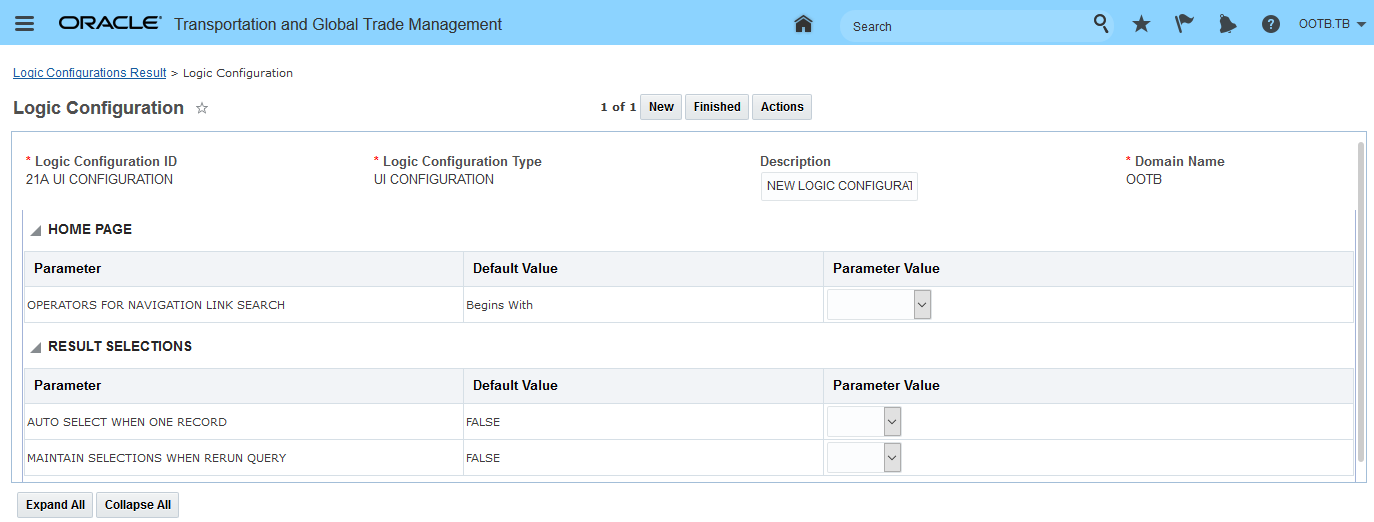

This feature provides you with a UI Configuration Logic Configuration Type that you can use to configure some UI behaviors.

The parameters available with the UI Configuration Logic Configuration include:

HOME PAGE PARAMETER

- OPERATORS FOR NAVIGATION LINK SEARCH - allows you to set the search criteria to Begins With or Contains for the Navigator Links.

NOTE: Does not apply to Saved Searches.

- Default Value=Begins With

- New Option=Contains

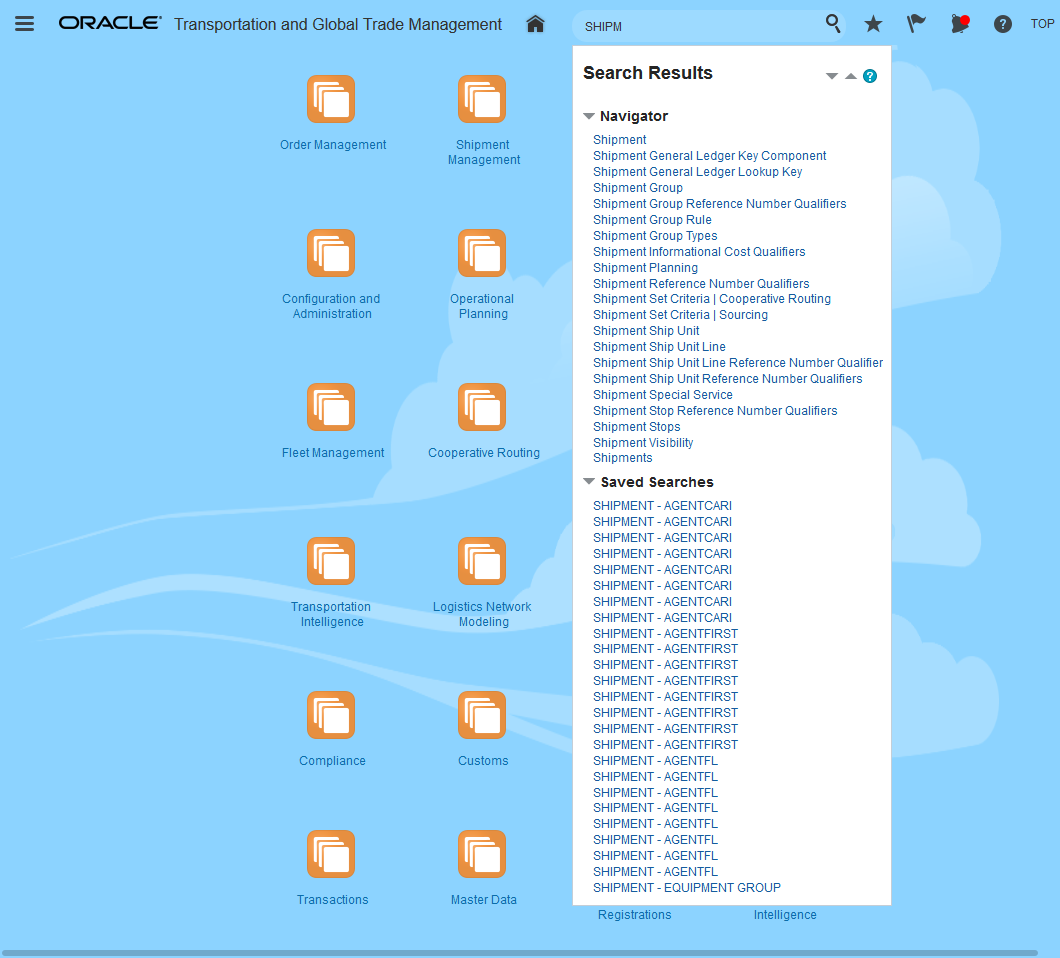

Below is an example of the default/current behavior. All navigation links that begin with "SHIPM" are returned.

Operators for Navigation Link Search - Default Begins With

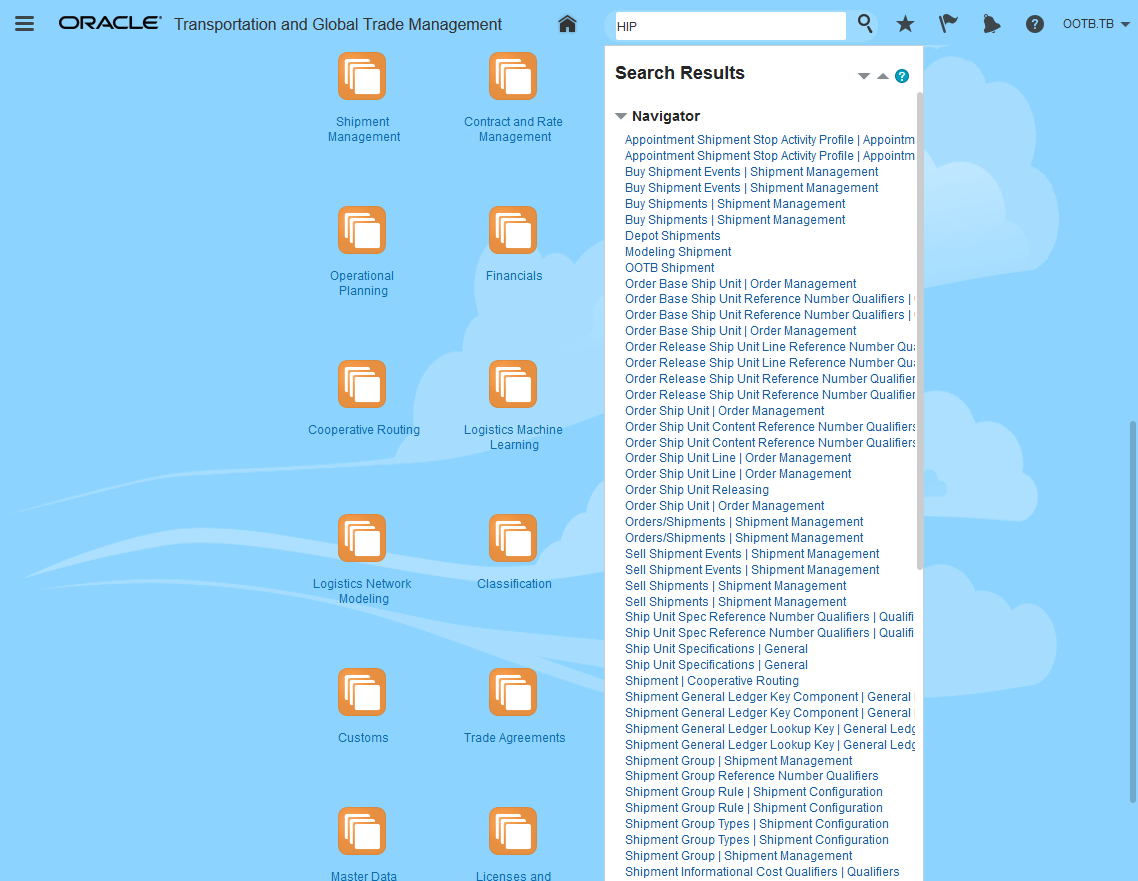

Below is an example using the parameter OPERATORS FOR NAVIGATION LINK SEARCH set to the Contains. The search here is for Navigator links that contain "HIP". Note that many more options are returned using the Contains option.

Operators for Navigation Link Search - Contains

RESULT SELECTIONS PARAMETERS

- AUTO SELECT WHEN ONE RECORD - in the situation where one record is returned/available to perform an operation/action - this feature allows you to proceed without forcing you to select the one/only record available.

- Default Value=FALSE - not selected - current behavior.

- New option=TRUE - single record is selected - new behavior. This will apply to finder, edit, and action results screen.

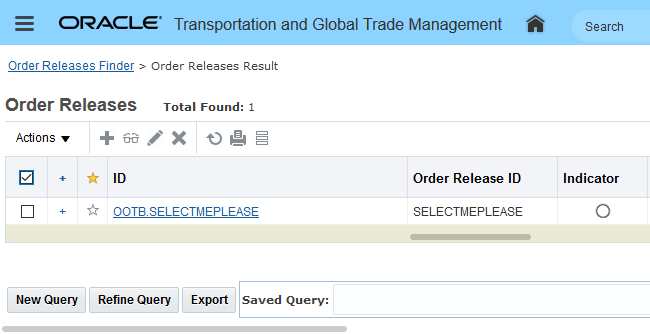

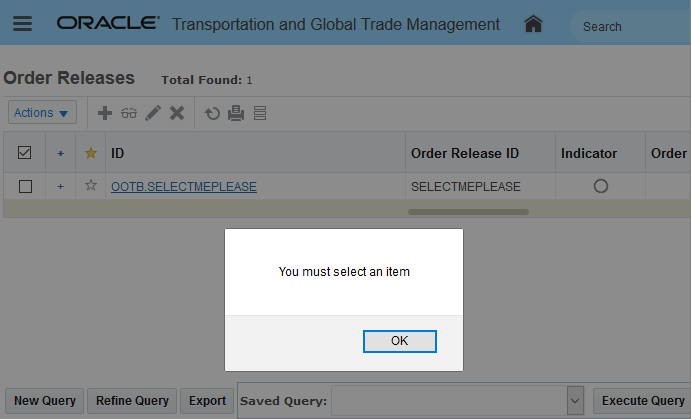

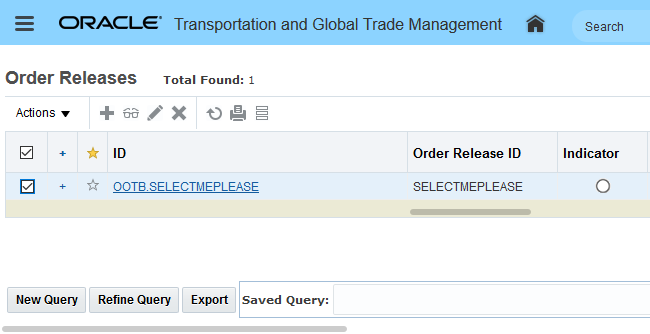

Below is an example of the default/current behavior. When a finder result returns one record the returned result is not selected automatically and if you attempt to proceed with running an action the popup message appears..

Auto Select When One Record Default/Current Behavior

Below is an example of the new behavior. With the parameter for AUTO SELECT WHEN ONE RECORD set to TRUE, the finder result with one record result automatically selects the single record.

Result Selection - Auto Select When One Record - True

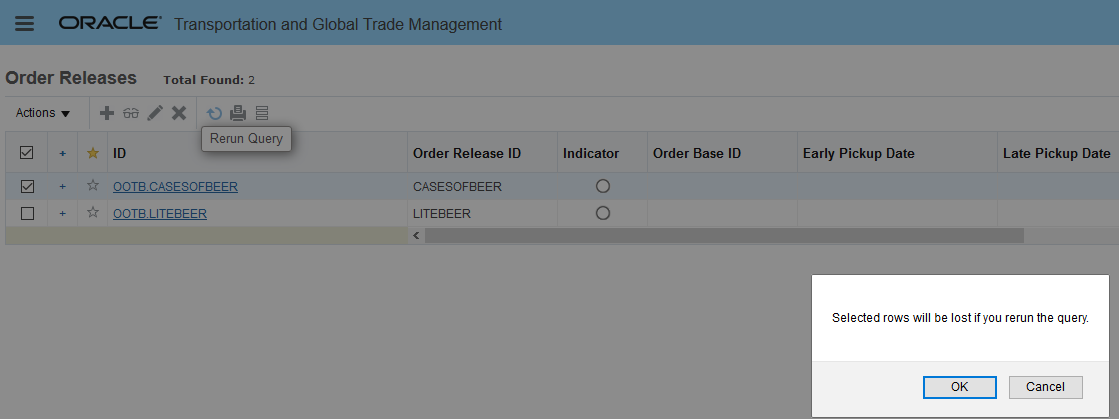

- MAINTAIN SELECTIONS WHEN RERUN QUERY - provides you with the option to retain your selected records (new behavior) or not retain your selected records and receive a warning that the selection will be lost when you re-run the query - current behavior.

- Default Value=FALSE

Below is an example of the default/current behavior. When MAINTAIN SELECTIONS WHEN RERUN QUERY is set to the default value of FALSE a warning message is displayed informing you that the selected records will be lost if you proceed with running the query.

Maintain Selections When Rerun Query - Default Value - FALSE

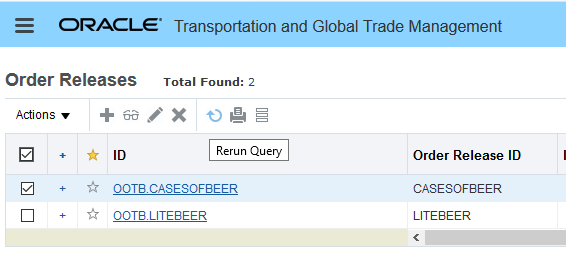

When MAINTAIN SELECTIONS WHEN RERUN QUERY is set to TRUE the selection is maintained and the message "Selected rows will be lost if you rerun the query" is no longer shown.

Maintain Selections When Rerun Query - Set to TRUE - New Option

The new UI Configuration Logic Configuration Type is below.

UI Configuration Logic Configuration Type

You have the following options for setting the UI Configuration Logic configuration:

- You can use the seeded public Logic Configuration which is provided with the parameters set to the default settings, ID = UI CONFIGURATION DEFAULT

- You can create your own UI Configuration Logic Configuration and use that in your assorted domains.

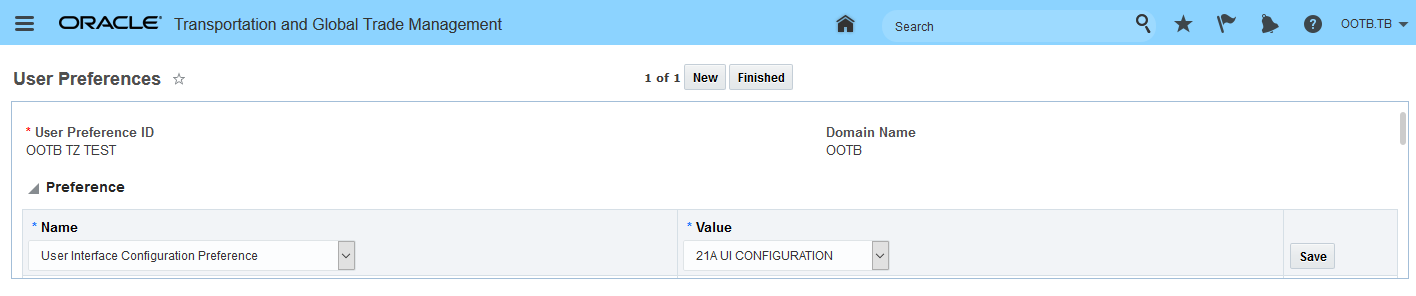

- You can create your own UI Configuration Logic Configuration and assign the desired UI Configuration for your users using the User Preference UI Configuration Preference option.

- You can set the glog property glog.webserver.ui_configuration_default_logic_config to select the Logic Configuration to use at the instance wide level.

Below is an example of a setup at the User Preference level.

UI Configuration Set on User Preference

This feature improves the user's access to navigator links and improves the user's efficiency by eliminating unnecessary mouse clicks.

Steps to Enable

You don't need to do anything to enable this feature.

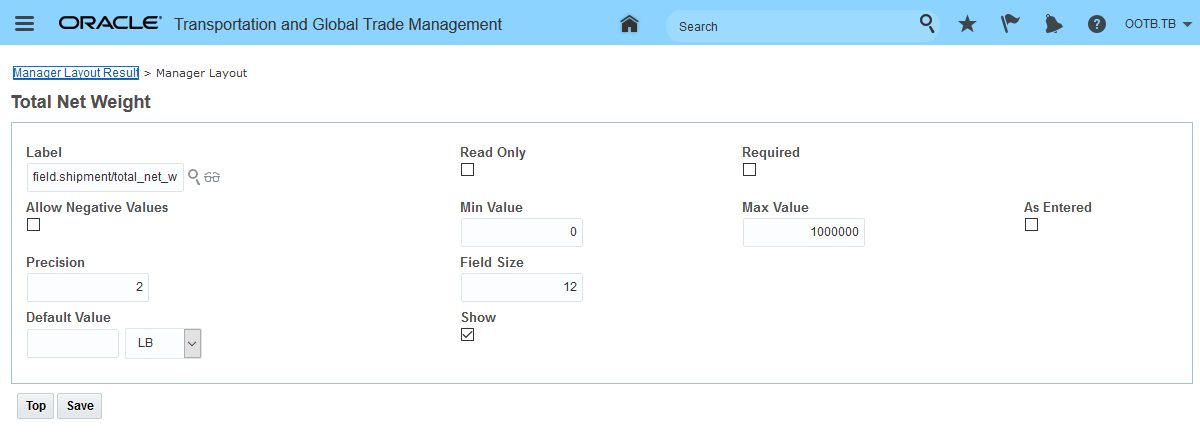

Manager Layout - UOM and Currency Field Size Setting

This feature provides you with the option of modifying the field size of your UOM and Currency fields. You can change the field size of your UOM and Currency fields by editing the field in the Manager Layout and then setting the Field Size attribute to the desired size.

Field Size Attribute

This feature will allow you to increase or decrease the field size of your UOM and Currency fields, which will provide you with less wasted space on your UIs.

Steps to Enable

You don't need to do anything to enable this feature.

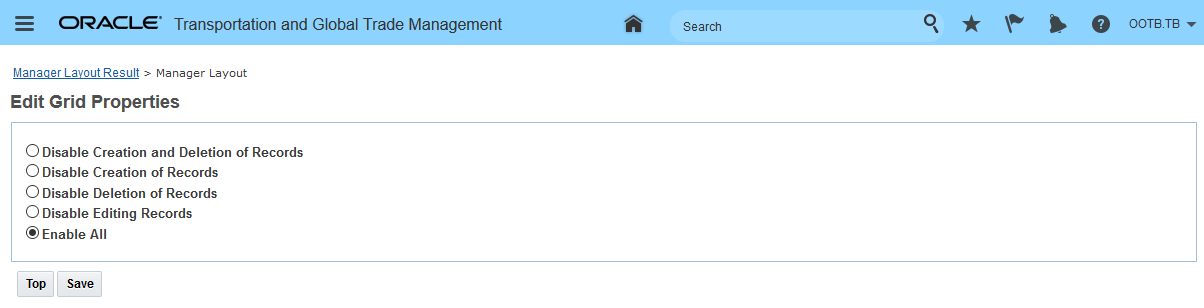

Manager Layout Grid Configuration - Separate Disable Options for Creation and Deletion

This feature provides you with two additional options for configuring your manager layout grids. Specifically, this feature allows you to configure your grids with creation disabled while deletion is allowed or with deletion disabled while creation is allowed. Previously, the options related to creation and deletion were combined into one Disable Creation and Deletion option - so you either enabled or disabled both creation and deletion options together.

.

Manager Layout Grid Configuration

The additional manager layout grid configuration will be extremely beneficial for all clients who have business scenarios that required the configuration of grids that required separate configuration control for the creation or deletion of grid entries.

Steps to Enable

You don't need to do anything to enable this feature.

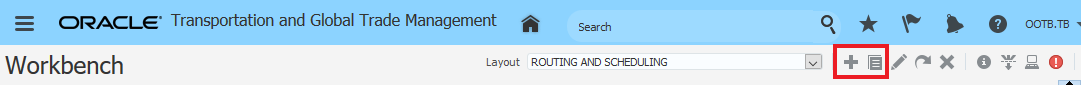

Workbench - Create/Copy Access Control Enhancement

This feature provides you with a new Access Control List value "Workbench - Create" that you can configure to control access to the Workbench Create/Copy options at the User or User Role level.

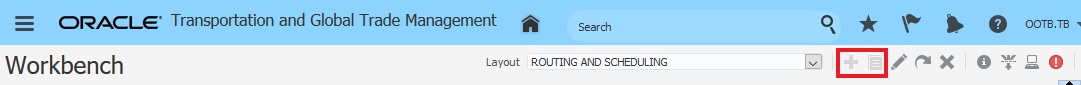

By default, most users will have access to the Create/Copy buttons as highlighted below.

Create/Copy Available in Workbench

This feature provides you with the option - at the user and user role levels - to disable the Create/Copy buttons on the Workbench - as highlighted below.

Create/Copy Buttons Disabled (grayed out)

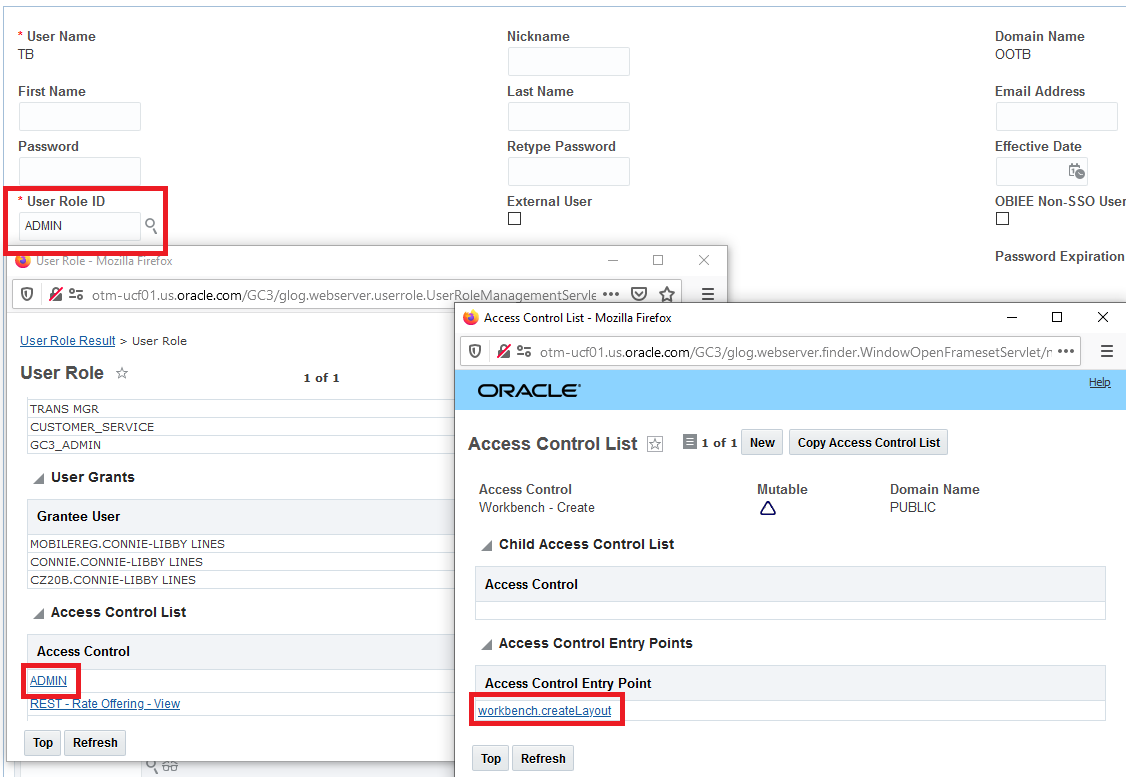

This feature is controlled by a new Access Control List value "Workbench - Create". This new Access Control has been provided as a child of the "DEFAULT" and "ADMIN" Access Control Lists so that all users with the "DEFAULT" and "ADMIN" roles will have access to the create and copy buttons by default. You - as ADMIN - have the option to grant/not grant access for your users at the User or User role level.

Provides you with additional controls for the access your users will have to create/copy the Workbenches the user(s) have access to in your implementation.

Steps to Enable

- To prevent a user from Create and Copy buttons, you can revoke the "Workbench - Create" ACL from the User

.

Starting Setup ADMIN User Role with Workbench Create Layout Access

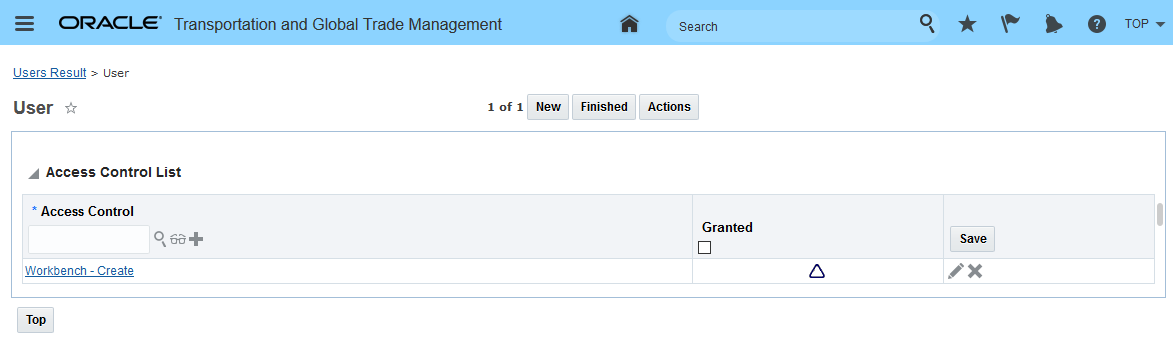

To remove workbench create and copy access for a user - add the 'Workbench - Create' entry below (with the Granted option unchecked) to the user's Access Control List.

Access Control Entry to Remove Create/Copy Access for a User

To remove workbench create and copy access for a User Role - add the 'Workbench - Create' entry, as shown above (with the Granted option unchecked), to the User Role Access Control List.

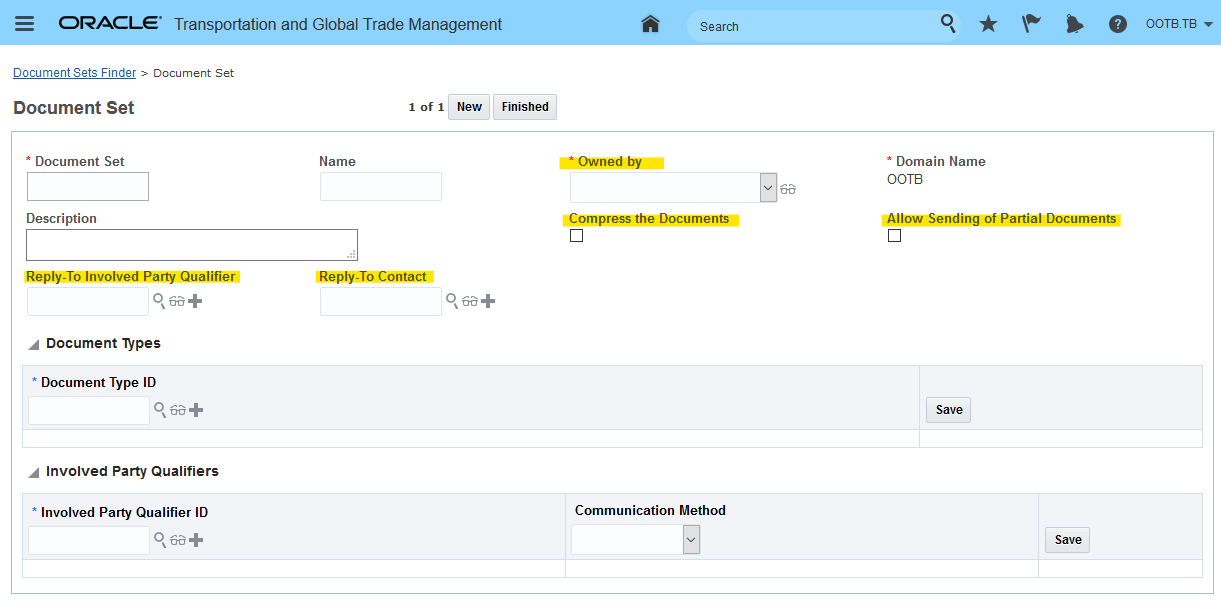

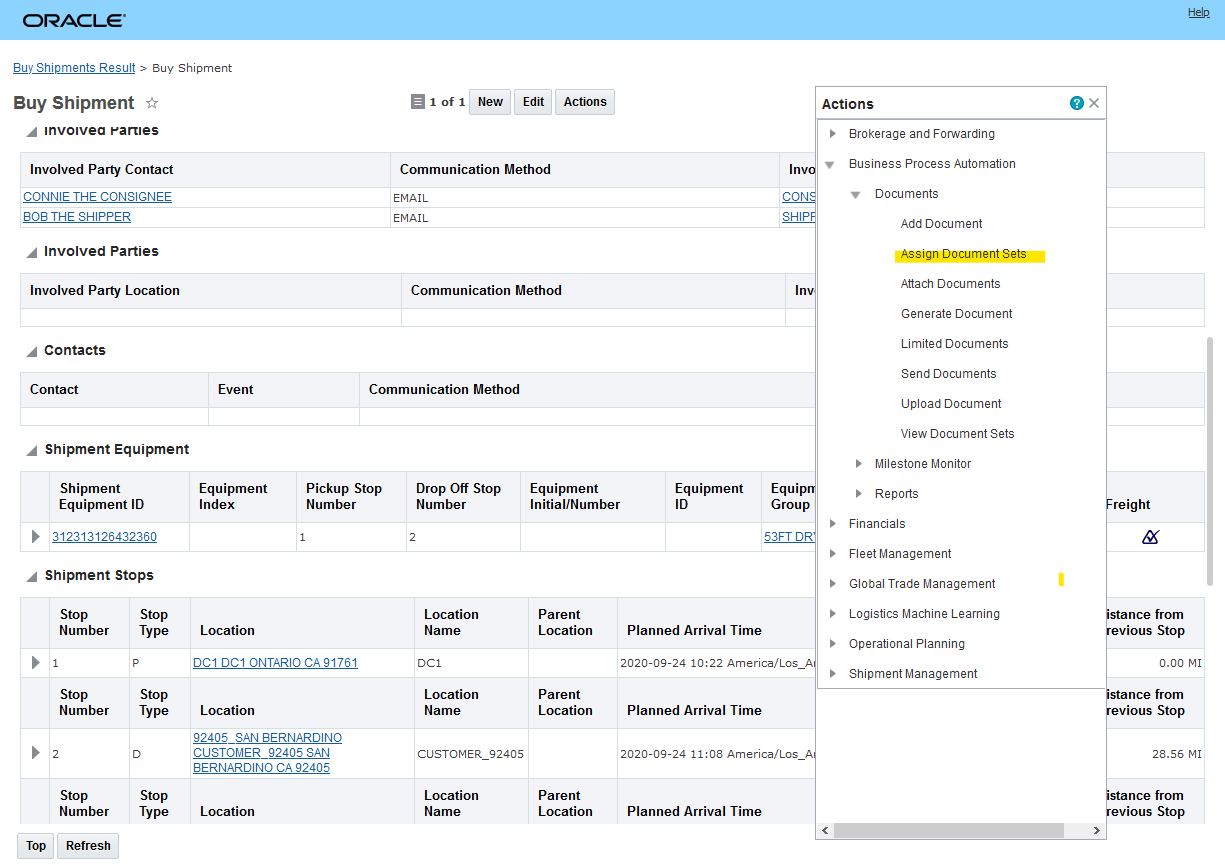

The Document Sets feature allows you to predefine a set of document types that you want to send as a set to one or more involved parties based on the party's involved party qualifier. You'll find this feature extremely useful in any situation where the set of document types sent to your involved parties is repetitive.

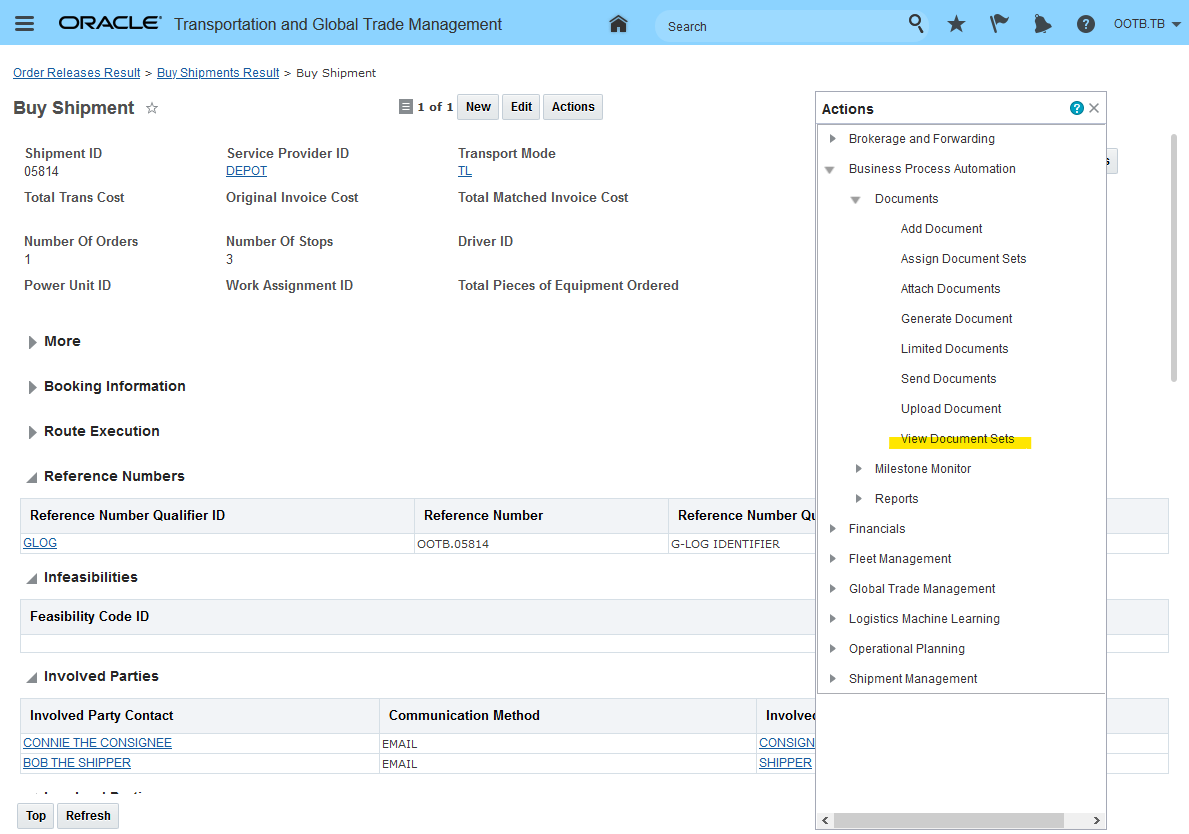

For the supported objects - Shipment (both Buy and Sell), Trade Transaction and Declaration - this feature provides you with the ability to:

- Use the UI Action - Assign Document Sets - to assign document sets to the supported objects

- Use the UI Action - View Document Sets - to view or remove assigned document Sets

- Use the enhanced UI Action - Send Documents - to send document sets or documents

- Use the Agent Action - Send Document Sets - to send the assigned document sets from the supported objects

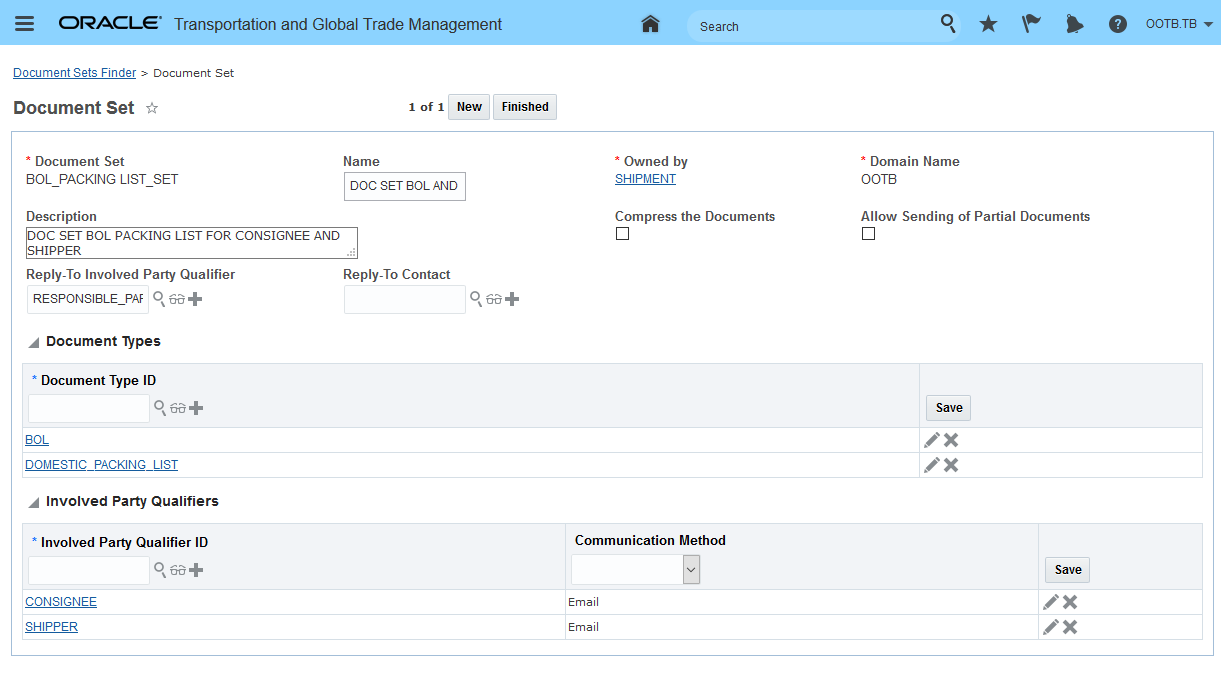

In the example below - a document set (BOL_PACKING LIST_SET) owned by the shipment has been created. This Document Set will - when assigned to an object (in this case a Shipment), allow you to send the assigned document types of BOL and Domestic Packing List to the Consignee and Shipper Involved Parties via email using the Send Document Action..

Document Set Example Setup

The setup is straightforward - a few items to note on the Document Set manager:

- The Owned By drop down allows you to select the objects in OTM and GTM that you want to assign a Document Set to - the currently supported objects are Shipment (Buy/Sell), Trade Transaction and Declaration.

- Selecting the Compress the Documents check box will compress the documents in the set and sends them via email as an attached .zip file. If you do not select this check box, documents will be sent as individual attachments.

- The Allow Sending of Partial Documents check box will allow you to send the document set if only some of the document types in the document set are on the business object. If you do not select this check box, an email will be sent only if all the document types defined for the Document Set are on the business object.

- Reply-To - you have the option of entering the Reply-To for the Document Set by either specifying a Reply-To involved party using the Reply-To Involved Party Qualifier field or you can enter a Reply-To contact ID directly in the Reply-To Contact field. The value entered in Reply-To Contact field will take precedence over the value mentioned in the Reply-To Involved Party Qualifier field.

.

Document Set Features

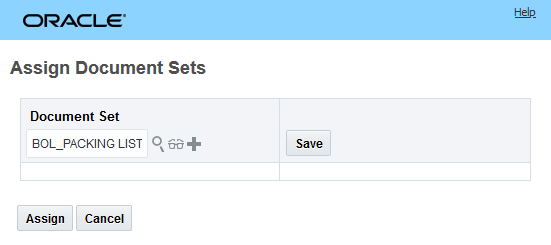

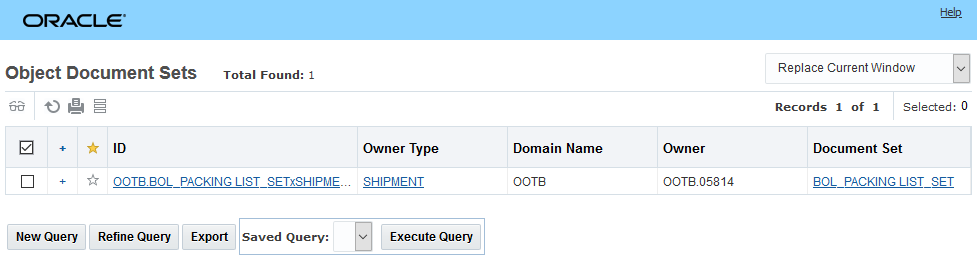

Once defined - the Document Set can be assigned to an object and then sent. In the example below - the Document Set created above is manually assigned.

NOTE: You can assign more than one Document Set to an object.

Manually Assign Document Set to Shipment

Assign Document Set Input

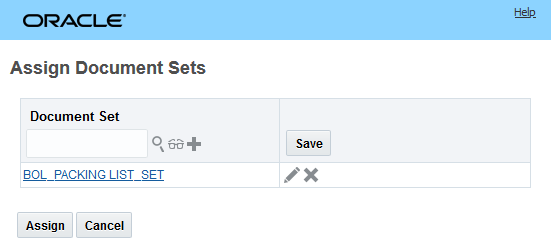

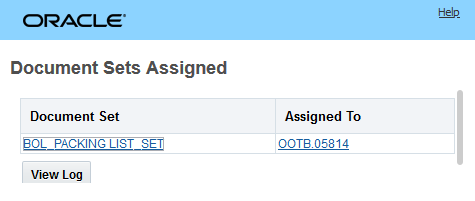

Assign Document Set Result

To see the Document Sets assigned to an object you can use the View Document Sets Action.

View Assigned Document Sets

View Document Sets Results

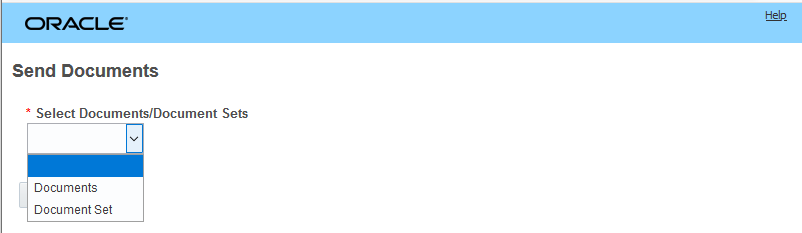

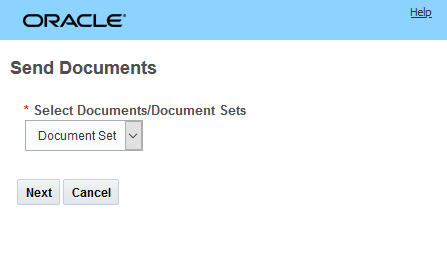

To send document sets - you will use the Send Documents Action - this action has been enhanced to support sending individual documents or document sets.

Send Documents Action - Documents and Document Sets Supported

Send Document Sets

Select the document set or sets to send.

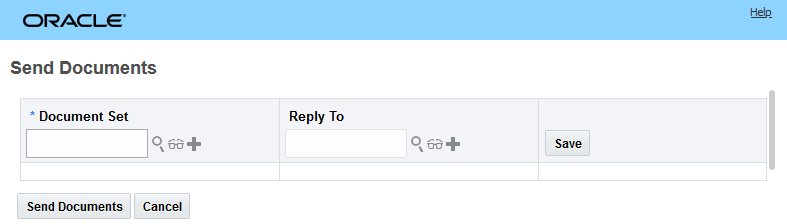

Send Document Sets - Select Document Set to Send Action Input

Send Document Success

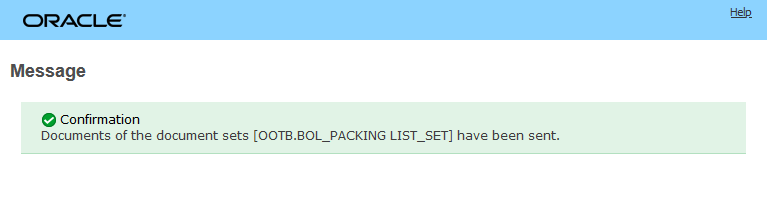

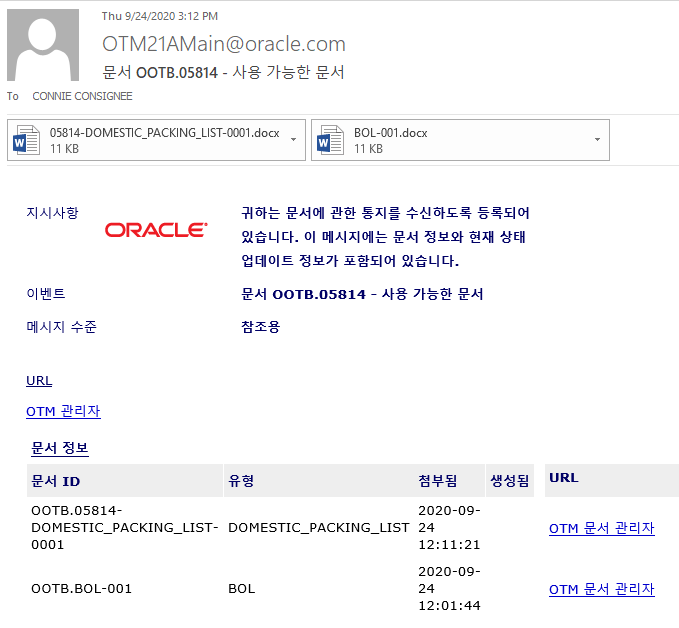

Both of the involved parties Bob Shipper (Involved Party Shipper) and Connie Consignee (Involved Party Consignee) receive the two documents in the defined Document Set via email. Email received below.

Emails Received by Bob Shipper and Consignee

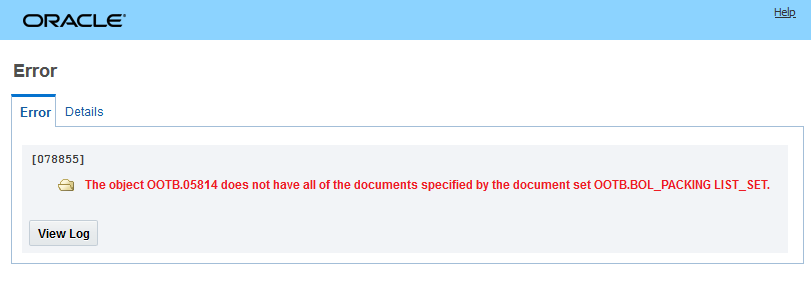

If the selected Document Set assigned to the shipment required that all document types be present on the object and if this requirement was not satisfied, then in this case the Send Documents action will fail and the message below will be provided..

Not All Documents Assigned to Object Error

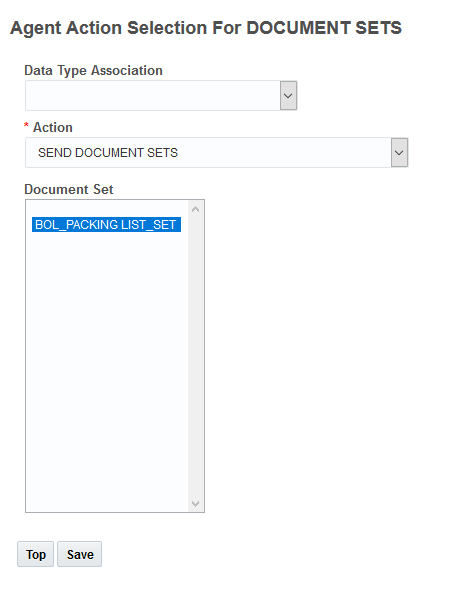

In the simple example below, when the agent action is triggered - assuming the Involved Parties and Document Types have been assigned to the shipment - then the documents will be transmitted to the defined involved parties in the Document Set.

Send Document Agent Action Setup

For the Shipment (both Buy and Sell), Trade Transaction and Declaration, this feature simplifies the steps required for selecting the set of document types that should be sent and the involved parties who should be receiving those various document types.

Steps to Enable

To use/send a Document Set you will need to create a document set first. The steps for adding a Document Set are provided below.

Navigate to Business Process Automation > Power Data > Document Generation > Document Types to create a Document Set.

- Enter a unique identifier in the Document Set field.

- Enter the name of the document set in the Name field.

- In the Owned By drop down field select the business object for which the document set will be applicable.

- Enter a description of the document set in the Description field.

- Select the Compress the Documents check box to compress the documents and send them via email as an attached .zip file. If you do not select this check box, documents will be sent as individual attachments.

- Select the Allow Sending of Partial Documents check box to send email even if documents of only some of the document types on the business object are present. If you do not select this check box, an email will be sent only if documents of all the document types mentioned on the business object are present.

- Enter the involved party qualifier on the object that would be used to specify a contact to send reply emails in the Reply-To Involved Party Qualifier field.

- Enter a contact ID directly in the Reply-To Contact field. This contact will receive the reply emails. The value entered in this field will take precedence over the value mentioned in the Reply-To Involved Party Qualifier field.

Tips And Considerations

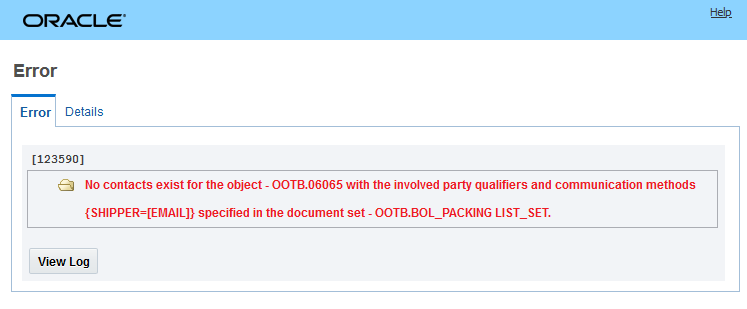

The Send Document Set Action - in addition to checking if the object does or does not have all the required documents (based on the configuration) will also check if the object has all of the Involved Party Qualifiers defined in the Document Set.

For example, if the Document Set has a Shipper and Consignee Involved Party Qualifier defined and the object you wish to send the Document Set from only has one of the required Involved Parties defined, the error message below will be provided when sending the document set using the web action. An equivalent error message will be provided in the Logs if you trigger the Send Document Set via an agent action.

Object Missing Document Set Involved Party Qualifier

REST - New Query String Parameters to Hide/Show Primary Key Fields in REST Payload

Almost all resources in OTM/GTM use a Unique Global Identifier, or 'GID', as the primary key for records in the database. The GID value is a concatenation of an External Identifier, or XID, and a Domain Name. Sub-resources can also have their own GID field as well as their parent GID field. In an earlier release of the REST API, the data returned for a specific resource request contained all GID, XID and Domain Name attributes which meant that there was a level of redundancy between those values, and most of the sub-resources returned since the parent GID was repeated in each sub-resource even though the parent GID is implicit within the enclosing context.

In Release 19B, two properties were introduced to control whether or not the primary and parent GIDs were returned by default:

- glog.fusion.cil.restapi.config.hideParentPks

- glog.fusion.cil.restapi.config.hidePks

To support backward compatibility, the property settings were set so that the GIDs were returned and the recommendation at that time was to change the properties to not return the GIDs as it was intended to be the default logic in a future version. In Release 20C, the default property values were updated so that these GIDs were not returned.

In Release 21A, two new URL query parameters have been added to replace these properties and therefore allow the GIDs to be returned on a request by request basis. REST client applications should therefore be modified to use the new query parameters instead of the system properties.

The new parameters allow the GIDs to be returned on a request by request basis.

Steps to Enable

Review the REST service definition in the REST API guides, available from the Oracle Help Center > your apps service area of interest > REST API. If you're new to Oracle's REST services you may want to begin with the Quick Start section.

Tips And Considerations

The properties provided previously are no longer considered - your REST client applications should therefore be modified to use the new query parameters instead of the system properties.

REST - Batch Processing/Asynchronous REST API

This feature provides you with the option of using the REST APIs to perform batch loading of OTM objects. Previously, the OTM/GTM Rest Services only supported a synchronous one record at a time operation versus the asynchronous processing available using the XML-based SOAP APIs.

New Capabilities added as part of this feature:

- Transmissions resource - capability to POST the Transmission resource

- Transmission supports mixed resource types with (potentially) mixed operation types e.g. POST & JSON PATCH

- Support for Transmissions with refnums

- Support Transmissions with sender reference

- Support for Transmission and Transactions with Process Groups and sequencing

This feature introduces the option of using the REST API in JSON format to load batches of data into OTM/GTM.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

The intention of this feature is to cover all batch scenarios using REST, however, there is the possibility (this being the first release of this new functionality) that some scenarios may not work in an optimal fashion and/or some of your desired scenarios are not yet fully supported.

The REST Asynchronous/Batch Processing capabilities provided by this feature should be considered as an additional integration option available for you to use depending on your integration requirements and the scenarios that need to be supported. This feature is not intended to replicate or serve as a replacement for the XML Soap Based APIs that have been in the application for 20 plus years. We suggest starting with a mixed/hybrid integration approach where the heavy lifting/high volume interfaces remain (for now) on the XML based APIs - while the available REST capabilities are used to support scenarios where the REST architectural style, protocol and message format provide a better fit.

Key Resources

- See the REST API online documentation for a complete description of the new capability.

REST - Power Data Phase 2 - for Major Objects

This feature represents the second release of REST Service enabled power data resources. This second phase deliverable is focused on more complex multi-table power data elements related to OTM/GTM major objects - like order base, order release, item, location, shipment, tracking event, trade transaction etc. The supported power data resources along with information regarding these resources can be found in the REST services documentation.

In addition to the newly added power data resources, User Access Control List entries have been added so you can control which users are and are not allowed to have access to the REST APIs for View and Update.

User Access Control List Additions:

- REST - Exchange Rate Configuration - Update

- REST - Exchange Rate Configuration - View

- REST - Transmission Configuration - Update

- REST - Transmission Configuration - View

- REST - Voucher Configuration - Update

- REST - Voucher Configuration - View

The additional power data REST resources allows you to extend the application for reporting purposes, UI development or mobile application development.

Steps to Enable

Review the REST service definition in the REST API guides, available from the Oracle Help Center > your apps service area of interest > REST API. If you're new to Oracle's REST services you may want to begin with the Quick Start section.

Key Resources

- REST API for Transportation and Global Trade Management Cloud document available here

REST - POST, PATCH, DELETE Methods Supported for Document Resources

This feature provides you with the ability to POST, PATCH, and DELETE your document resources. With these additions - you now have the GET (provided in an earlier update), POST, PATCH, and DELETE methods available to use with your document resources.

Similar to uploading a document in the Document manager the code will attempt to ascertain the Type (BLOB or CLOB) and Mime Type (text/plain, image/jpeg, etc.).

- The clobContent attribute should be used when uploading text documents (text/plain, text/xml, text/html, etc.). It should be a BASE64 encoded version of the string, which is to be saved.

- The blobContent attribute should be used when uploading binary documents (image/jpeg, image/pdf, etc.). It should be a BASE64 encoded version of the file, which is to be saved.

This feature allows you to upload/create documents using REST services.

Steps to Enable

You don't need to do anything to enable this feature.

REST - Add JSON Patch Test Operation

This feature expands the available JSON PATCH operations to include "test" capability to make the JSON PATCH operations conditional based on the object data content. For OTM/GTM, this means accepting a JSON PATCH compliant message to apply a number of modifications to a REST API resource.

Provides you with the option of applying a number of modifications to a REST API resource.

Steps to Enable

Review the REST service definition in the REST API guides, available from the Oracle Help Center > your apps service area of interest > REST API. If you're new to Oracle's REST services you may want to begin with the Quick Start section.

This feature will allow you (the DBA.ADMIN) to - when necessary - run an incremental ETL data load from a date (in the past) that you specify (the Lookback Date) which will allow you to load data that may have been skipped as part of your daily/standard ETL load process.

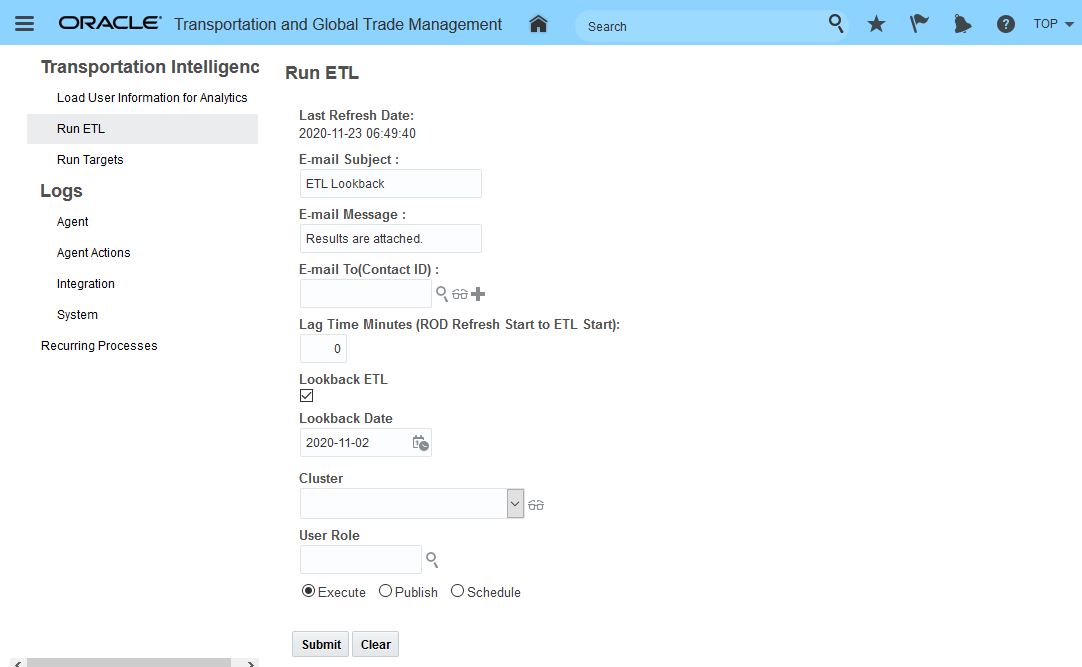

In the example below, the Last Refresh was on 2020-11-23 06:49:40, and by default the next daily ETL run would load data from this date/time forward, however, the Lookback setup below (Lookback ETL checked and Lookback Date specified) will run an incremental ETL starting on the specified Lookback Date of 2020-11-02 and will load data looking forward 14 days i.e., to 2020-11-16. Any data in this range that failed to load previously will be loaded as part of this incremental run.

Process manager ETL Lookback Example

This feature provides you with the ability to load data that, for whatever reason, failed to load/was skipped in prior ETL runs.

Steps to Enable

You don't need to do anything to enable this feature.

XML Schema Validation - Update

The XML Schema Validation feature was originally released with the 20A update with the Opt In set to FALSE/not enabled. For 21A, the Opt In is now TRUE/enabled by default. In addition, the Optional Until upgrade has been moved to the 21C update.

This feature, when enabled, will validate every inbound XML message against the set of XML Schema definitions. Strict validation will enforce rules like sequence of elements, invalid empty elements etc., all of which were allowed in the previous 'lax' validation logic. Any validation failure messages will be written to the application log and may require cross reference to the associated XML schema file to resolve the error.

Enforcing valid XML messaging improves instance security.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

Key Resources

- See Integration Guide for more details.

Restrict External ID (XID) Creation to Valid Characters

The Validate ID feature, when enabled, will validate newly created records in OTM to insure that the external IDs (XIDs) entered do not contain restricted characters. The goal is to restrict the creation of XIDs to containing only numbers, upper-case letters, spaces, underscores and dashes.

The set of restricted characters is: , x > < = / & ? ; # $ ' " \r \n ( )

If a potential XID for a new record contains a restricted character, the transaction will fail. The validation for the XID will be handled for records entered via the XML and/or REST based APIs as well as records entered using the managers.

When the feature is enabled, you will receive a warning message in the managers listed below, if your proposed XID contains a restricted character.

- Buy Shipments

- Sell Shipments

- Location Manager

- Order Release

- Order Base

- Order Movement

- Item

- Packaged Item

- Driver Manager

- Itinerary Manager

- Rate Offering

- Rate Record

This feature will eliminate problems caused when invalid characters are used to generate object XIDs.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

Create all your XIDs so they contain only numbers, upper-case letters, spaces, underscores and dashes.

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

Disable IntXmlService and IntGtmXmlService

The Disable IntXmlService and IntGtmXmlService feature disables the IntXmlService and IntGtmXmlService. This feature is set to TRUE/enabled by default.

While these services have been deprecated for several update cycles, this optional feature has been provided as a final notice that these services are beyond end-of-life and should no longer be used.

As background, these two services were replaced by a redesigned schema that was delivered in the v6.4.2 release (Q1 2017). The original GLogXML and GLogXML-GTM schema files had become cumbersome and problematic for modern SOA integration tools and needed to be updated. Changing the schema definitions also meant we had to produce a new SOAP service – TransmissionService – which supported the new schema messages.

The Integration Guide, starting with the 6.4.2 release, has explained that the IntXmlService and IntGtmXmlService were deprecated.

The benefits for moving to the the new schema are many and include:

- Access to features involving schema enhancements provided since v6.4.2.

- Improved performance. Pre-6.4.2 message formats are passed through an XSLT transformation to internally convert to the newer syntax and so avoiding this will improve performance.

- Required to support the Strict Schema Validation feature which is also enabled in 21A.

Disabling features that are no longer supported and should no longer be used.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

DBXML Maximum Export Size Restricted

The DBXML Export Limit feature restricts the DBXML maximum export size, when the size limit is hit you will receive a 'DBXMLExport exceeded maximum export size.' message. This feature is set to TRUE/enabled by default.

The Opt In/Opt Out for this mandatory feature expires with the 22A update.

The business benefit of this feature is that excessively large DBXML exports will be aborted rather than overloading the server.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

The Use Nested GID in Agent DTA feature when enabled, will remap the $GID inside a Data Type Association loop to be the child object of the association and the $PARENT will be assigned to the agent's business object.

This feature is set to True/enabled by default.

Optional Until 22C

This feature remaps $GID and $PARENT variables within agent Data Type Association loops.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

The CSV Upload Cache Refresh feature was originally released in the 20A update, in the 21A update the Optional Until version has been moved to the 21C update.

This feature allows you, the DBA, to have OTM support immediate cache updates when CSV files are uploaded. By default the Opted In is set to TRUE/enabled.

When uploading CSV files via integration, impacted database changes are now collected. These changes are used to properly update any web-tier or app-tier caches across all clustered servers. Note that this feature also applies to any update statements made via the DIRECT SQL UPDATE agent action when using DML Returning cache refresh.

Improves CSV file integration processing.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

Load Balance Topic Interface - Update

The Load Balance Topic Interface feature was originally released with the 20A update. In 21A, the Load Balance Topic Interface feature's Opt In has been set to TRUE/enabled by default and the Optional Until update version has been changed to 21C.

This feature, once enabled, allows you to setup OTM so that inbound Topic requests are published to Process Control and load balanced across multiple servers. When disabled, the inbound Topic requests are executed immediately on the server that received the request.

Provides you with the ability to so that inbound topic requests are published to the process control and load balanced across multiple servers.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

Optimize Data Query Footprint - Update

The Optimize Data Query Footprint feature was originally delivered with the 20A update. For 21A, the Optimize Data Query Footprint Optional Until update has been moved to 21C.

This feature provides you with a Restructured Data Query memory usage that allows the memory used by one custom event topic to be released when all work associated with that topic is completed. This memory optimization feature is applied to all Data Query topics by default, i.e., the feature set to Opt In = TRUE/enabled by default.

This feature involved a number of lifetime and workflow changes focused on cleanup timing and event completion.

Improves performance.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

Process Manager - Run As User Role

This feature allows you to setup your Recurring Processes so that they run using a specified User Role. The functionality provided for Process Manager is meant to be equivalent to the Run As functionality provided with automation agents.

On the Process Manager, you now have the option to enter a User Role. When you execute, publish, or schedule the recurring process, the specified user role will be used to perform the process, just like when you execute automation agents. The specified User Role can be used to specify a separate VPD role or another domain to run with.

In the Process Manager example below for the Release Orders - you now have the option to specify the User Role to run the process as.

Process Manager - User Role

Adding the Run As User Role option to the Process Manager allows the process to be run based on the User Role specified.

Steps to Enable

You don't need to do anything to enable this feature.

This feature provides you with the ability to collect various performance metrics over time, and persist the performance metrics to the database in hourly, daily and weekly rollups. Once persisted, you can retrieve the historical metric data for a given time period and review the raw data, and/or export the data for additional analysis.

The recurring process, Persist Metrics, accessed via Configuration and Administration > Process Management > Persist Metrics is used to persists diagnostic metrics into tables that are aggregated by hour/day/week. A reserved recurring process runs this process hourly, so you should not need to run this process yourself.

Reserved Recurring Persist Metrics Process

This Persist Metrics process:

- retrieves all completed hourly data from the metric registry

- bulk inserts the data into the PERF_METRIC_DATA_HOUR table

- inserts data into the PERFM_COLLECT_HISTORY table to reflect completed hours, pending days and pending weeks

- queries the PERFM_COLLECT_HISTORY table to determine if any daily or weekly data is ready for rollup

- bulk inserts rollups into the PERF_METRIC_DATA_DAY and PERF_METRIC_DATA_WEEK table

- updates the PERFM_COLLECT_HISTORY table to reflect completed daily and weekly rollups

- inserts placeholders into the PERF_METRIC_DATA_INDEX table to support metric queries with missing data

This process was designed to minimize contention points, optimize database performance and support metric persistence in a SCA environment.

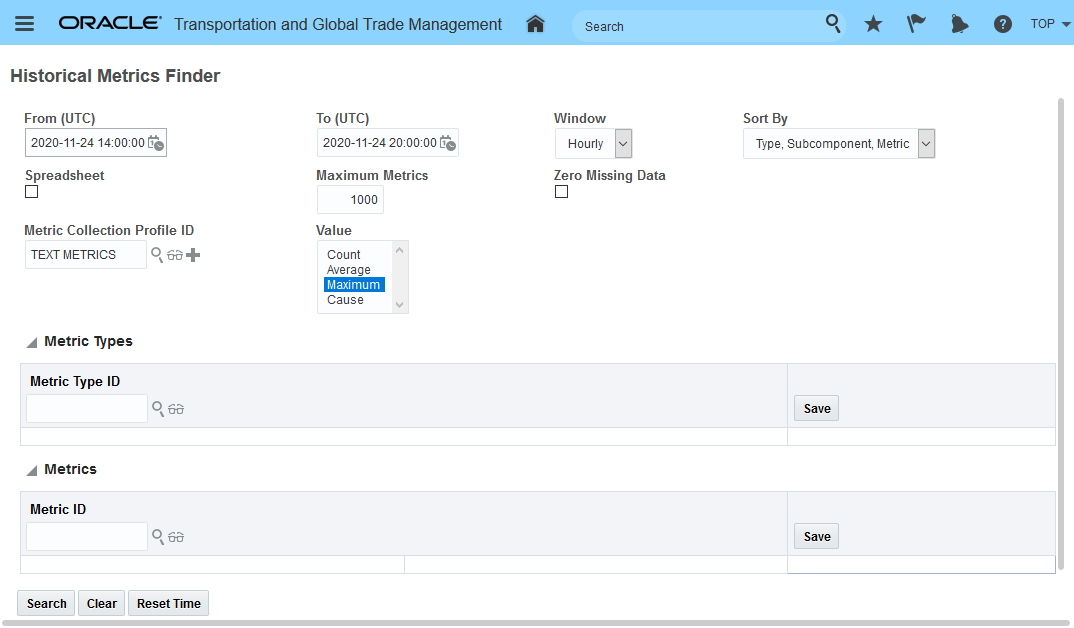

HISTORICAL METRICS UI

The Historical Metrics UI is used to review gathered metrics, this page is accessed via Configuration and Administration > Technical Support > Historical Metrics.

NOTE: You must be a DBA to access this page.

Historical Metrics UI

This page is used to gather metrics on your system.

- Count: A count metric measures a number of times some event occurs over an hour. E.g., for a given log ID, the number of log lines logged for that ID in an hour.

- Performance: A performance metric measures the time for some process to complete. E.g., the process time for a workflow topic in the batch Event Queue. Note that performance metrics maintain the total count, total time and maximum time for the metric. Thus, they implicitly hold a count metric for the number of times the process was executed.

- Enter a From and To range for your query.

- Select the Window. This controls whether hourly, daily, or weekly data is used. Each window type has a default time range. For example, Hourly defaults to the previous day, while Daily defaults to the previous month.

- Select a Sort By to control the display of the output.

- If you want the output to be saved as a tab-delimited spreadsheet file, select the Spreadsheet check box.

- Set the maximum number of results returned in the Maximum Metrics field.

- Select the Zero Missing Data check box to fill in empty data columns with zeros. If this is not selected, then any columns which have no data are excluded from the results of your query. While excluding empty data is useful in some cases, if you are generating a chart or graph from the returned data, then including zero value results will give you a more accurate graph.

- If you have a set of metrics that you frequently query and have saved that set in a metric collection profile, enter it in the Metric Collection Profile field.

- Select one or more Values that you want to display.

- Count: The total number of metrics submitted in the hour.

- Average: The average metric.

- Maximum: The maximum metric.

- Cause: Displays which topic caused the maximum metric value.

HISTORICAL METRICS UI RESULTS

After you click the Search button, the results of your query are displayed, sorted according to the Sort By field. If you included both metric types and metrics, the metrics are listed after the metric types. The results can be displayed on the screen or exported as a tab-delimited file.

Historical Metrics UI Results

The result above was generated by this Historical Search UI input.

Historical Metrics UI Search

Provides you - the DBA - with the tools required to monitor the overall performance of your OTM/GTM instance.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

This feature replaces the Optional Feature - User Interface Performance Metric - that was delivered in 20C.

OTM User to Oracle Identity Cloud Service Auto Creation

This feature supports the creation of Oracle Identity Cloud Service (IDCS) users from OTM eliminating the previous requirement of having to create the OTM/GTM users in both OTM/GTM and IDCS. With this feature, the user(s) that you create in OTM/GTM will automatically be created in IDCS.

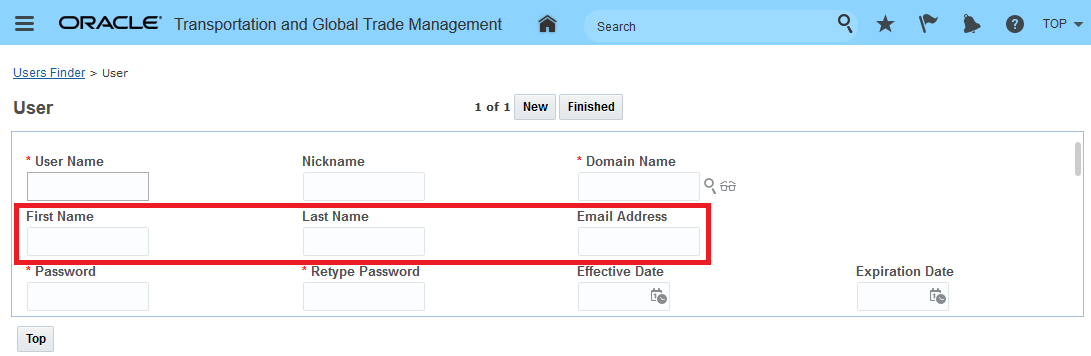

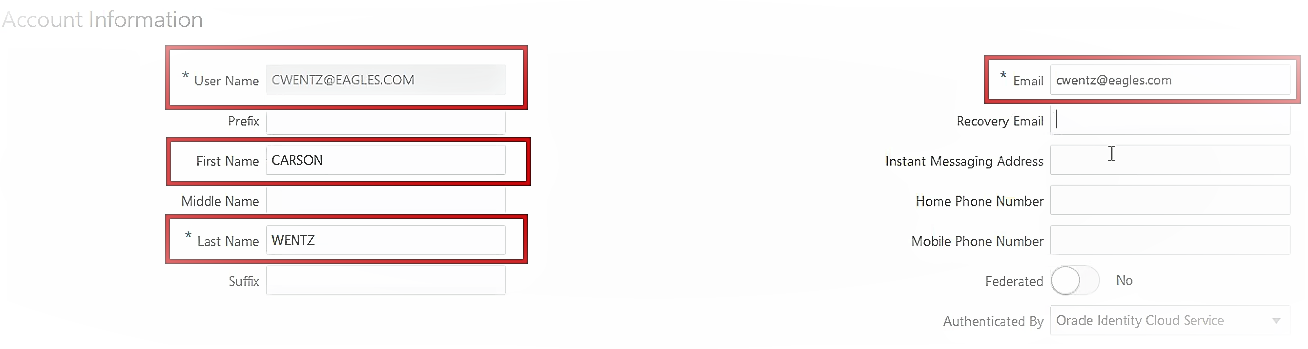

As part of this feature, the information captured for OTM/GTM users has been expanded to capture the IDCS required fields - First name, Last Name and Email Address.

New User Fields Added For IDCS

The IDCS user record will be created based on the information provided in the follow 4 OTM/GTM fields:

- Nickname - required for IDCS and is mapped to the User Name in IDCS

- First Name - required for IDCS, maps to First Name

- Last Name - required for IDCS, maps to Last Name

- Email Address - a valid email address is required for IDCS, maps to Email address and may be mixed case

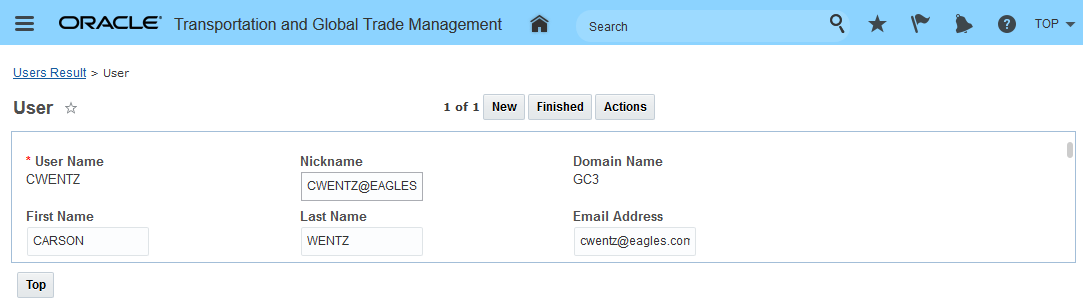

For example, the user below will be created in IDCS automatically.

OTM/GTM User

The automatically created IDCS user record for the user above in OTM/GTM is below. Note the fields automatically mapped into the created IDCS user - User Name (mapped from Nickname in OTM/GTM), First Name, Last Name and Email Address.

Automatically Created IDCS User

This feature simplifies the creation of users in IDCS by providing you with the option to automatically create your IDCS user entries directly from your OTM/GTM user entry.

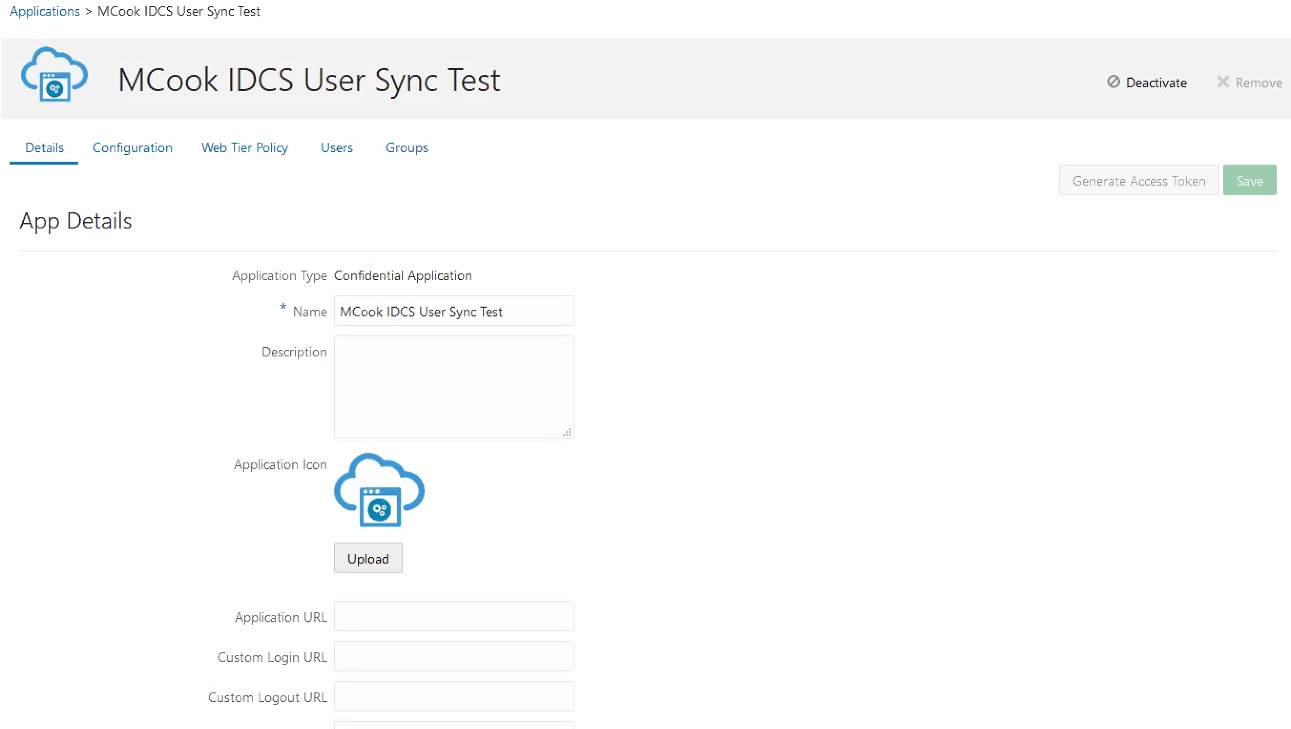

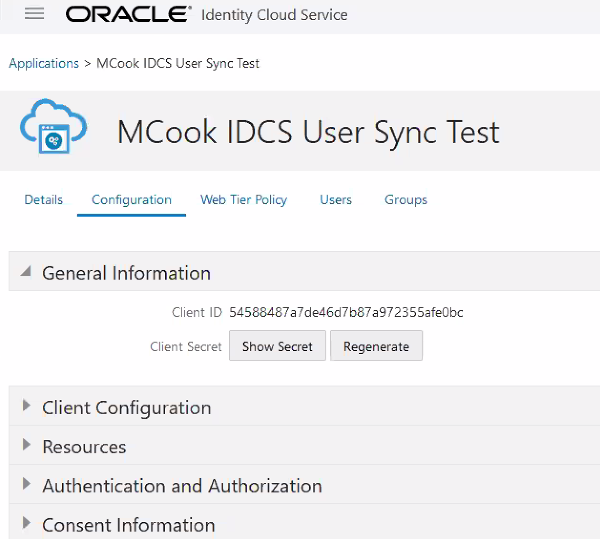

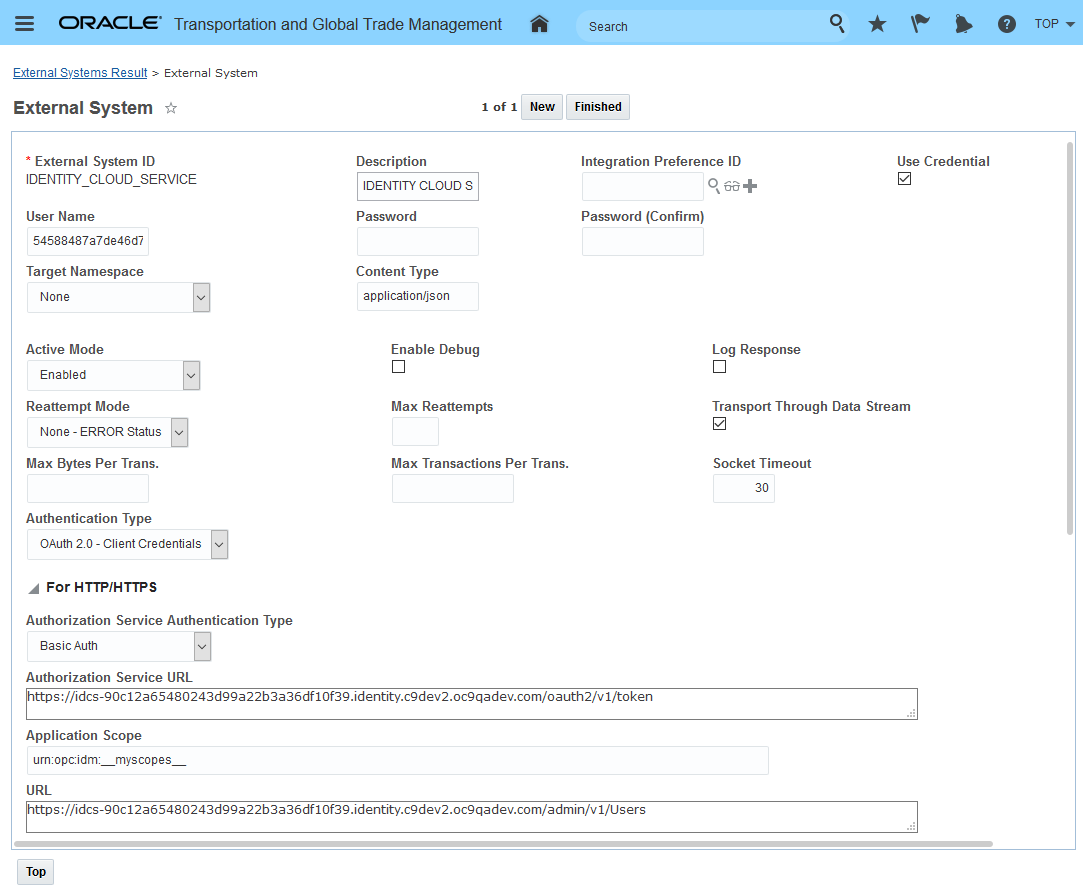

Steps to Enable

- In IDCS create a Confidential Application (trusted Application)

IDCS Create Confidential Application

- In IDCS Capture Client ID and Secret

IDCS Generate Secret Code

- In OTM/GTM create an external system with the:

- IDCS-Service-Instance URL

- Authorization Service URL

- Application Scope

- Client ID and Secret

External System Example

- In OTM/GTM set the following properties to enable auto synchronization with IDCS.

Instruction Key Value Description Set glog.security.user.idcs.autosynchronization

true Set glog.security.user.idcs.externalSystem

IDENTITY_CLOUD_SERVICE

IDENTITY CLOUD SERVICE External System

Tips And Considerations

NOTE: This setup/option is available to Gen2 cloud infrastructure clients using IDCS.

The user synchronization is managed using the properties below. Create is enabled by default, Delete is disabled by default.

- Create is controlled by this property - glog.security.user.idcs.allowCreate=true

- Delete is controlled by this property - glog.security.user.idcs.allowDelete=false

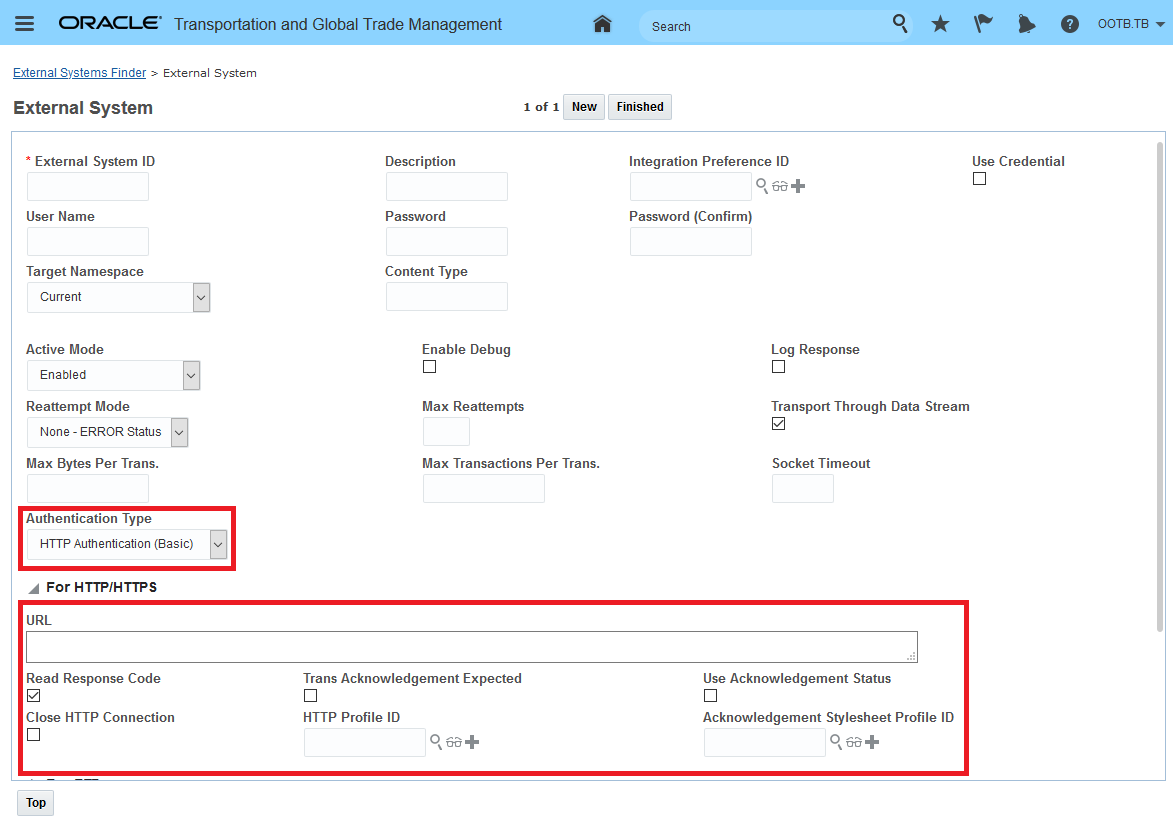

External System Support for OAuth2.0

This feature extends the options available to you for defining your external system Authorization Type to include HTTP Authentication (Basic), Pre-authenticated URL and OAuth 2.0 - Client Credentials. Additional configuration options have been provided within the OAuth 2.0 - Client Credentials Authorization Type to support the HERE Technologies OAuth 1.0 Signature authorization implementation.

On the External System UI, the fields displayed in the For HTTP/HTTPS section of the UI are now tied to the Authentication Type selected.

HTTP AUTHENTICATION (BASIC)

HTTP Basic authentication is the simplest technique for enforcing access controls to web resources.

HTTP Authentication (Basic)

When you select HTTP Authentication (Basic) as the authentication type, the following fields are available.

- URL: Specify URLs with both HTTP or HTTPS in this field.

- The Read Response Code should be selected if you want the HTTP response code to be validated.

- The Trans Acknowledgement Expected should be selected if you expect the transaction acknowledgement to be received when sending via synchronous protocol.

- The Use Acknowledgement Status check box specifies if the transmission acknowledgement status should be used as the status of the transmission.

- The Close HTTP Connection check box should be selected to close the HTTP connection after interacting with the external system.

- Use the HTTP Profile ID to define a connection to an EBS instance.

- Enter an Acknowledgement Stylesheet Profile ID if you are using Stylesheet Profiles to format your OTM messages.

PRE-AUTHENTICATED REQUEST

Pre-authenticated URL provides a way to let users access an object without having their own credentials, as long as the request creator has permissions to access those objects. Only use this option if you receive the pre authenticated URL from the source whose data you need to access. For example, Logistics Machine Learning uses a pre authenticated URL to allow customers to save objects to an Oracle Cloud Infrastructure or OCI data store.

Pre-Authenticated URL

When you select the Pre-Authenticated Request authentication type, the Pre-Authenticated URL is visible.

- Enter the Pre-Authenticated URL. This URL is only visible when you initially create the external system. If you edit the external system, you only see asterisks and cannot change the URL.

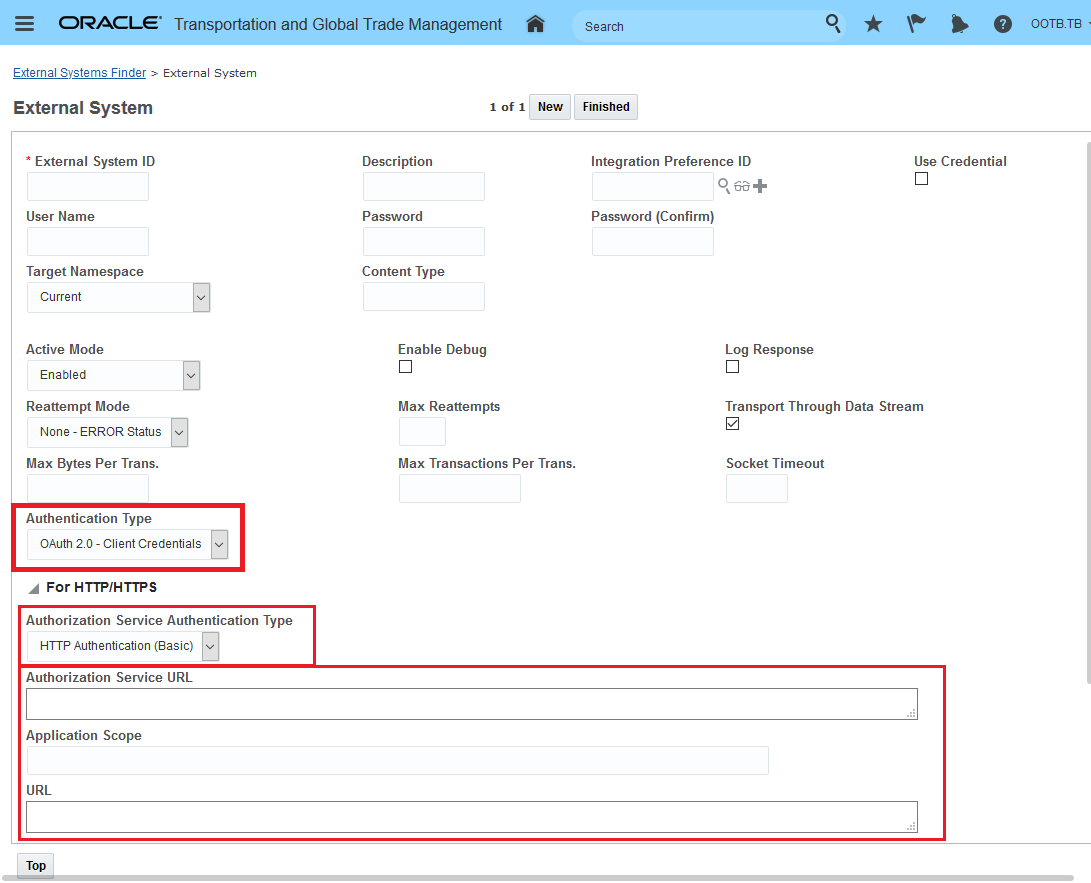

OAUTH 2.0 - CLIENT CREDENTIALS

This option allows you to configure your external system following the OAuth 2.0 specification.

OAuth 2.0 - Client Credentials With Authorization Service Authentication Type = HTTP Authentication (Basic)

OAuth 2.0 - Client Credentials with Authorization Service Authentication Type = HTTP Authentication (Basic)

- Select an Authorization Service Authentication Type in this case HTTP Authentication (Basic). The option you choose determines what fields are available in this section. This is the method used to request authorization from authorization service on behalf of the client.

- Enter the Authorization Service URL to call the authorization service.

- Enter the Application Scope. This is a blank delimited set of strings defined by the authorization service that limit the access scope for this client.

- Enter the URL.

OAuth 2.0 - Client Credentials With Authorization Service Authentication Type = HERE OAuth 1.0 Signature

OAuth 2.0 - Client Credentials with Authorization Service Authentication Type = HERE OAuth 1.0 Signature

- Select an Authorization Service Authentication Type in this case HERE OAuth 1.0 Signature. The option you choose determines what fields are available in this section. This is the method used to request authorization from authorization service on behalf of the client.

- The Consumer Key field - This is the key required by authentication service which is provided by HERE Technologies.

- The Consumer Secret field - Password related to the consumer key - again this is provided by HERE Technologies.

- The Signature Hashing Algorithm field - This is the algorithm used to sign the message if required by the authentication type. Option HMAC-SHA256.

- Enter the Authorization Service URL to call the authorization service. Value provided by HERE Technologies.

- Enter the Application Scope. This is a blank delimited set of strings defined by the authorization service that limit the access scope for this client.

- Enter the URL. Review HERE configuration to determine appropriate value.

OAuth 2.0 has become the defacto standard for REST API security adding this option supports the larger industry trend towards this approach to authentication.

Steps to Enable

You don't need to do anything to enable this feature.

Oracle Transportation Management (Base)

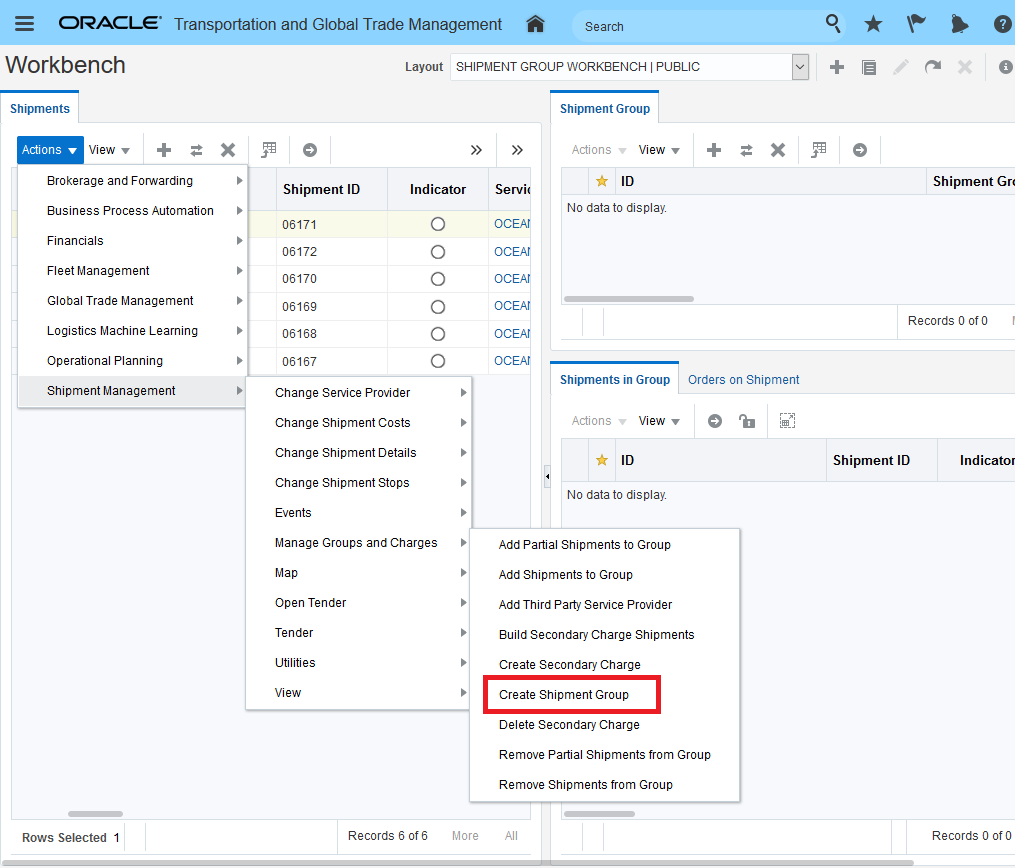

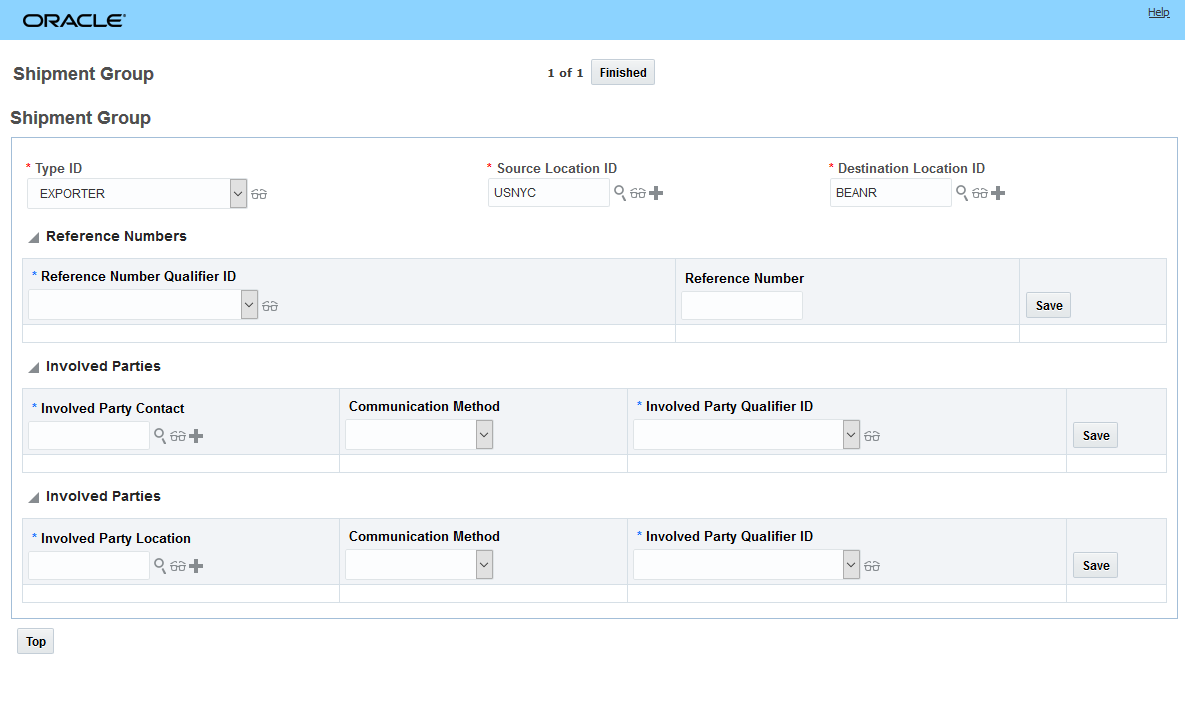

Shipment Group - Stop Level Tracking Event Enhancement

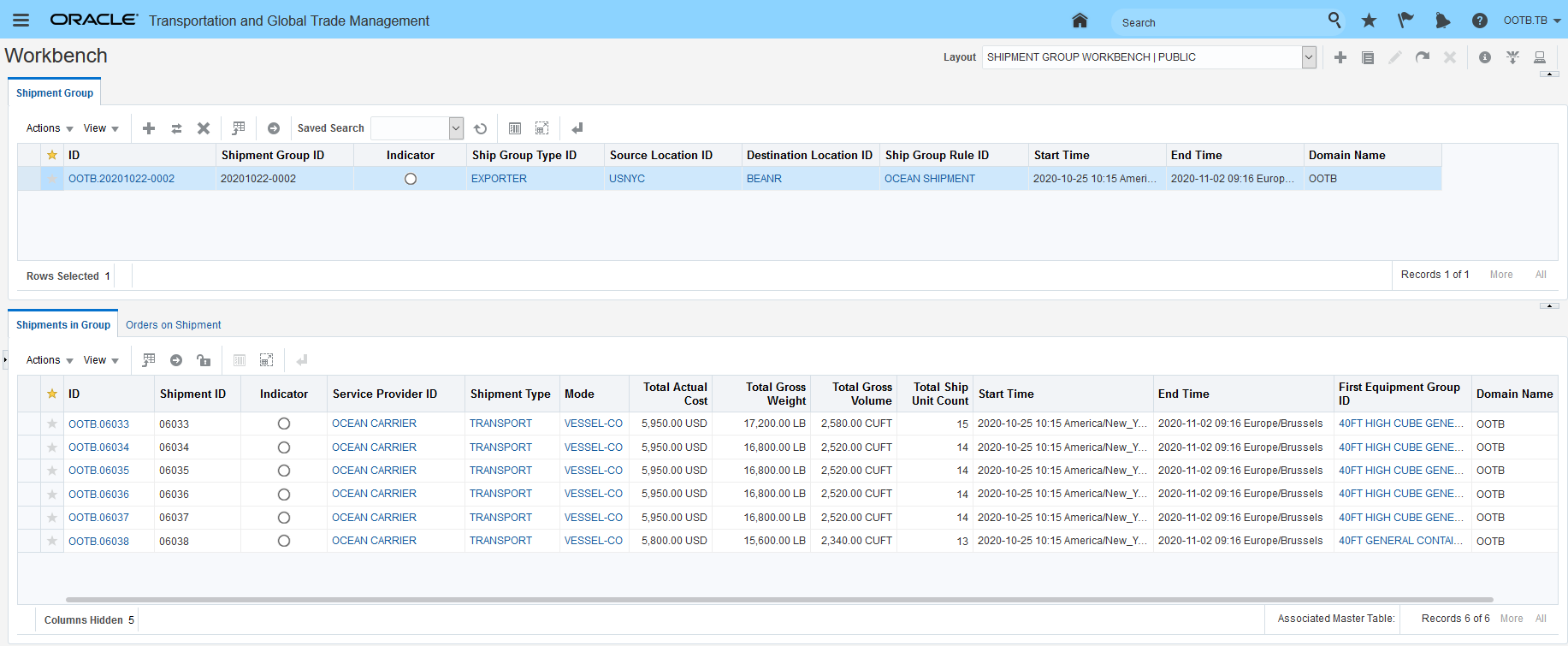

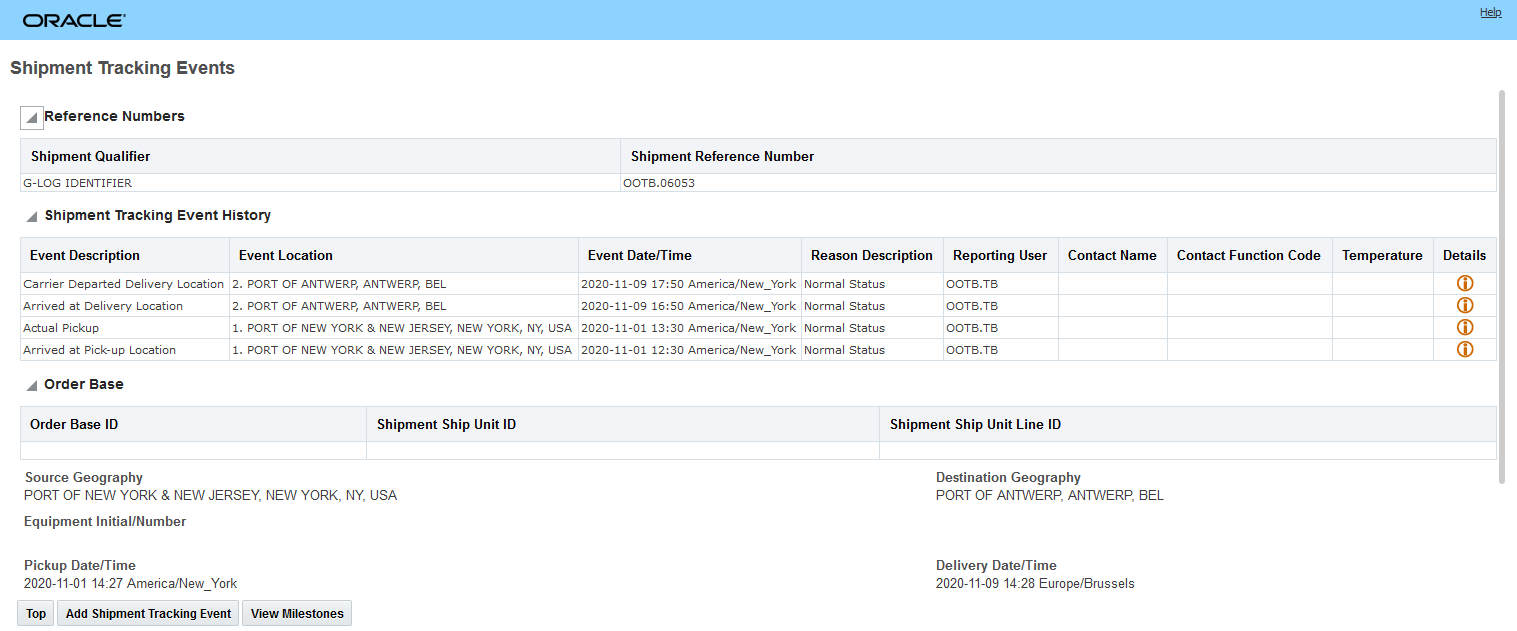

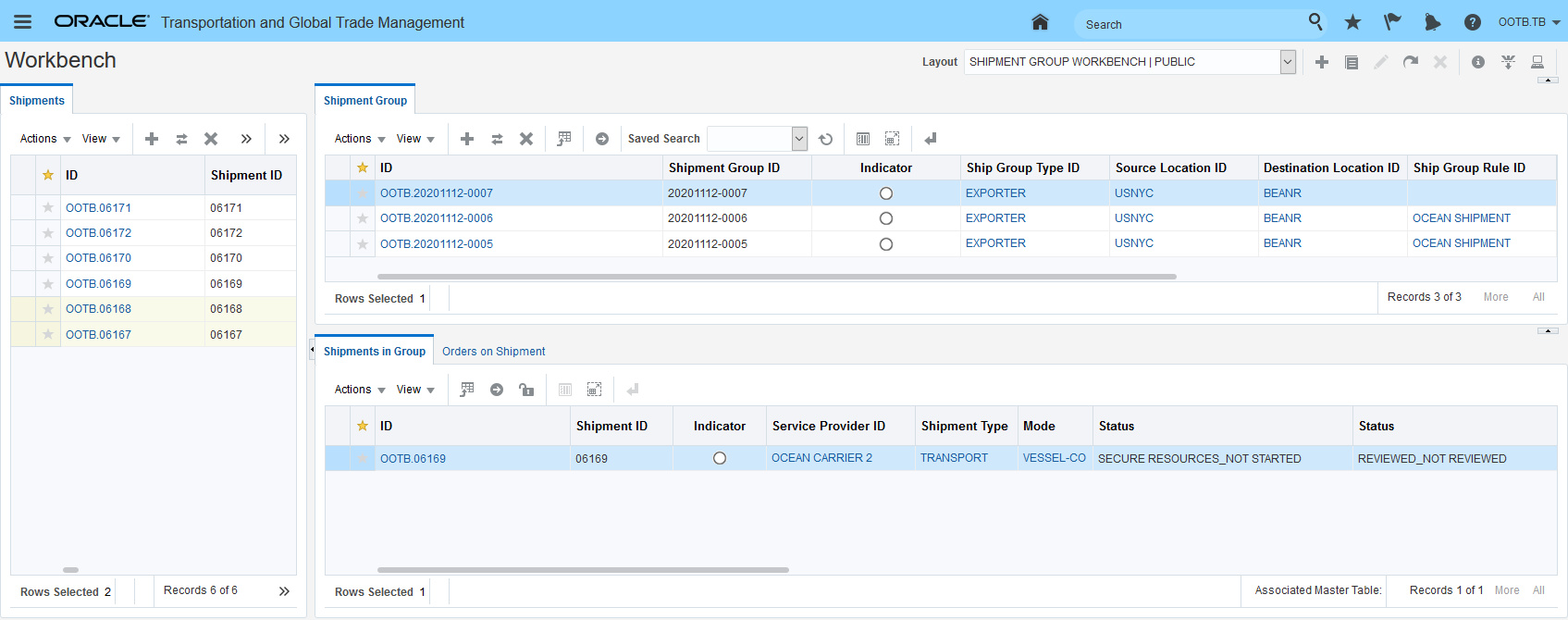

This feature provides you with the ability to enter stop based events against your shipment groups and then have the stop based events propagated to all the shipments (with that stop) so that additional actions can be triggered. You will find this feature extremely beneficial for any scenario where the set of shipments in your shipment group share the same source and destination stops. For example, if you use shipment groups to model an ocean leg - where all the shipments in your shipment groups are on the same vessel/voyage and share the same source stop (POL) and destination stop (POD) - this feature will allow you to enter one stop based tracking event at the shipment group level and have that single tracking event raise the stop event for all the shipments in the group that share the related stop.

Previously - OTM did have a way to validate and process stop based tracking events at a shipment group level - all of your stop level tracking events had to be entered on a per shipment basis for each shipment in the group.

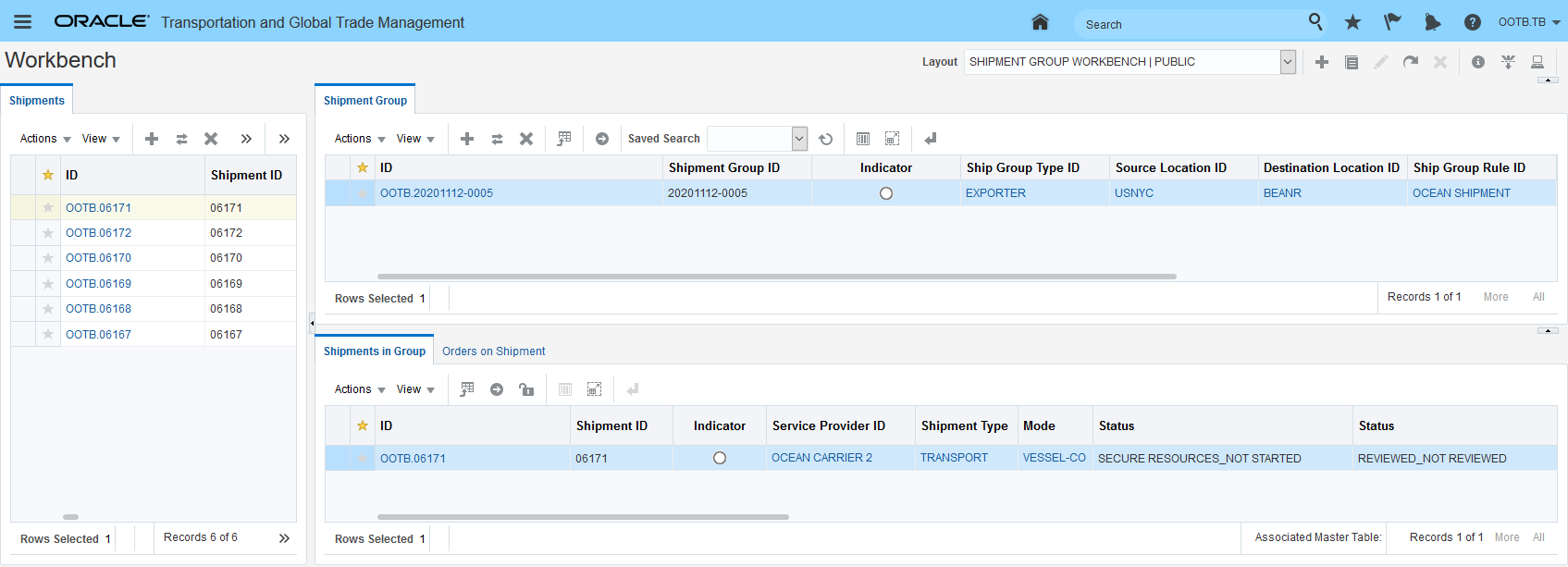

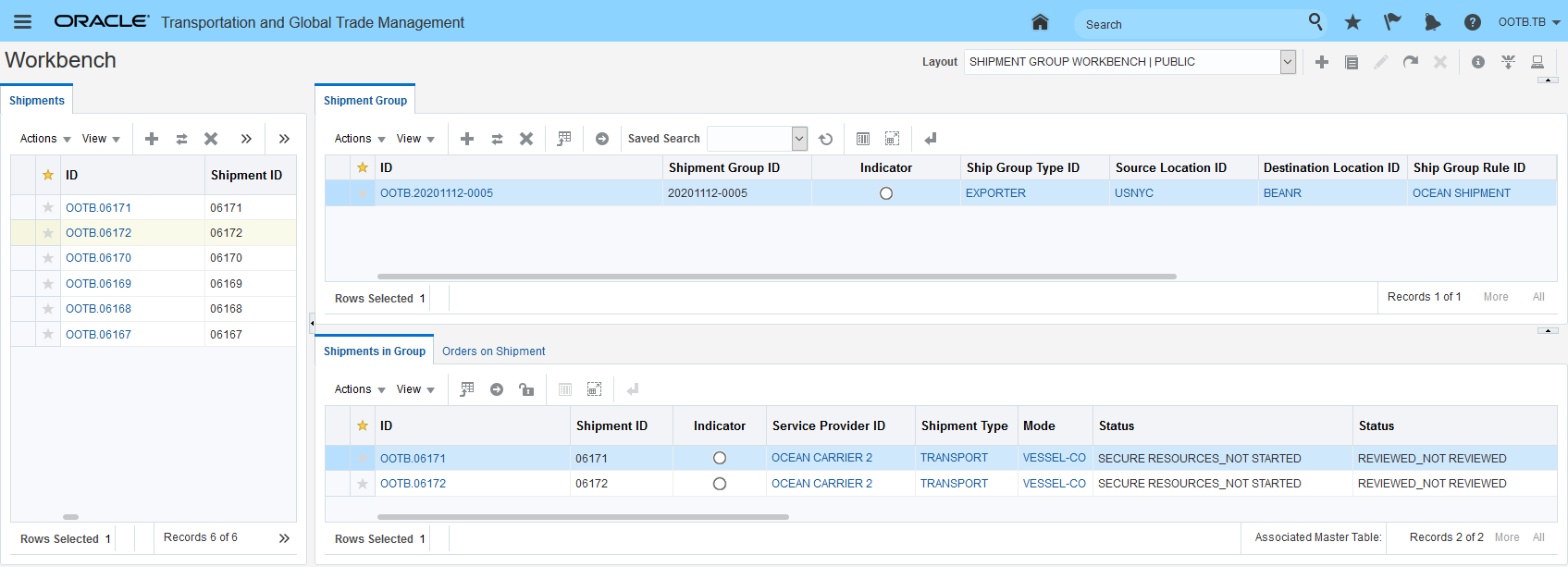

In the example below, all six shipments in the shipment group are booked onto the same vessel/voyage going from source location (POL) of USNYC to the destination location (POD) of BEANR. A set of stop based tracking events will be entered at the shipment group level to highlight the enhancements made to the Tracking Event UI and to show the propagation to the related shipments once the shipment group stop event(s) are added.

Shipment Group Example

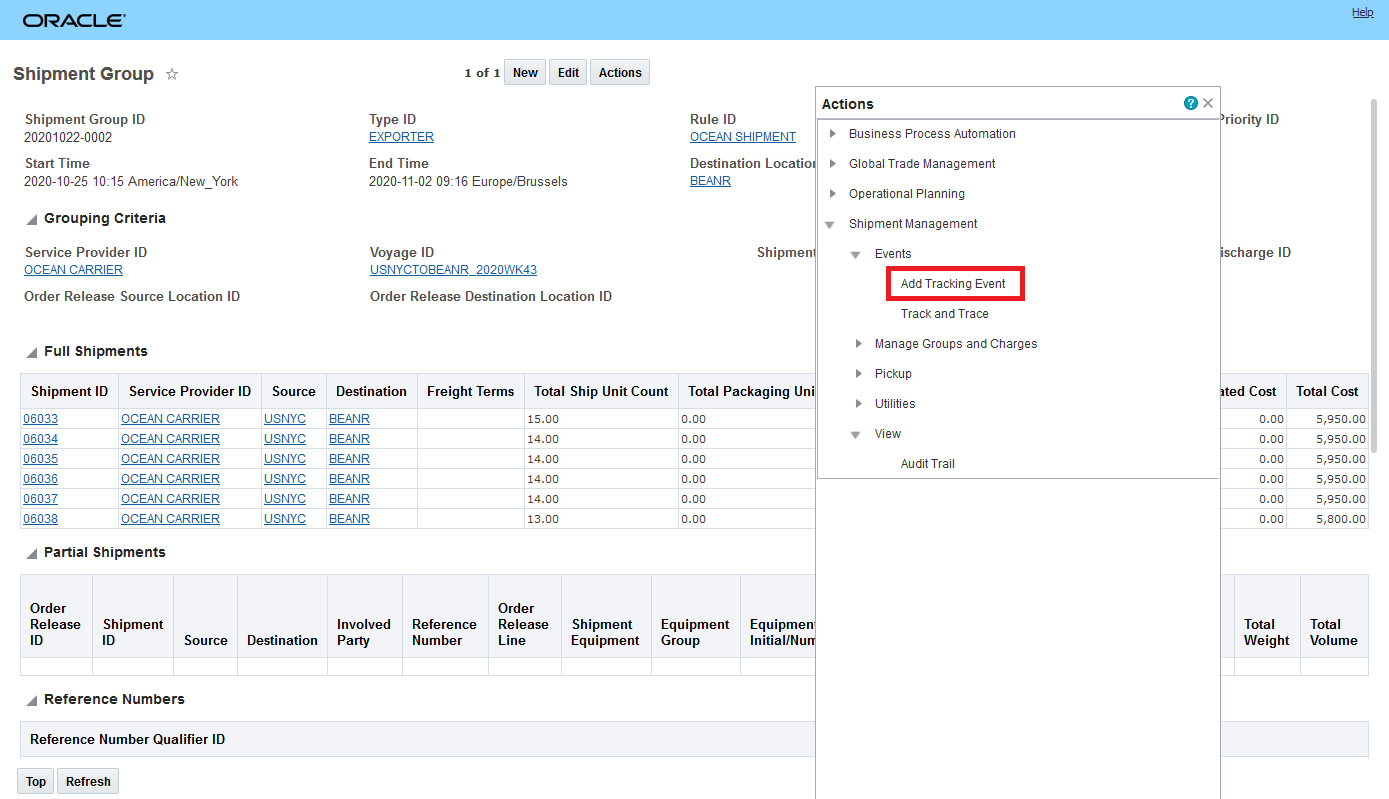

To enter an event against the shipment group run the Add Tracking Event Action as shown below.

Add Tracking Event Action

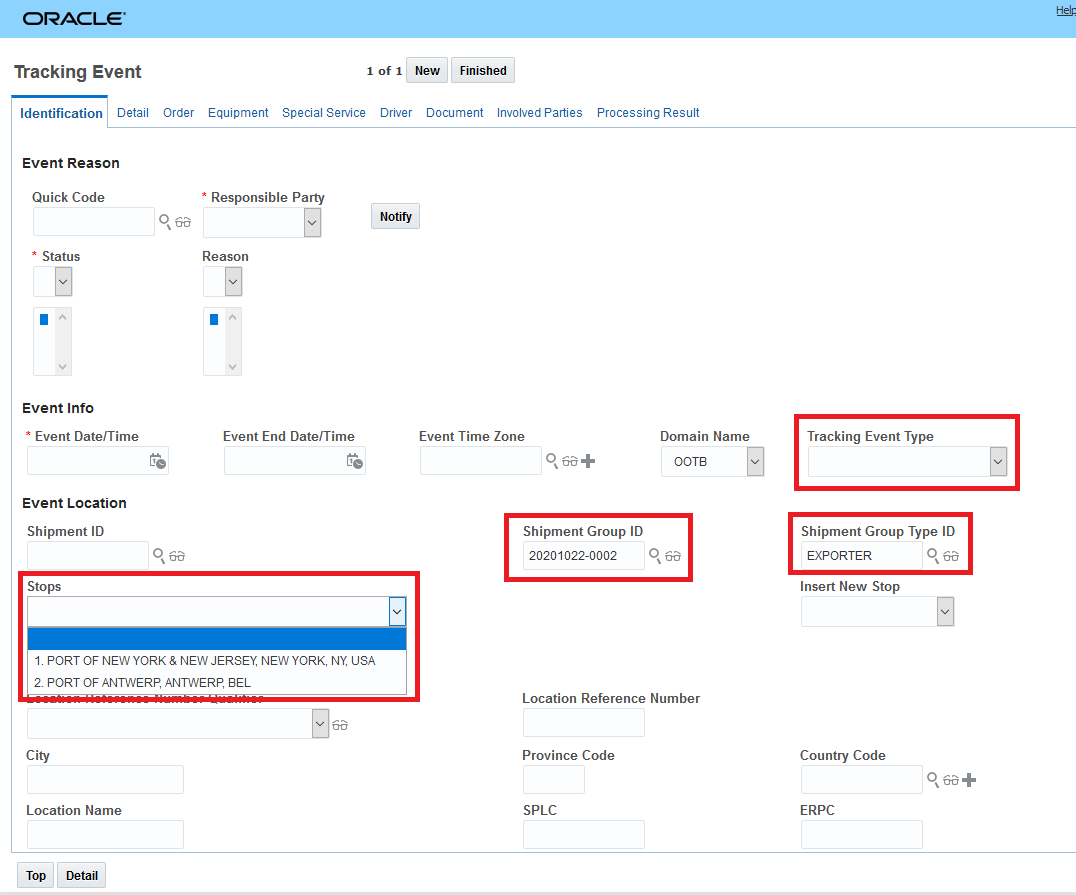

The Tracking Event UI has been enhanced with the highlighted changes below. The Shipment Group ID and Shipment Group Type ID are now provided/visible when entering Shipment Group Related Events. The new Tracking Event Type field allows you to tag your tracking events by a type classification for query purposes. The stops related to the Shipment Group are now validated and are available for selection when creating a shipment group stop based event.

Shipment Group Stop Based Tracking UI Enhancements

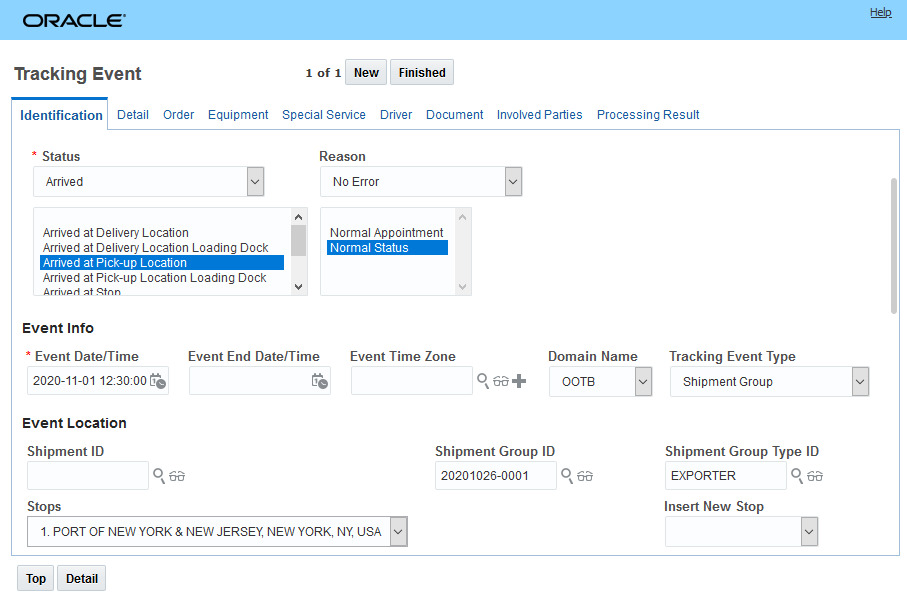

Shipment Group Stop Based Tracking Entry - Tracking Event 1 - Arrived at Pickup Location

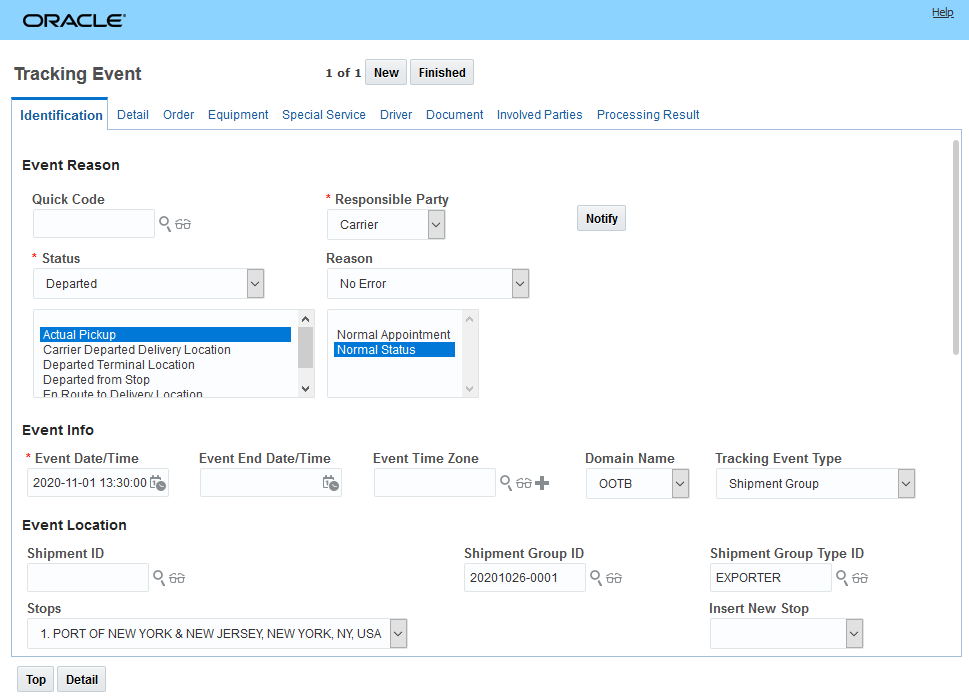

Shipment Group Stop Based Tracking Entry - Tracking Event 2 - Departed from Pickup Location

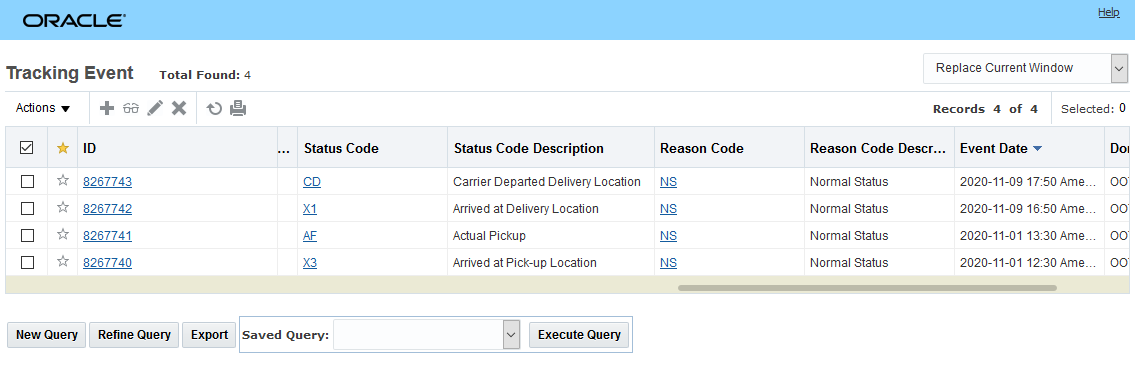

The complete set of Shipment Group Stop Events is provided below - tracking events added for arrival and departure from USNYC and tracking events added for the arrival and departure from BEANR.

Shipment Group Stop Based Tracking Entry Events View

Using a simple agent - the shipment stop tracking events entered at the shipment group level are also available on the shipments in the group that share the shipment group stop(s). The relationship between the shipment group stop and the shipments that share those stops allows you to do additional processing for the shipments - like redrive the shipments, set images etc.

Shipment Tracking Event View of the Stop Based Tracking Events Added for the Shipment Group

The stops considered for shipment group stop entry are the Port of Load and Port of Discharge - if available, if those stops are not available on the shipment group, then the Source Location and Destination Location of the shipment group are used. The following convention is followed for assigning stop numbers to the stop locations for a Shipment Group.

If Port of Load and Port of Discharge are populated on shipment group:

- Port of Load

- Post of Discharge

If Port of Load and Port of Discharge are not populated on Shipment Group

- Source Location of Shipment Group

- Destination location of Shipment Group

If a shipment group stop tracking event is entered against the shipment group and none of the shipments in the shipment group share that stop location you will see the error message below.

Invalid Stop Event

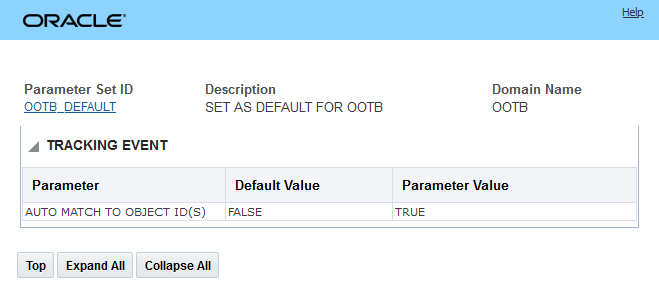

AUTO MATCH TO OBJECT IDS IMPROVEMENT

The planning parameter AUTO MATCH TO OBJECT ID(S) will now - when set to TRUE - perform an auto-match for tracking events entered against an object in the UI as well as for tracking events entered via integration - which was the previous behavior.

The AUTO MATCH TO OBJECT ID(S) parameter supports auto-match by ID for the following objects:

- Shipment

- Order Base

- Order Release

- Driver

- Power Unit

- Equipment and

- Shipment Group

Planning Parameter Auto Match to Object ID(S)

This enhancement simplifies the entry of stop based tracking events that are related to the shipments in a shipment group. Previously - for stop related events for shipments in a shipment group - you were required to enter the stop related tracking events for each of the shipments in the shipment group. This was true even in the situation where all the shipments in the group shared the same stop location(s) - for example - an ocean shipment group where all the shipments in the group share the same source and destination location. With this feature, you can now enter your stop related tracking events at the shipment group level and the lifetime events and tracking events can propagate down to the shipments in the shipment group allowing you to trigger agent actions against the shipments that share the same stop location.

Steps to Enable

You do not need to enable this feature, however, to take full advantage of the feature you will need to alter your process for entering tracking events - either via the UI or via integration. Specifically you will need to alter your processes to provide the required and optional information related to this enhancement - e.g., Tracking Event Type, Shipment Group ID, Shipment Group Type ID, Stop(s).

Tips And Considerations

We recommend using the AUTO MATCH TO OBJECT ID(S) parameter to match your tracking events to your shipment, shipment group, order release, order base, equipment, driver, or power unit. If you currently have an agent performing this match - we recommend that you migrate to the AUTO MATCH TO OBJECT ID(S) parameter to support the matching of your tracking events to the related object when the ID is provided of the object is provided.

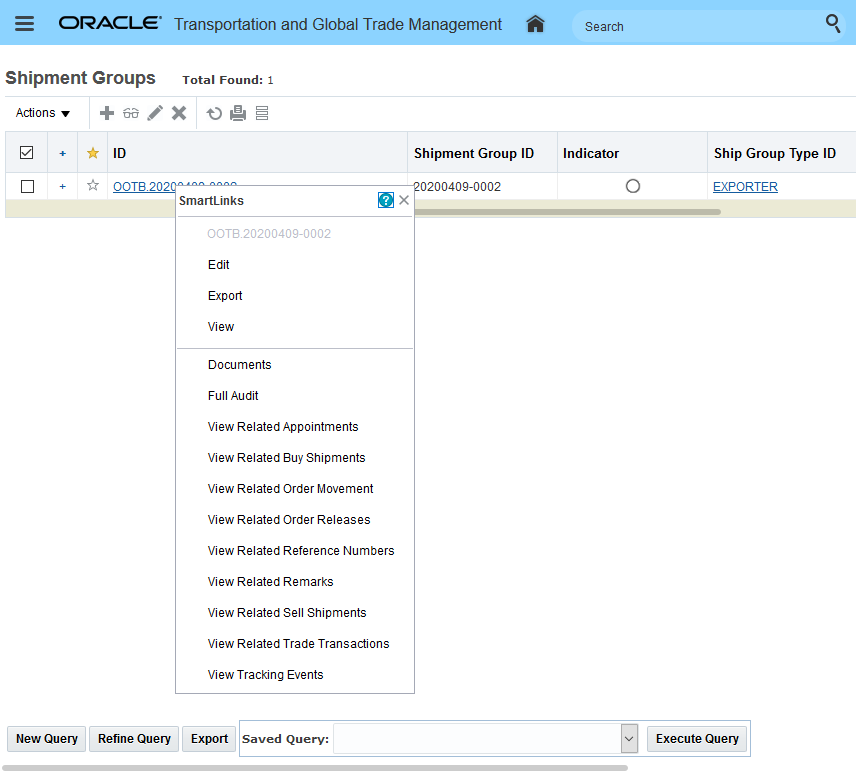

Shipment Group - Additional SmartLinks

This feature provides you with an expanded set of SmartLinks that you can use to navigate to and from your shipment groups and their related objects.

From the Shipment Group you now have the additional SmartLinks:

- View Related Buy Shipments

- View Related Sell Shipments

- View Related Order Movements

- View Related Order Releases

- View Related Reference Numbers

- View Related Remarks

From the Order Release, Order Movement, Buy Shipments and Sell Shipments Screens you now have the additional SmartLink:

- View Related Shipment Groups

The expanded shipment group SmartLinks menu is below.

Shipment Group Additional SmartLinks

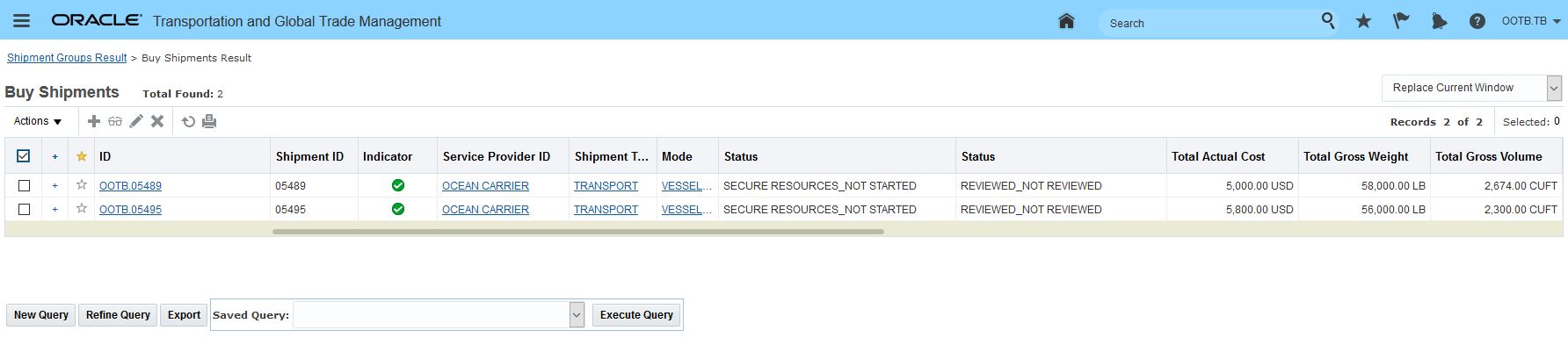

The View Related Buy Shipments, View Related Sell Shipments, View Related Order Movements, View Related Order Releases and View Related Shipment Groups all return a finder result.

For example View Related Buy Shipments

View Related Buy Shipments

The SmartLinks for View Related Reference Numbers and View Related Remarks provide a summarized multi-object view of the objects related to the shipment group.

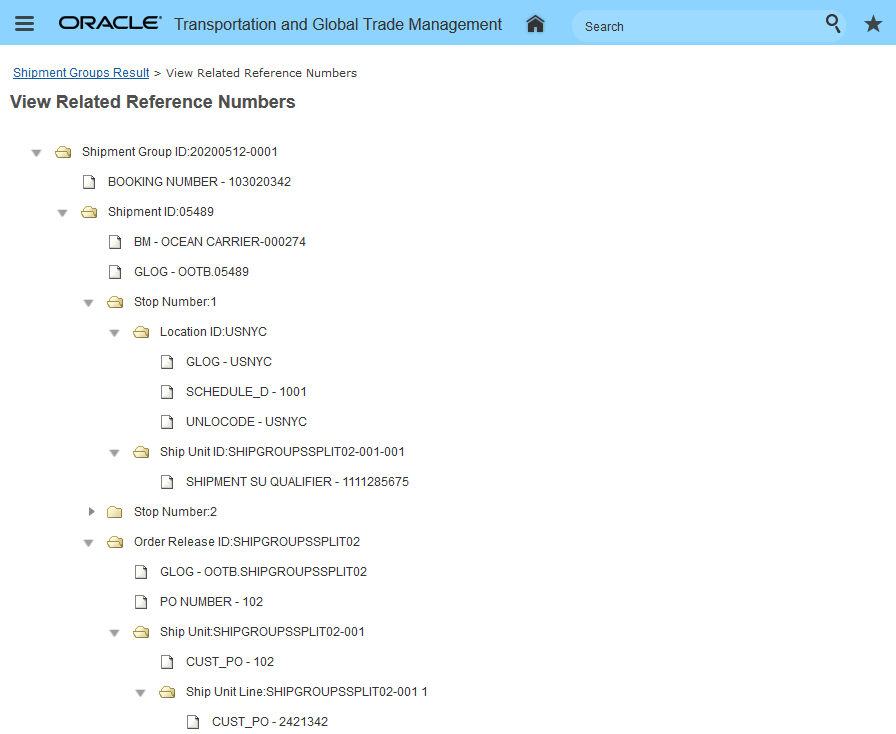

View Related Reference Numbers SmartLink will display a hierarchy of reference number records for the shipment group. This hierarchical view of the reference numbers at different levels is extremely beneficial for verifying that your required reference number information has been provided at all levels.

View Related Reference Numbers

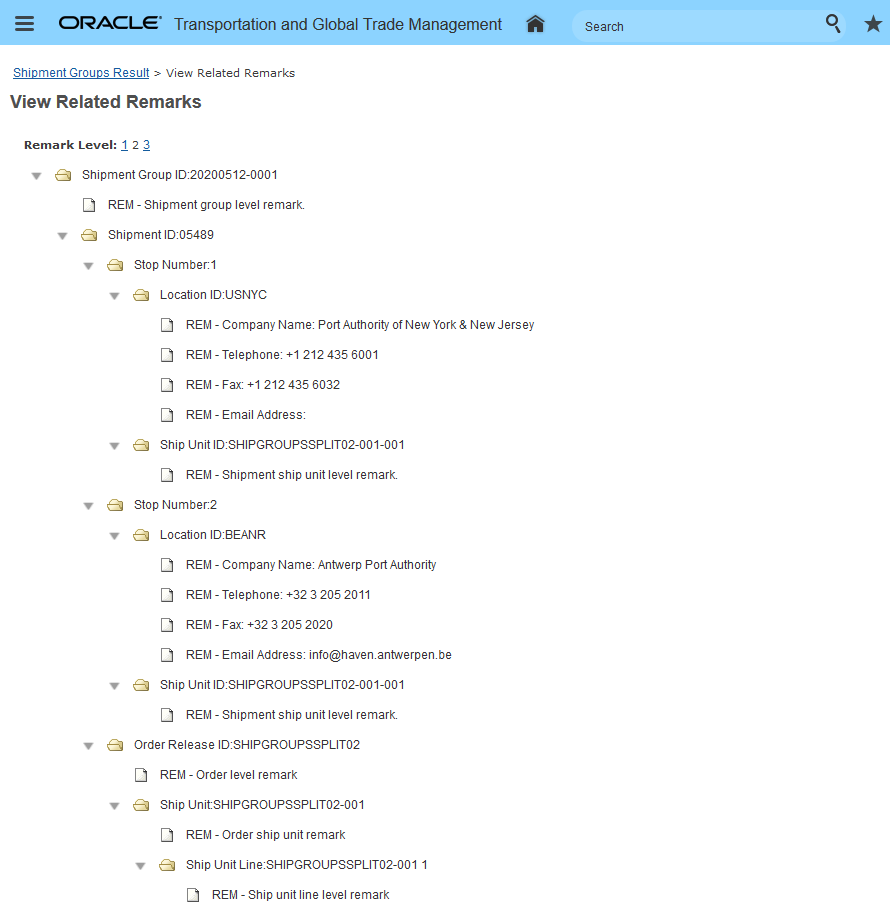

The View Related Remarks SmartLink like the View Related Reference Numbers SmarkLink displays a hierarchy of remark records for the shipment group. This view is extremely helpful in reviewing the remarks across the objects related to the shipment group. You must select the Remark Level that you wish to see - in the example below, the Remark Qualifiers are all level 2.

View Related Remarks

This feature simplifies your navigation as you move from a shipment group to the shipment group's related objects (e.g., shipments, order releases) or navigate from a shipment group's related objects to the related shipment group(s).

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

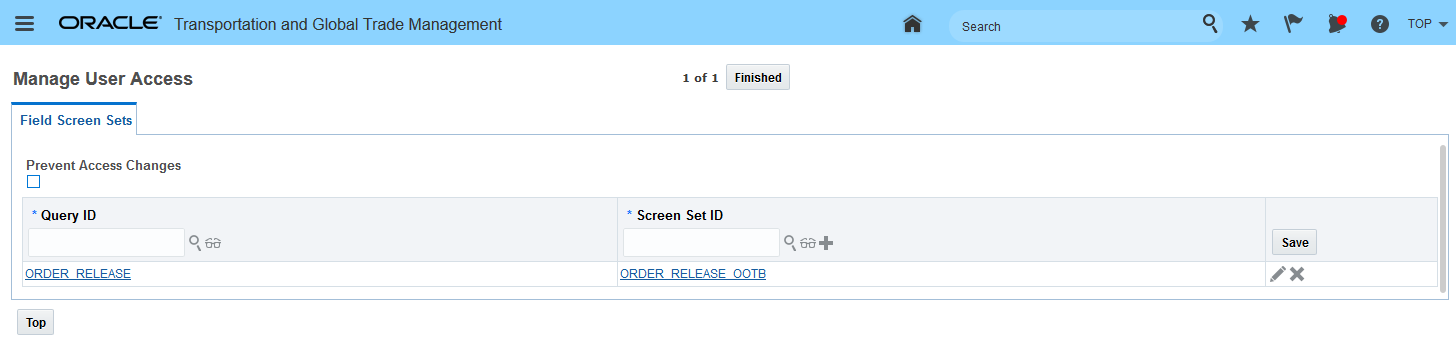

You (DBA.ADMIN) can select the screen set used for a user's SmartLink query results via Configuration and Administration > User Configuration > Manage User Access > Access Type = Field Screen Set. For example, in the setup below the SmartLinks for View Order Release (Query ID ORDER_RELEASE) will use the ORDER_RELEAE_OOTB screen set.

Finder Screen Set Example: Order Release Query

Shipment Group - Change Start Time Action

This feature provides you with a Change Start Time action on the shipment group level, which will allow you to change the start time assigned to the shipments in the shipment group as well as changing the start time and end time of the shipment group itself.

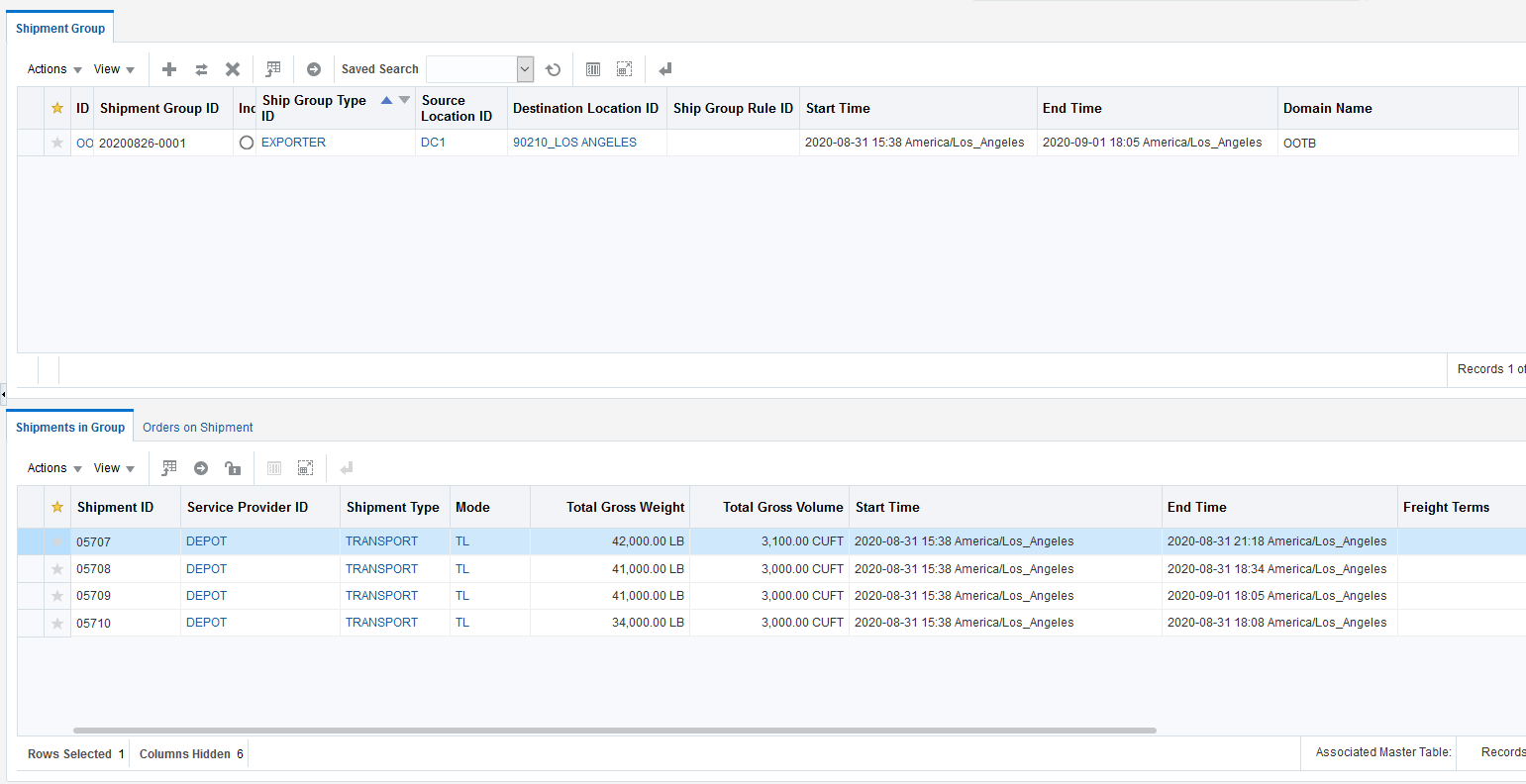

In the example below (using the Public Shipment Group Workbench) - a shipment group with four shipments all starting on 2020-08-31 15:38 will be changed to a new start time of 2020-09-07 16:21:00 using the shipment group Change Start Time action.

Shipment Group With Four Shipments Starting On August 31st

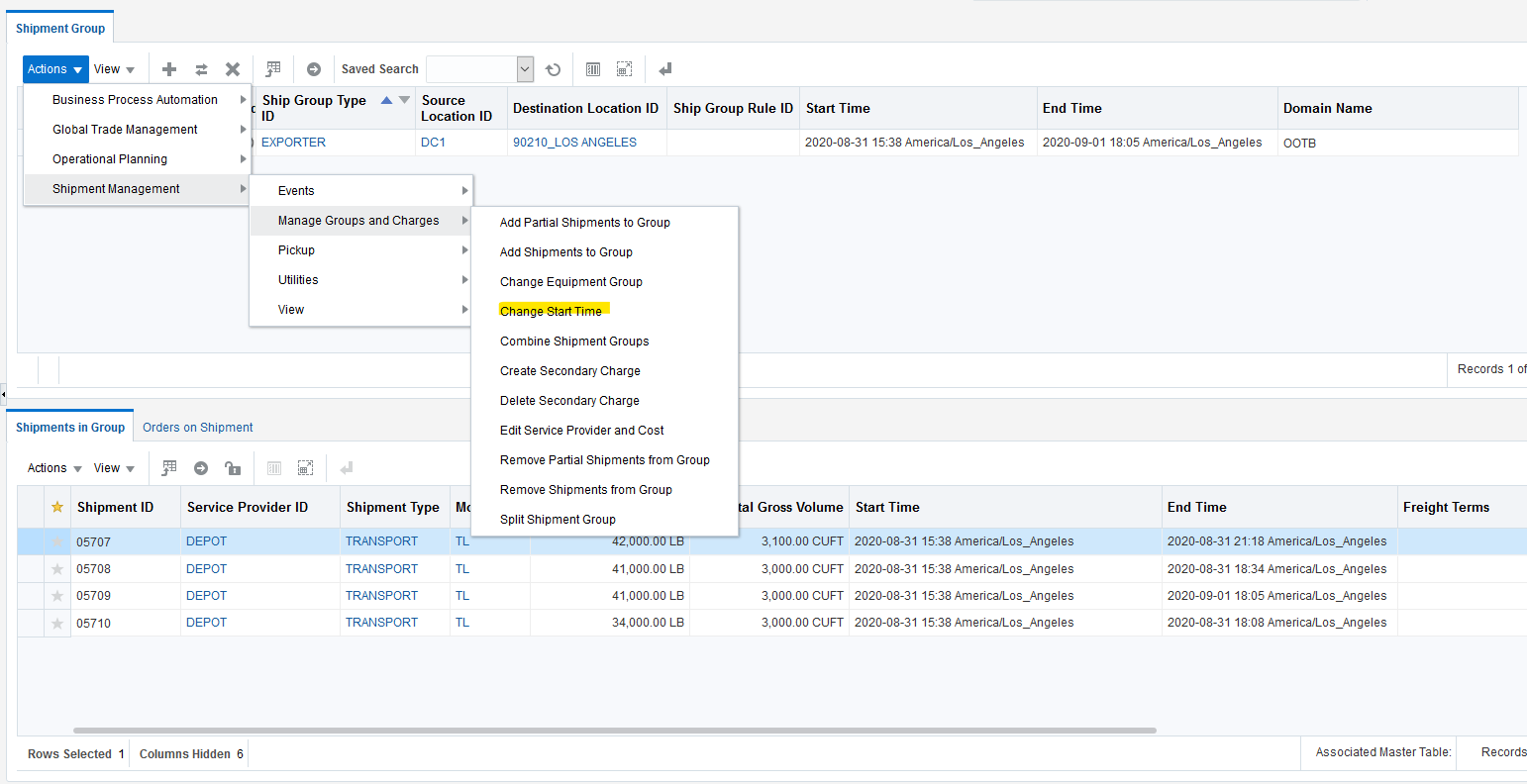

At the shipment group level the Change Start Time action is selected.

Change Start Time Action Initiation

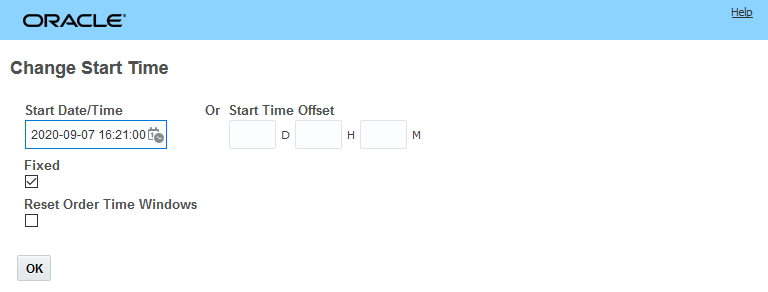

In the action input screen - the Change Start Time action will change all the shipments and the shipment group times to 2020-09-07 16:21:00 the start times on the shipments will be set to Fixed.

Change Start Time Action Input

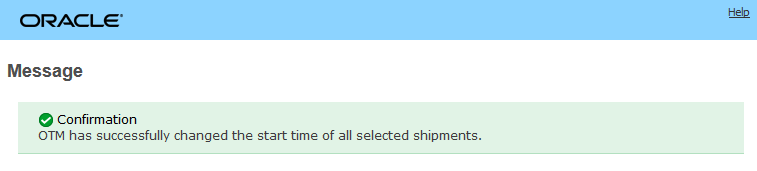

The result screen after the action is executed provides information related to the success or failure of the action. The Change Start Time action at the shipment group level operates on an all or nothing basis - all the shipments in the group must be successfully changed - or none of the shipments will be changed. In this example, all of the shipments were successfully changed.

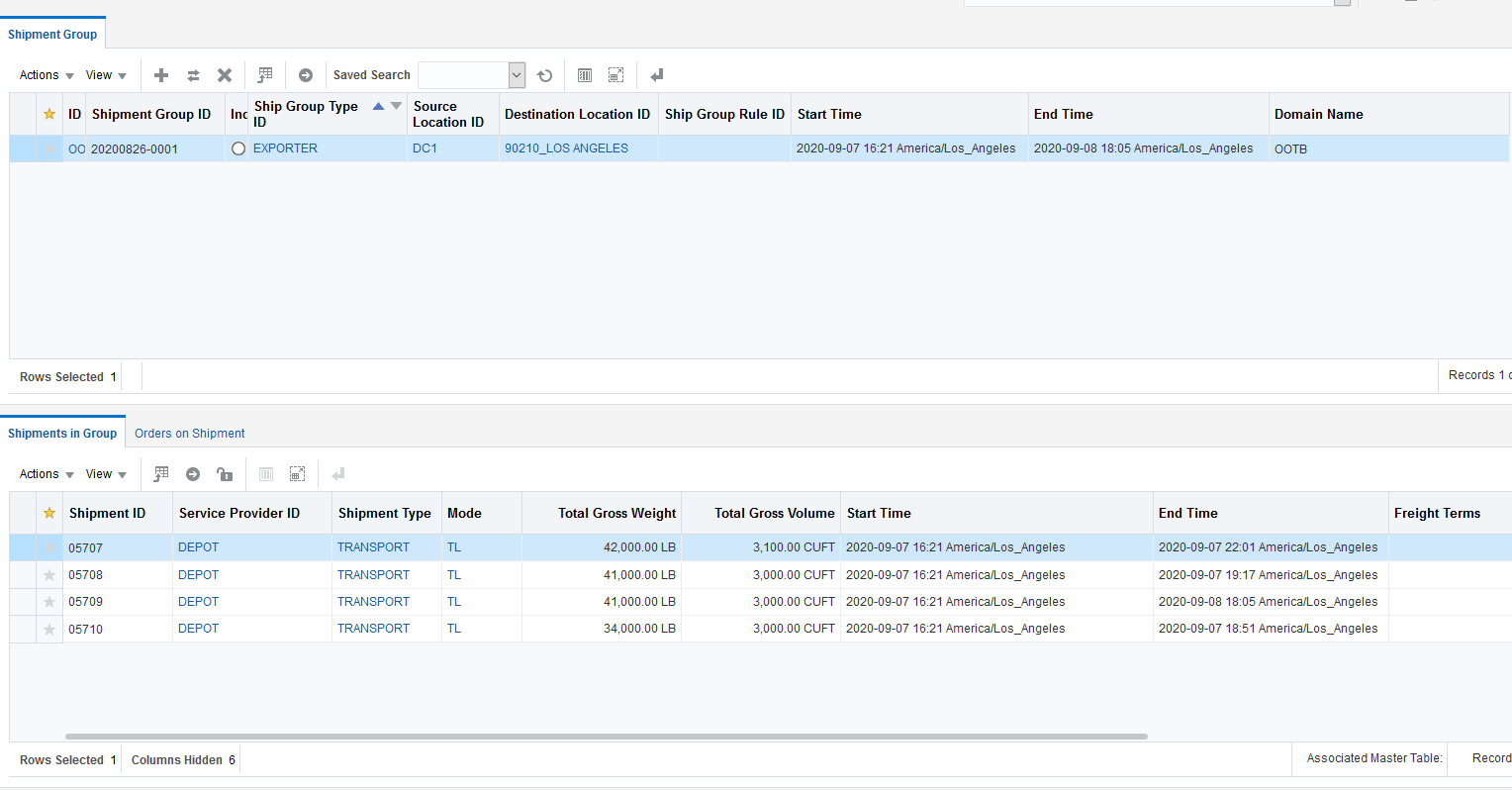

In the workbench view below the results of Change Start Time action are clear. The shipment group Start Time is 2020-09-07 16:21:00 (as specified in the action) and the End Time has also been updated to reflect the latest End Time for the shipments in the group. All of the shipments in the group have also been successfully updated with their new Start and End Times.

Change Start Time Action Workbench Result View

The Change Start Time action on the shipment group will provide productivity improvements when all of the shipments in your shipment group require a start time change.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

The behavior of the Change Start Time action run against a shipment group operates in an all or nothing fashion - meaning that all the shipments in the group must be successfully updated or none of the shipments will be updated. The behavior of the Change Start Time action run against a set of shipments in shipment manager is slightly different - in this case the action will note any shipments that fail to process, but will process the shipments that can be processed - so the shipments that can be changed will be changed, and those shipments that fail will be noted.

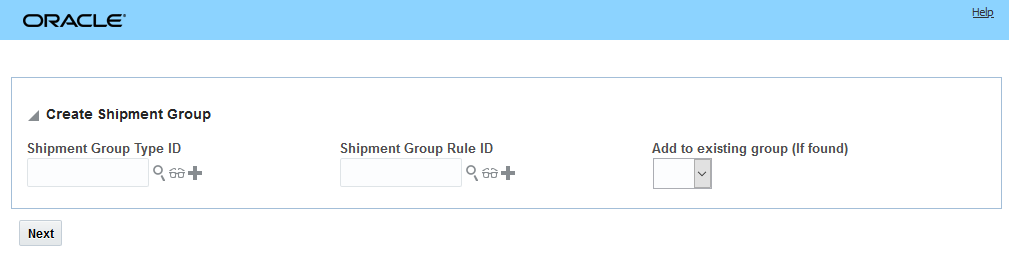

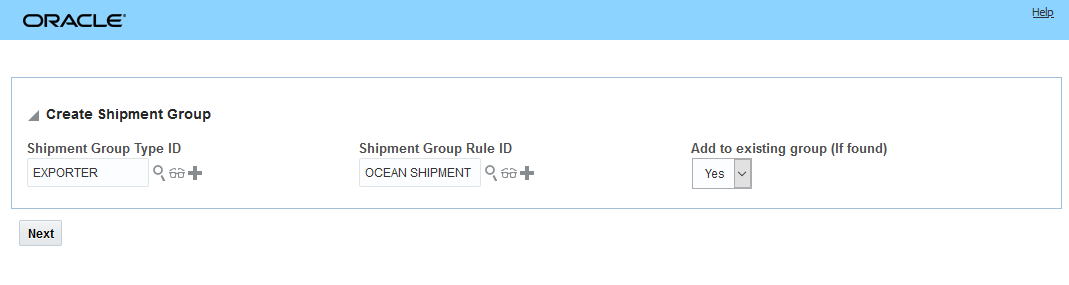

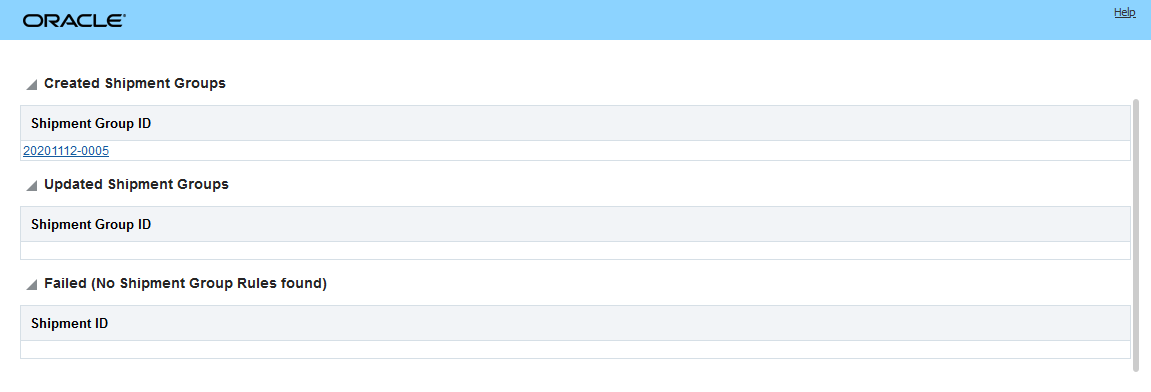

Shipment Group Rule - Match Date Enhancement

This feature provides you with an additional time based Shipment Group Rule criteria - Match Date - that you can use to generate your shipment groups based on time related attributes - either Start Date or Daily. The Start Date option will create shipment groups based on your shipment start dates - a different shipment group will be created for each of the start dates in the group of shipments being considered. You can use the Start Date option to easily create a shipment group that contains all the shipments shipped from your DC each day. For example, you can use this capability to create a parcel manifest to group all your parcel shipments shipped from your DC each day.

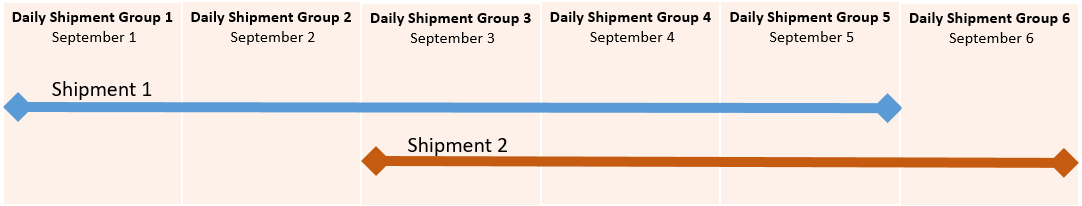

The Daily option creates daily shipment groups that include all the shipments where the shipment start and end dates cover the shipment group daily criteria. For example, given two shipments where one starts on the 1st of September and ends on the 5th and another shipment that starts on the 3rd and ends on the 6th. The Match Date Daily option will create 6 daily shipment groups where the first shipment will be included in the first five daily shipment groups and the second shipment will be included in 3 of the daily shipment groups starting on the 3rd and going to the 6th. - both shipments will appear in the daily shipment groups for the 3rd, 4th and 5th while only shipment 1 will appear in the daily shipment group on the 1st and only shipment 2 will show up in the shipment group on the 6th. The Daily option will allow you to calculate and assign secondary charge shipments to the shipment group to capture daily charges related to the shipments included in each of the daily groups. The charges calculated for the shipment group can then be allocate to all shipments and orders contained in the various daily shipment groups.

Daily Option

MATCH DATE - START DATE OPTION

In example below, the new Match Date option will be used to generate a daily manifest of parcel shipments shipping out of a specified DC.

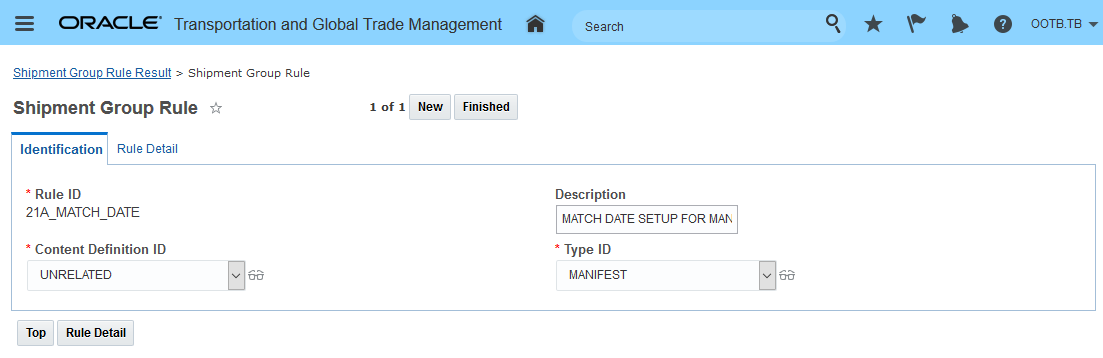

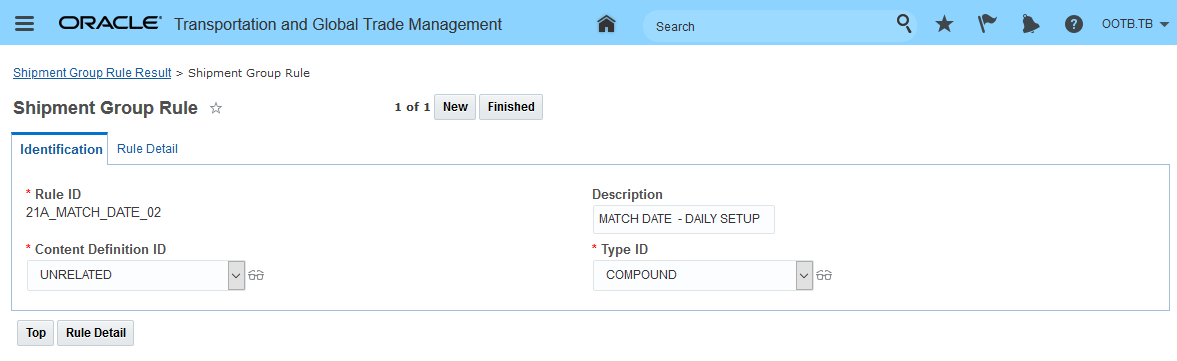

The match rule that will be used for this scenario is below. For the manifest scenario, the Content Definition should be set to Unrelated and the Type ID should be set to Manifest.

Shipment Group Rule Manifest Scenario Rule Identification

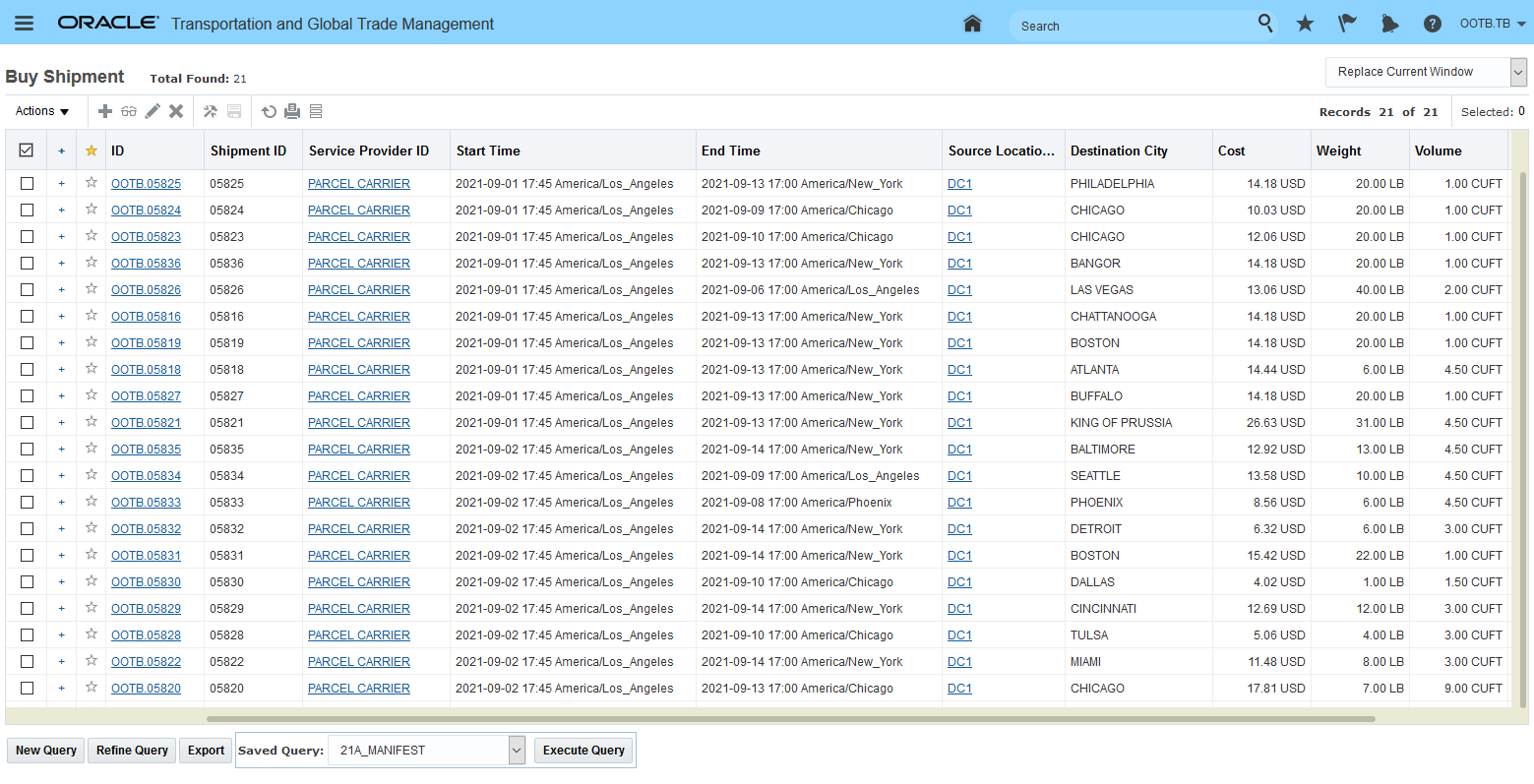

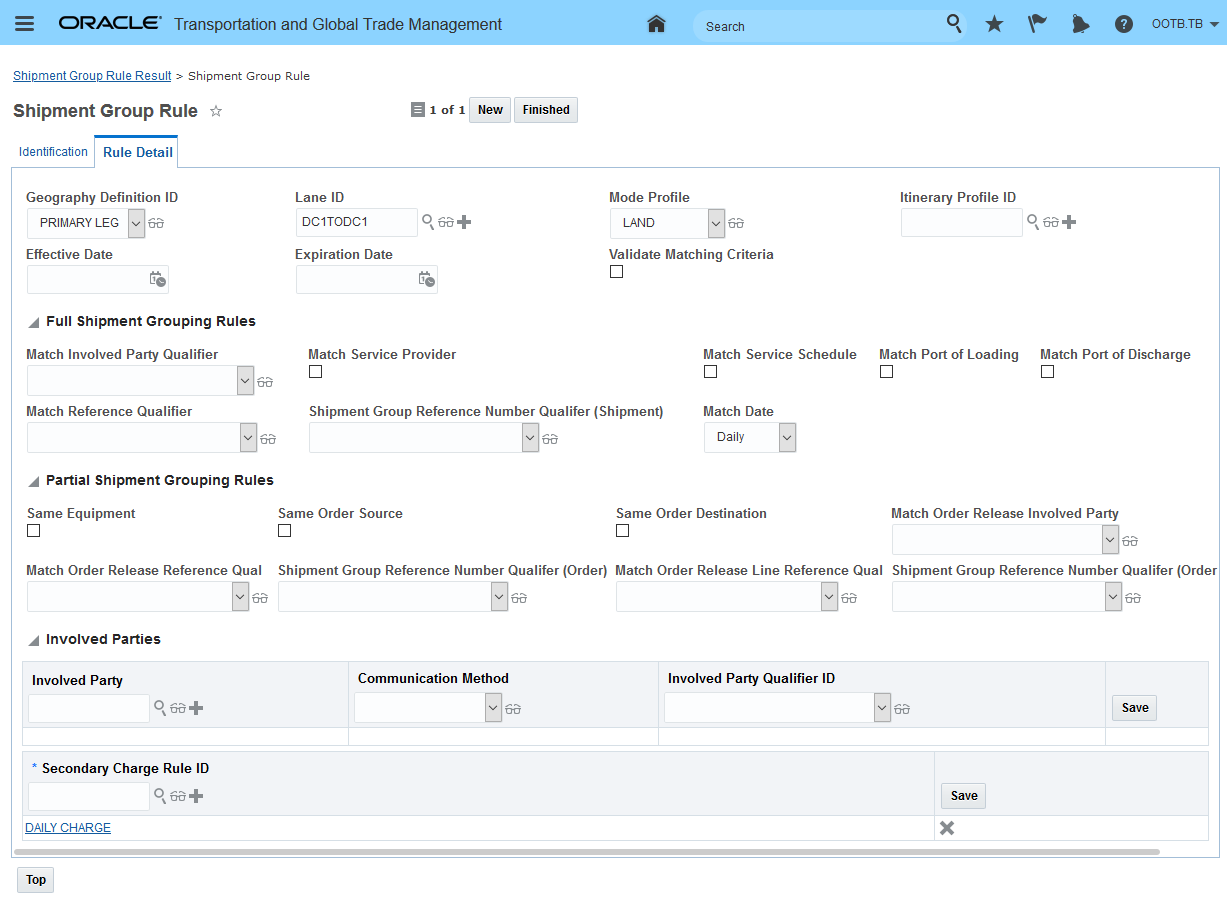

On the Shipment Group Rule Rule Detail tab, the Match Date option is set to the Start Date option. Since this is a manifest/shipment group rule to group the parcel shipments by carrier and date - the Mode Profile is set to Parcel, the Full Shipment Grouping Rules are set to Match By Service Provider and the Match Date option is set to Start Date.

Shipment Group Rule Manifest Scenario - Rule Detail

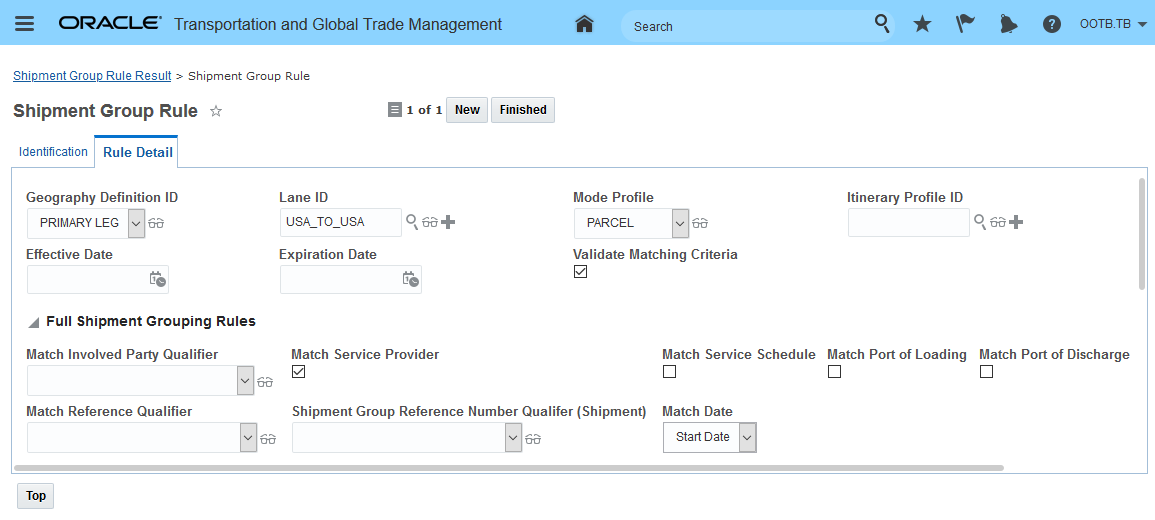

The shipments that will be evaluated and grouped are below they cover two days of shipping - September 1st 2021 and September 2nd 2021 - all of the shipments in this example are for the same carrier so the result will be two shipment groups for the two days involved.

Manifest Scenario Shipments

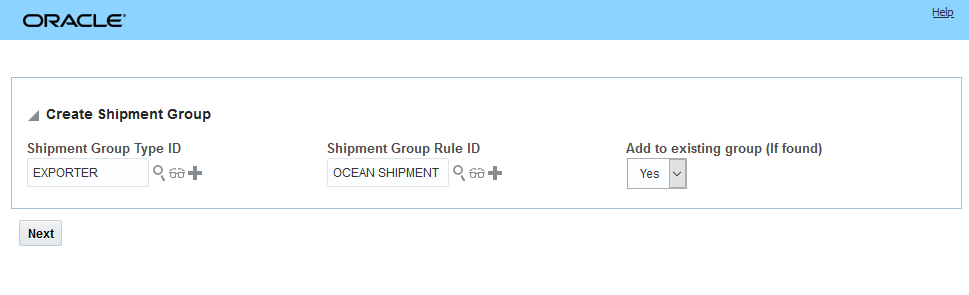

Business Process automation is used to run the rule against the set of shipments to be considered.

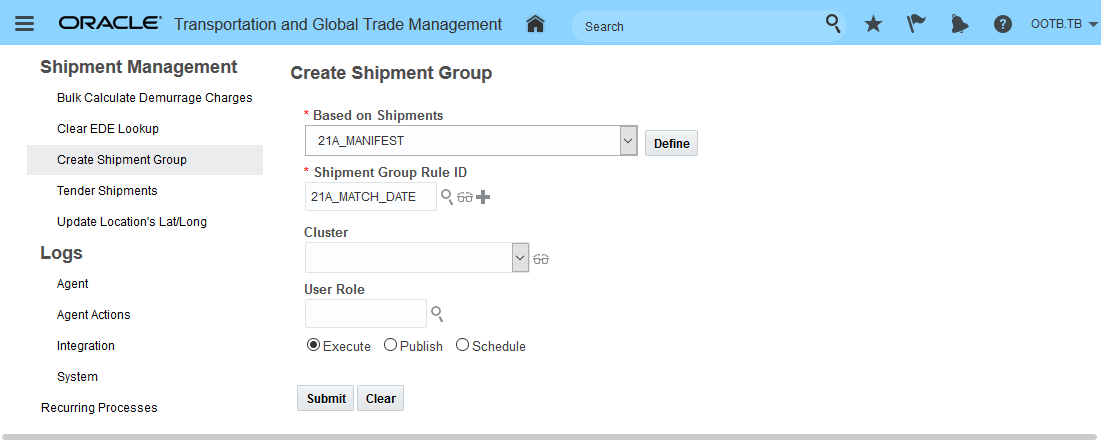

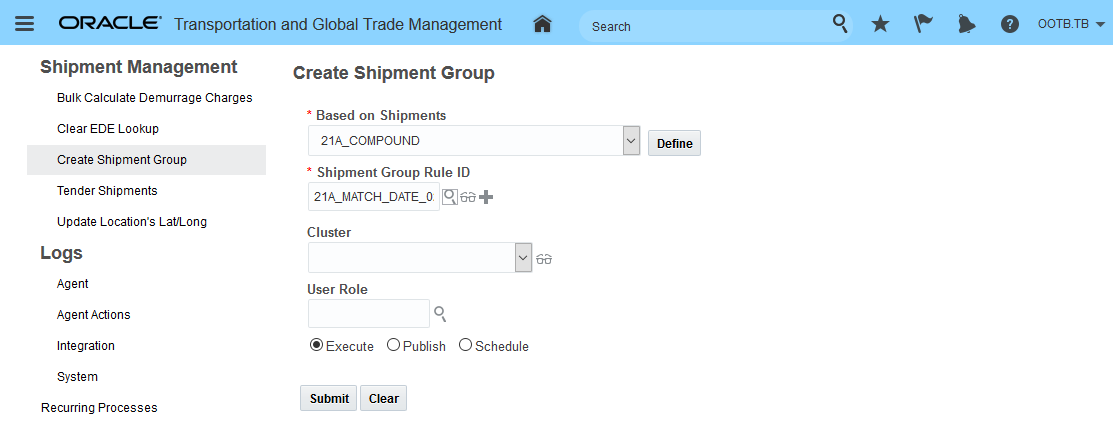

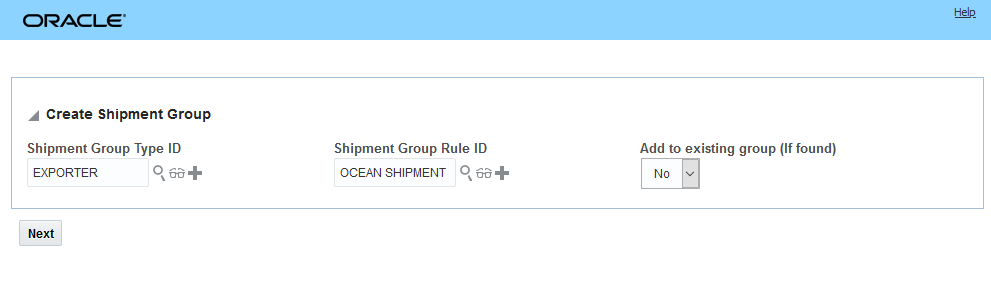

Create Shipment Group Process Management

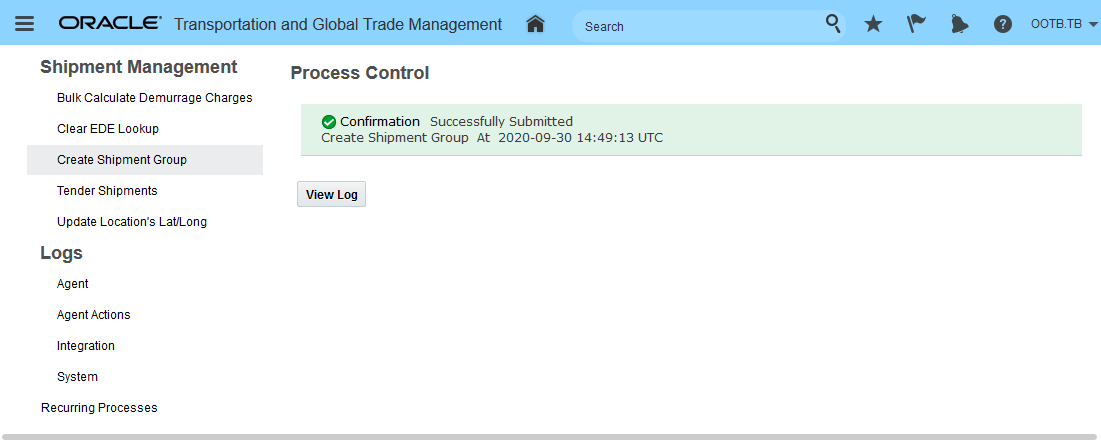

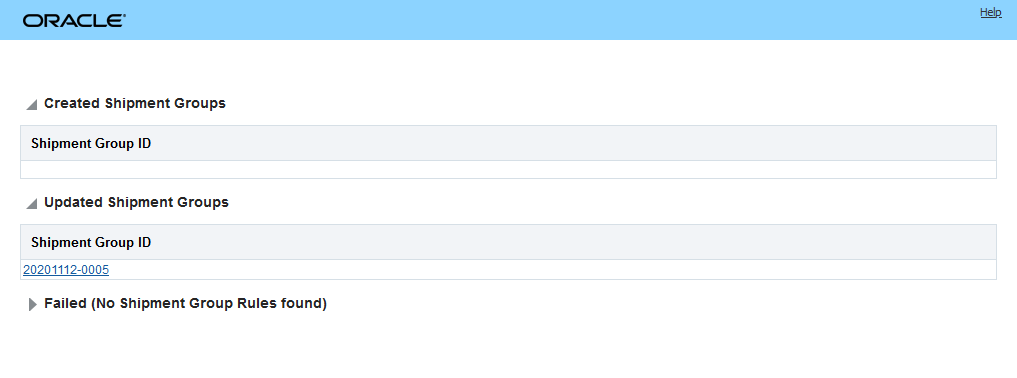

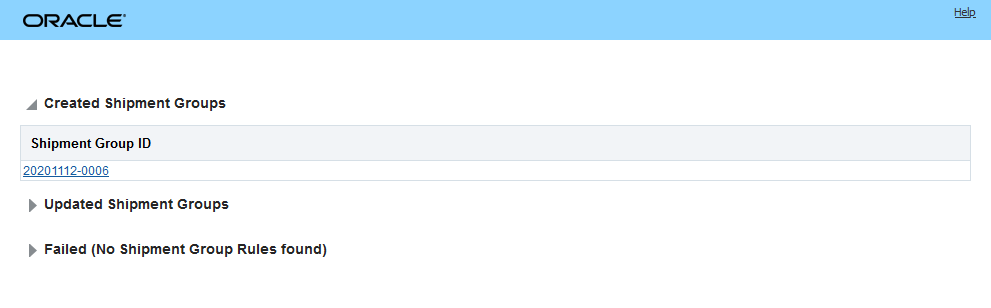

Result of Create Shipment Group Process Management.

Process Management Result Screen

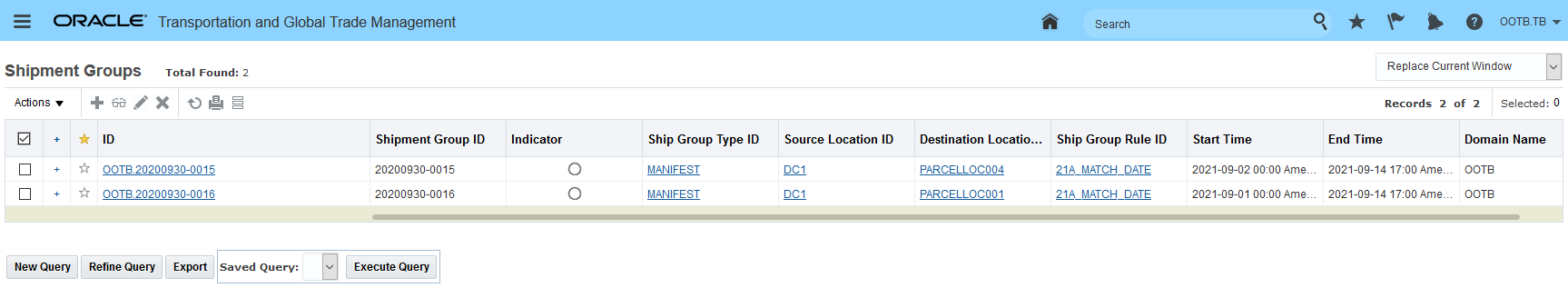

Below - are the two shipment groups created - one for the parcel shipments shipping on September 1st and a second for the shipment leaving on the 2nd.

Two Shipment Groups Created September 1st and 2nd

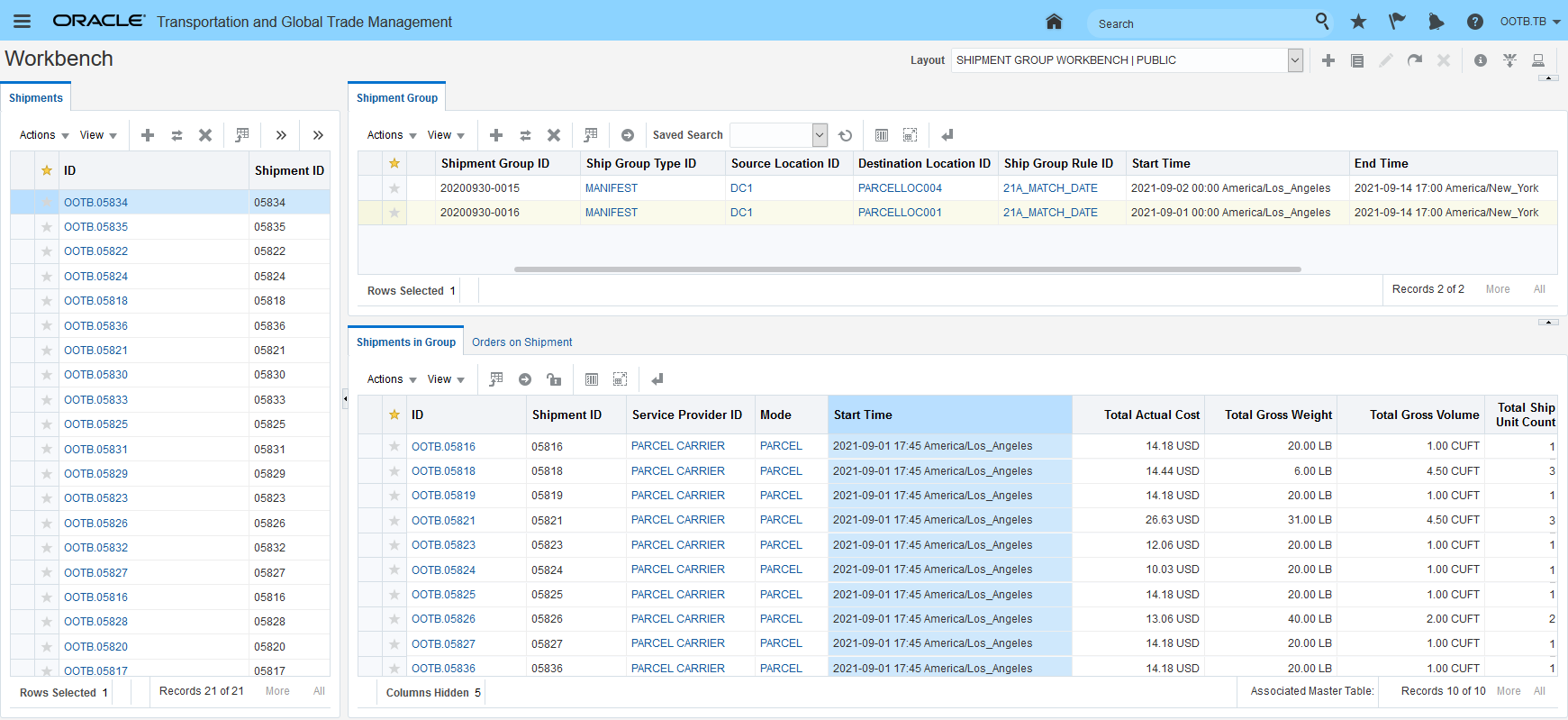

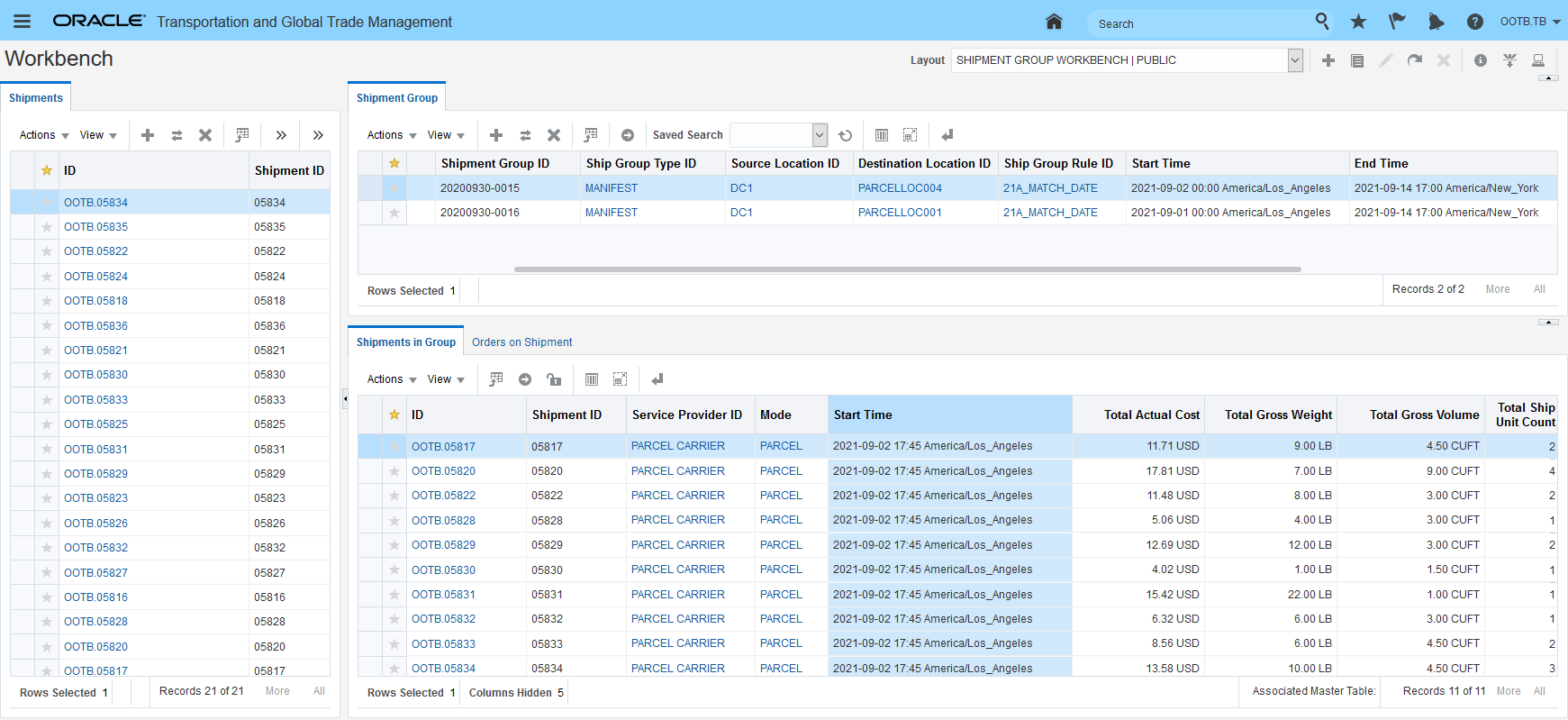

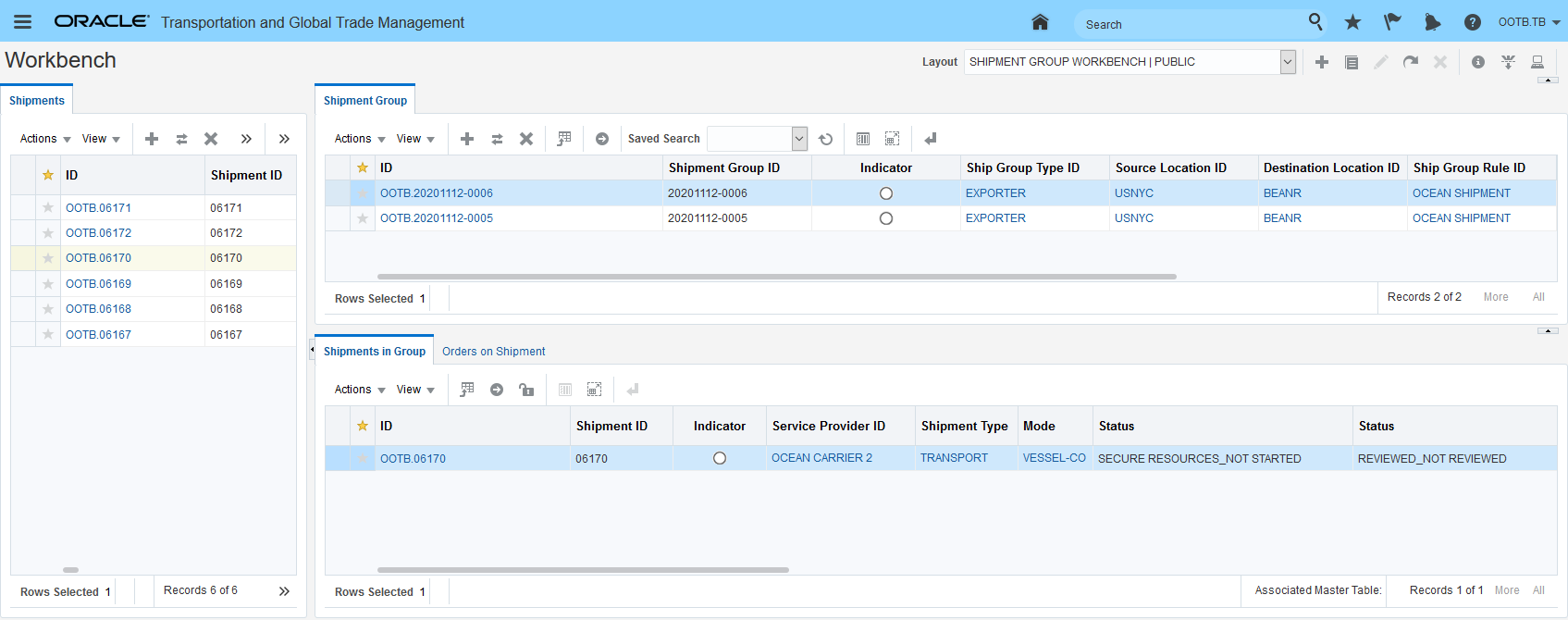

Below is a workbench view of the shipment groups and their grouped shipments by date.

Workbench View - Groups and Shipments September 1st

Workbench View - Groups and Shipments September 2nd

MATCH DATE - DAILY OPTION

In the scenario below, the Daily option on the shipment group rule is being used to generate daily shipment groups that include - for a Compound location - all of the shipments being held at the compound. In this scenario, there is a one time fixed charge per shipment on the compound and then a fixed cost per day that should be allocated to all the shipments in the compound. In this example - the per shipment cost is $100 per shipment - the daily charge of $200 is modeled using a secondary charge shipment assigned/generated with the shipment group using the Daily option. In this example, there are 7 shipments. On the first day, all 7 shipments are in the compound - so the generated shipment group contains all 7 shipments and all 7 shipments share in the $200 cost. On the second day - only 6 of the shipments remain - so the 2nd shipment group only has 6 shipments in the group - the pattern continues until the 7th day when only 1 shipment is on the lot.

The rule setup for this scenario is below. Note that the Content definition is set to UNRELATED. The Type ID of COMPOUND was created for this example and is not PUBLIC data.

Shipment Group Rule Compound Scenario Rule Identification

Since this scenario is modeling a holding location, the lane is from and to the same location - in this case DC1. The Mode Profile is LAND and includes Handling as a mode. The only Full shipment Group rule configuration is for the Match Date - which is set to Daily. The Shipment Group Rule also include the setup to create the per day secondary charge shipment when the group(s) are created.

Shipment Group Rule Compound Scenario Rule Detail

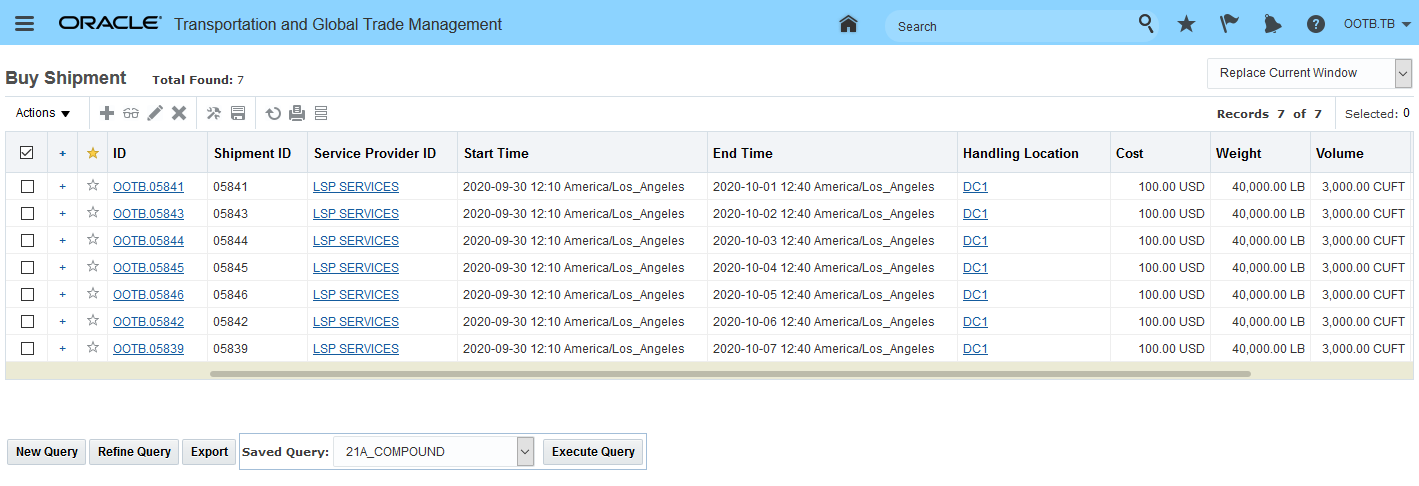

The 7 shipments that will be evaluated and grouped are below, they cover 8 days of handling activity at DC1 - from September 30th 2020 to October 7th 2020.

Shipments Considered for Grouping

Business Process automation is used to run the rule against the set of shipments to be considered.

Process Automation

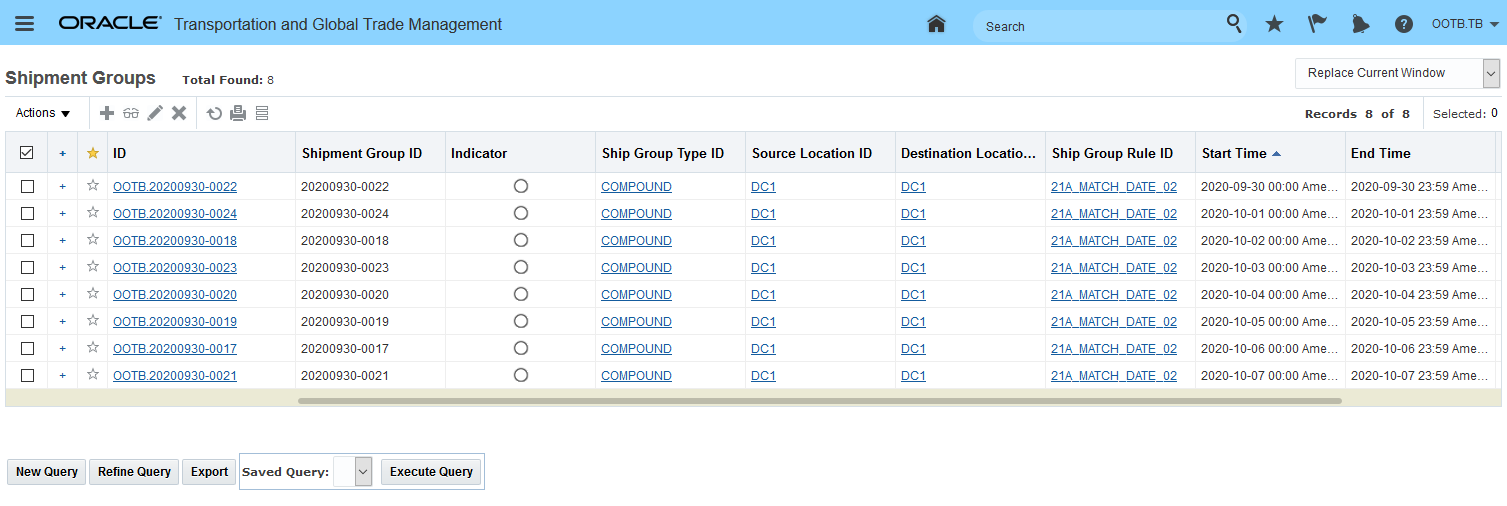

Results - eight daily shipment groups generated starting with September 30th and going to October 7th.

Daily Shipment Groups Generate

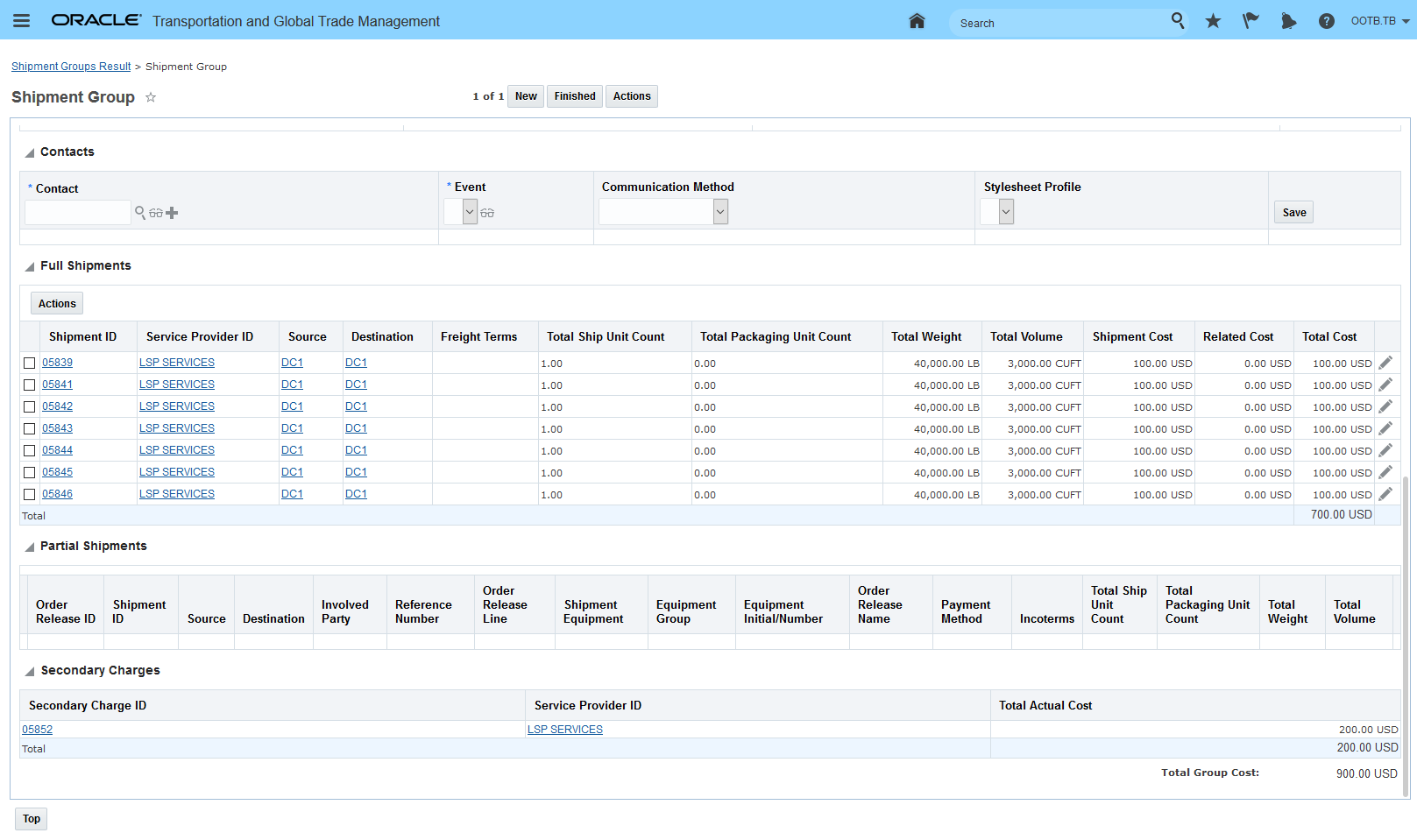

The daily shipment groups on the 30th (and the 1st of October) contain all 7 shipments. Note the calculation and inclusion of the secondary charge shipment.

Daily Shipment Group September 30th

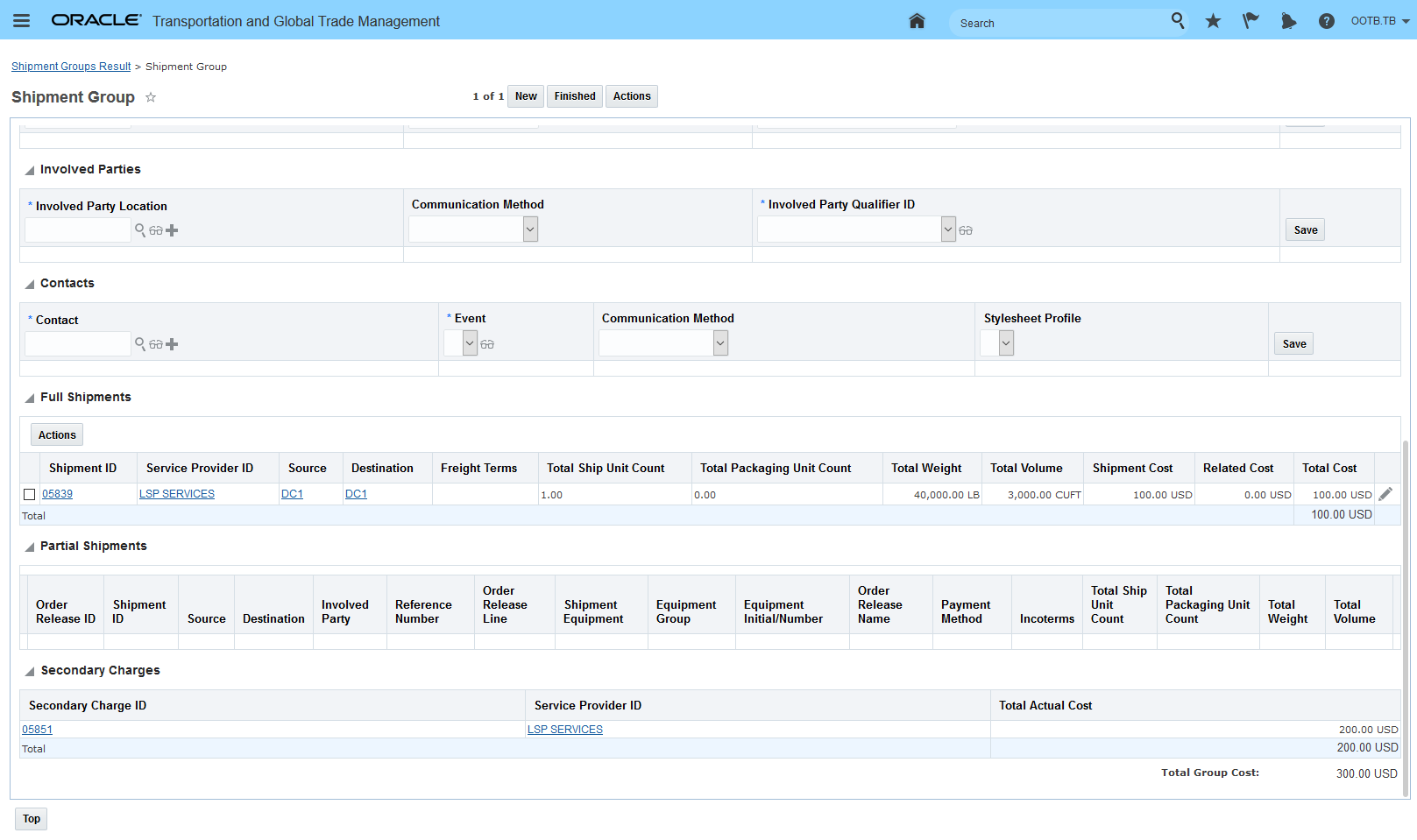

The last group in the daily series only contains 1 shipment - the last shipment that was on the DC1 compound on October 7th.

Daily Shipment Group October 7th

ALLOCATION

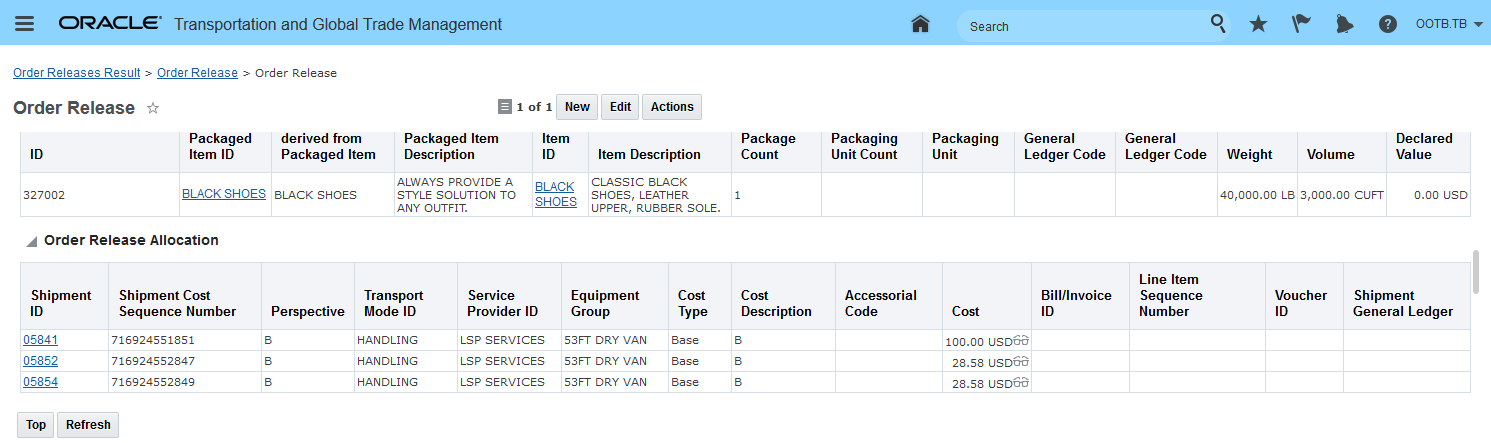

Below is an example of the order allocation that is available for the orders related to the shipments in the compound handling scenario. In the first example, the order (and shipment) were on the compound for the 30th of September and the 1st of October. In this case, the order has been allocated the $100 charge for entering the compound and then has been allocated the order's portion of the daily fixed charge of $200 that is shared across the orders/shipments on the compound each day. For this order - which was on the compound with 6 other orders/shipments - the order is allocated 1/7th of the $200 daily fixed charge ($28.58) for each of the two days the shipment was on the compound.

Order Allocation For 2 Days in the Compound - With 6 Other Shipments

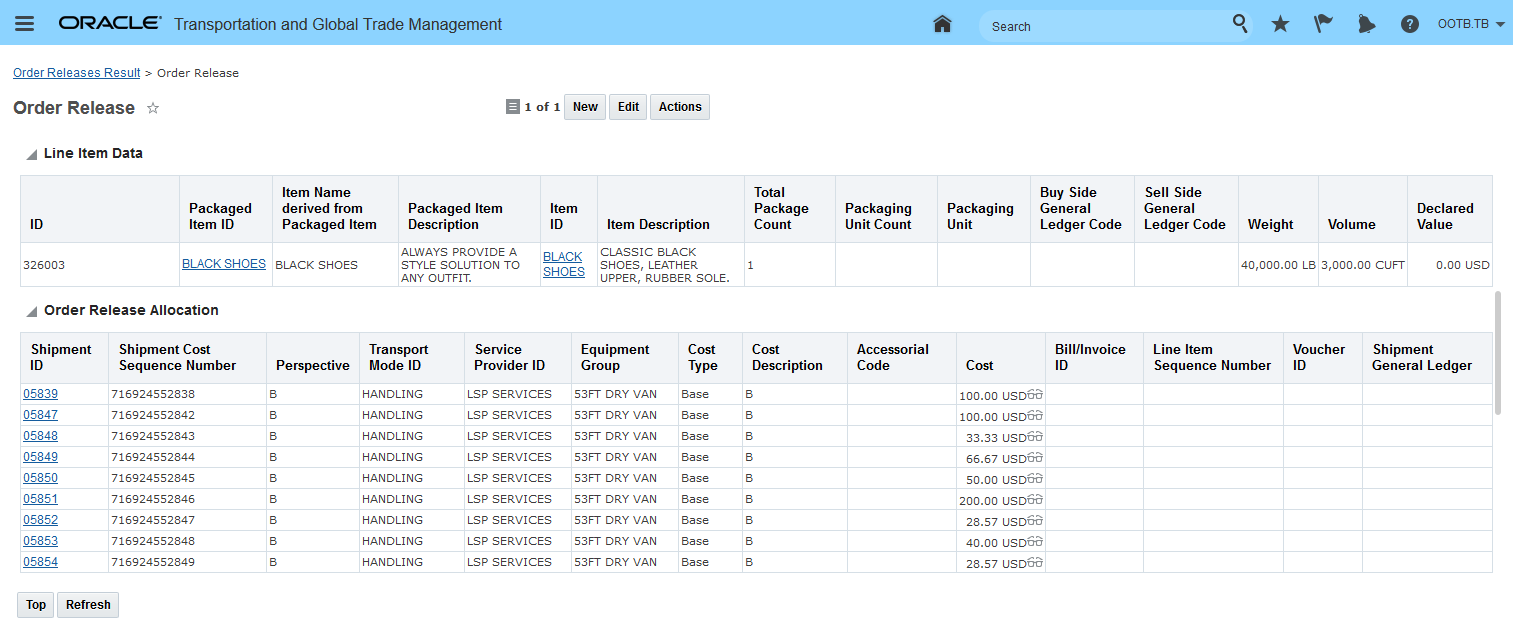

In the example below - the allocation has been run for the order that arrived on the 30th and departed on the 7th of October. In this case, the order has the allocated $100 cost for entering the compound and then the order receives it share of the proportioned $200 daily charge for each of the 8 days the order/shipment was on the compound. Allocation details and explanation below.

| Cost | Allocated Cost For | Number of orders/shipments In compound daily | Date |

|---|---|---|---|

| $100 | 1x entrance to compound charge | September 30th | |

| $28.57 | Portion of $200 daily fixed cost | 7 | September 30th |

| $28.57 | Portion of $200 daily fixed cost |

7 | October 1st |

| $33.33 | Portion of $200 daily fixed cost |

6 | October 2nd |

| $40.00 | Portion of $200 daily fixed cost |

5 | October 3rd |

| $50.00 | Portion of $200 daily fixed cost |

4 | October 4th |

| $67.67 | Portion of $200 daily fixed cost |

3 | October 5th |

| $100.00 | Portion of $200 daily fixed cost |

2 | October 6th |

| $200.00 | Portion of $200 daily fixed cost |

1 | October 7th |

Allocation of 8 Day Compound Order

Provides you with the ability to model common time based shipment grouping scenarios - like dwell time at a compound or a daily carrier manifest.

Steps to Enable

To use the Match Date option you will need to select this option when defining your Shipment Group Rules.

Navigate to Shipment Management > Power Data > Shipment Configuration > Shipment Group Rule.

On the Shipment Group Rule Identification Tab:

- Enter a Rule ID and Description for the rule you want to define

- Set the Content Definition ID to Unrelated

- Use the Type ID to select the shipment group type that you want to build using this rule. I would recommend creating meaningful Type IDs so you can categorize your Shipment Group Rule

On the Shipment Group Rule Rule Detail Tab enter the standard details for your rule:

- Geography

- Mode

- Etc

Full Shipment Grouping Rules:

-

Enter the option you wish to use for your Match Date (Start Date or Daily) - all shipments in the group must have the same time as defined for the group. Shipments will be grouped either based on the same start time or on a daily basis.

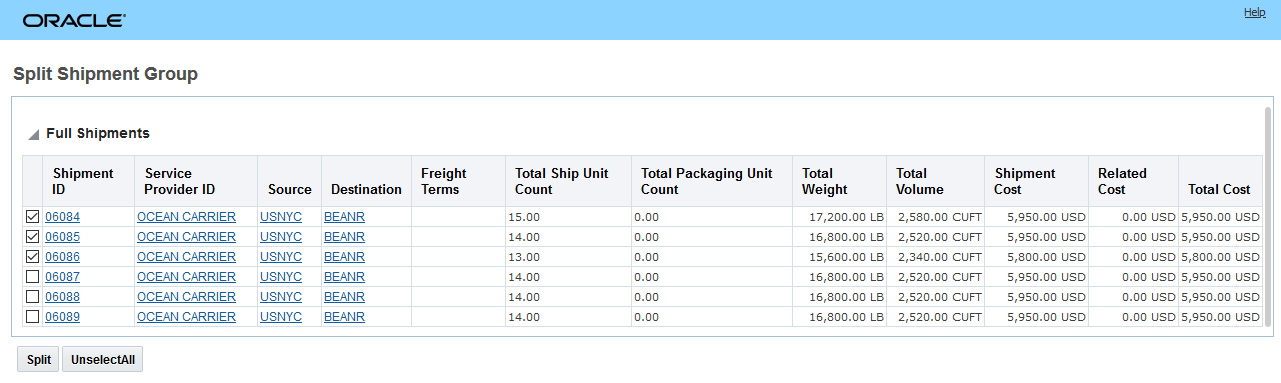

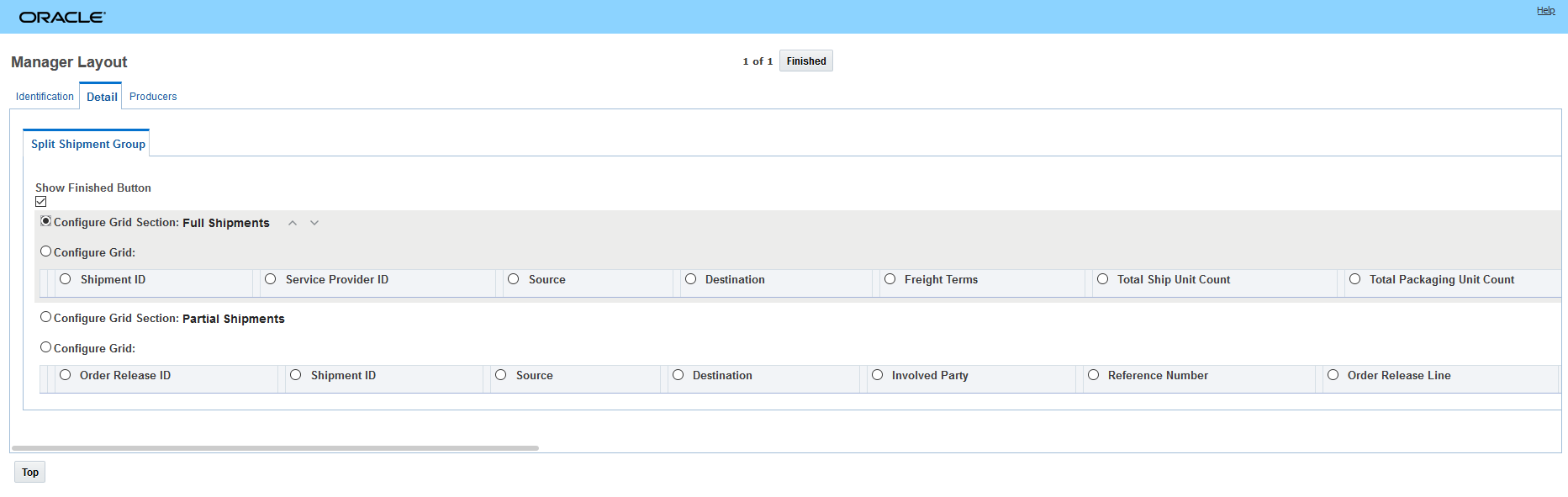

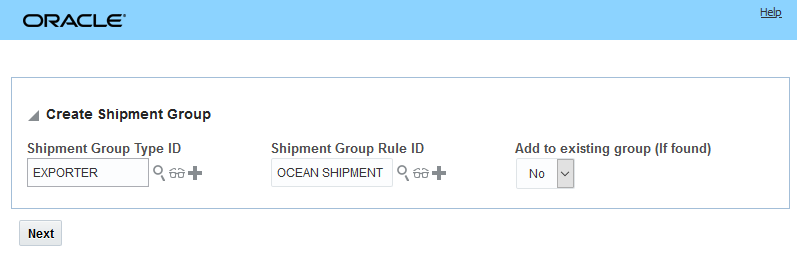

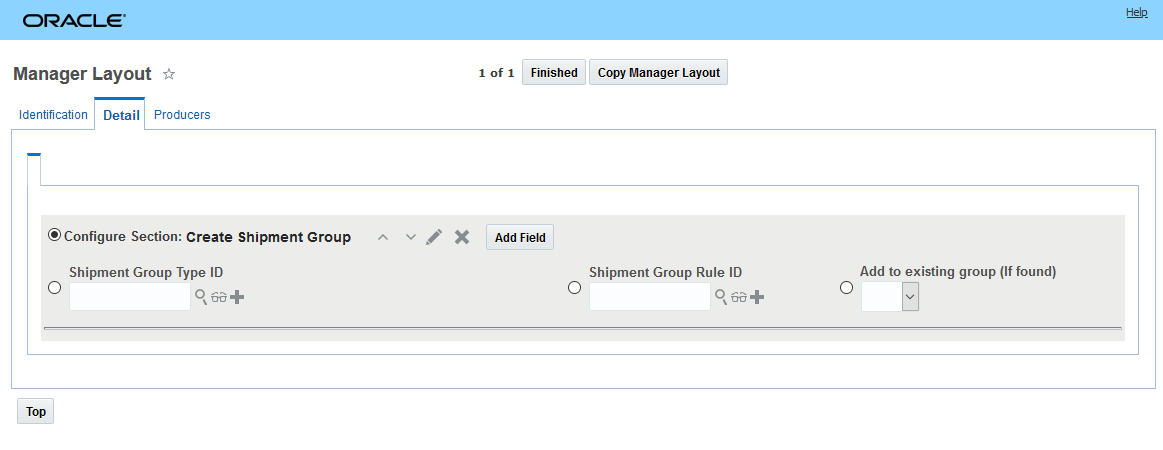

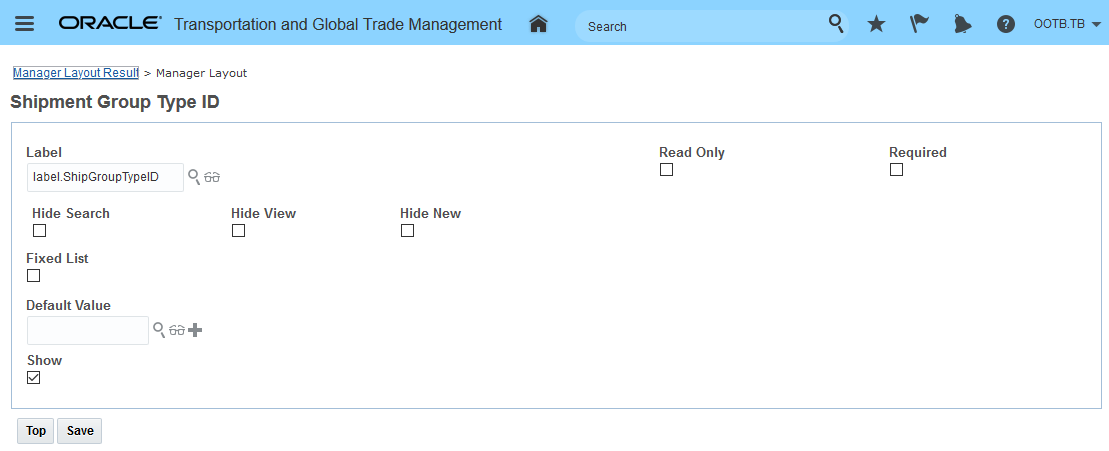

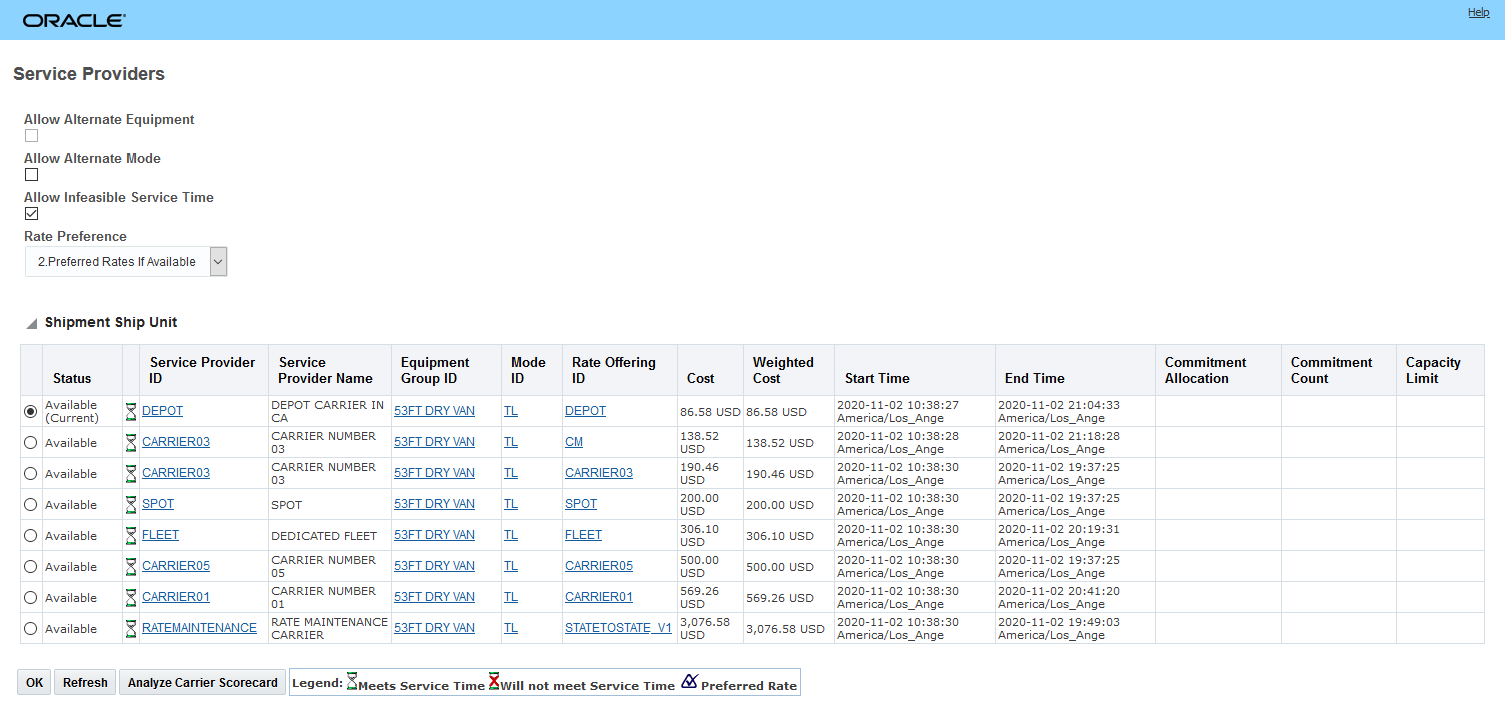

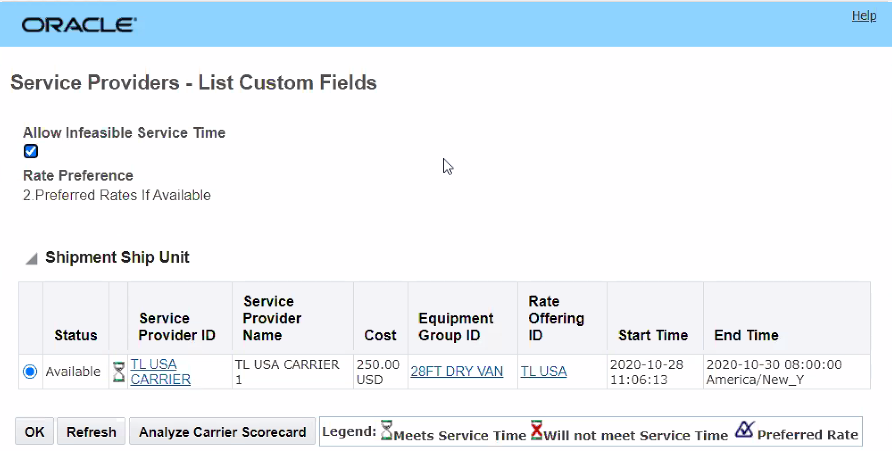

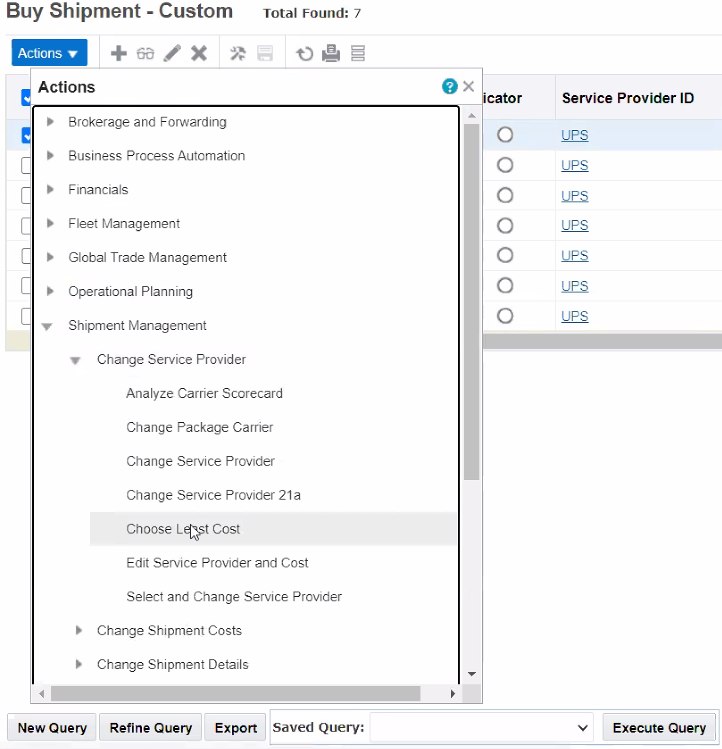

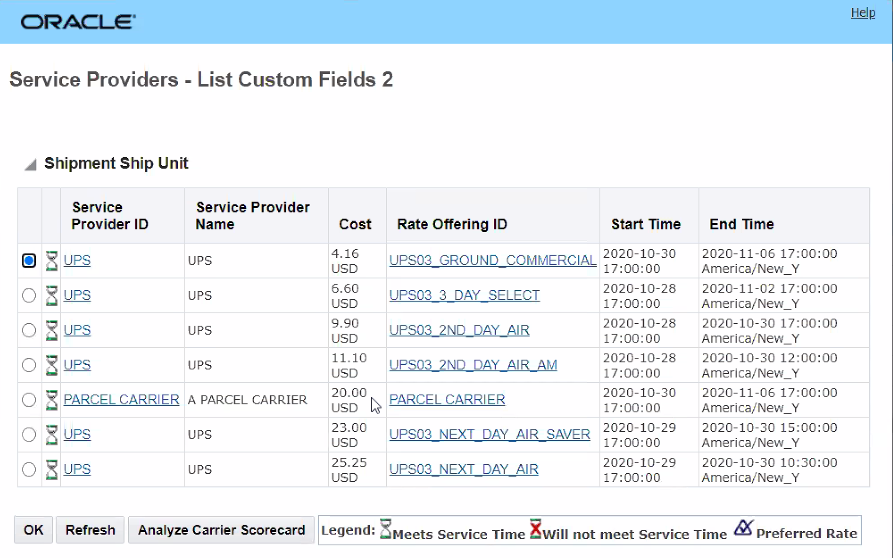

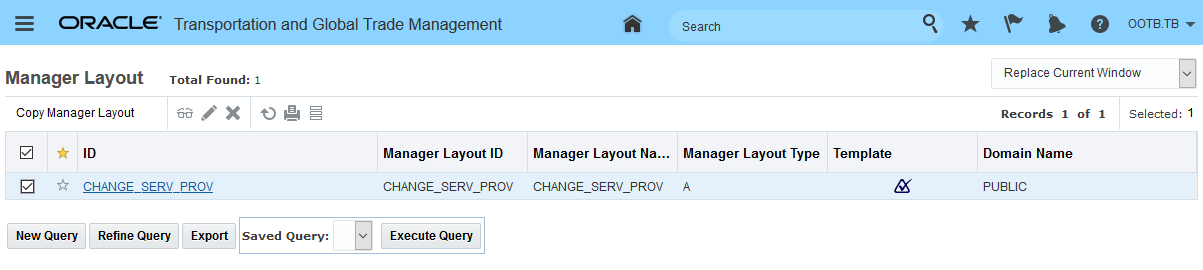

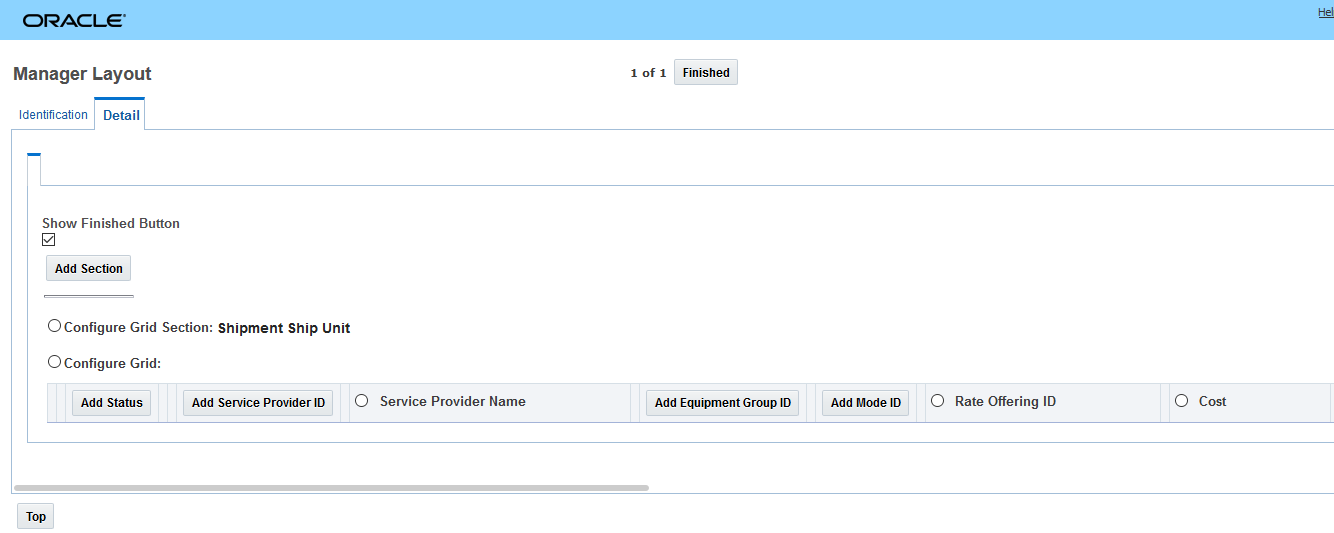

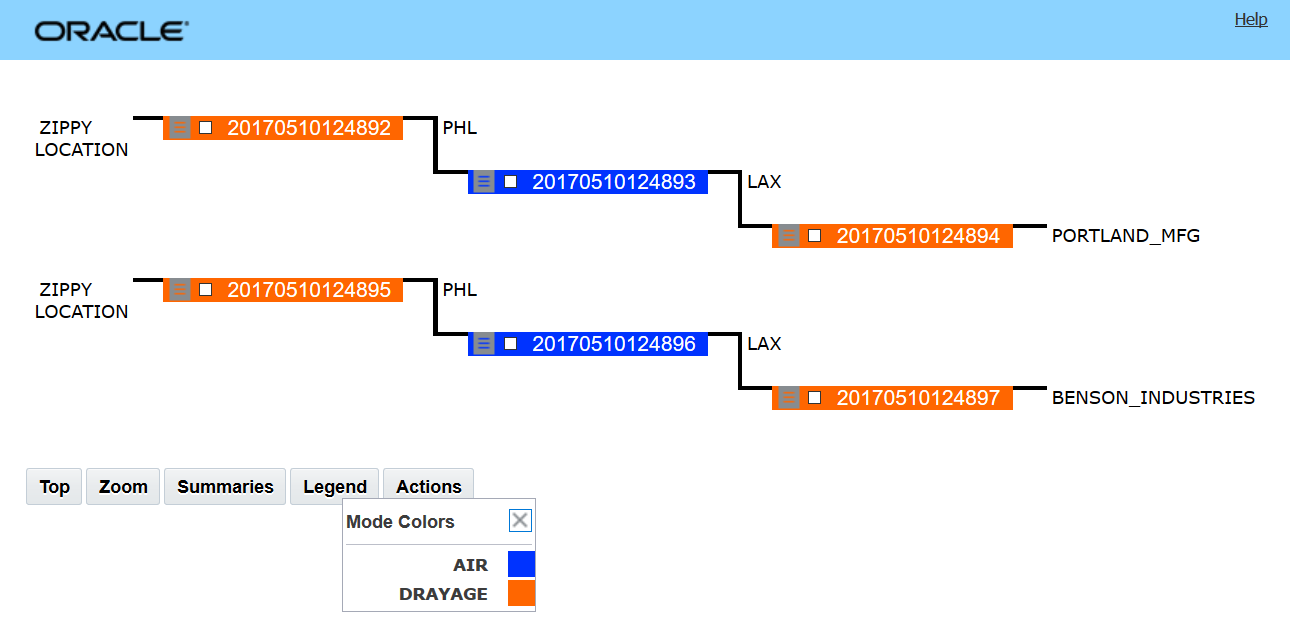

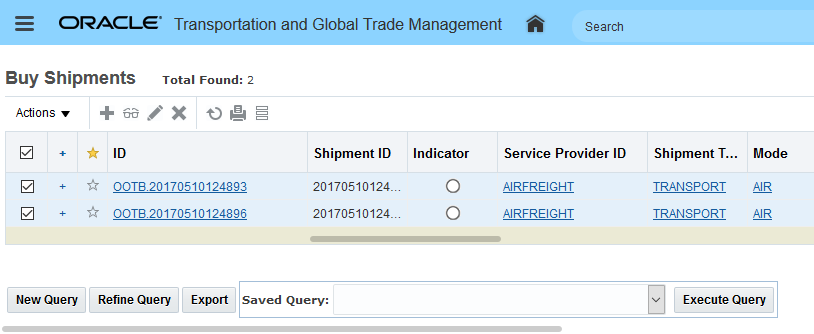

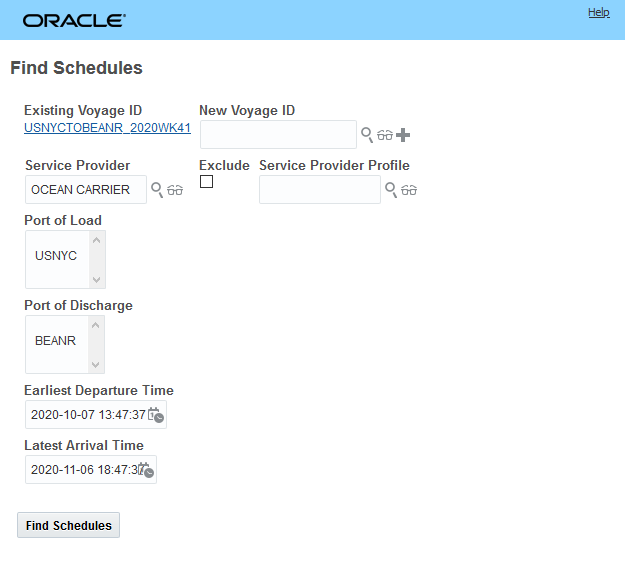

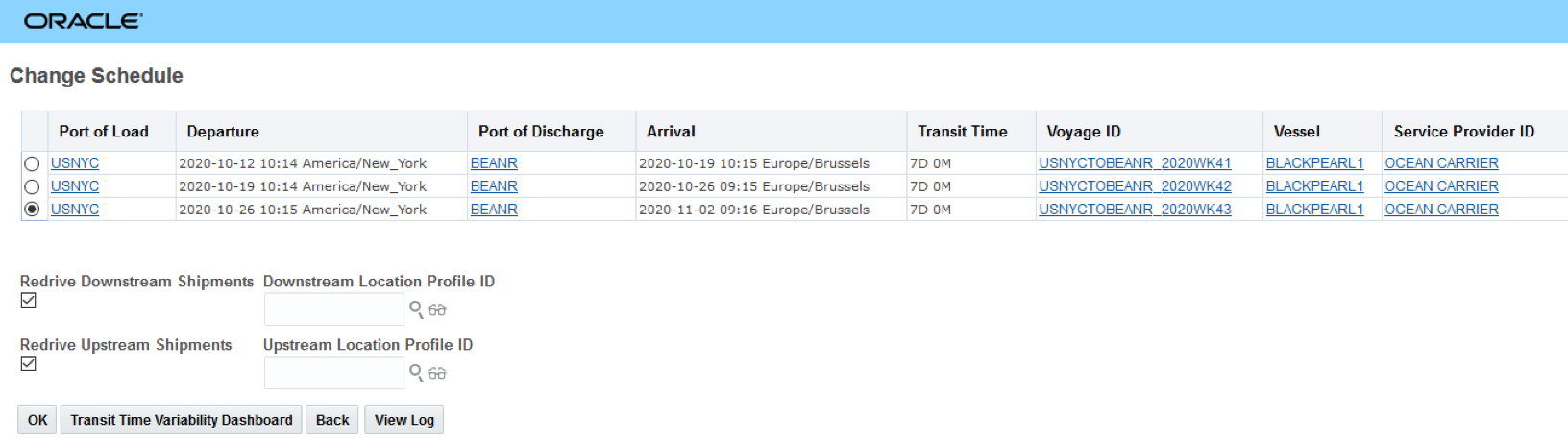

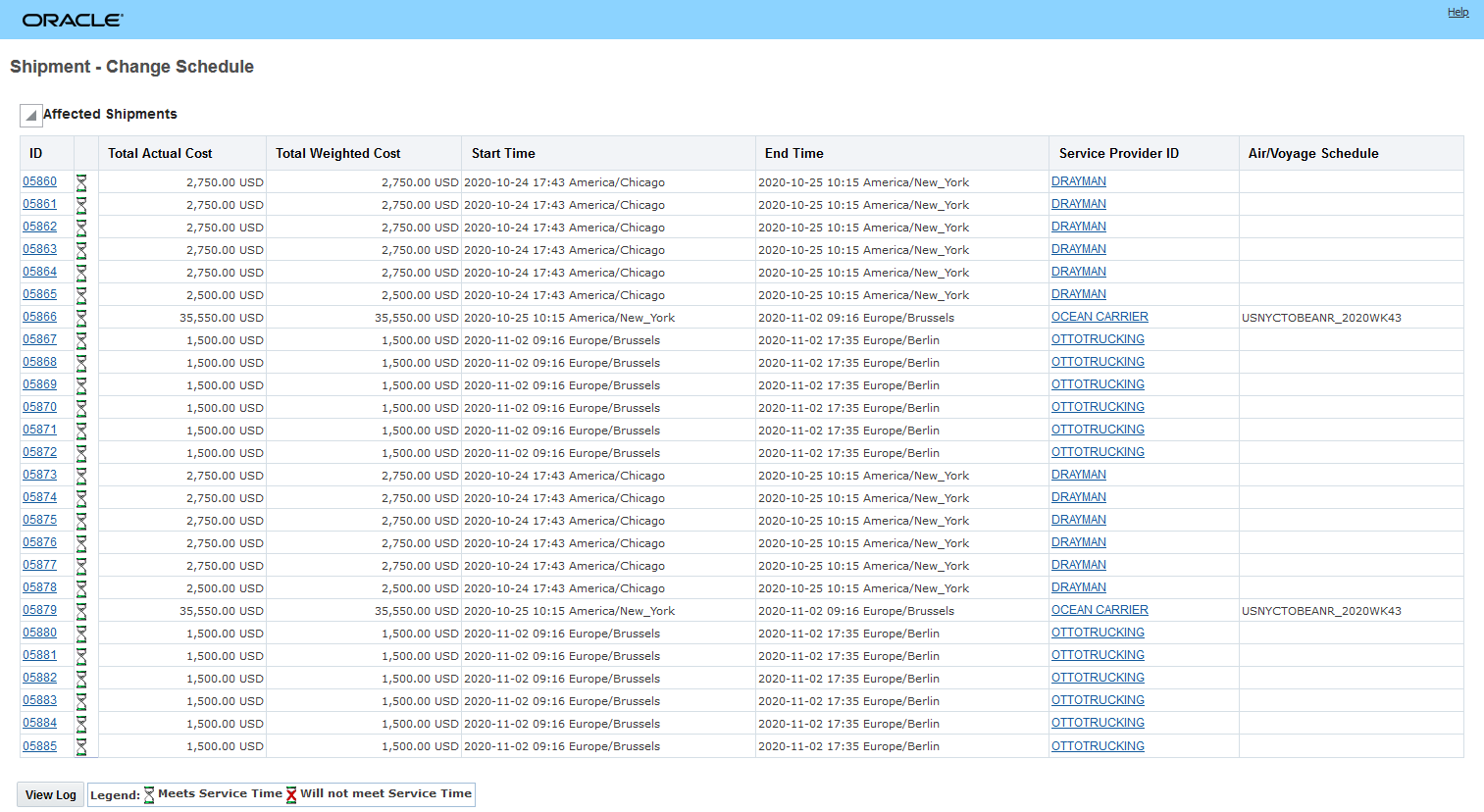

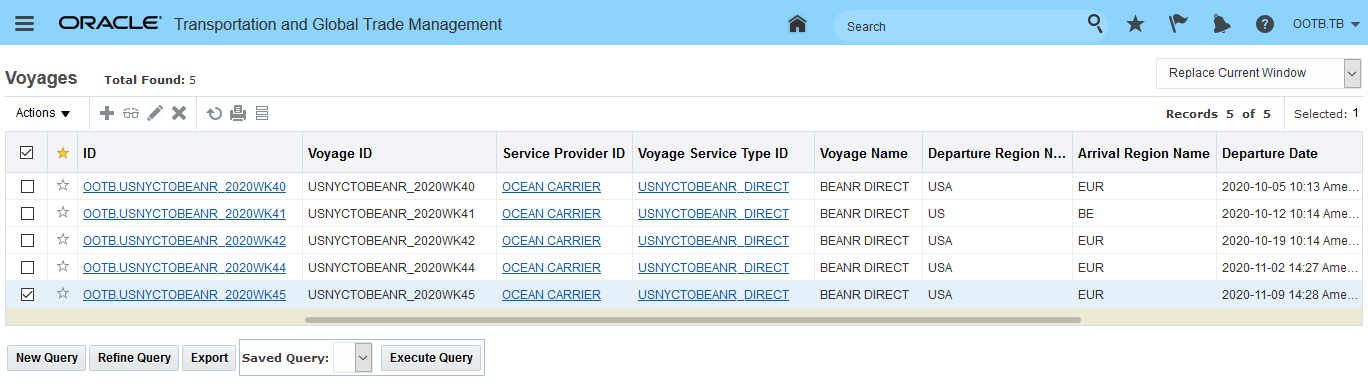

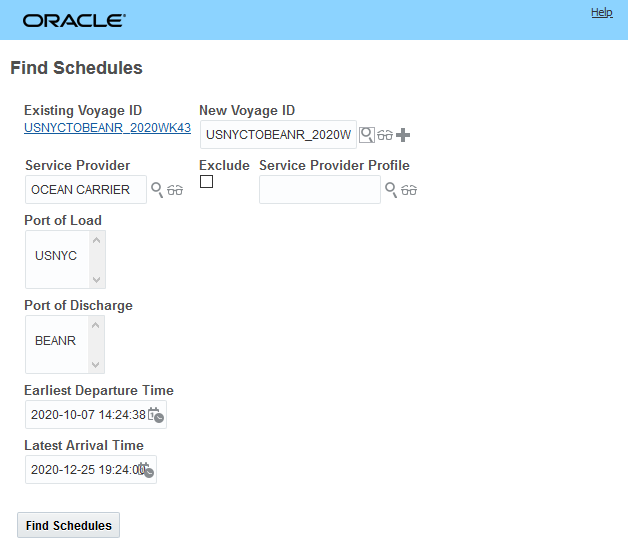

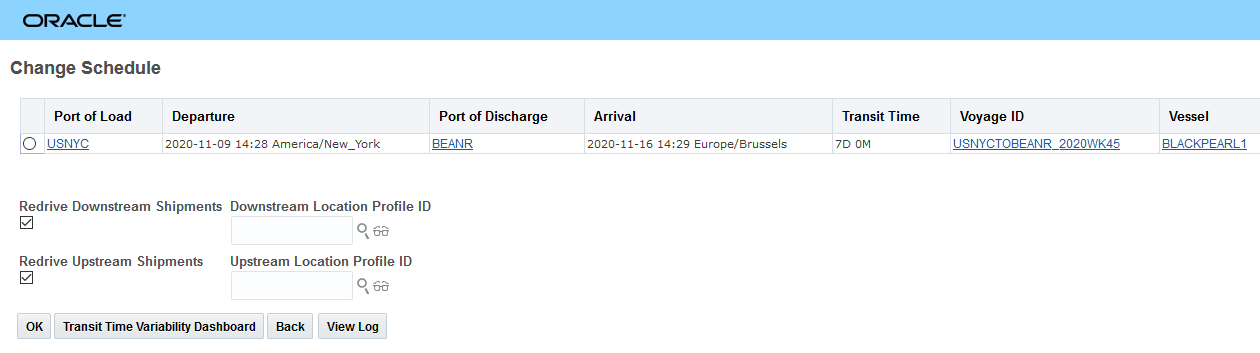

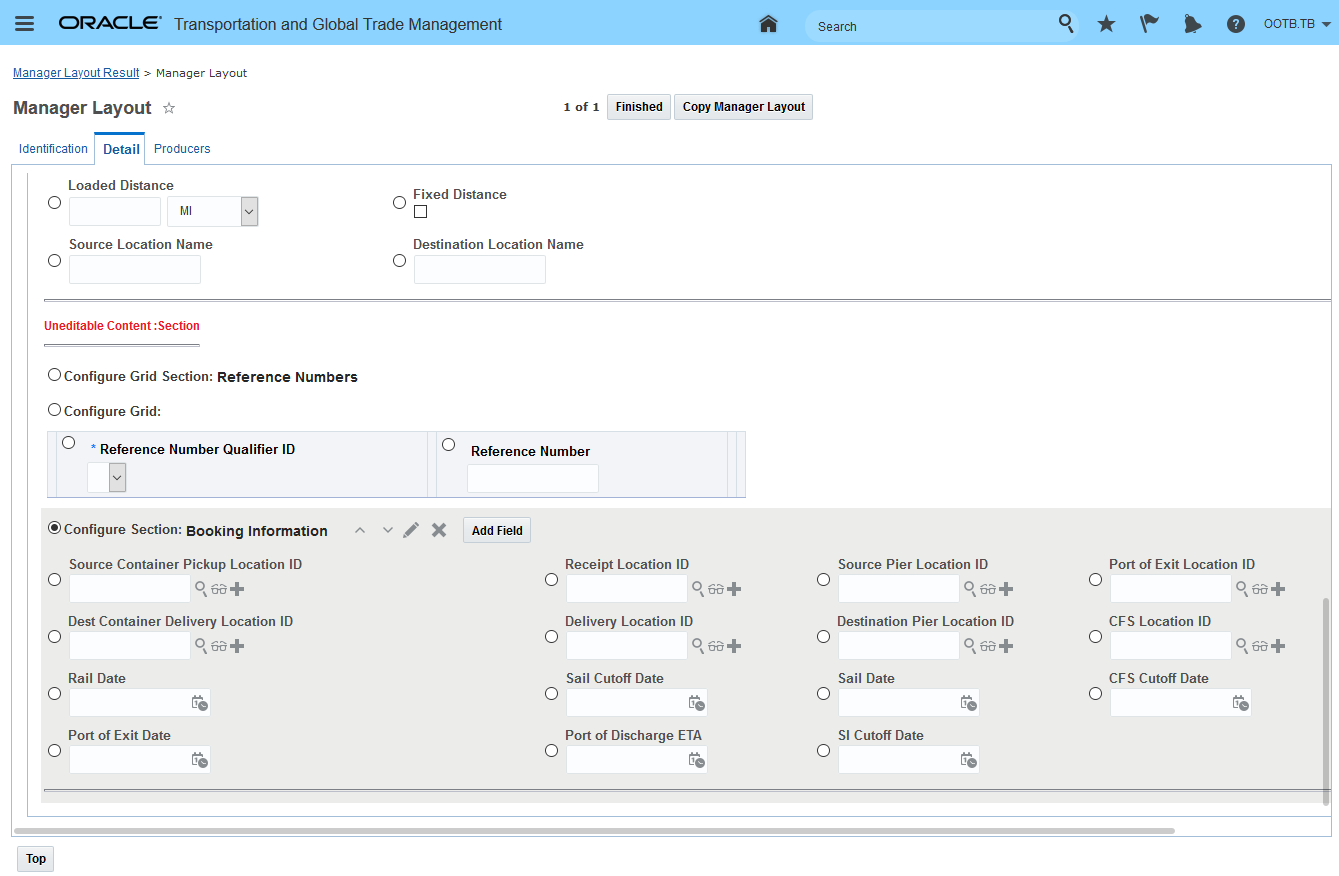

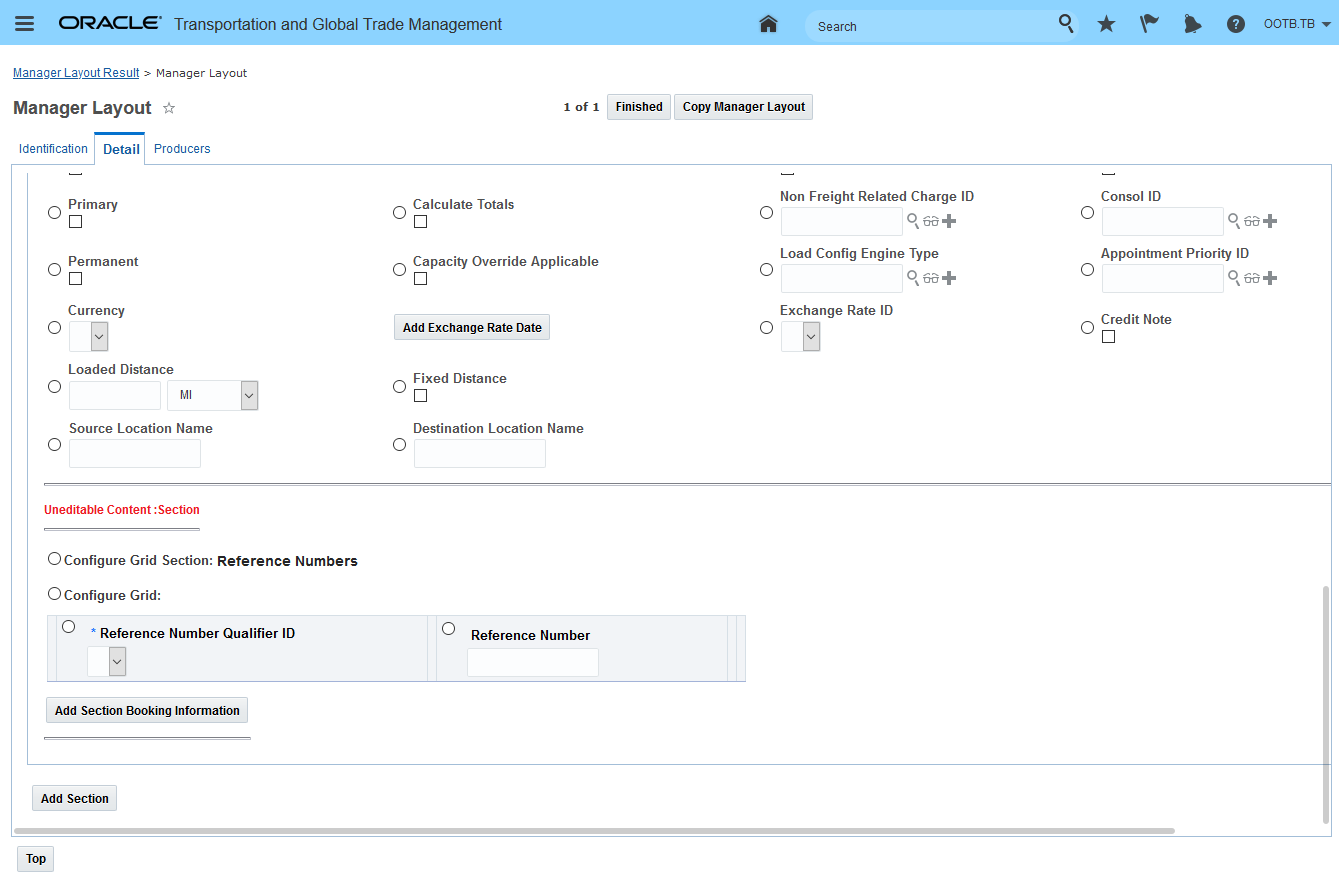

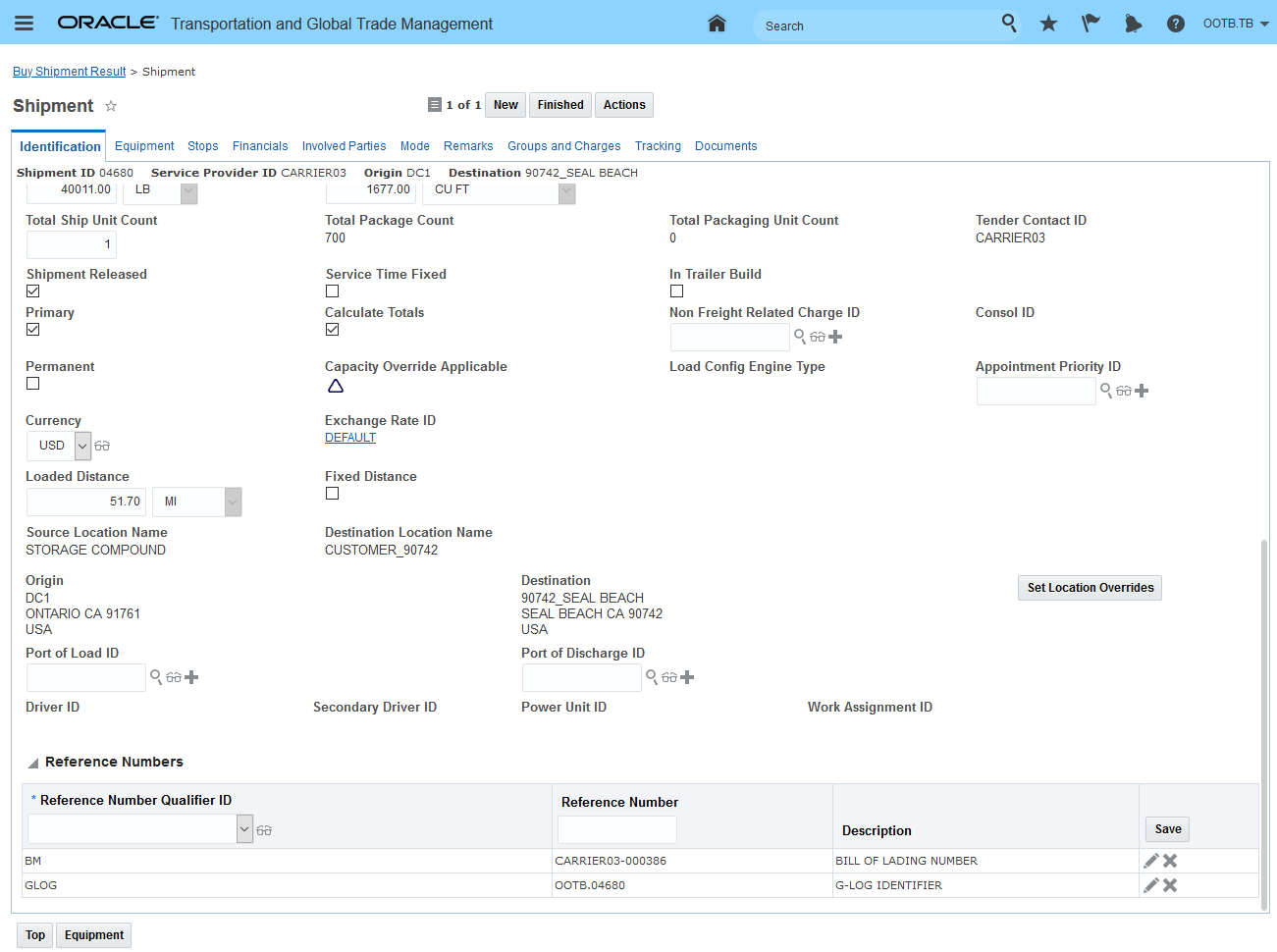

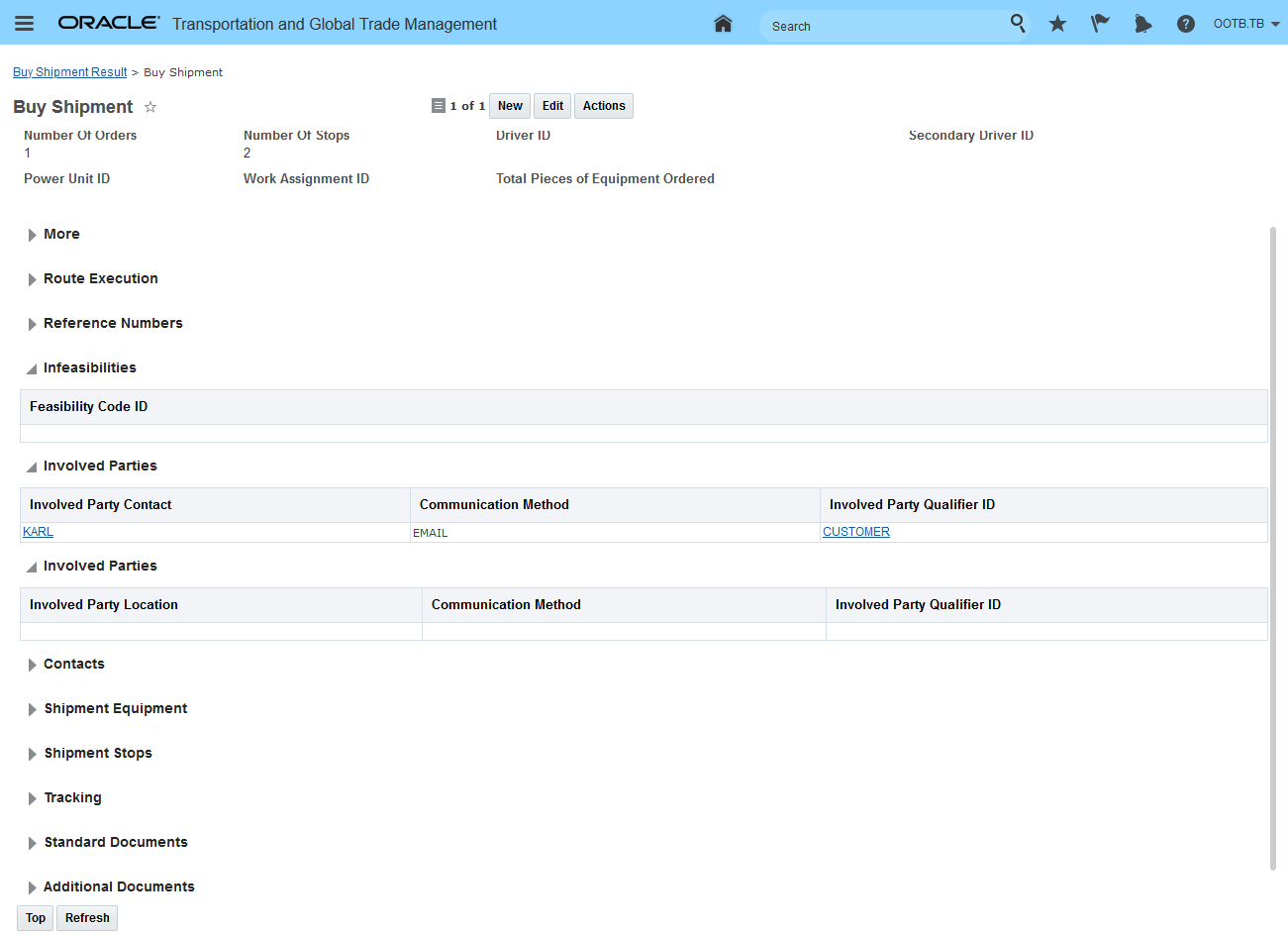

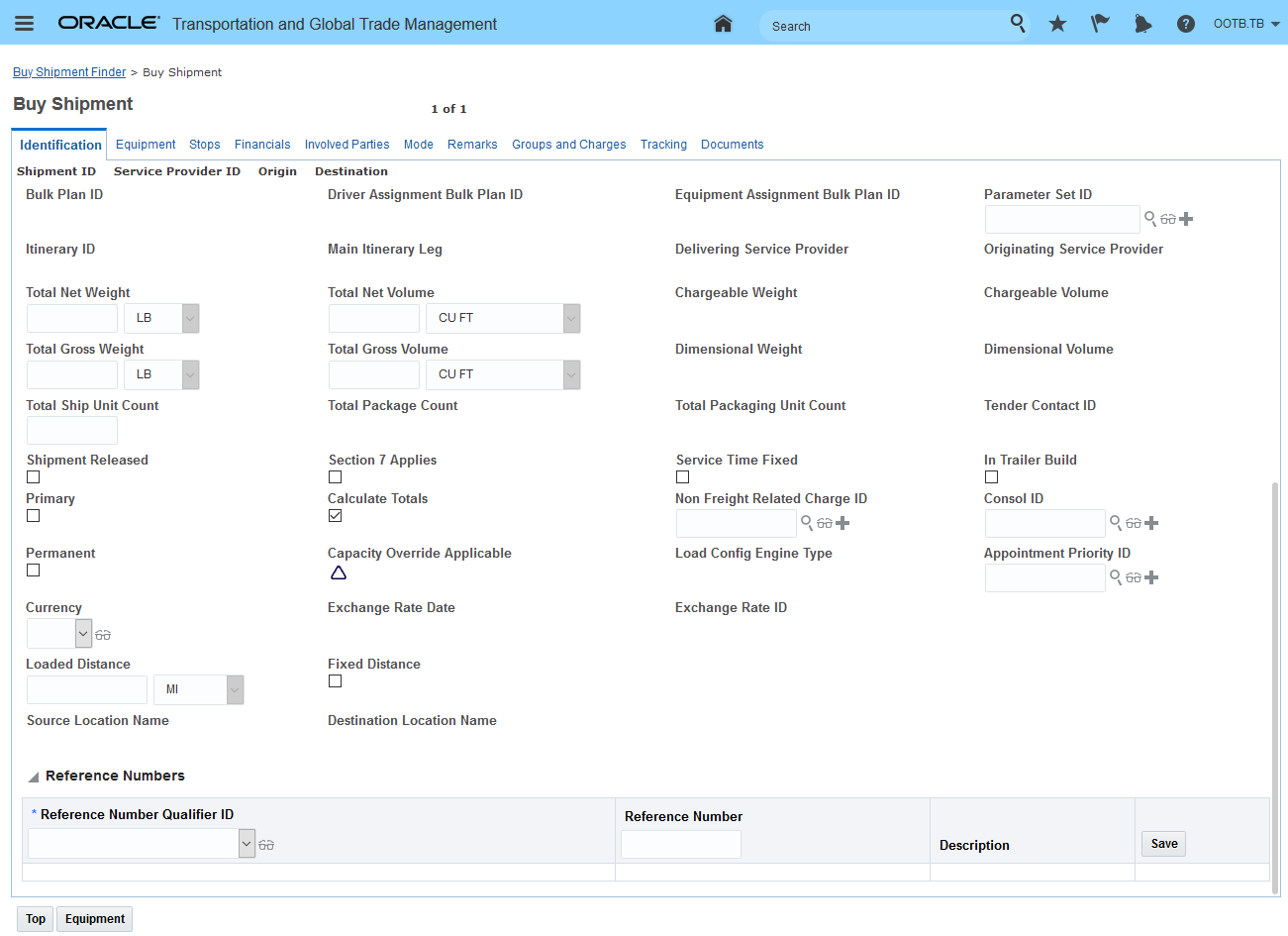

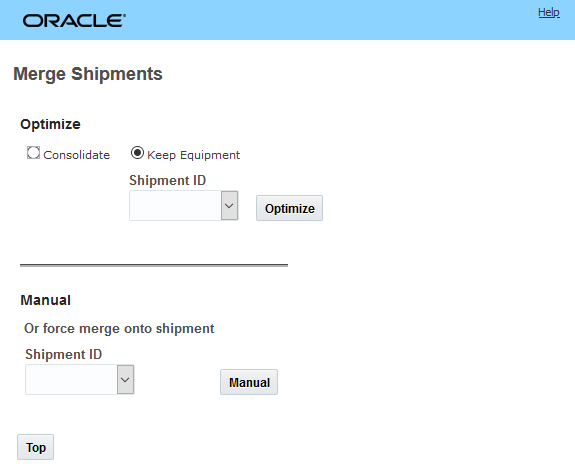

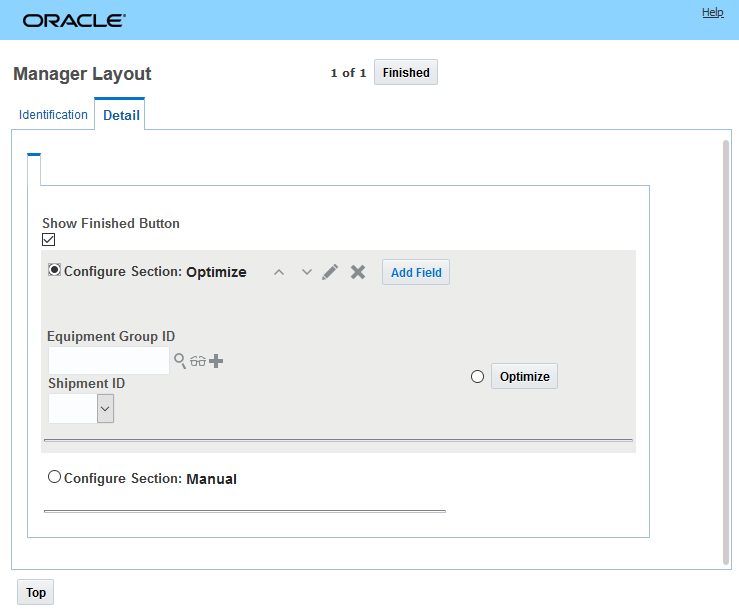

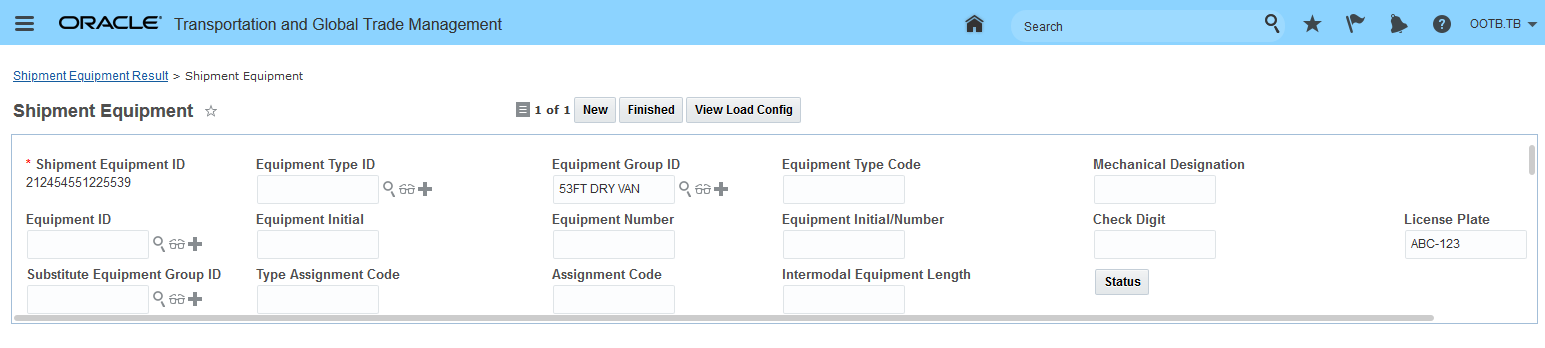

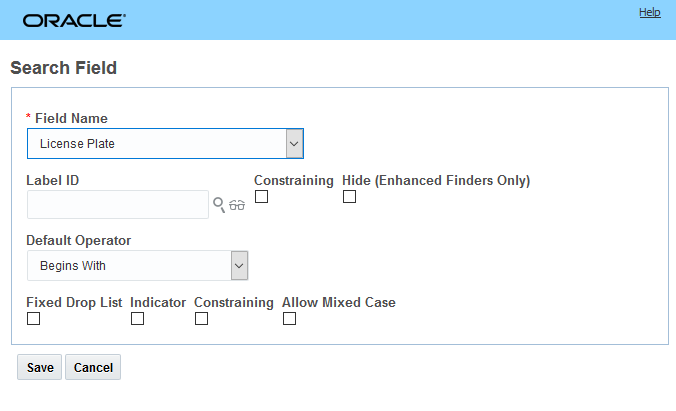

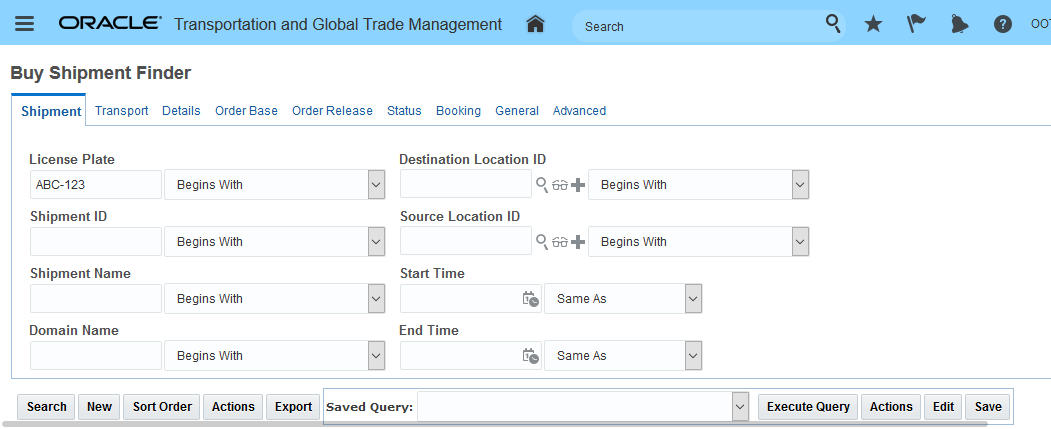

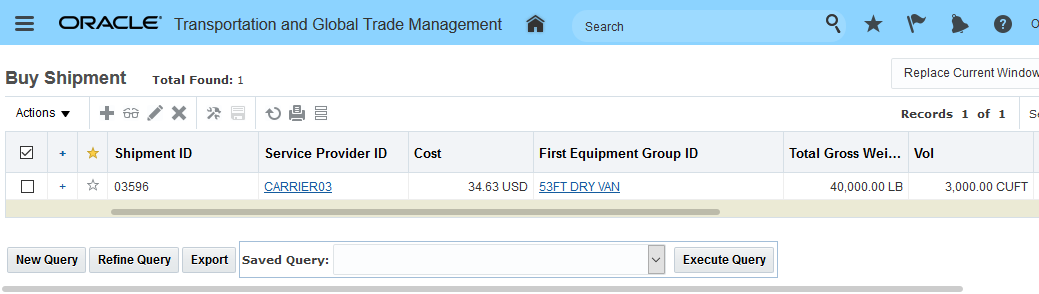

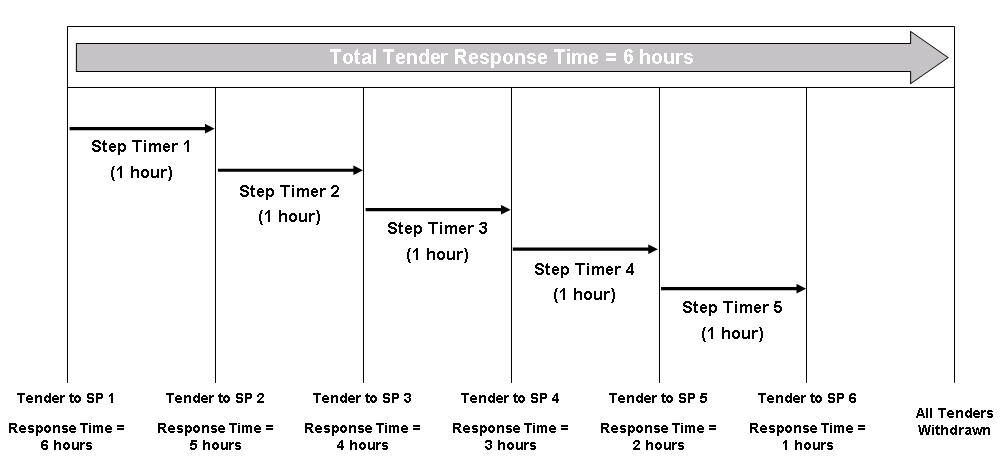

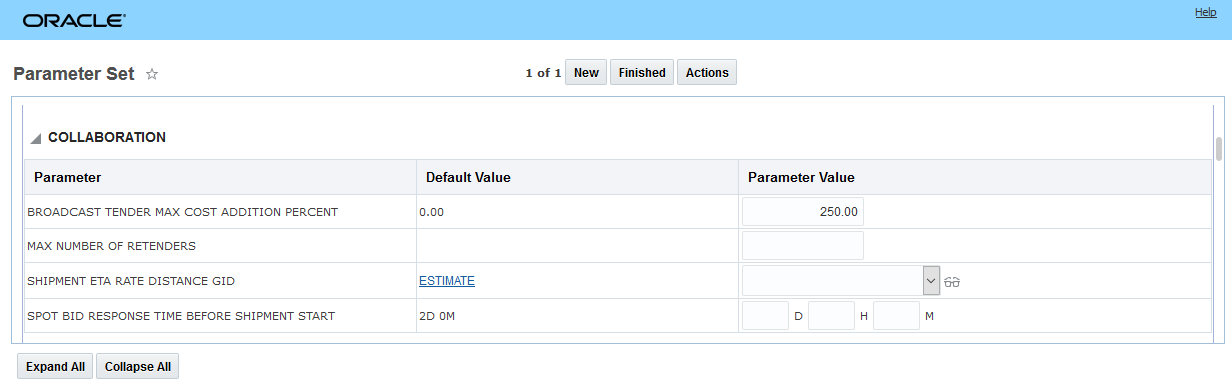

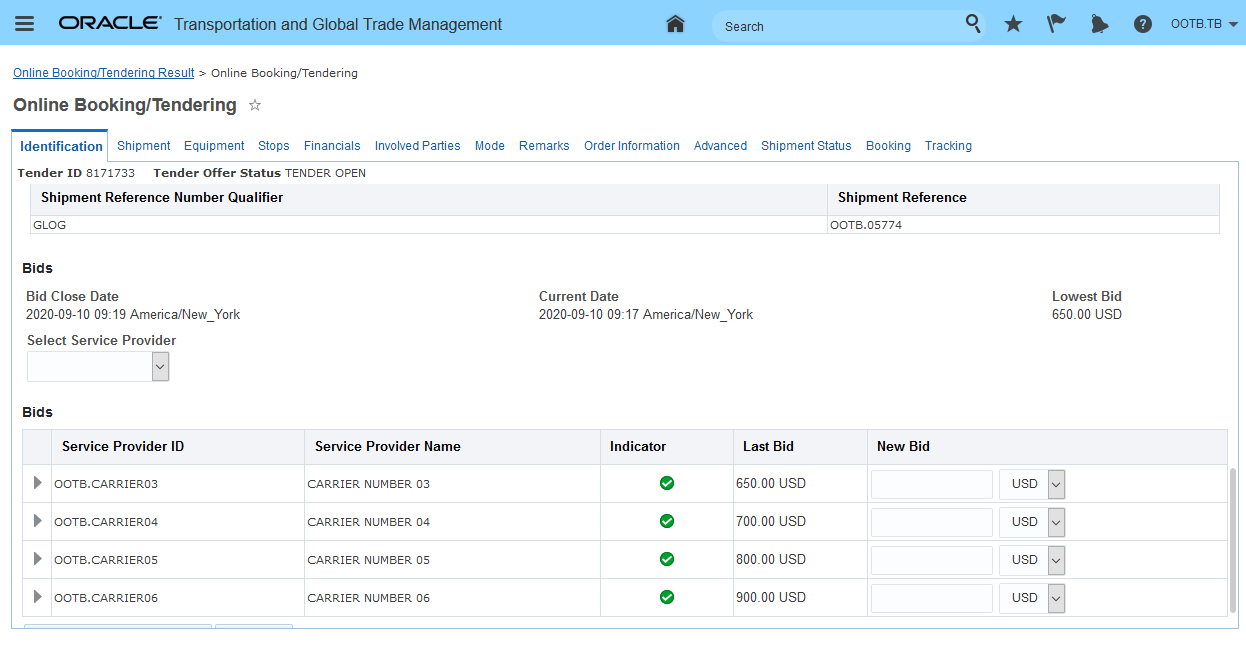

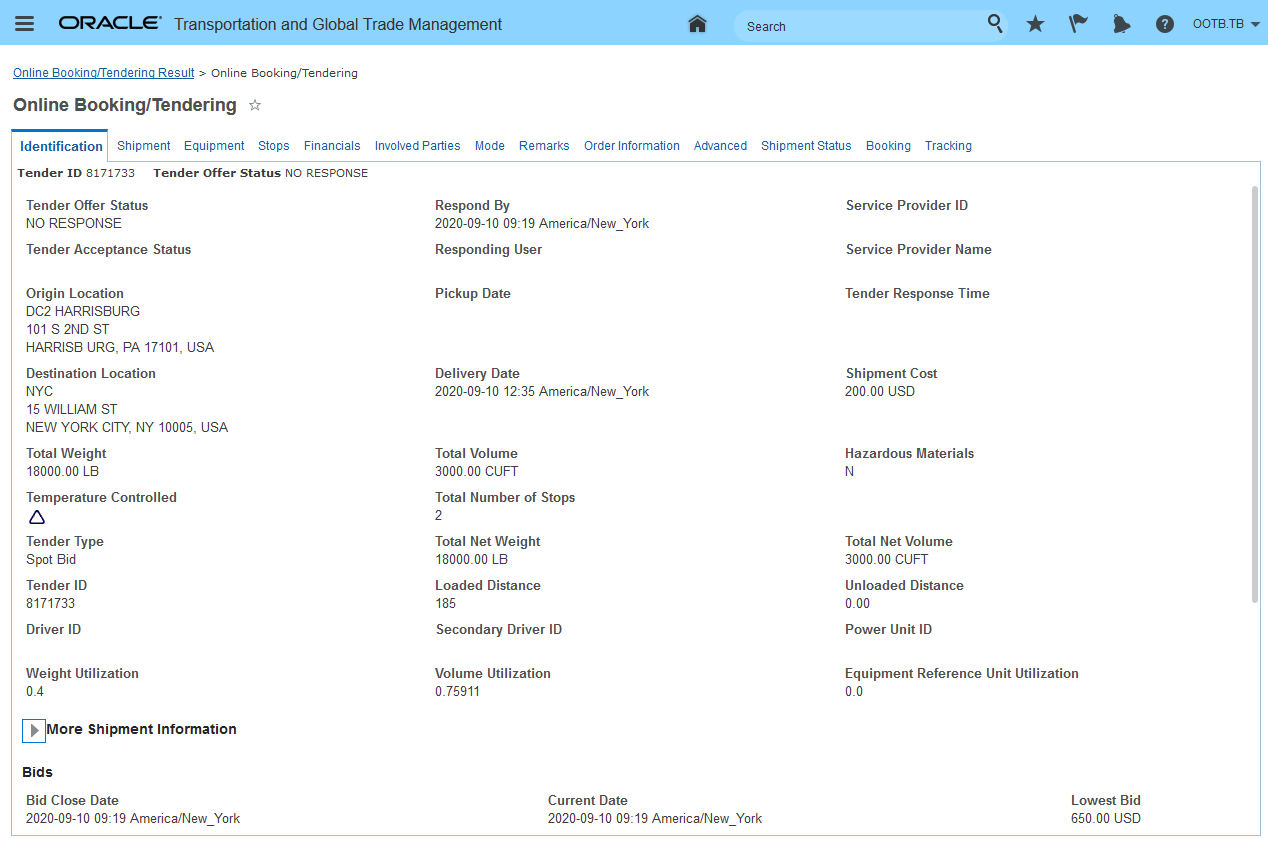

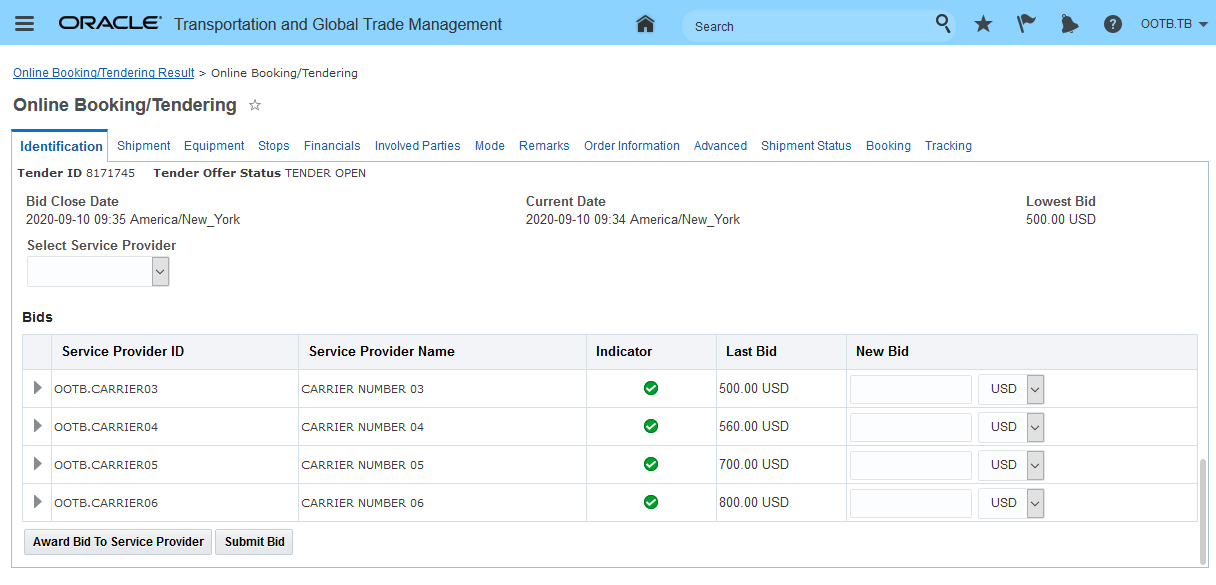

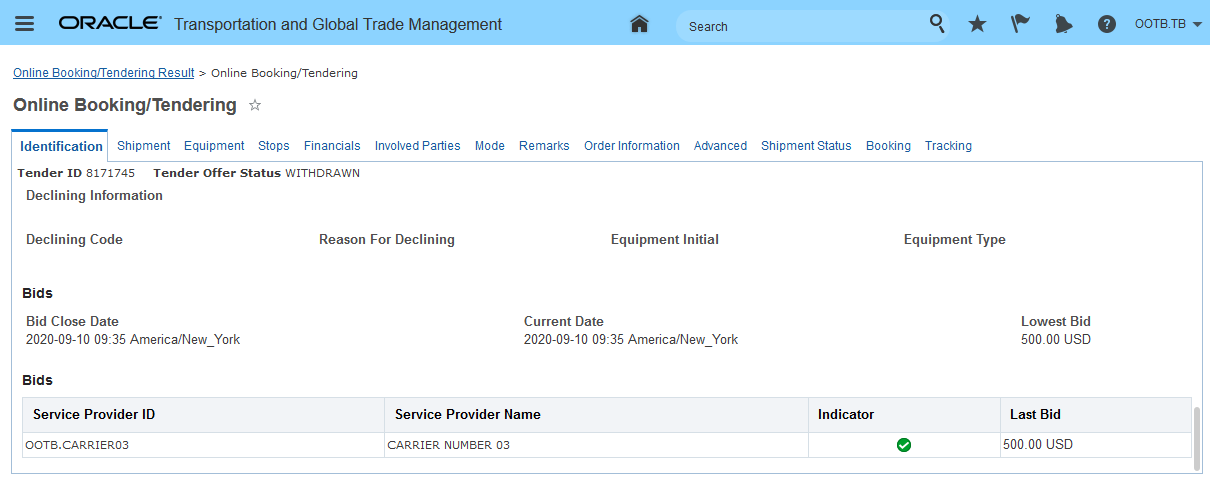

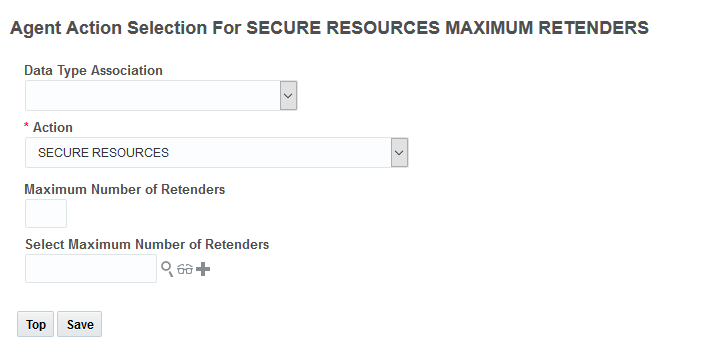

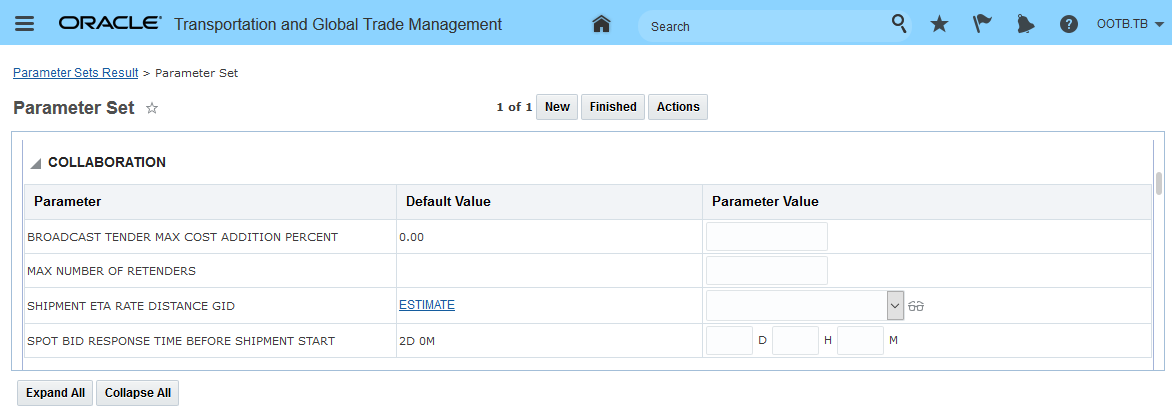

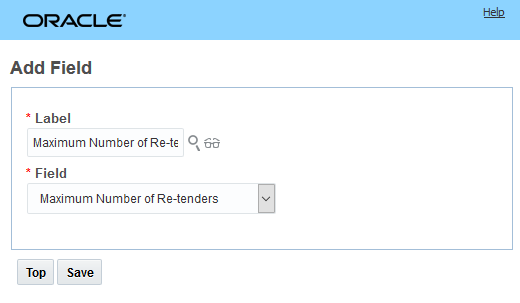

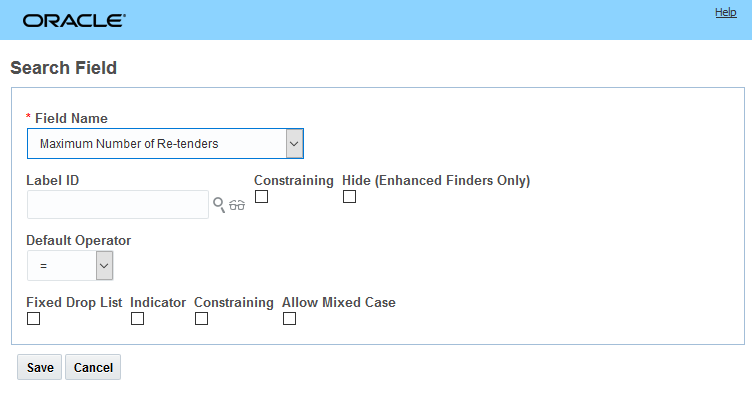

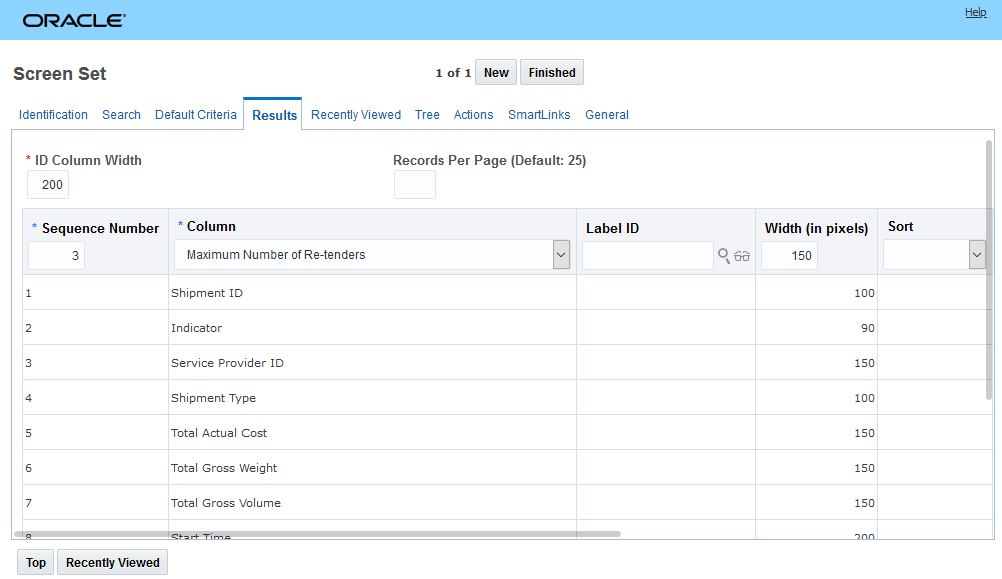

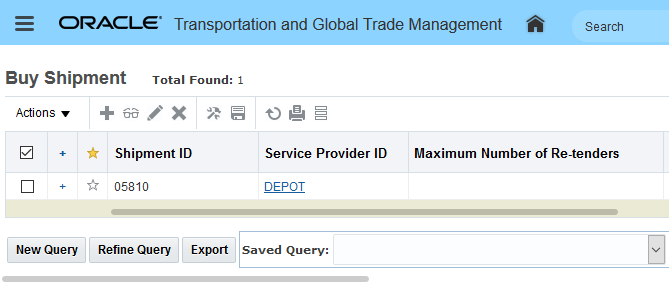

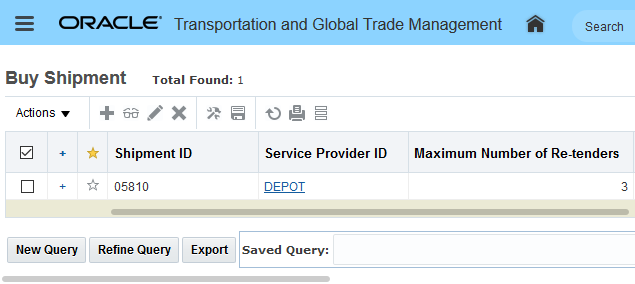

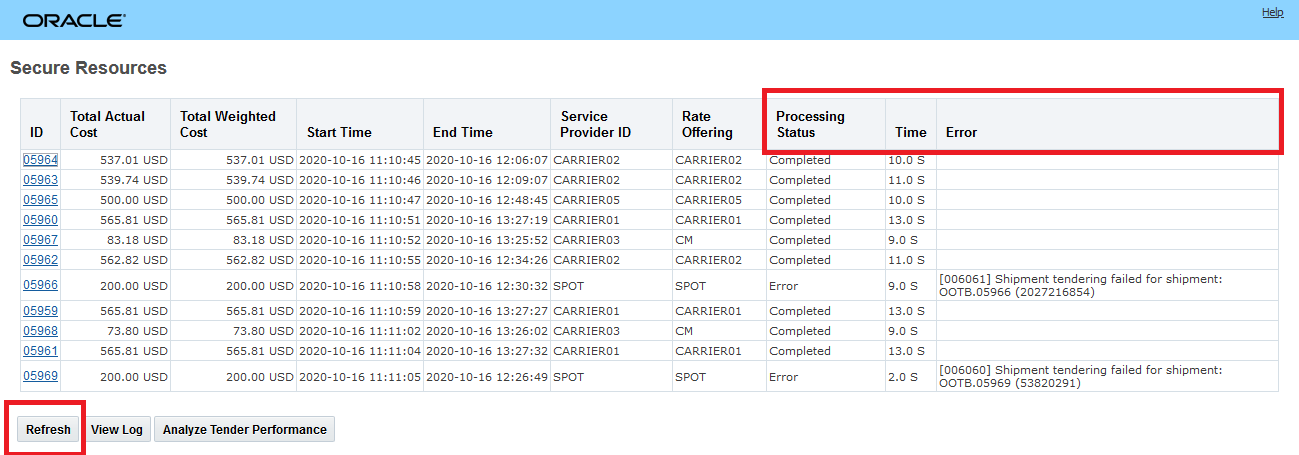

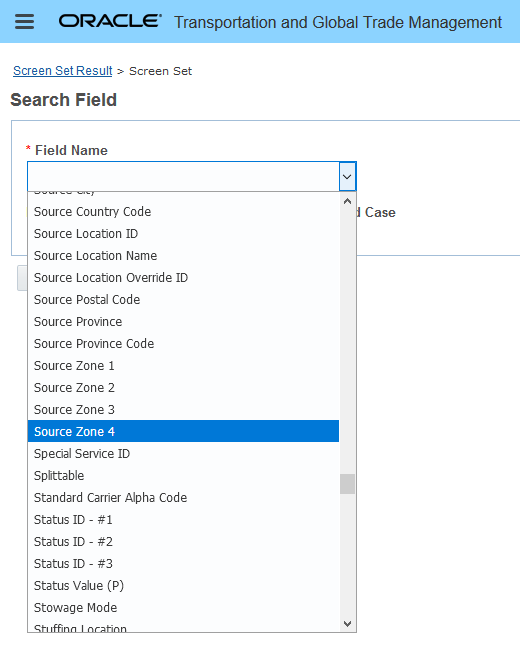

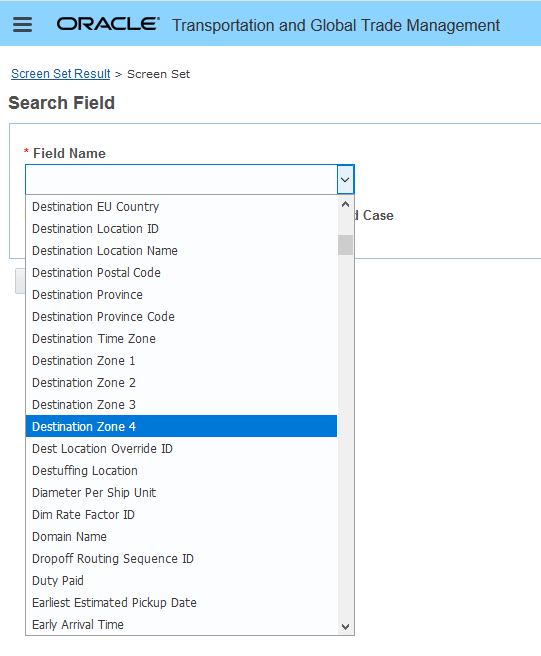

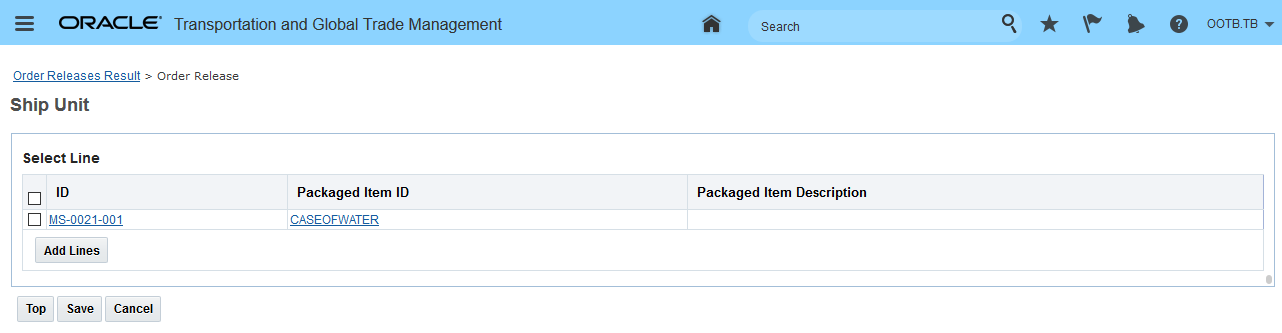

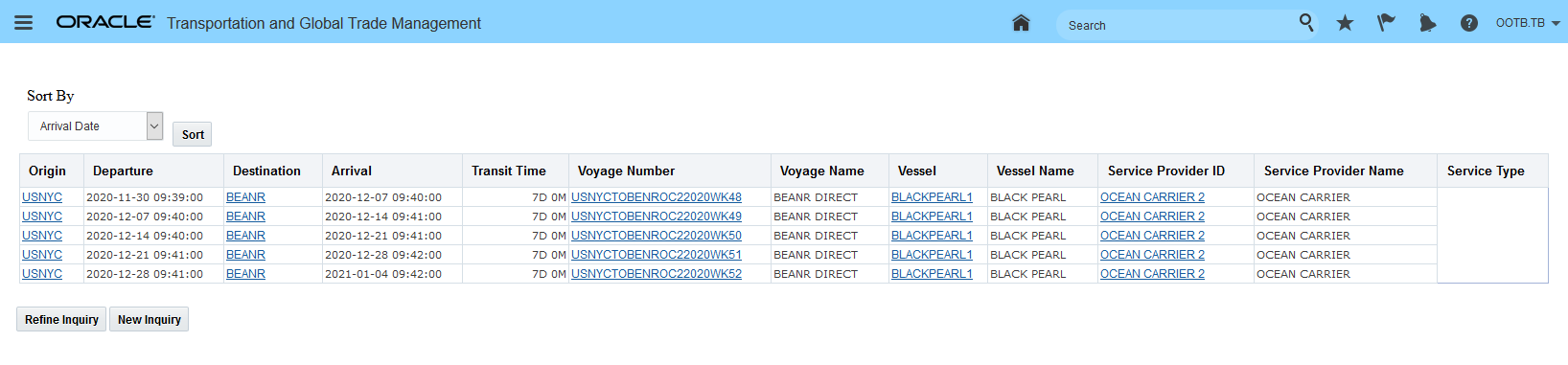

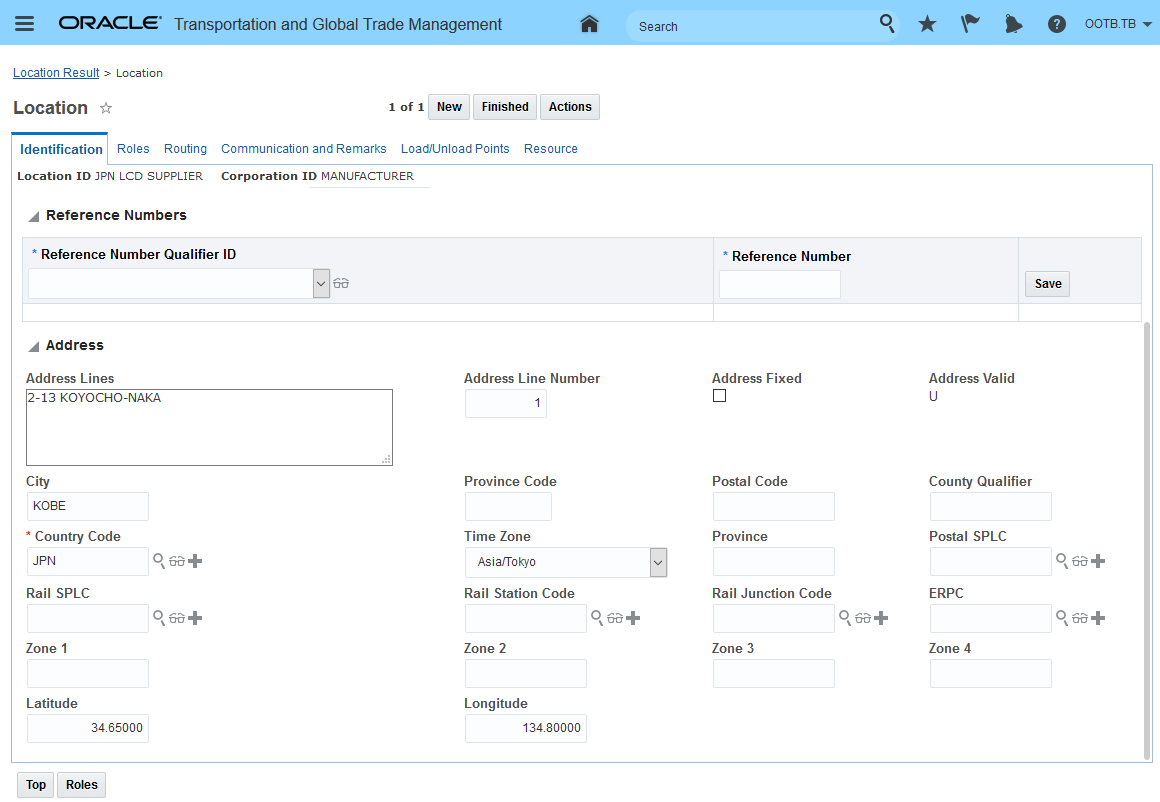

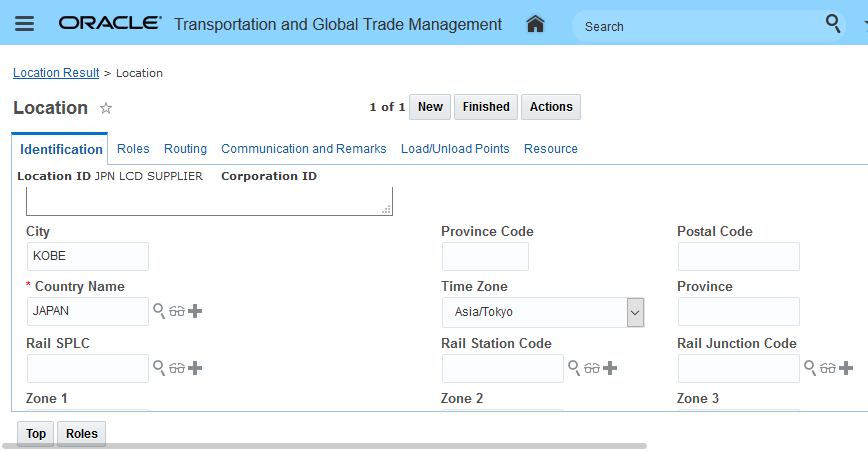

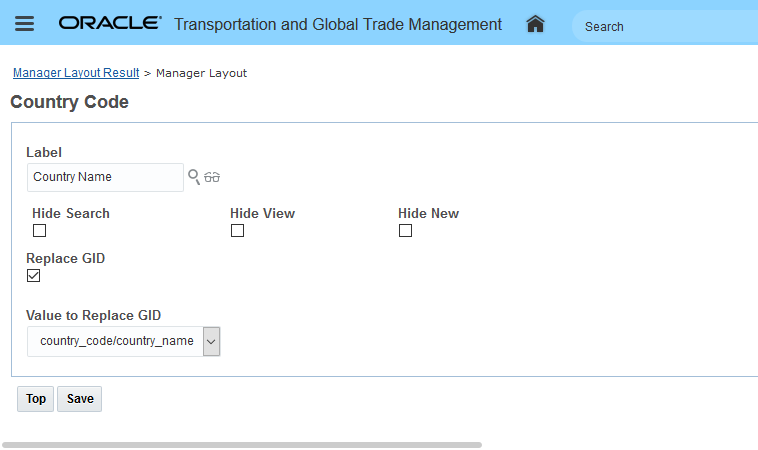

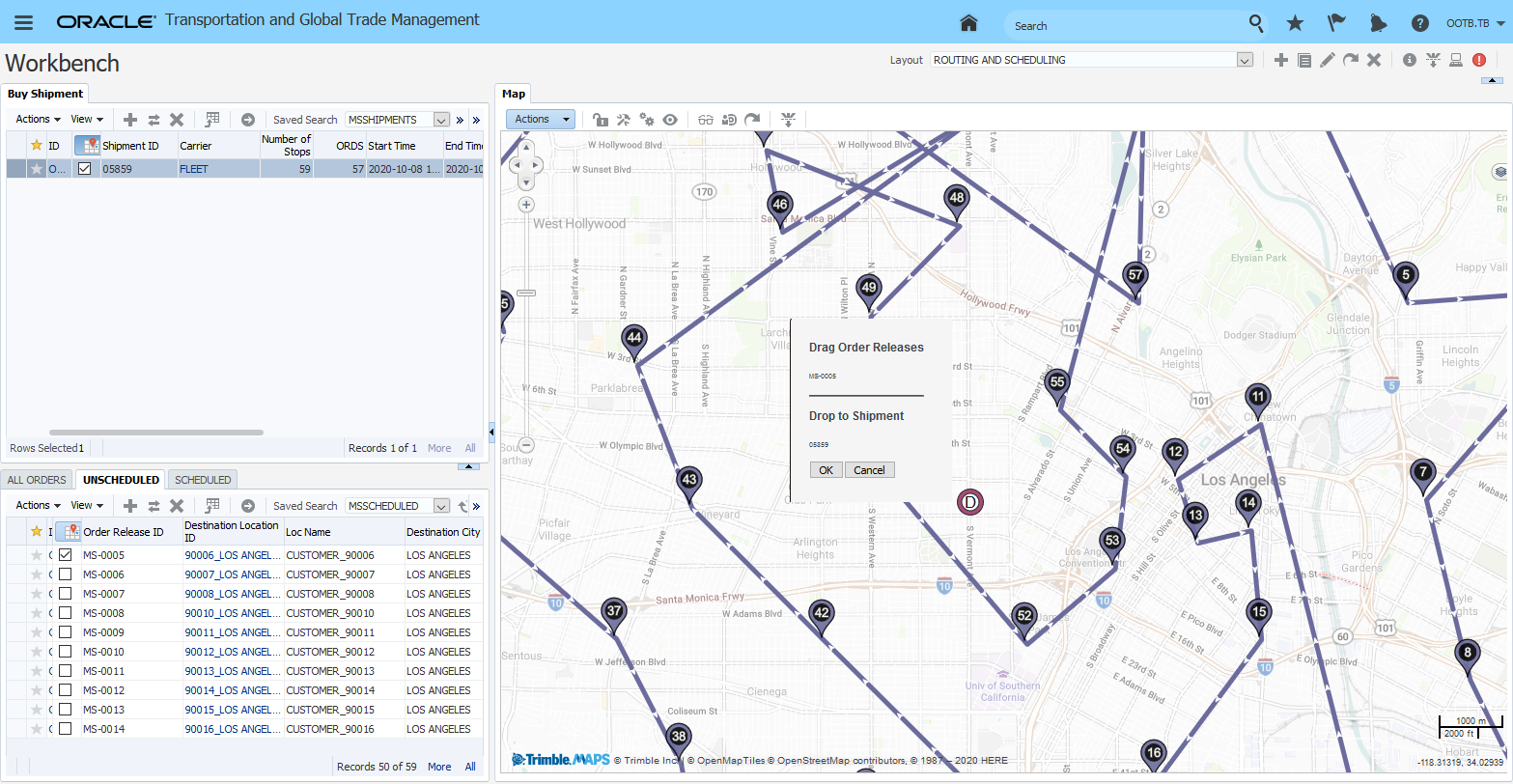

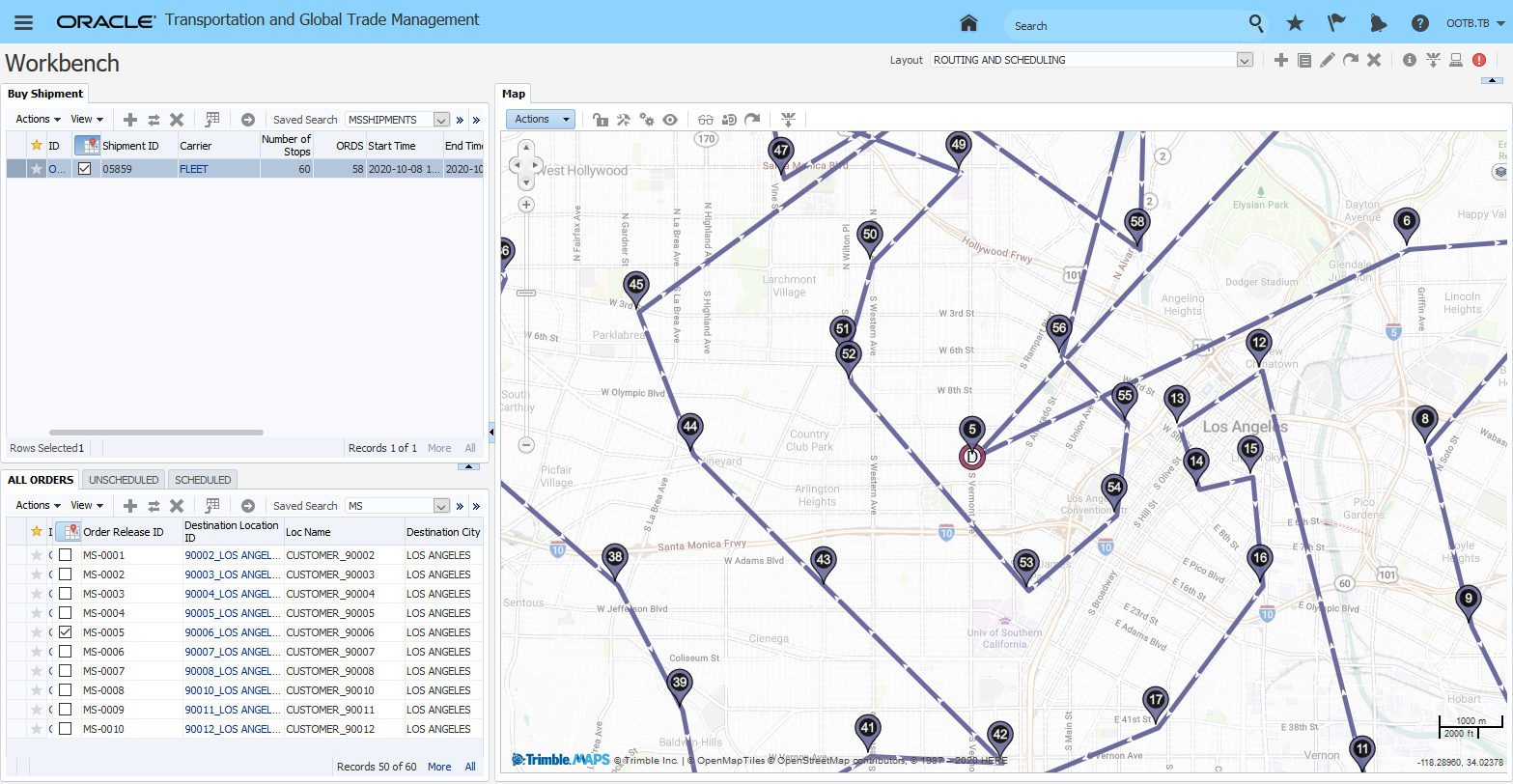

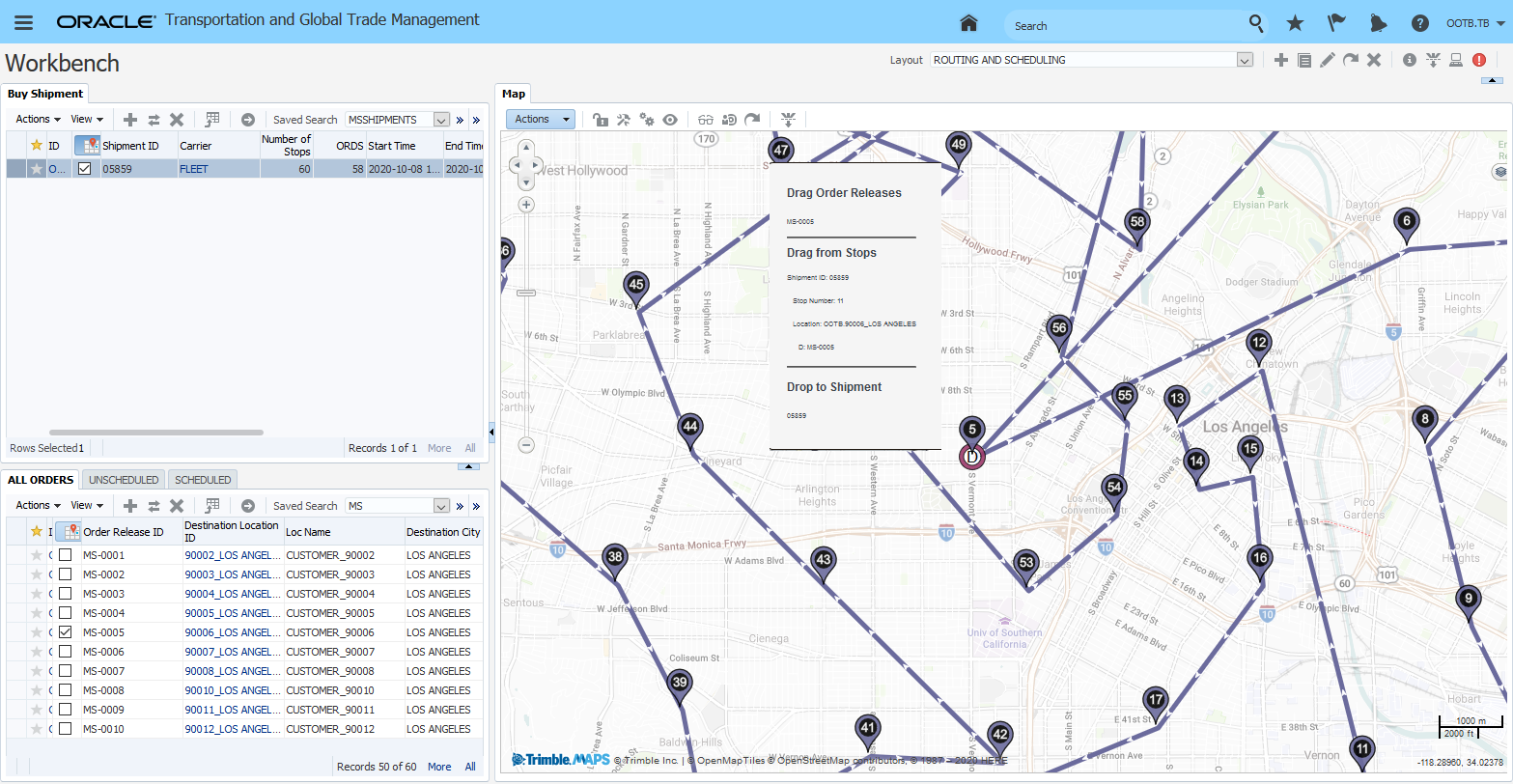

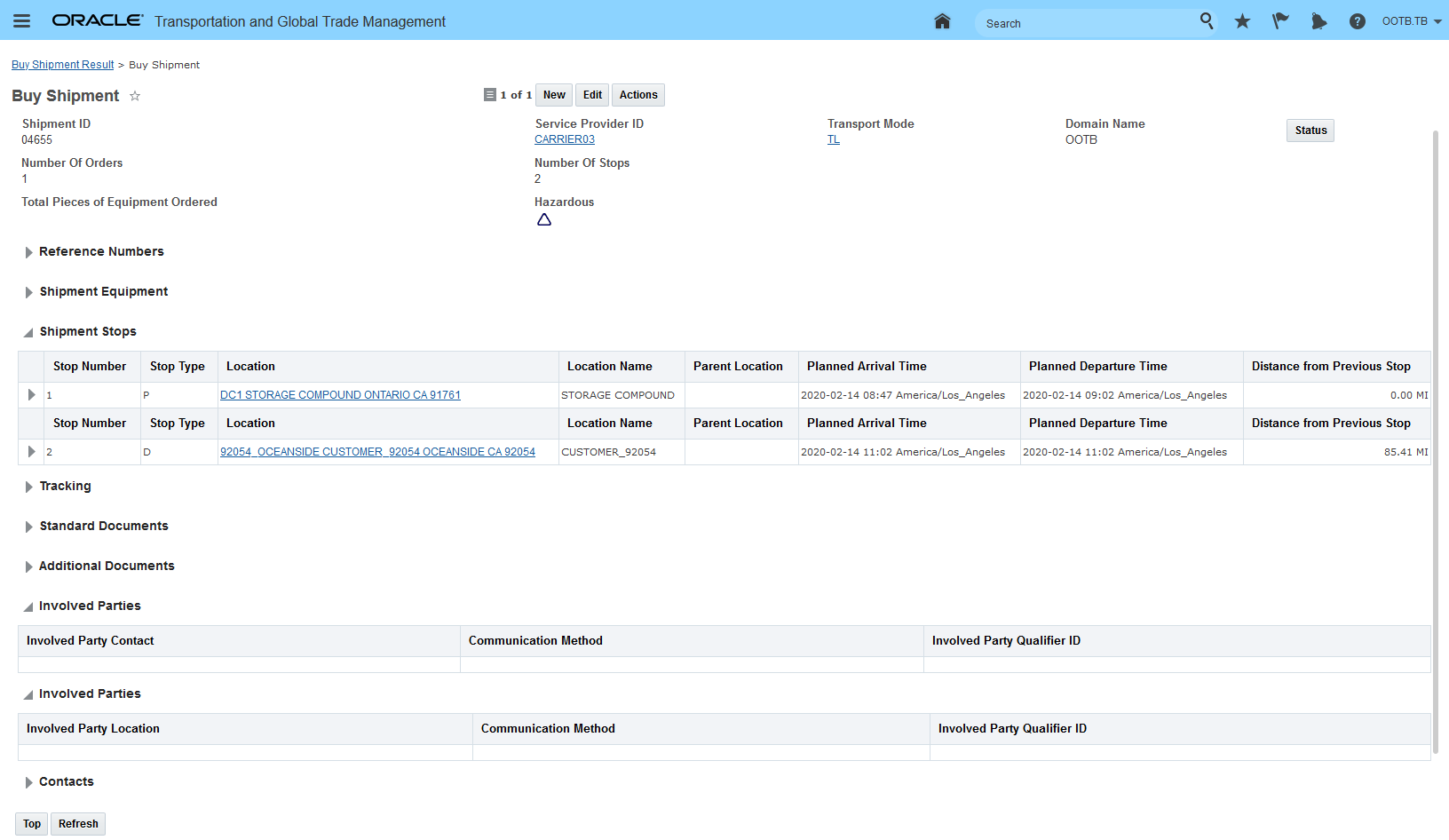

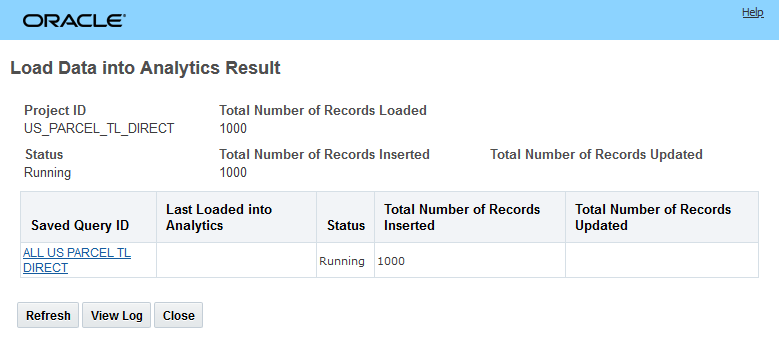

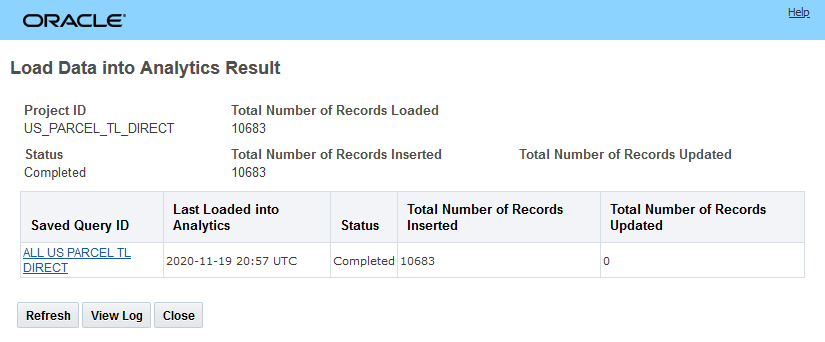

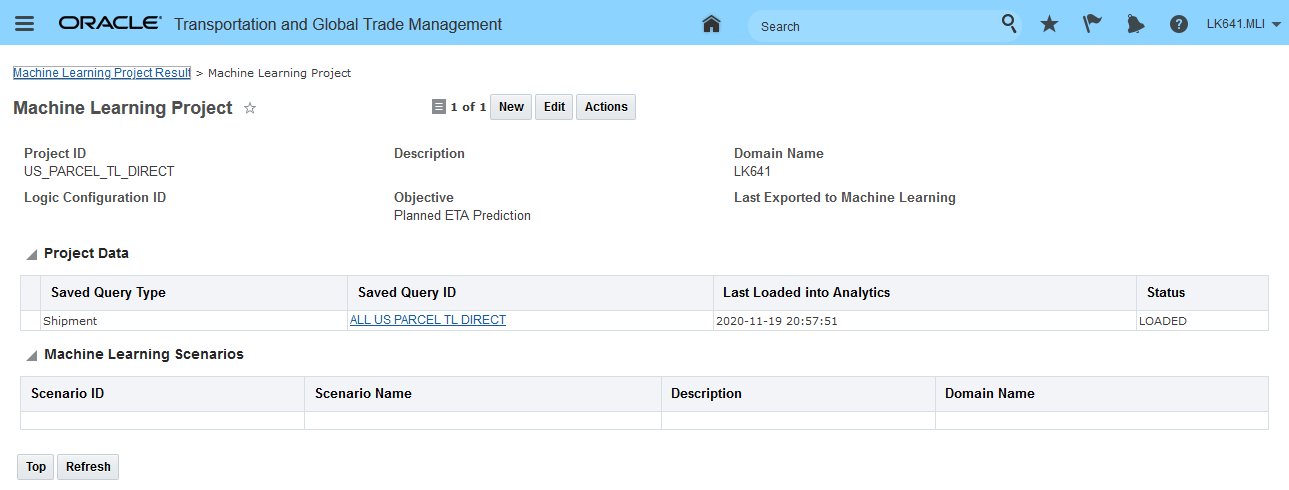

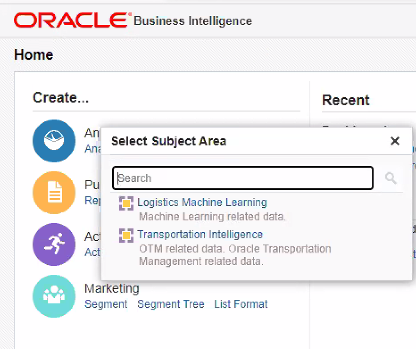

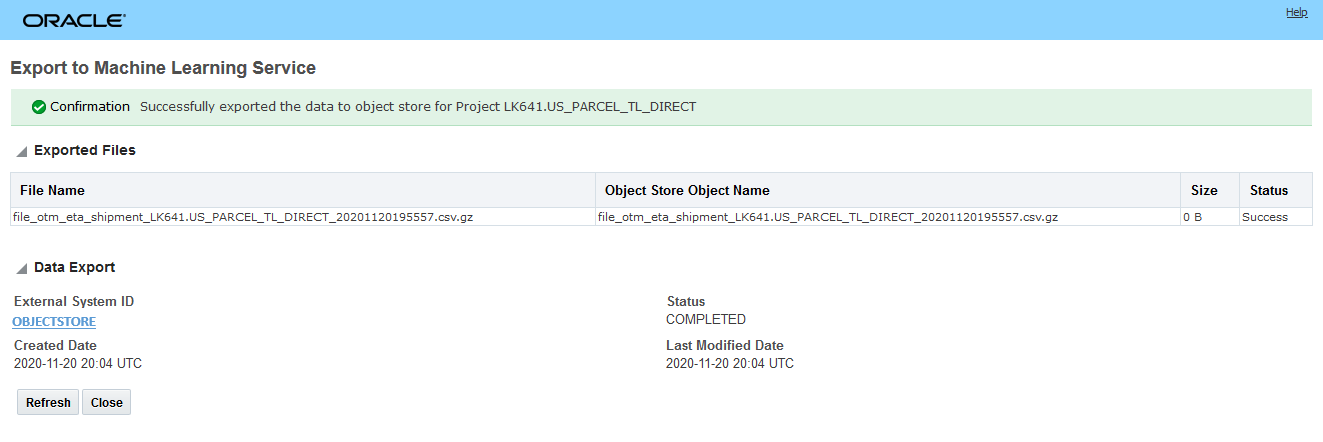

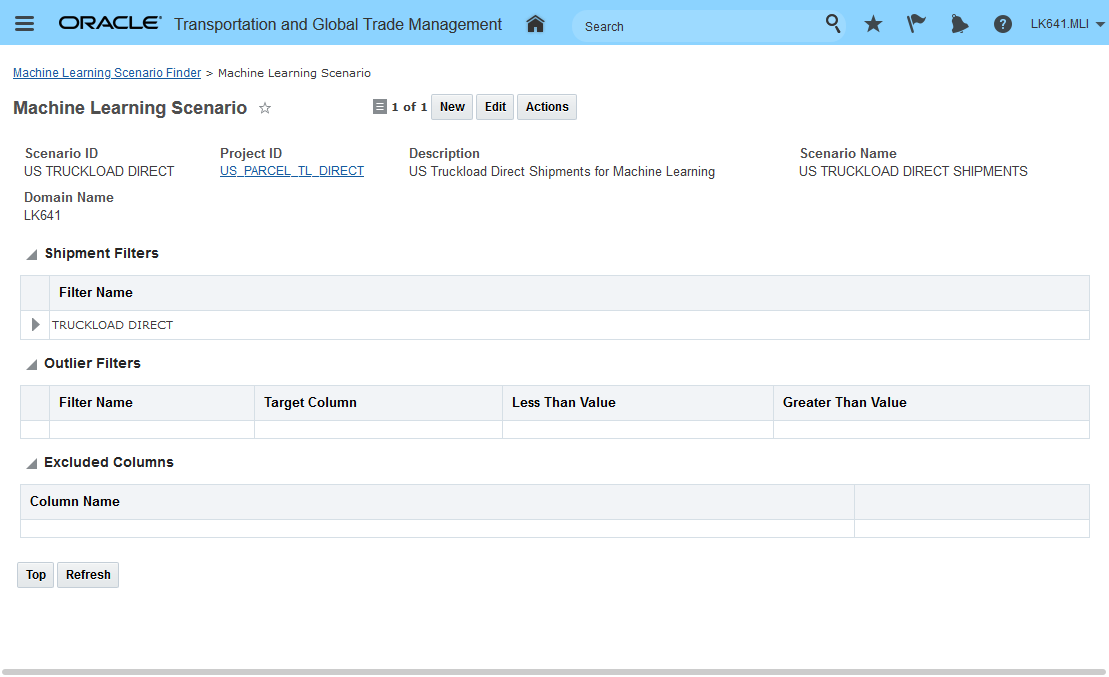

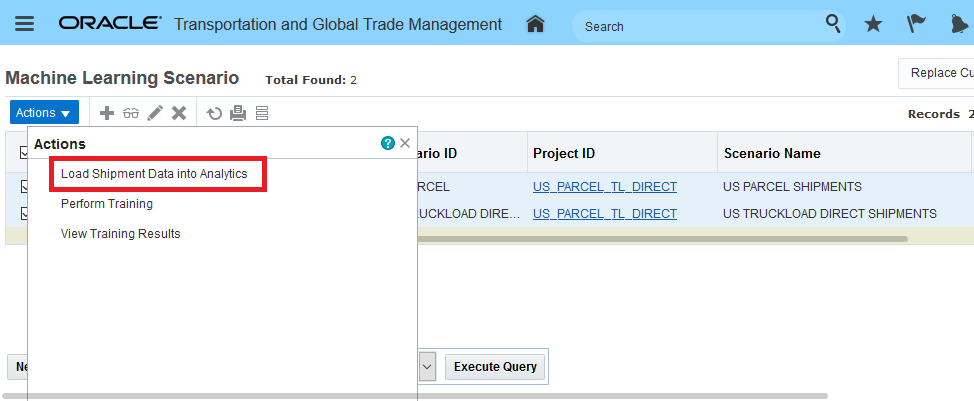

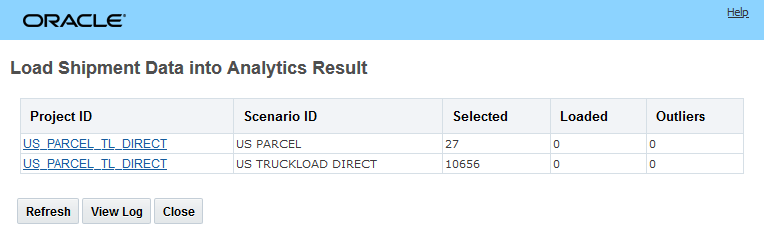

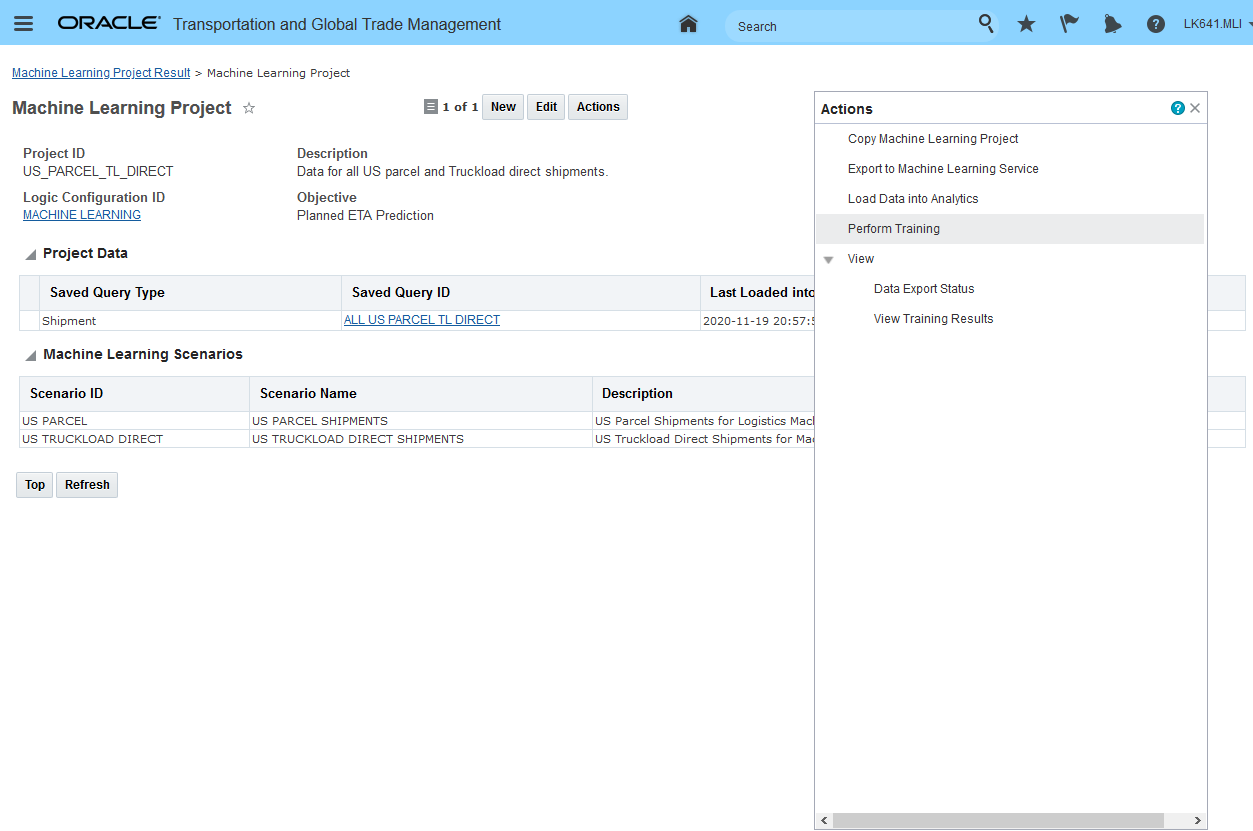

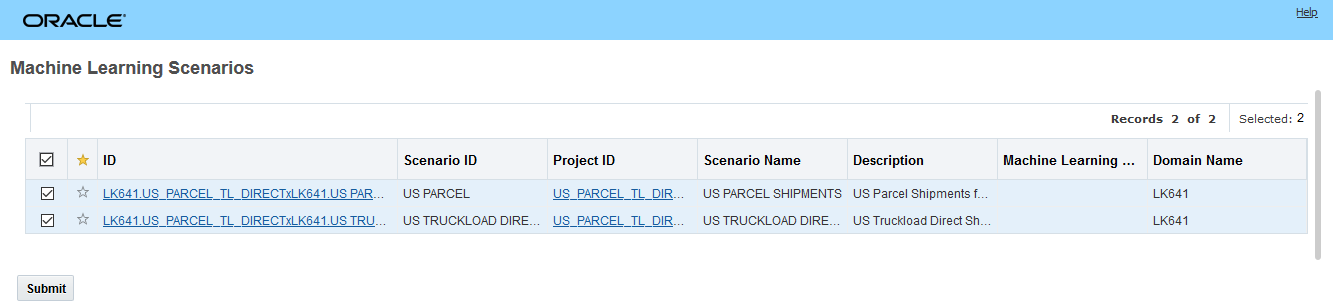

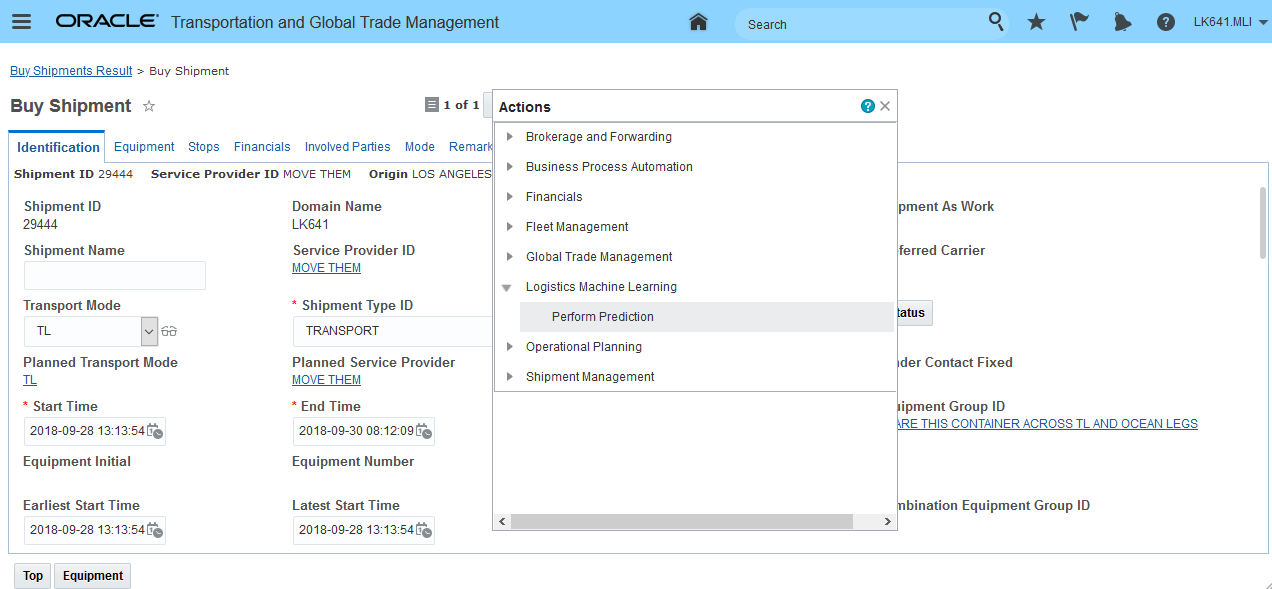

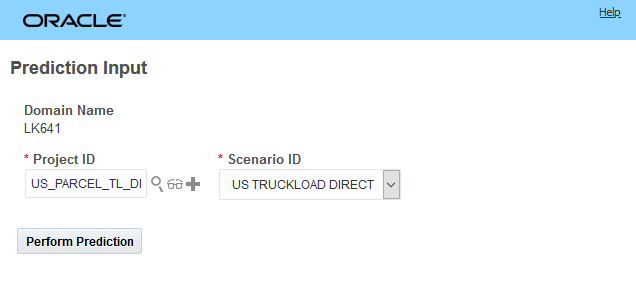

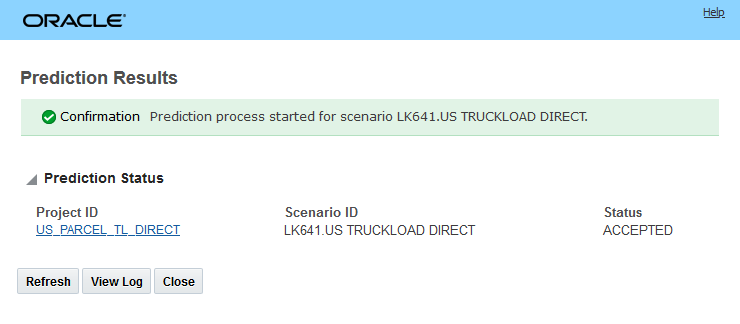

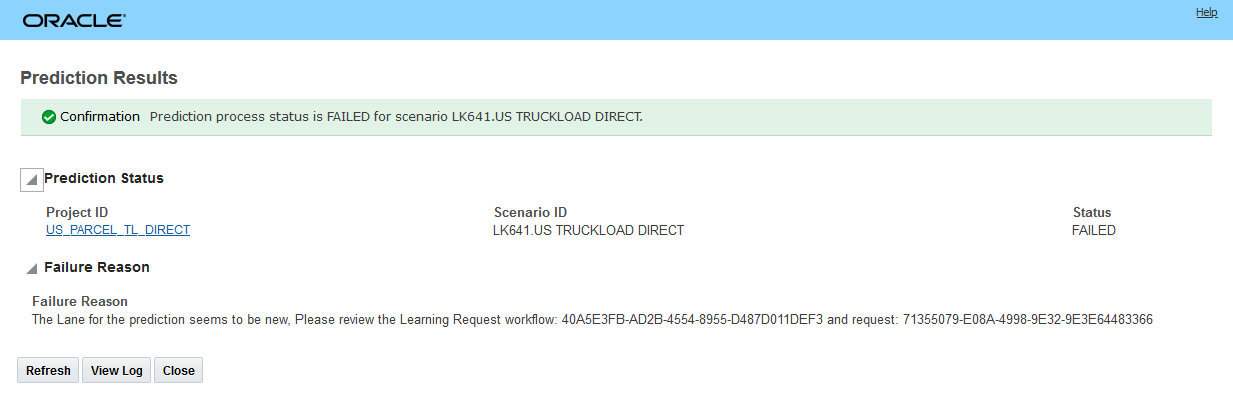

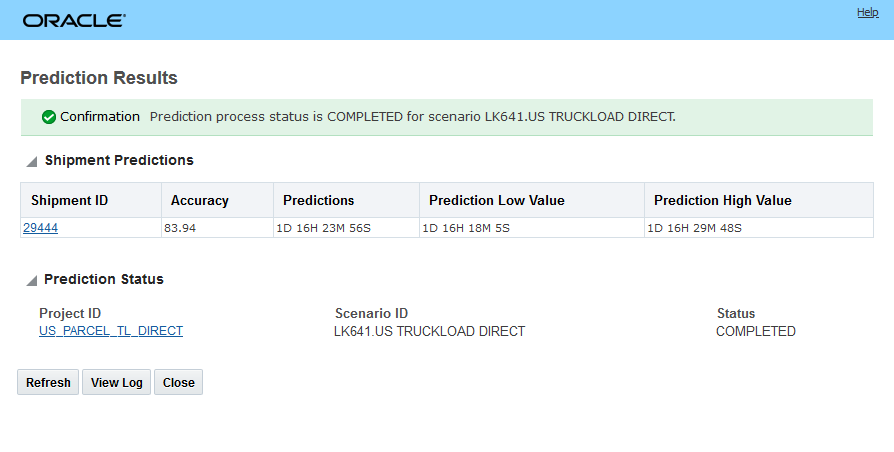

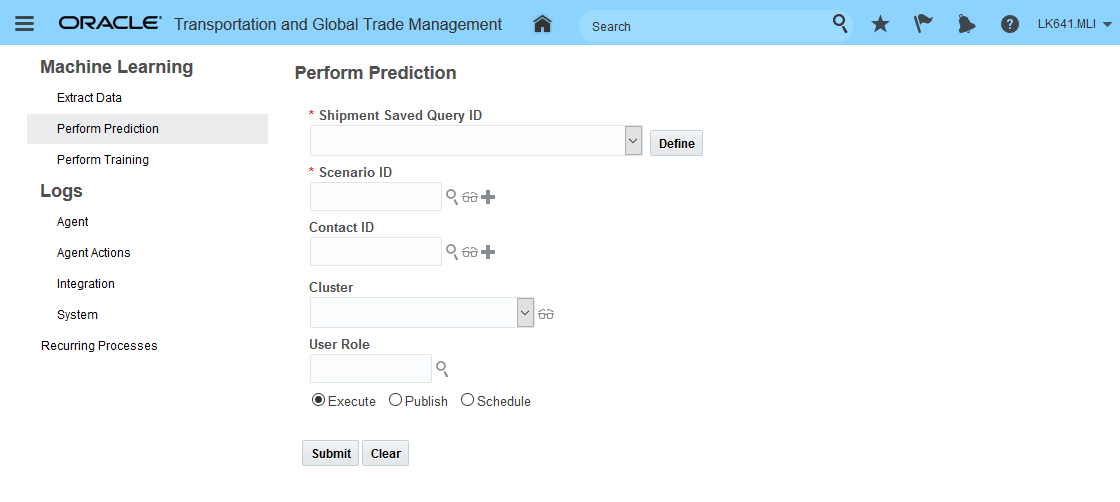

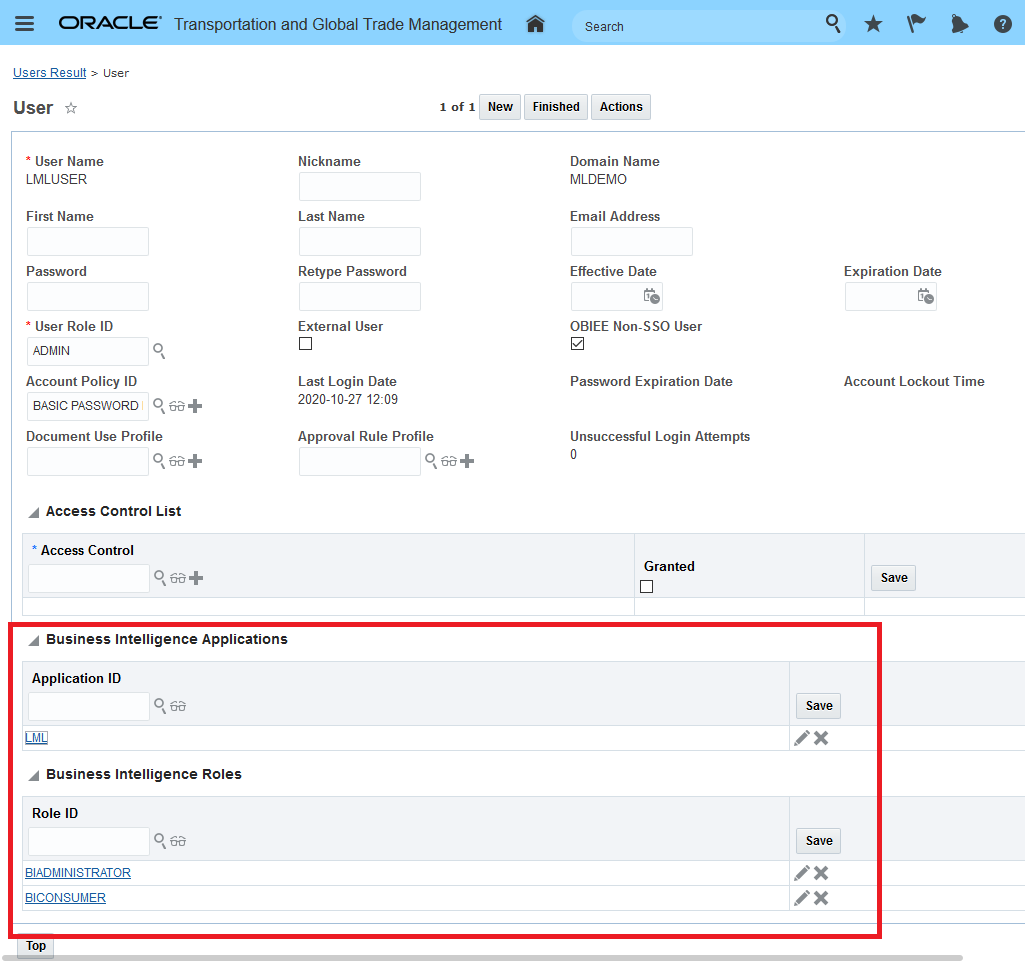

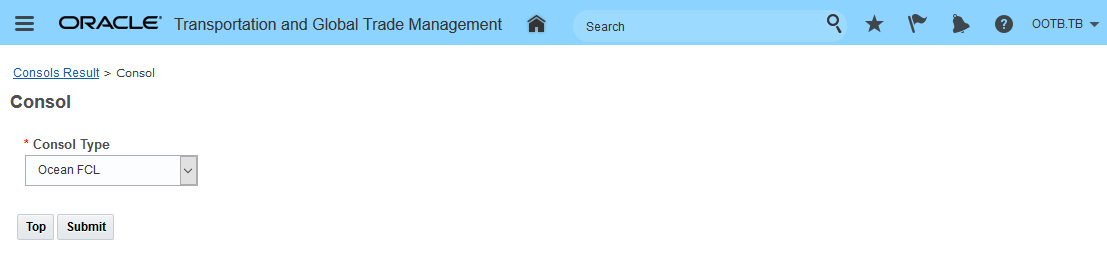

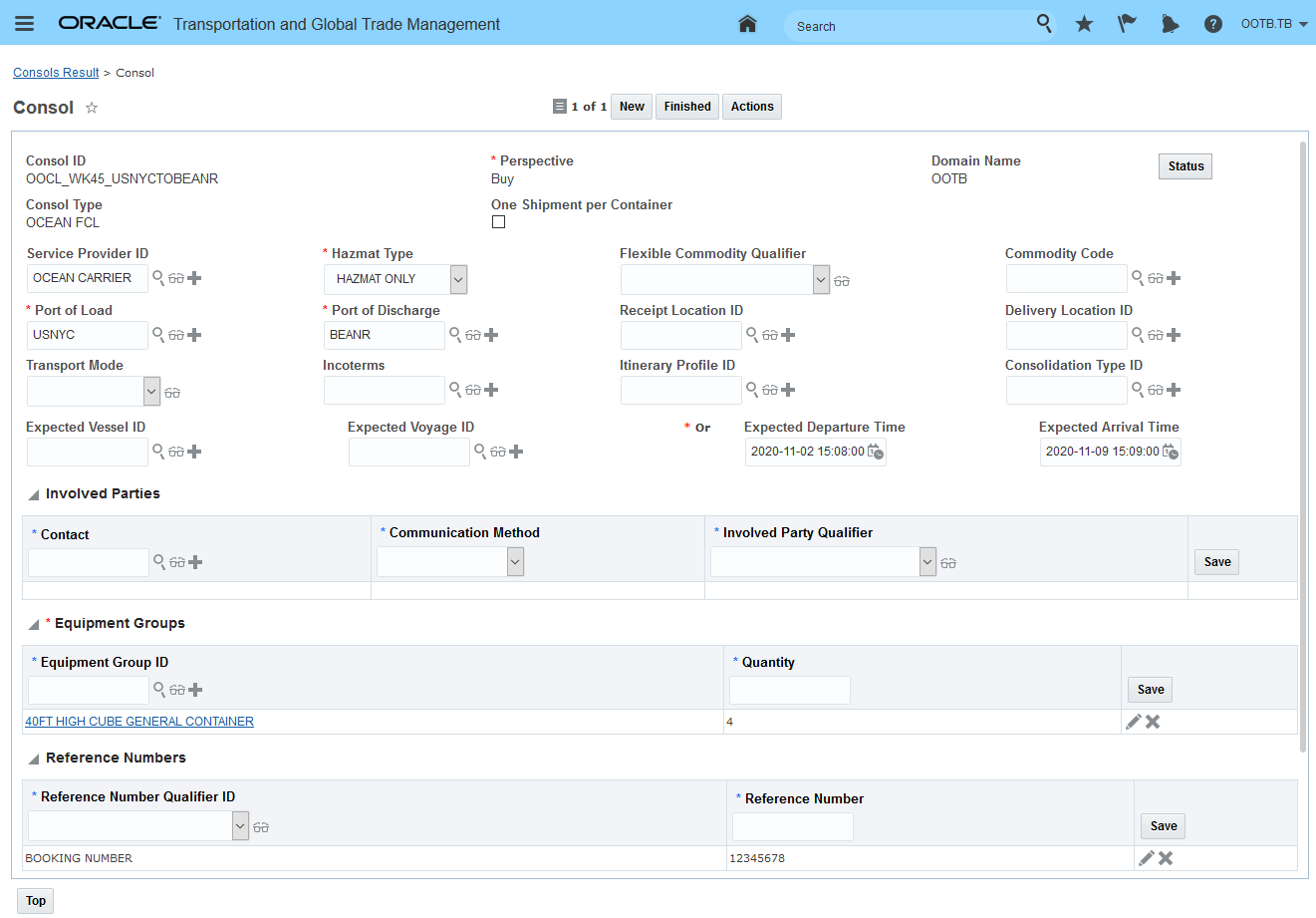

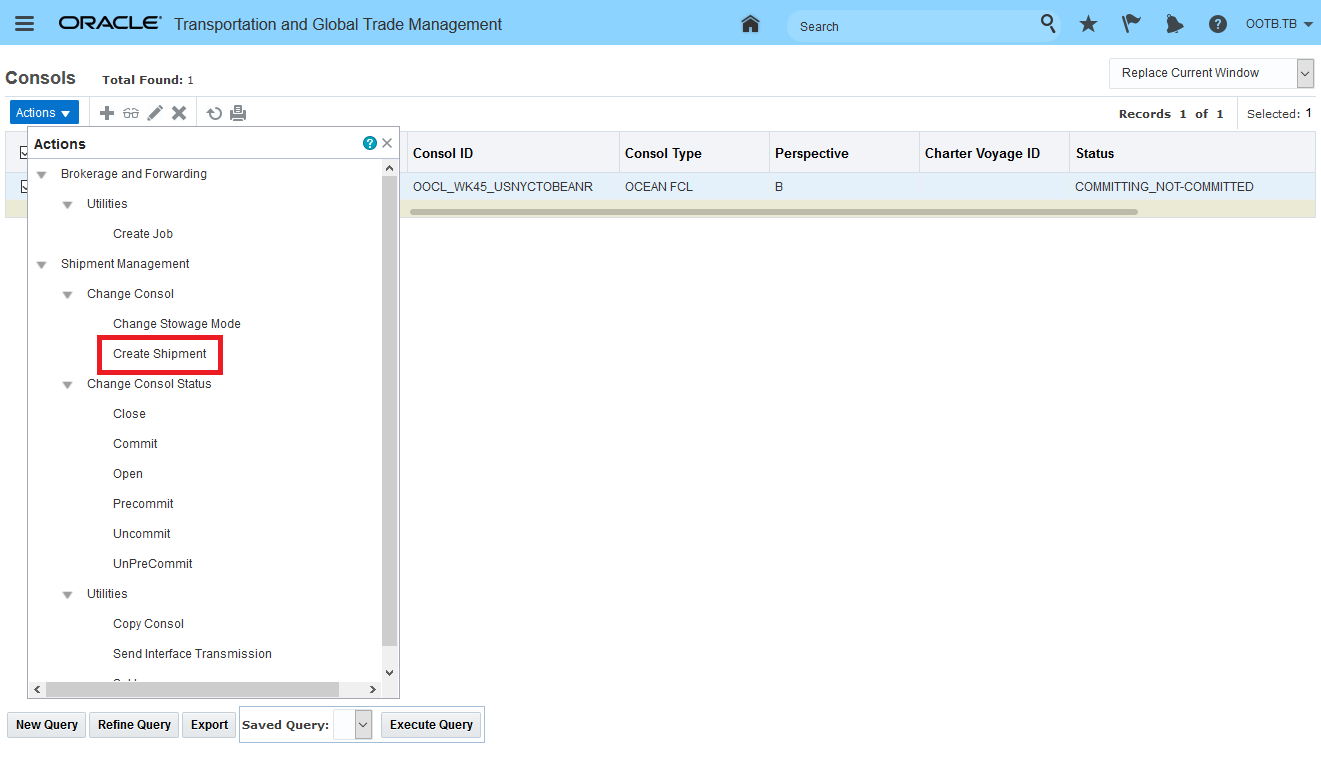

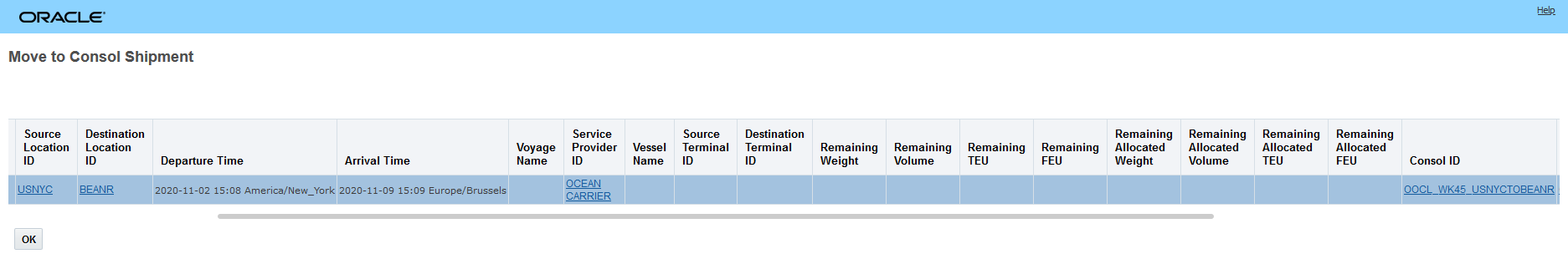

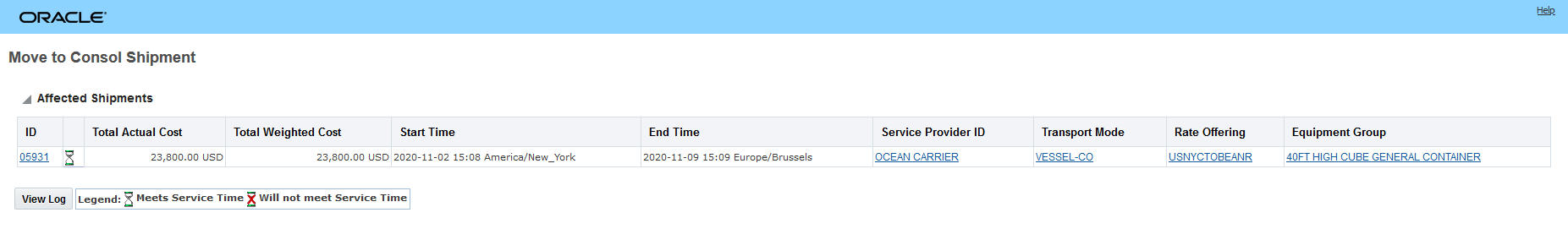

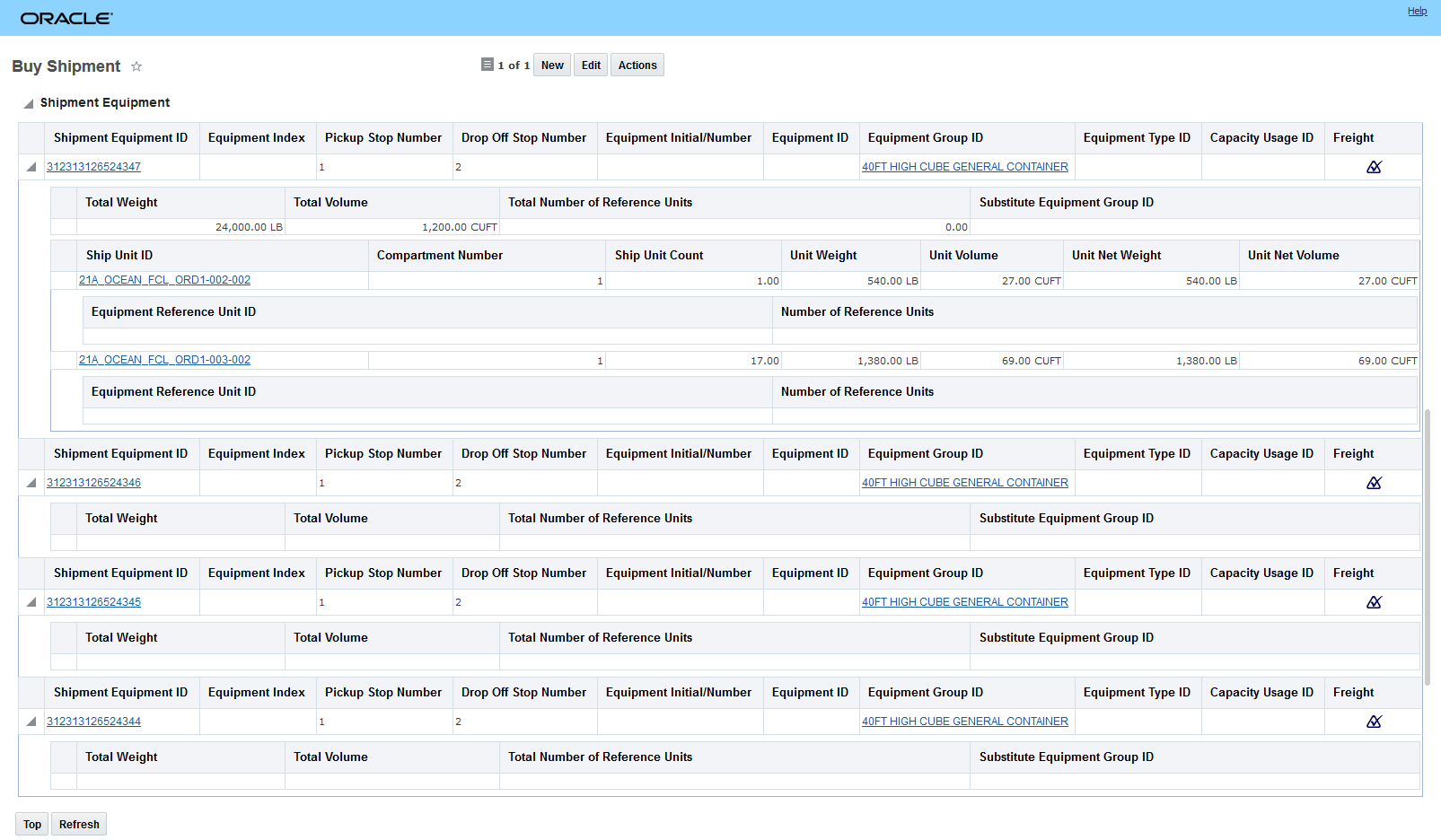

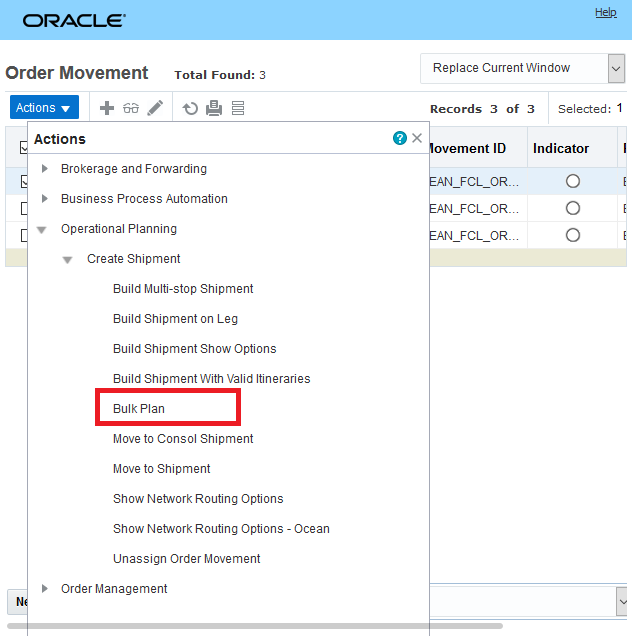

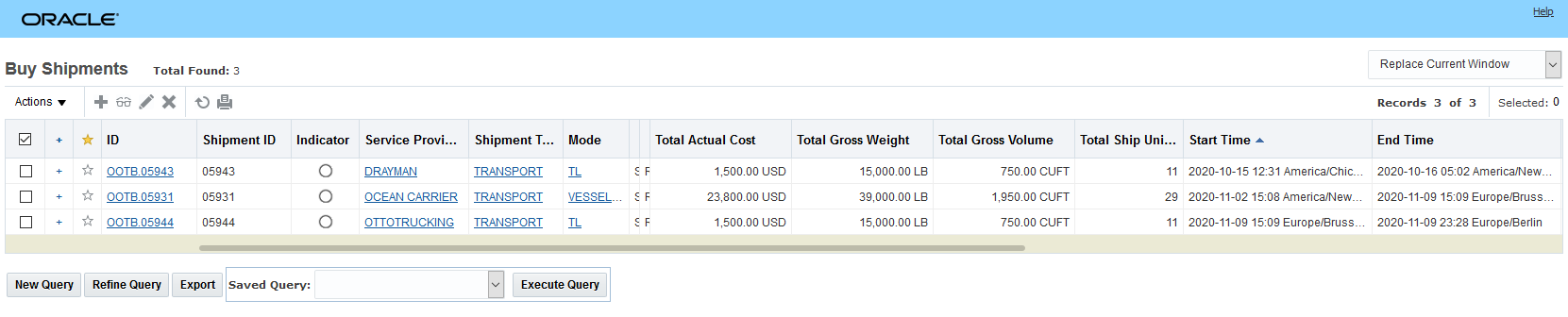

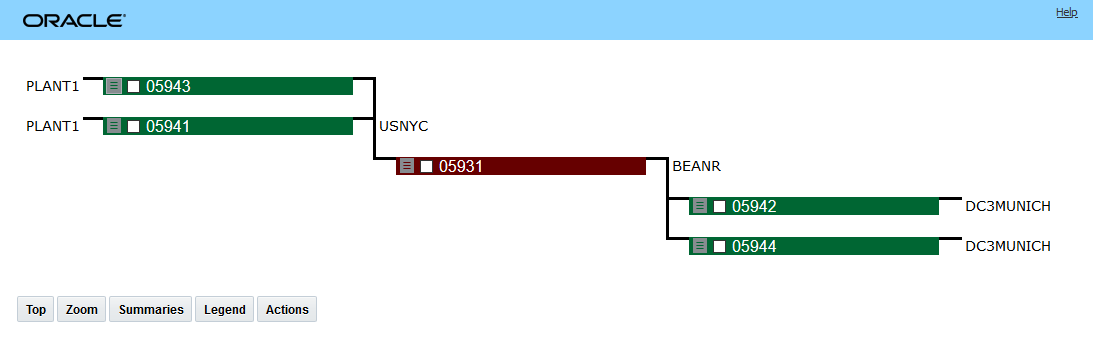

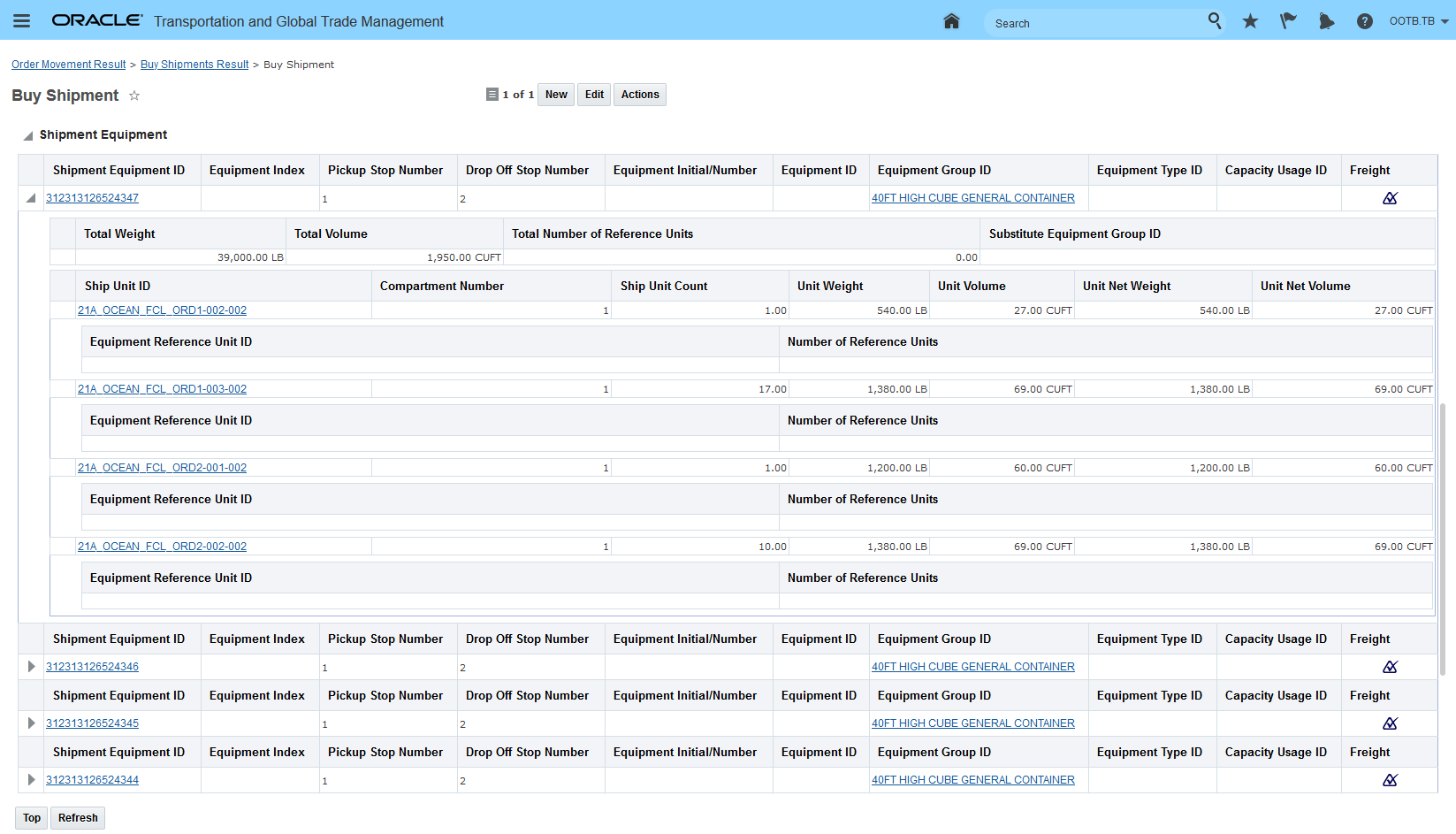

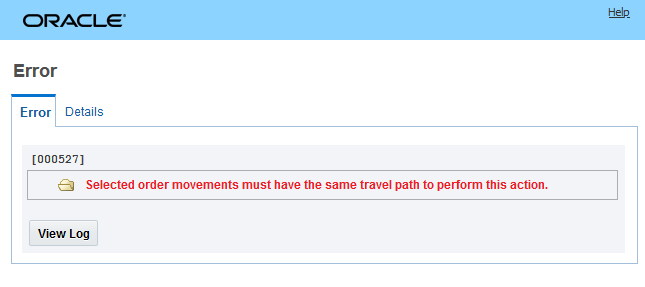

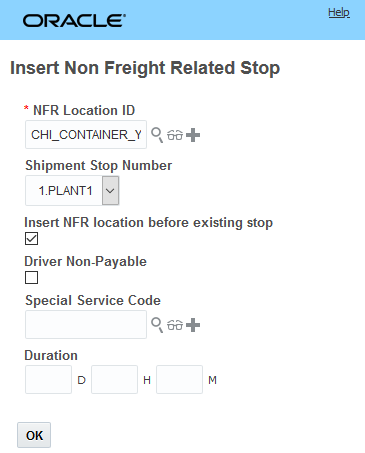

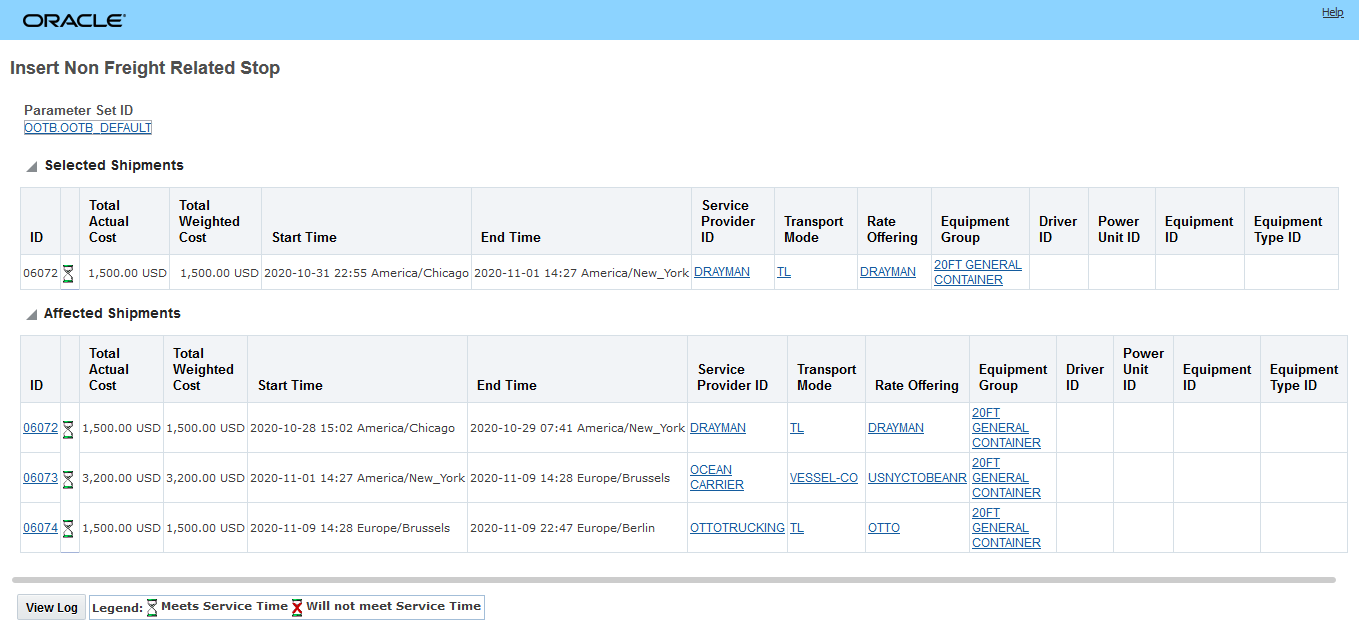

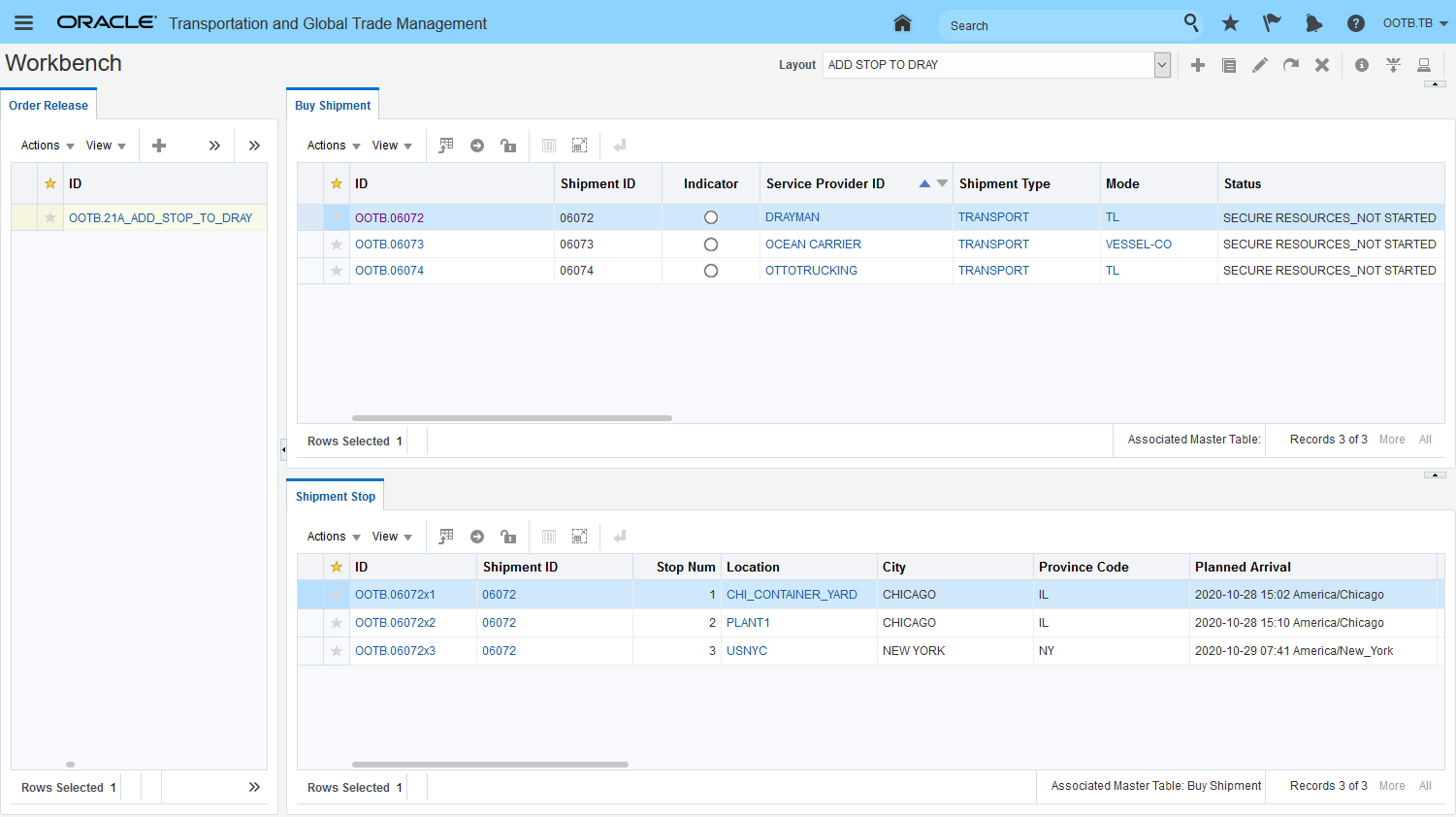

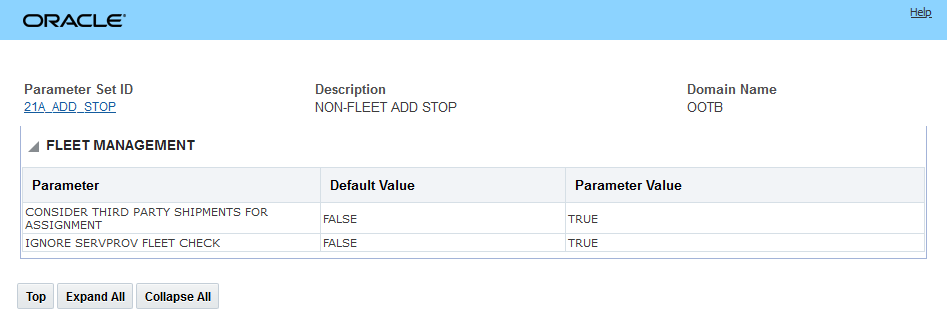

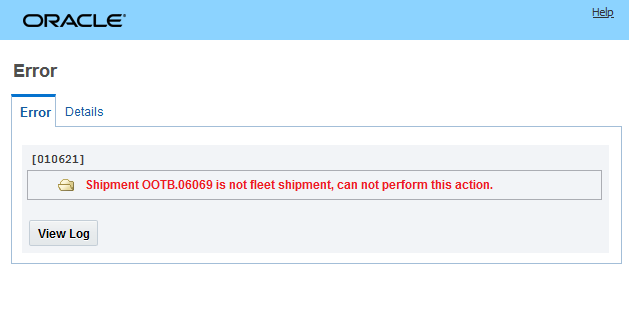

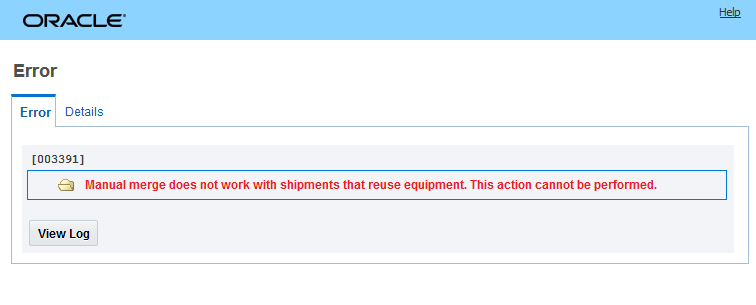

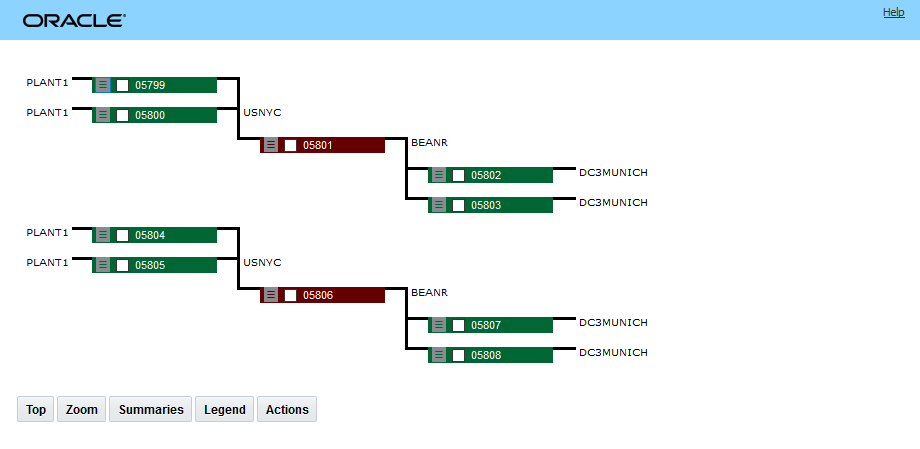

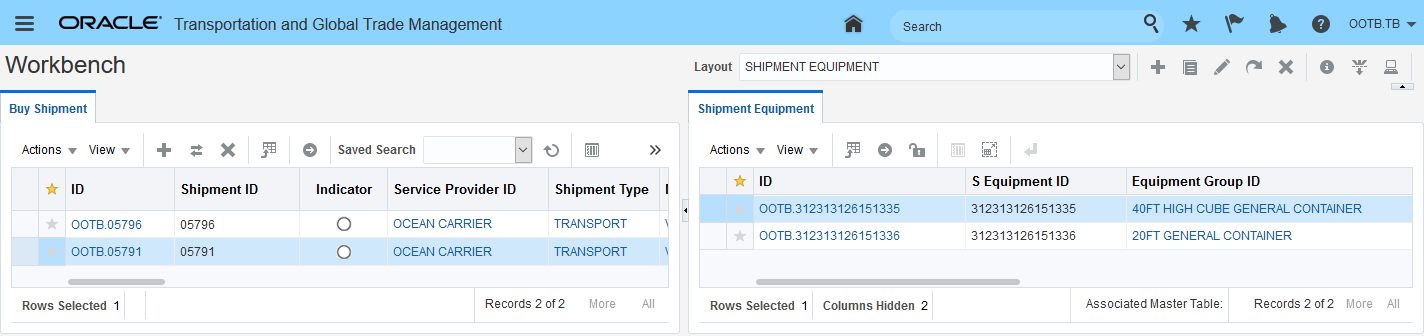

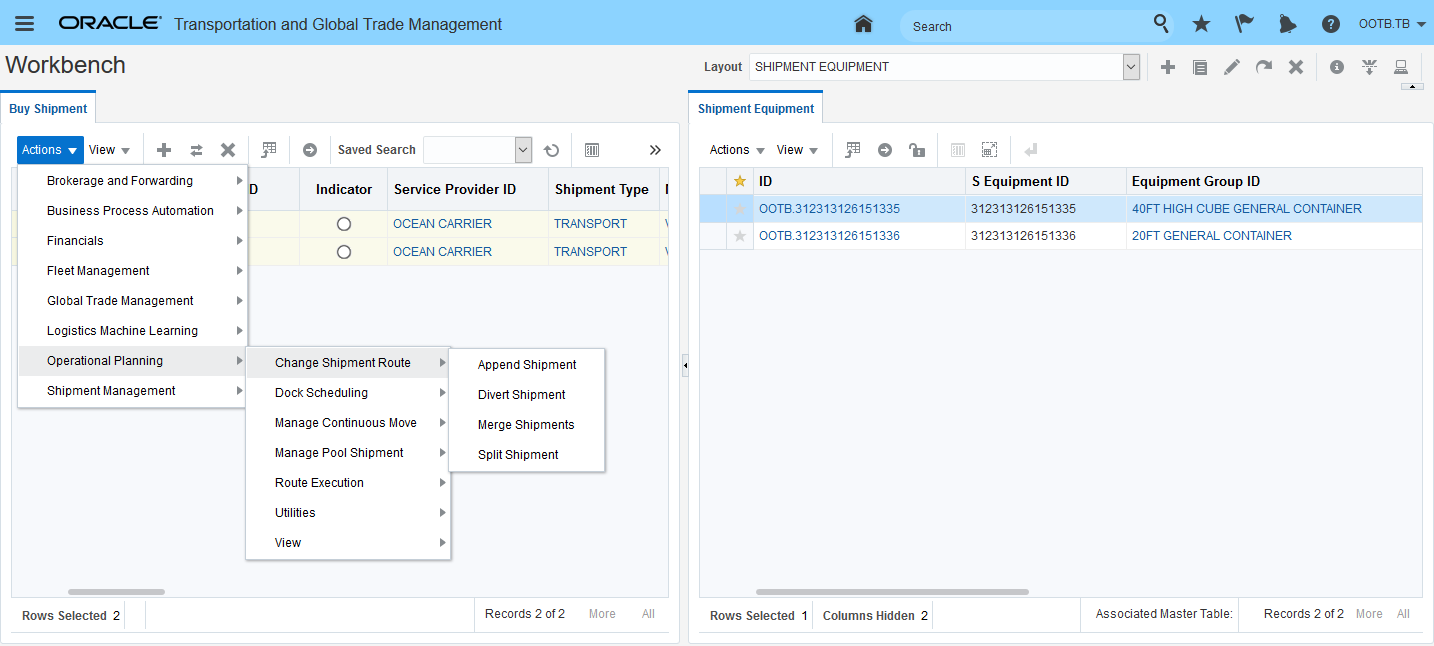

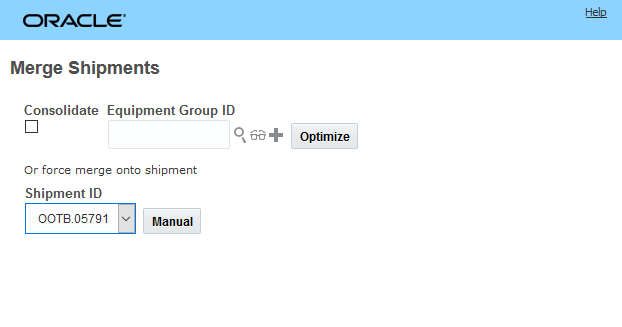

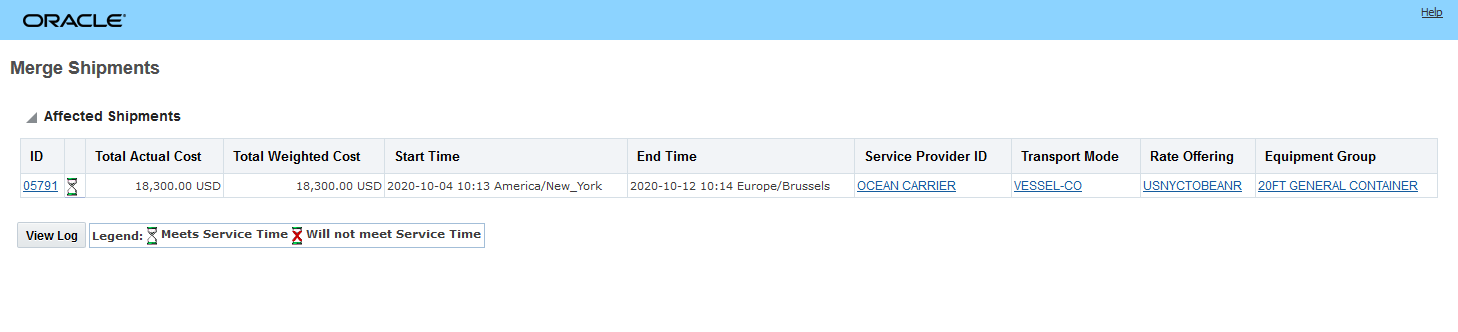

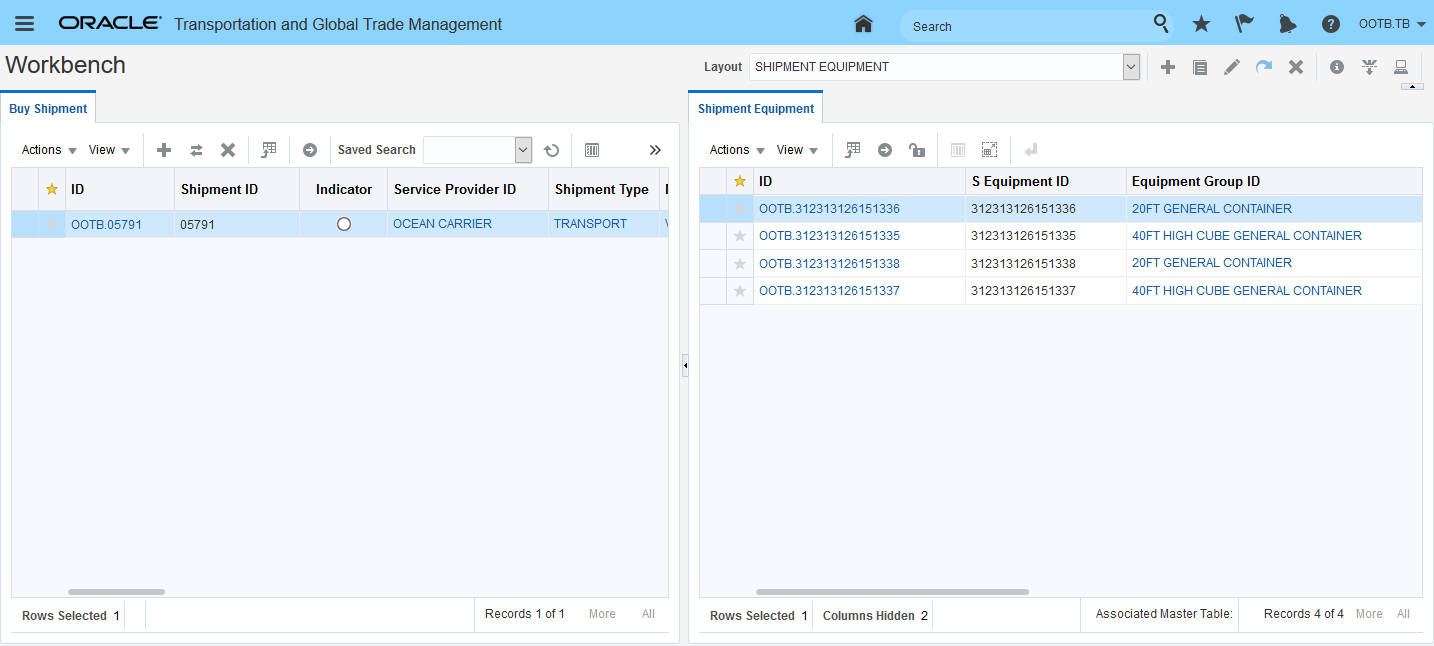

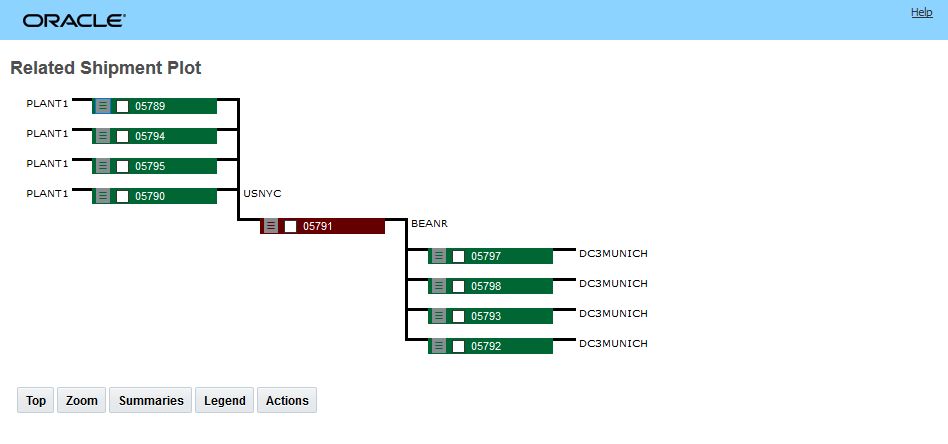

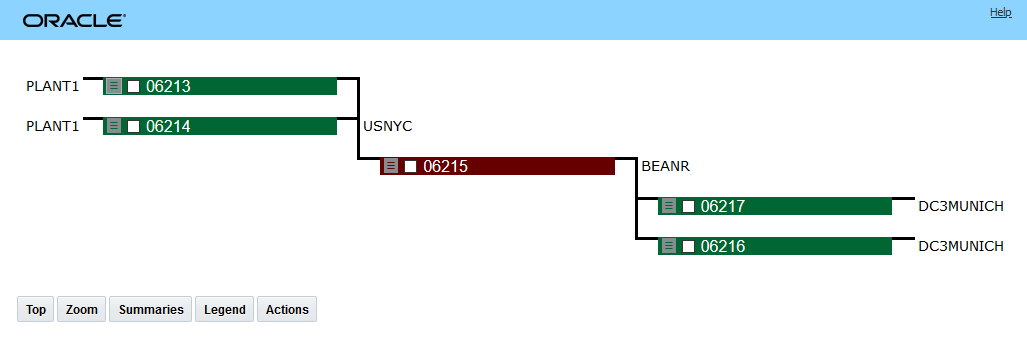

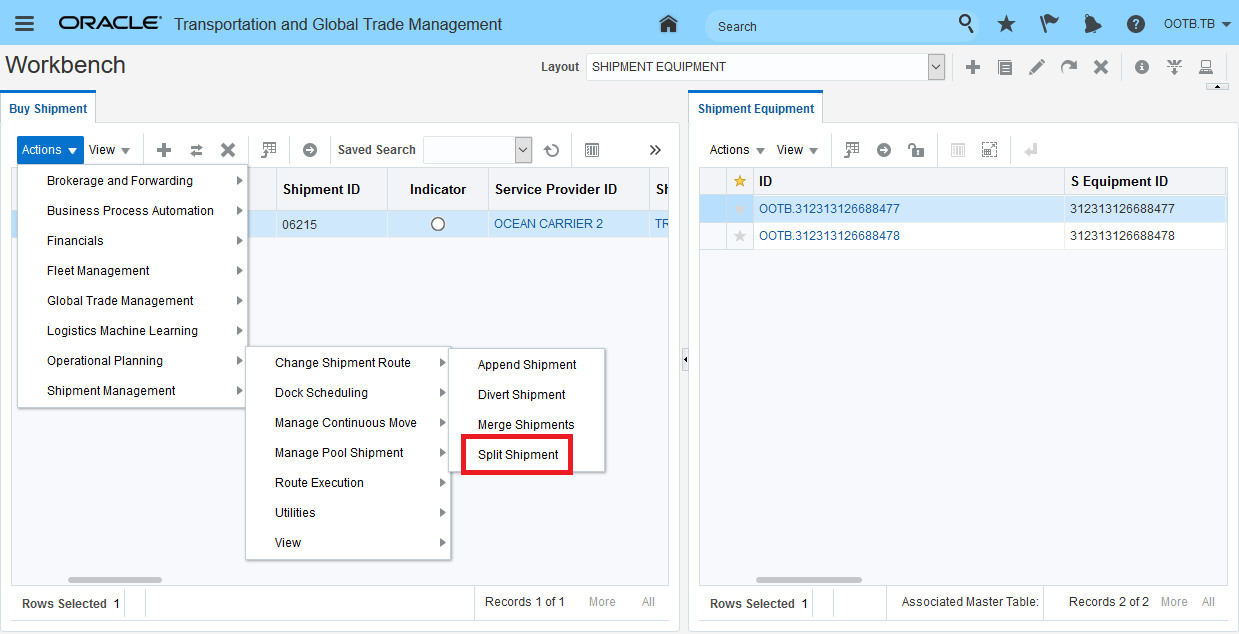

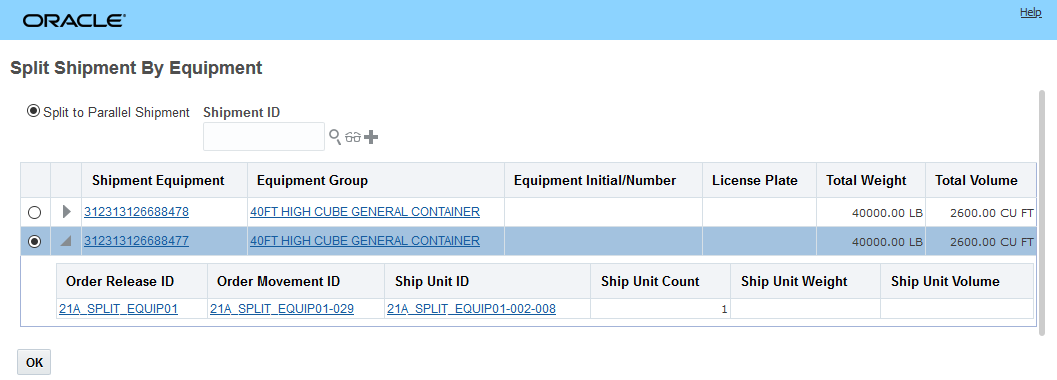

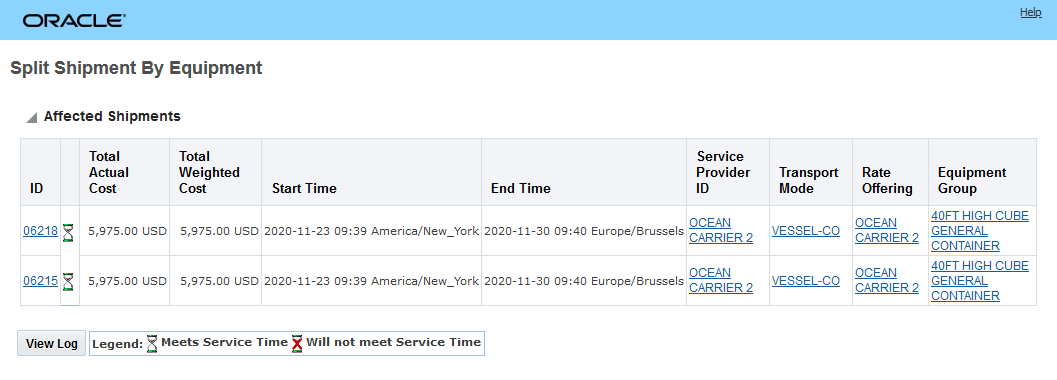

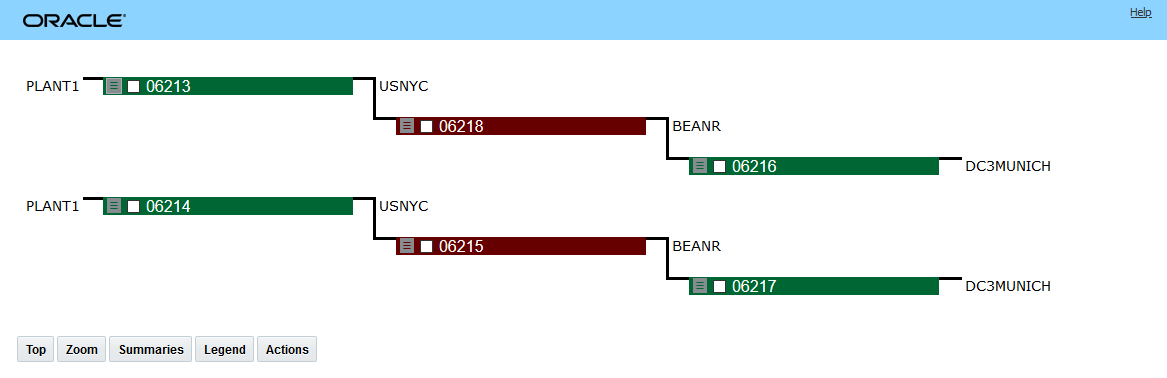

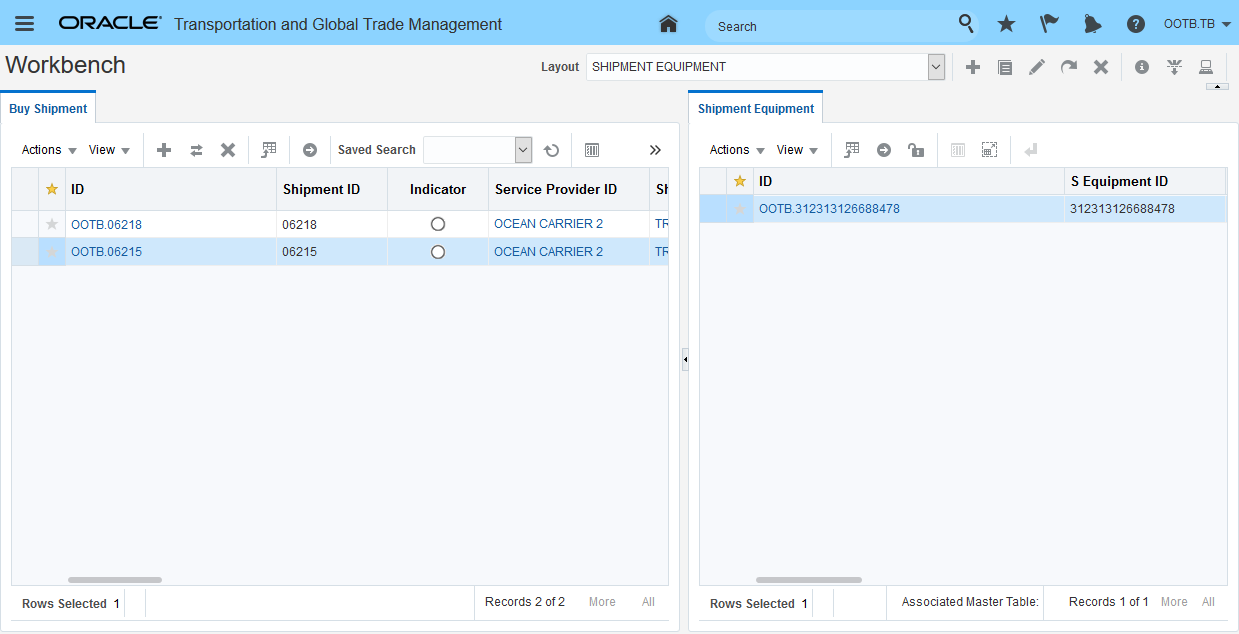

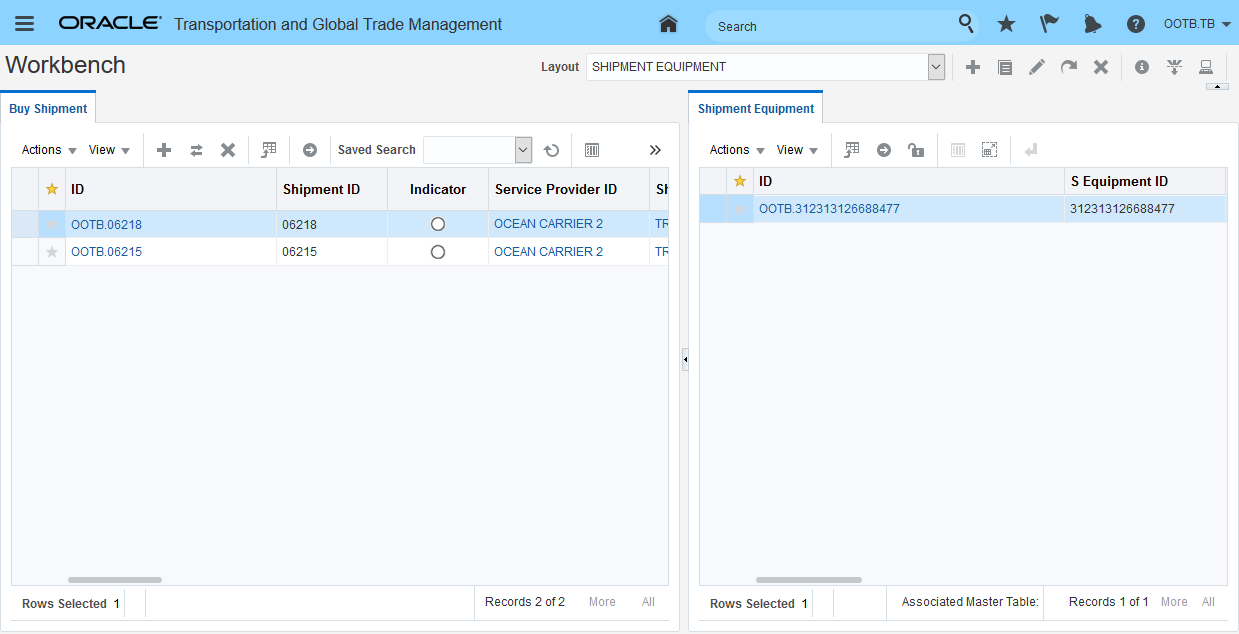

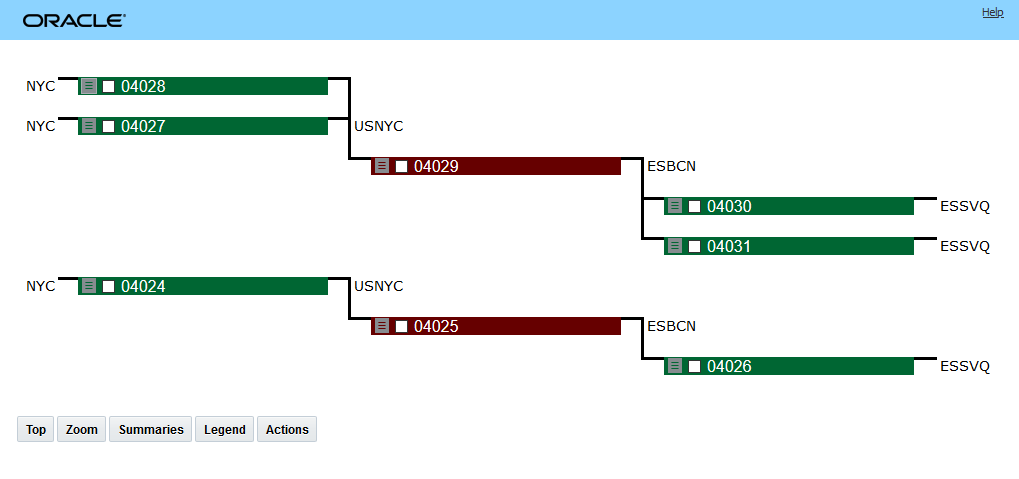

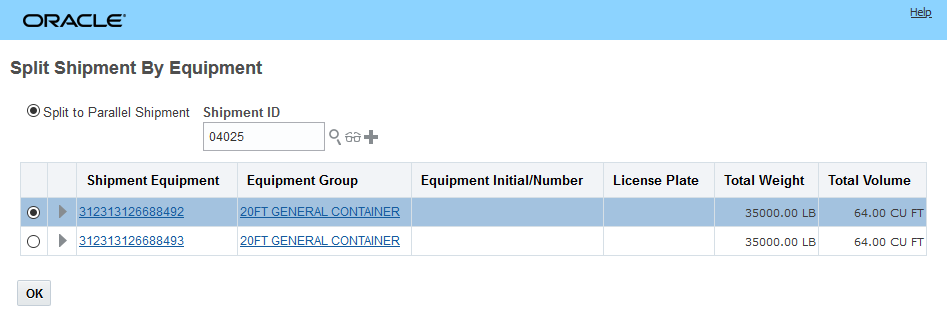

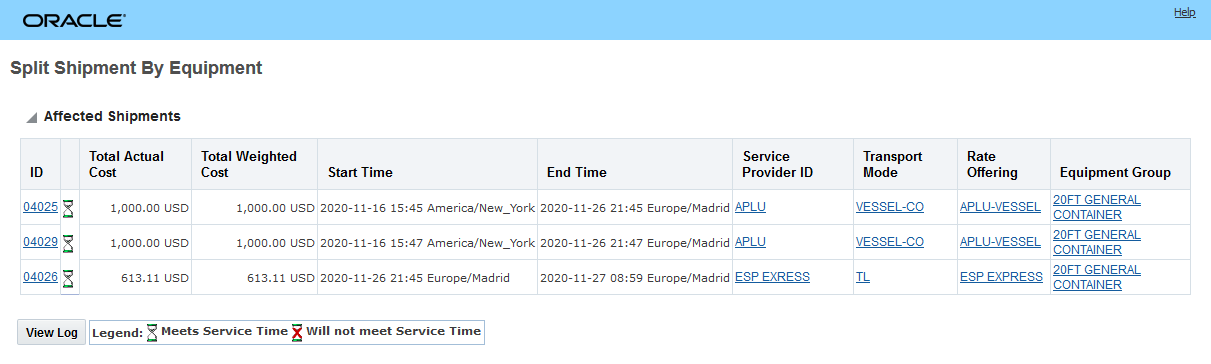

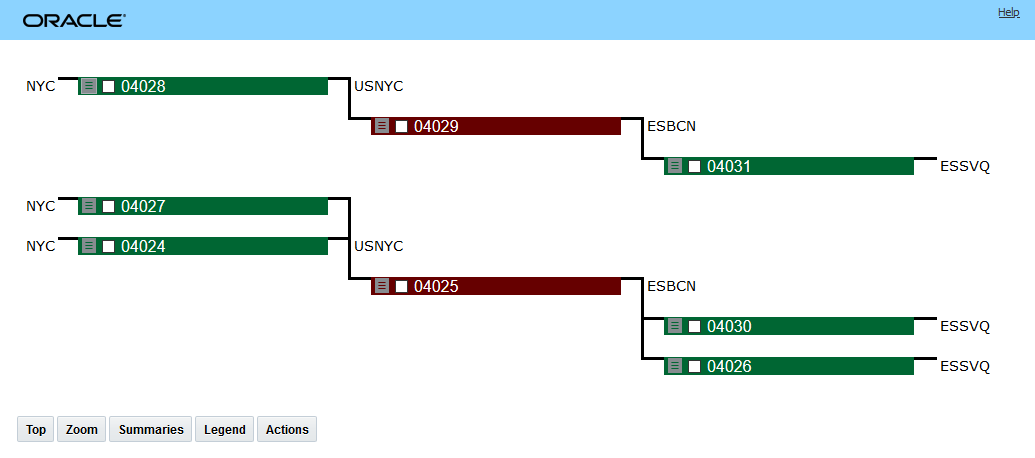

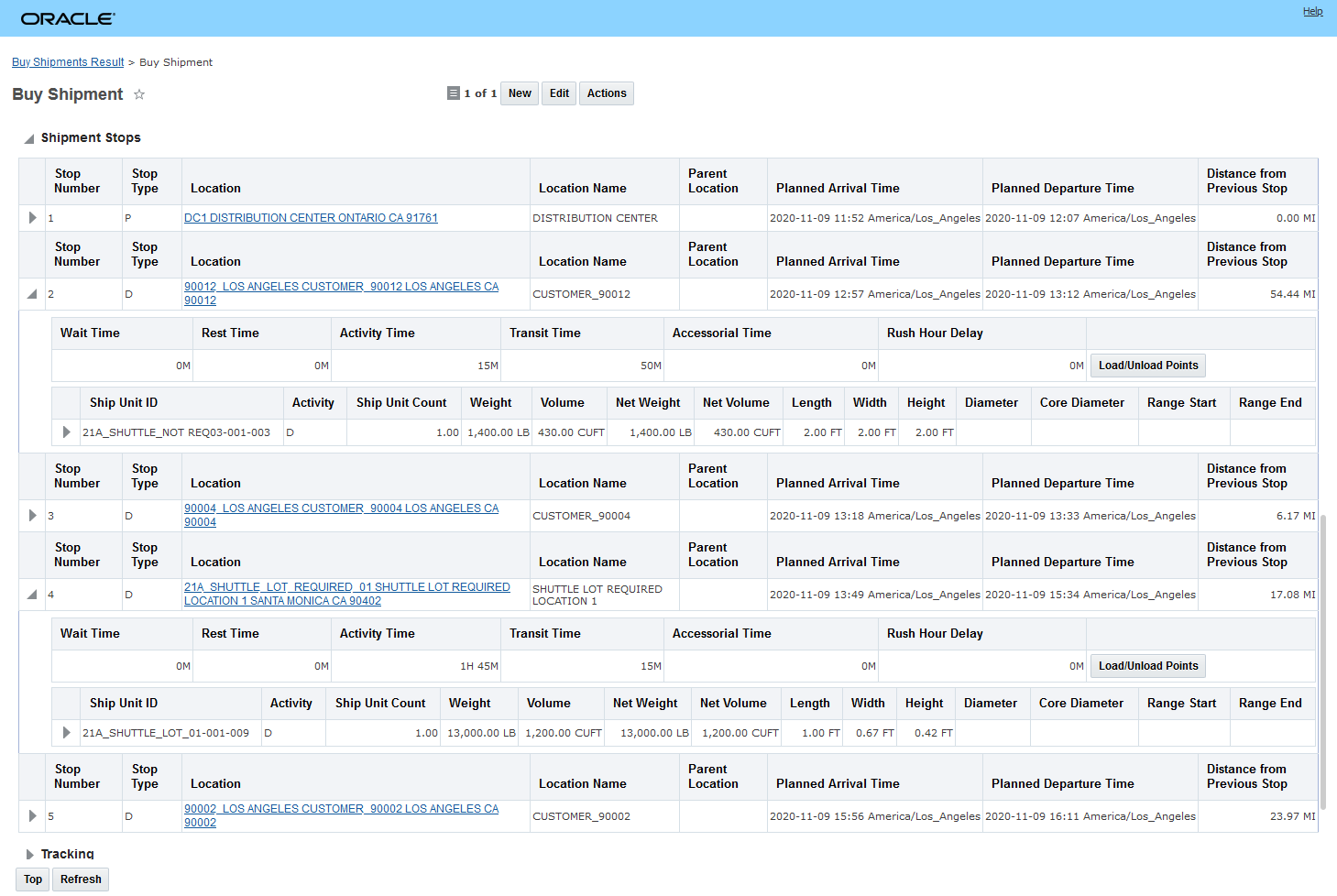

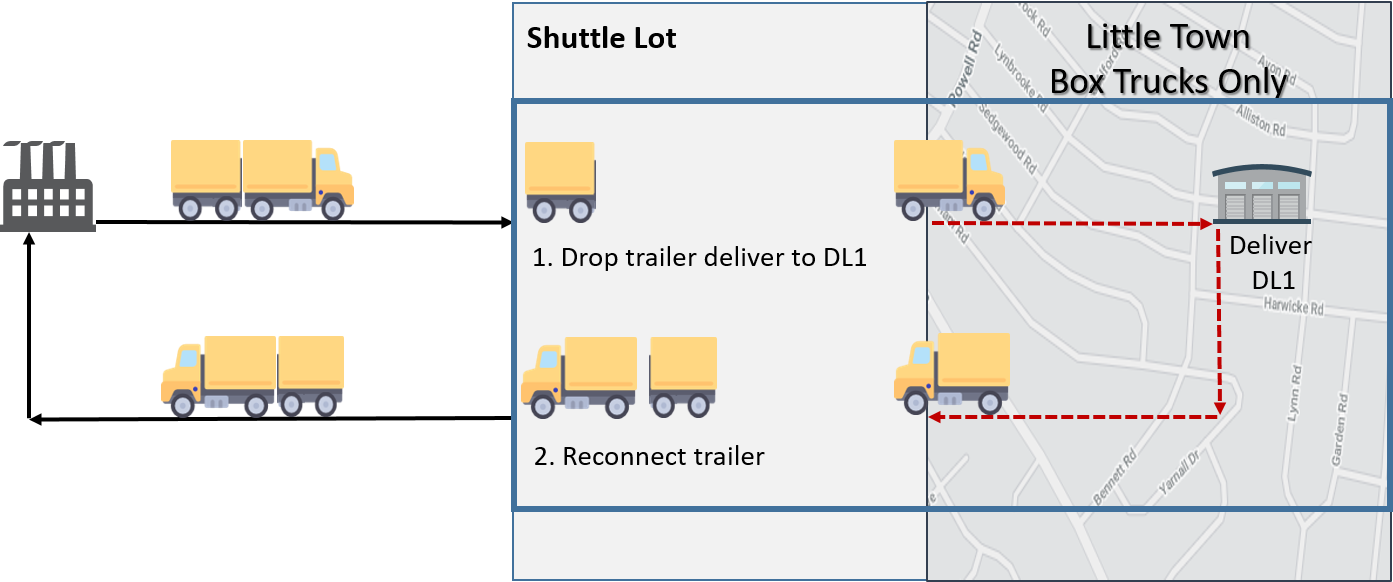

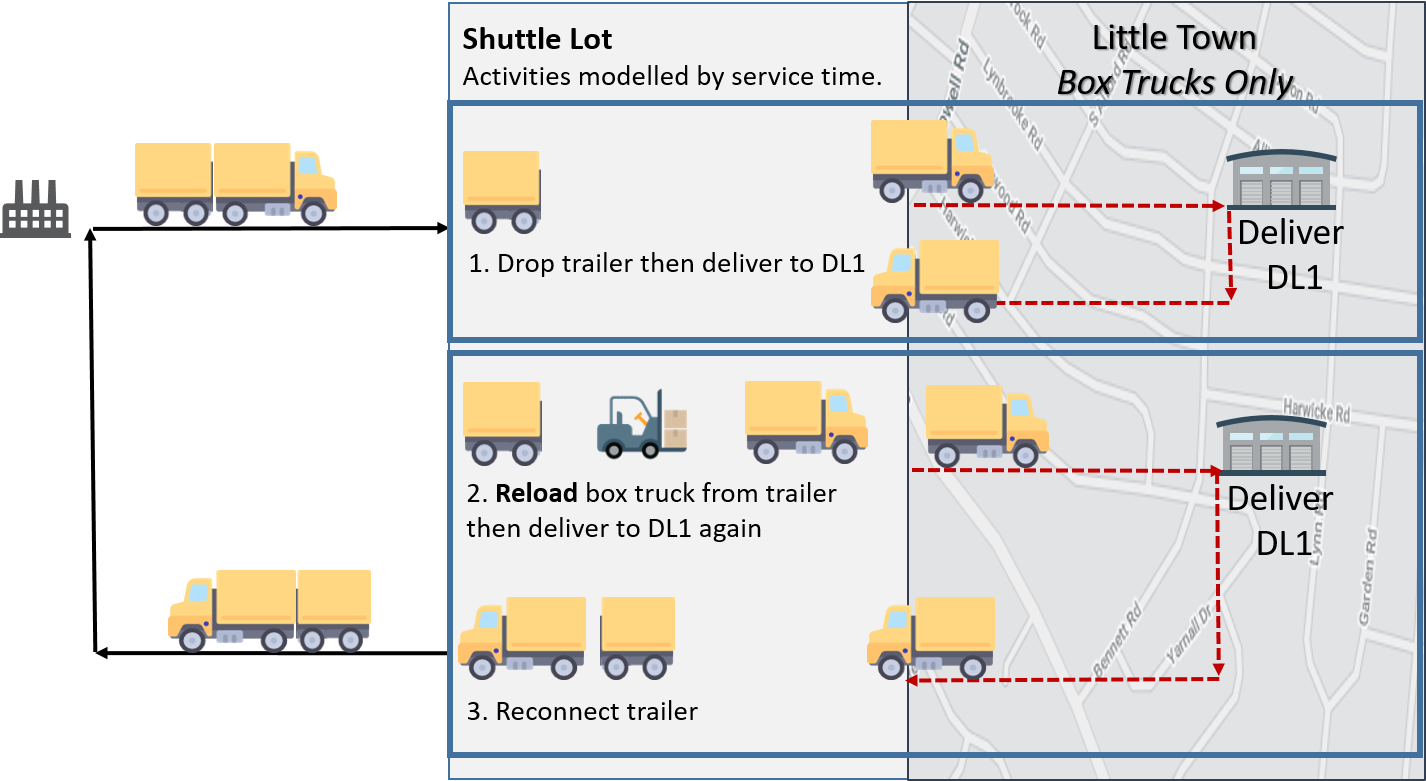

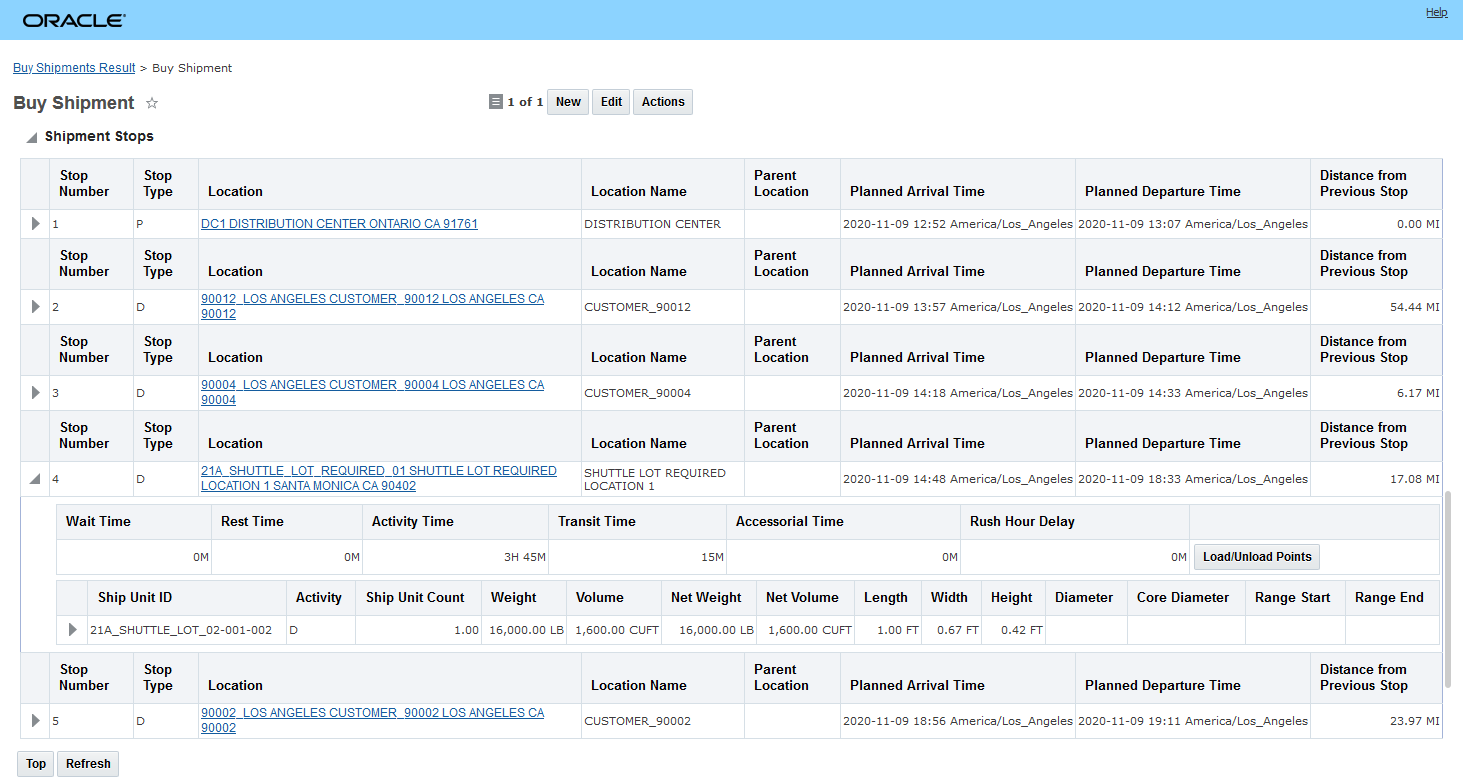

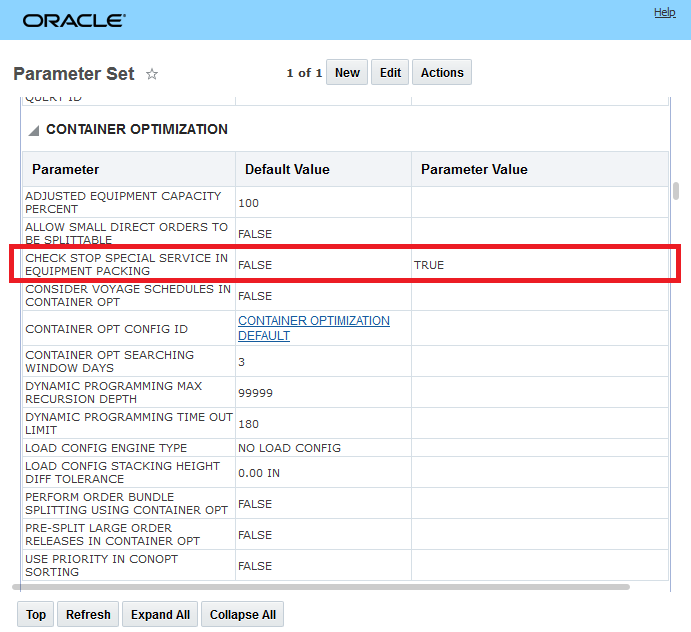

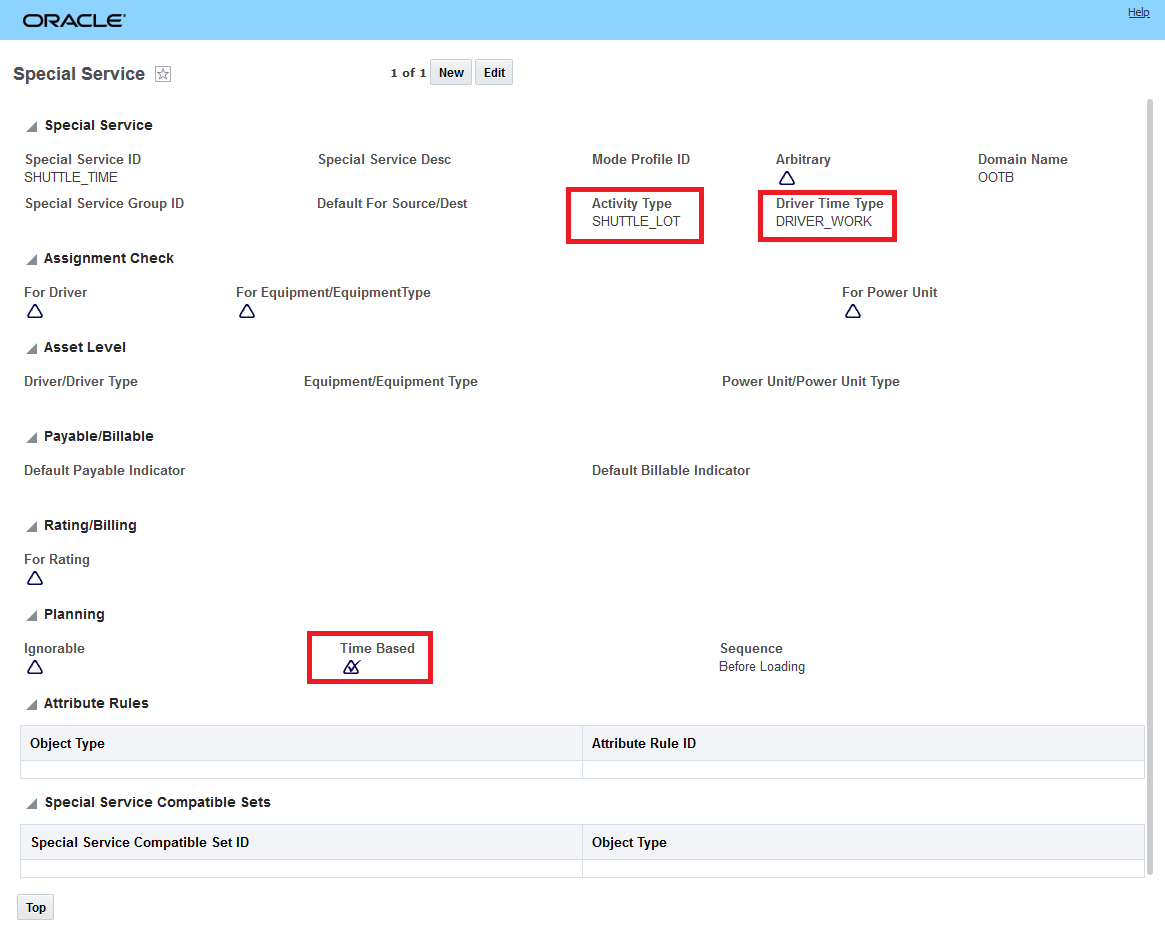

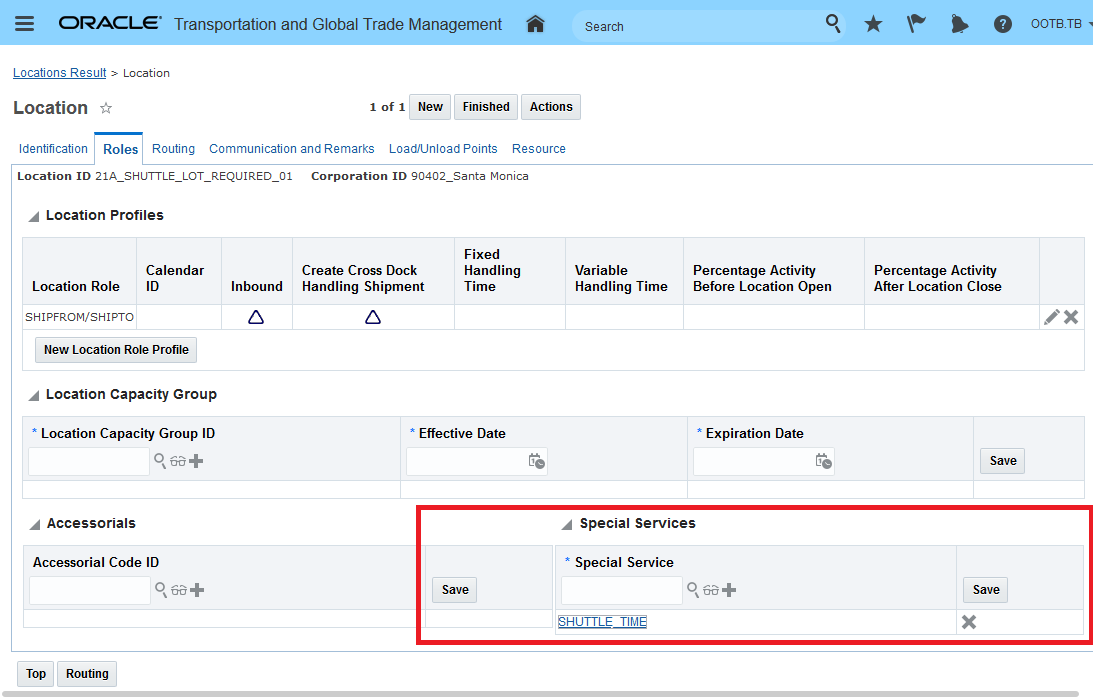

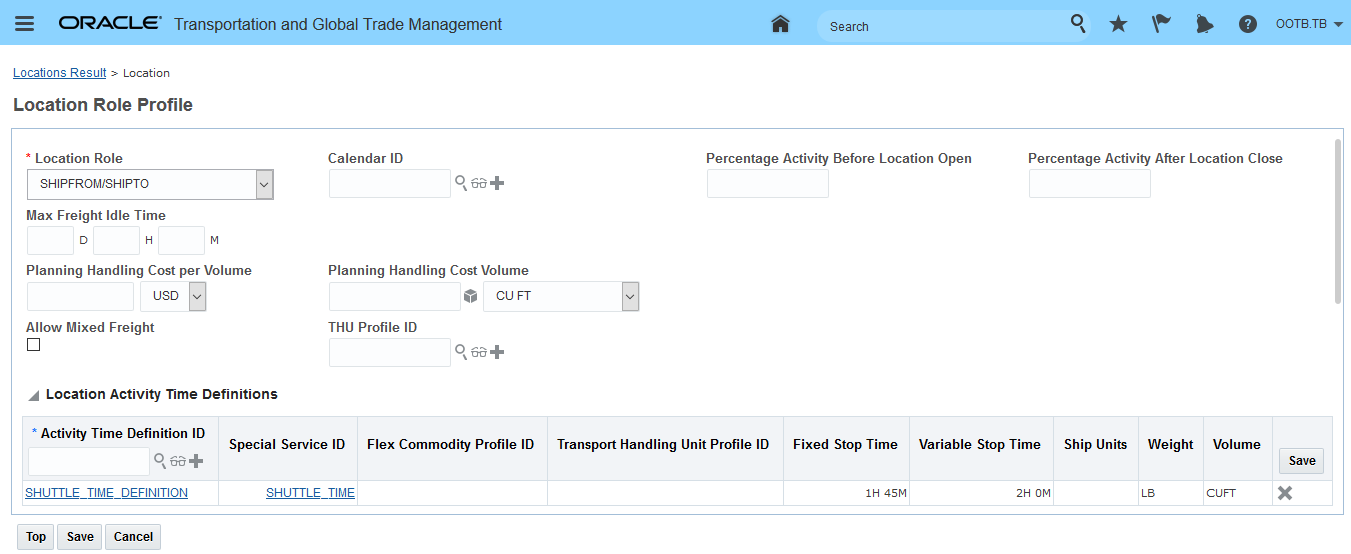

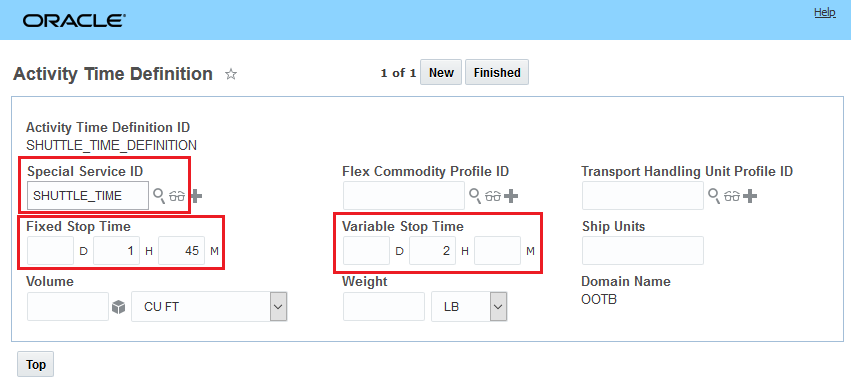

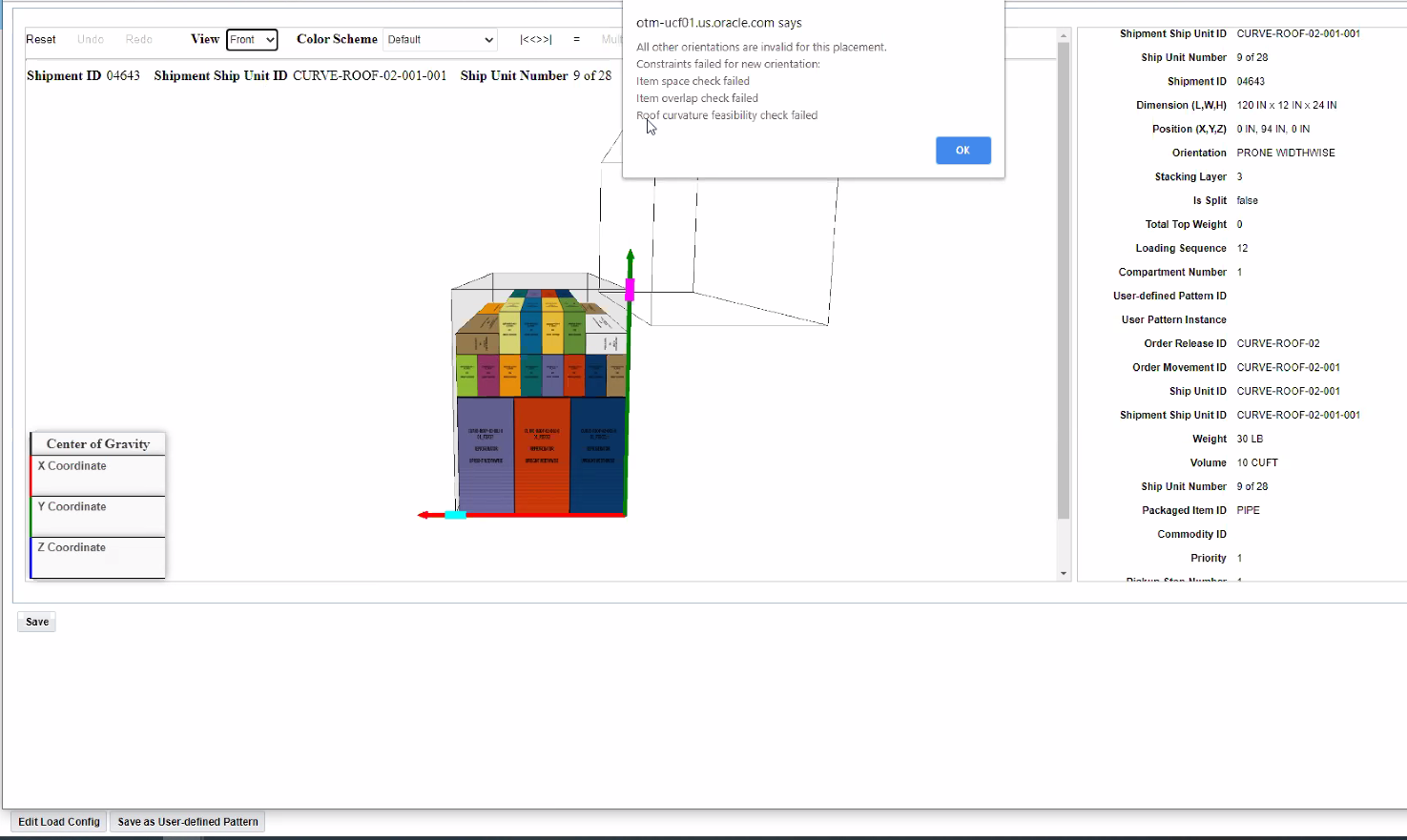

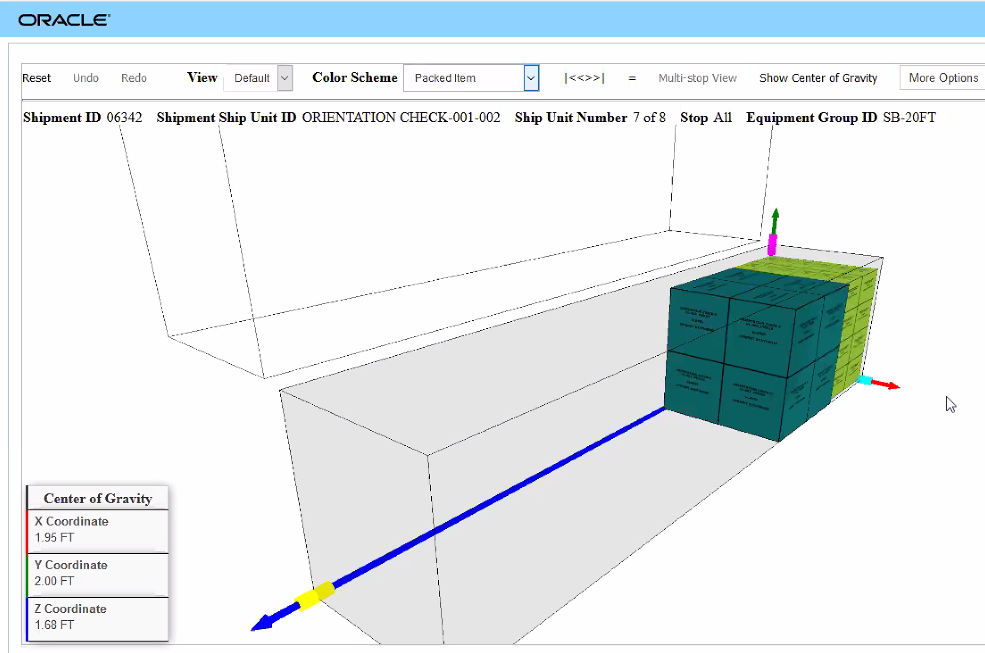

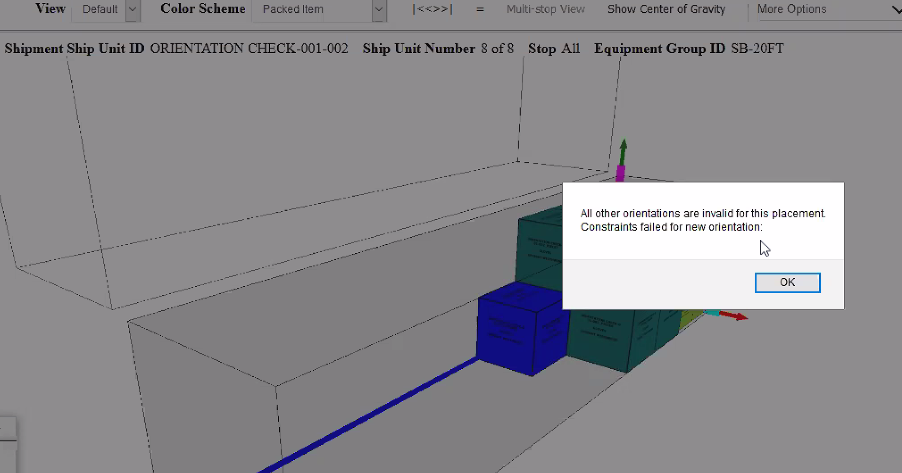

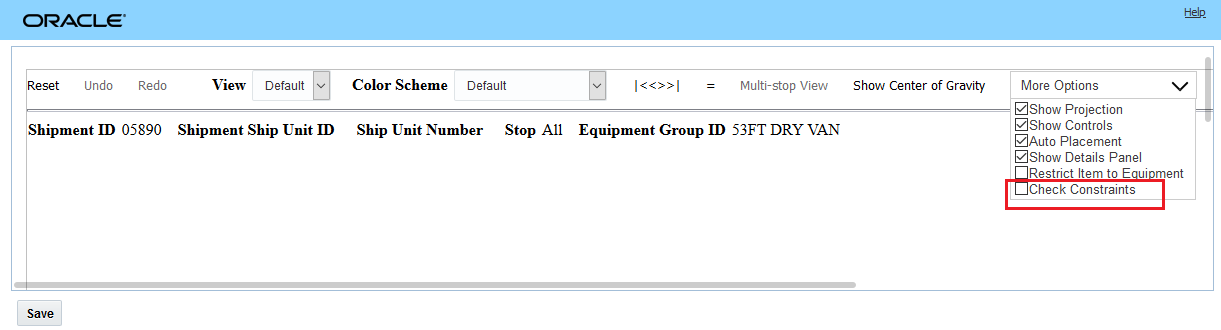

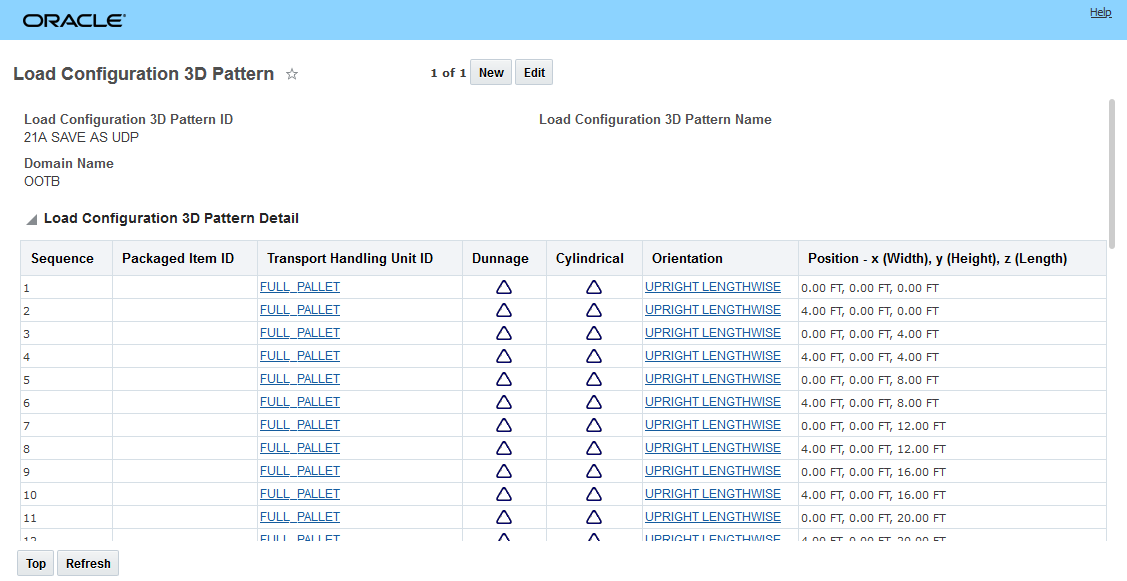

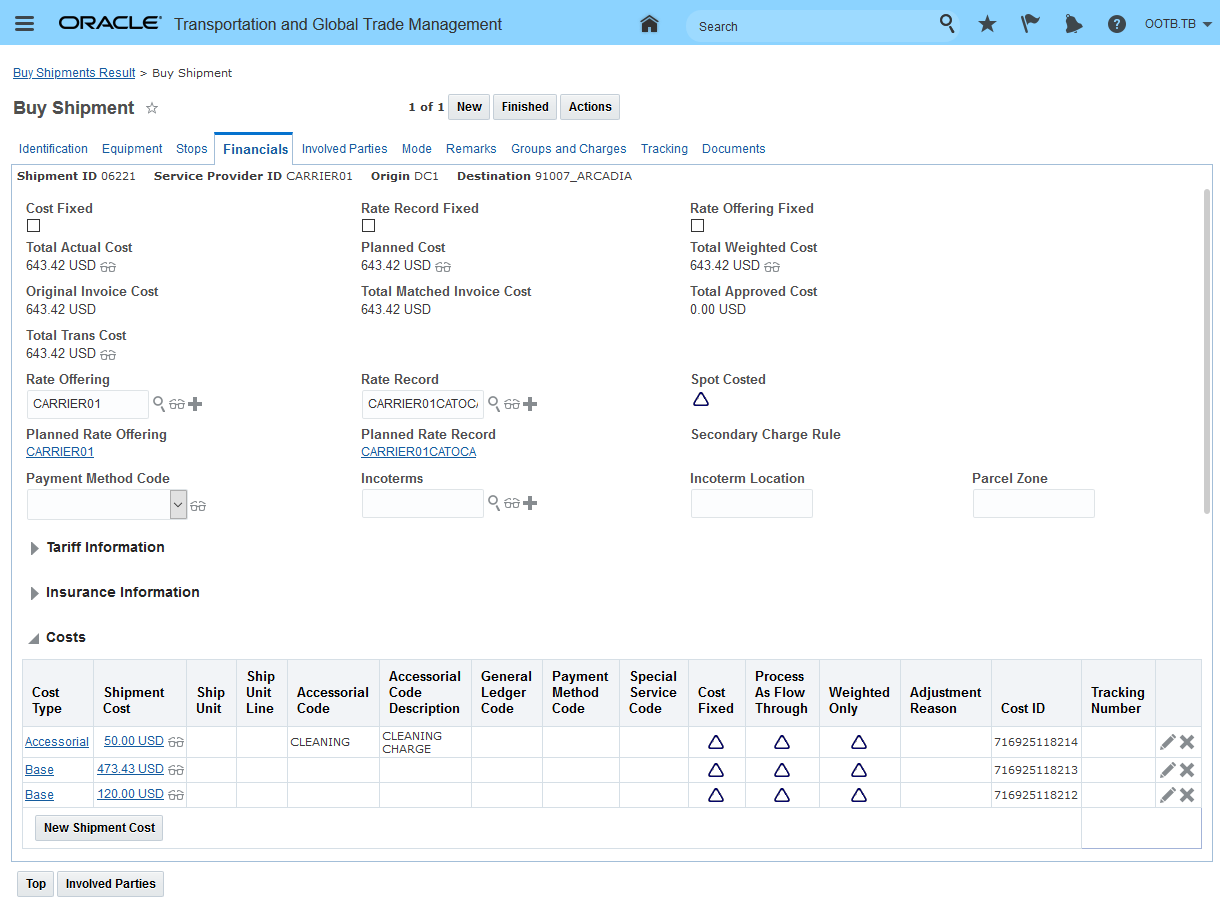

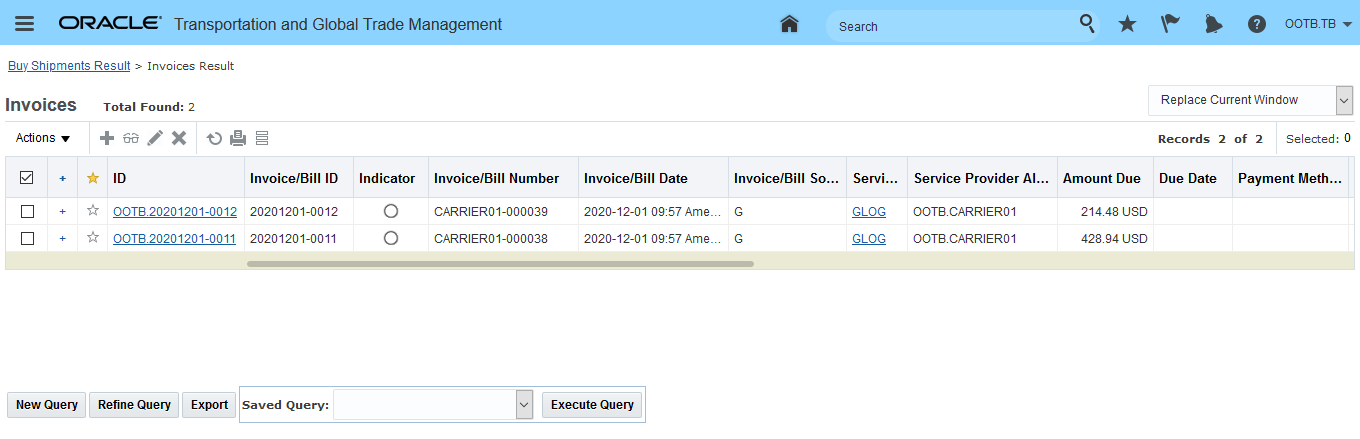

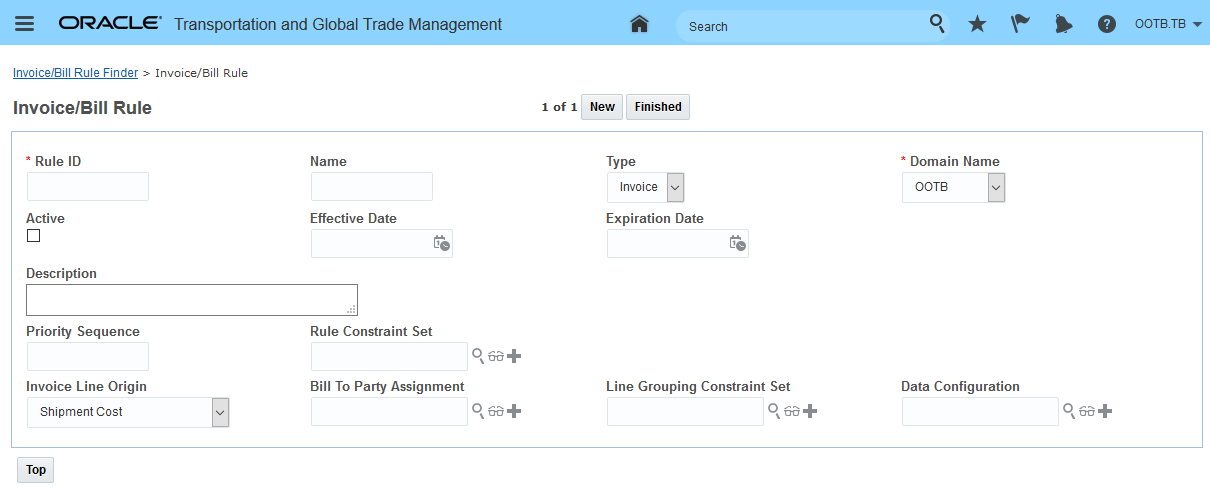

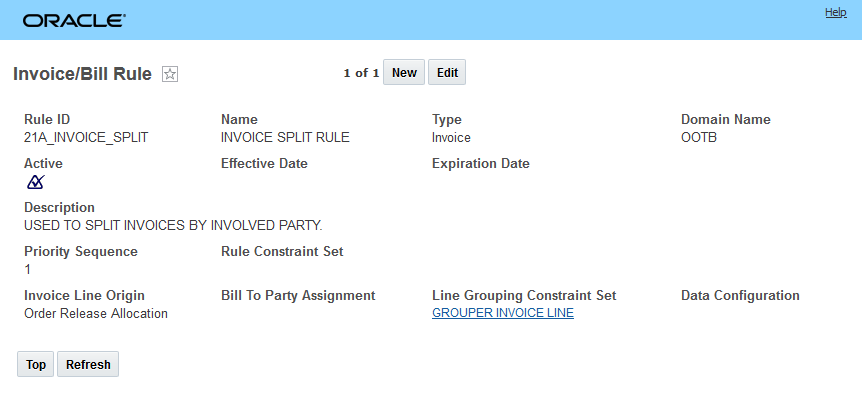

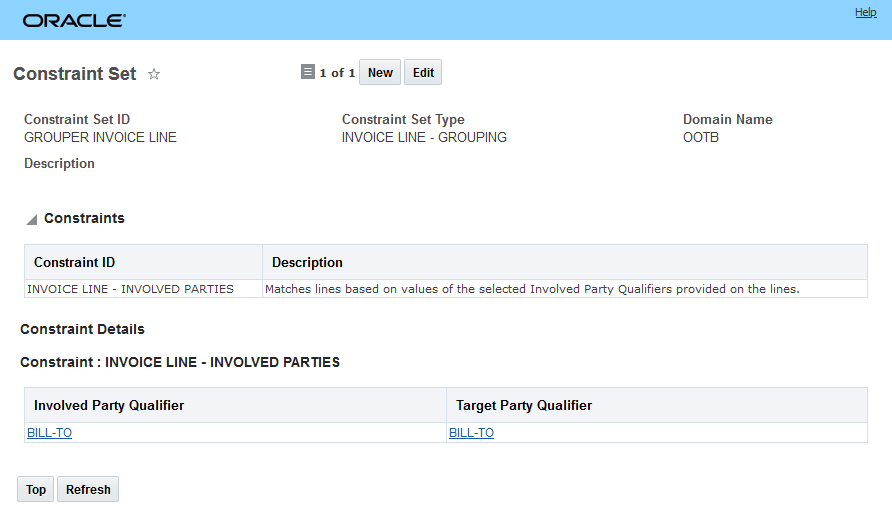

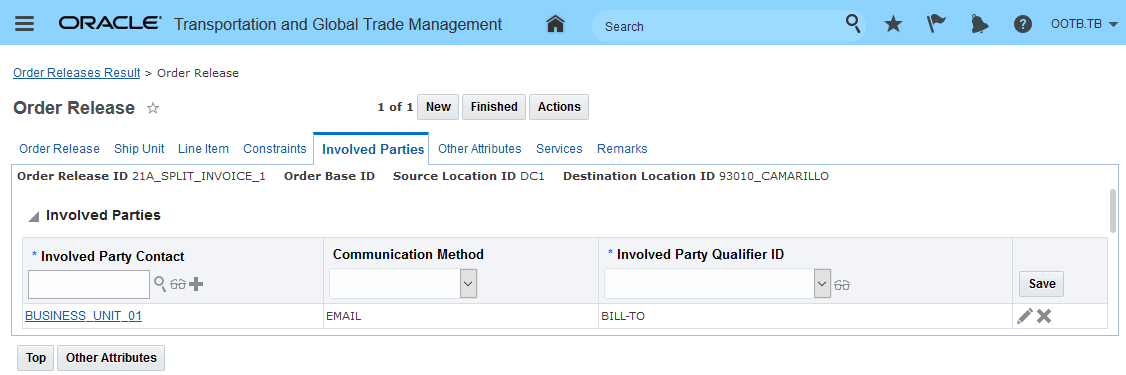

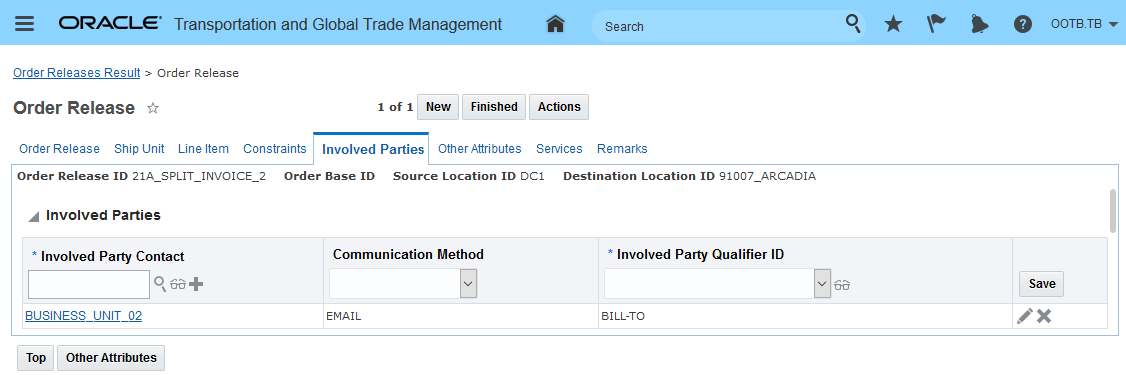

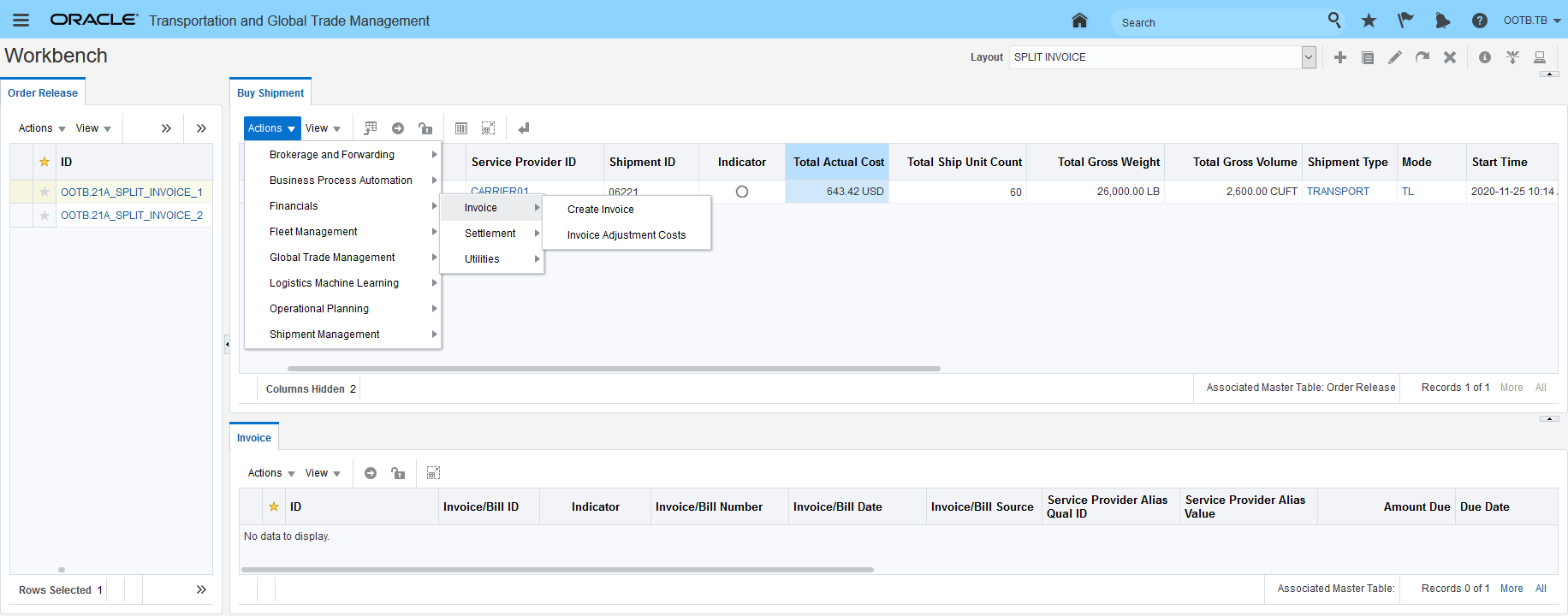

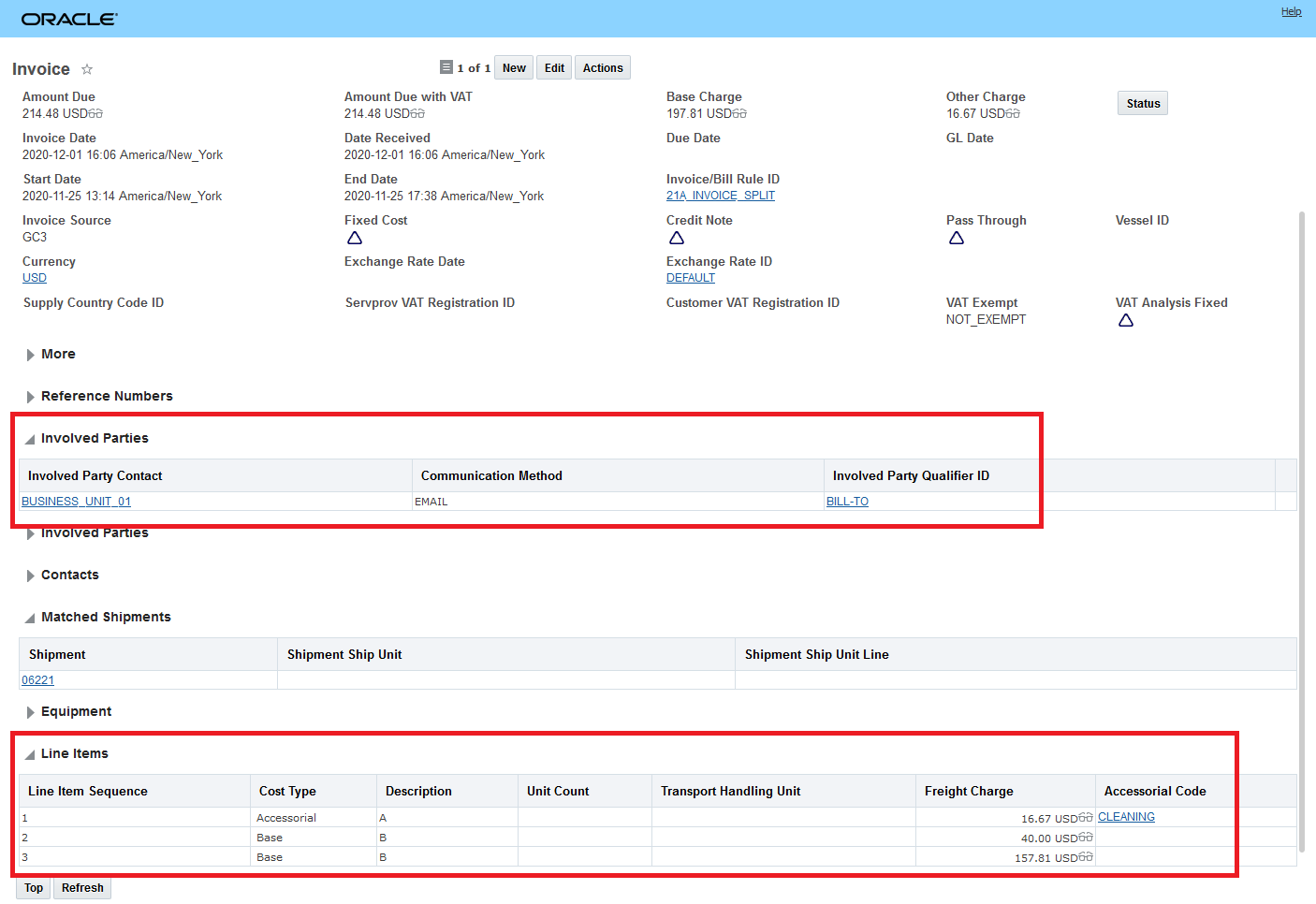

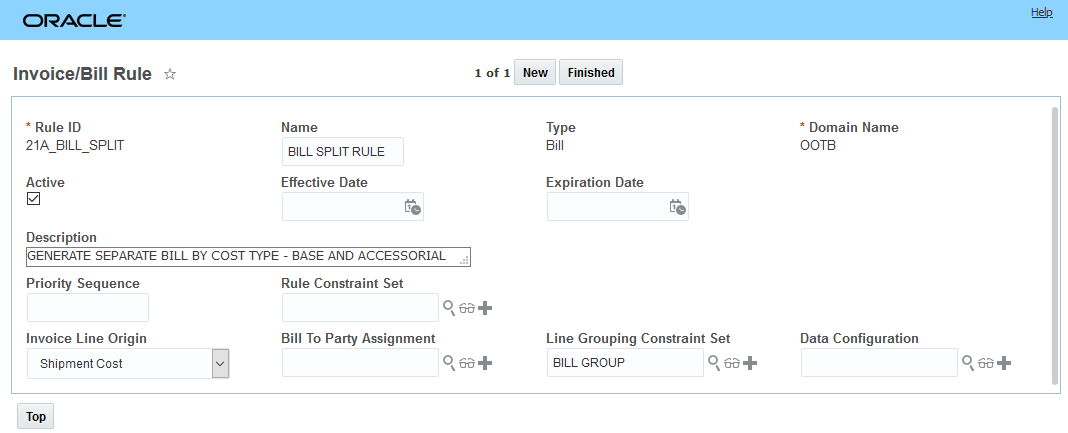

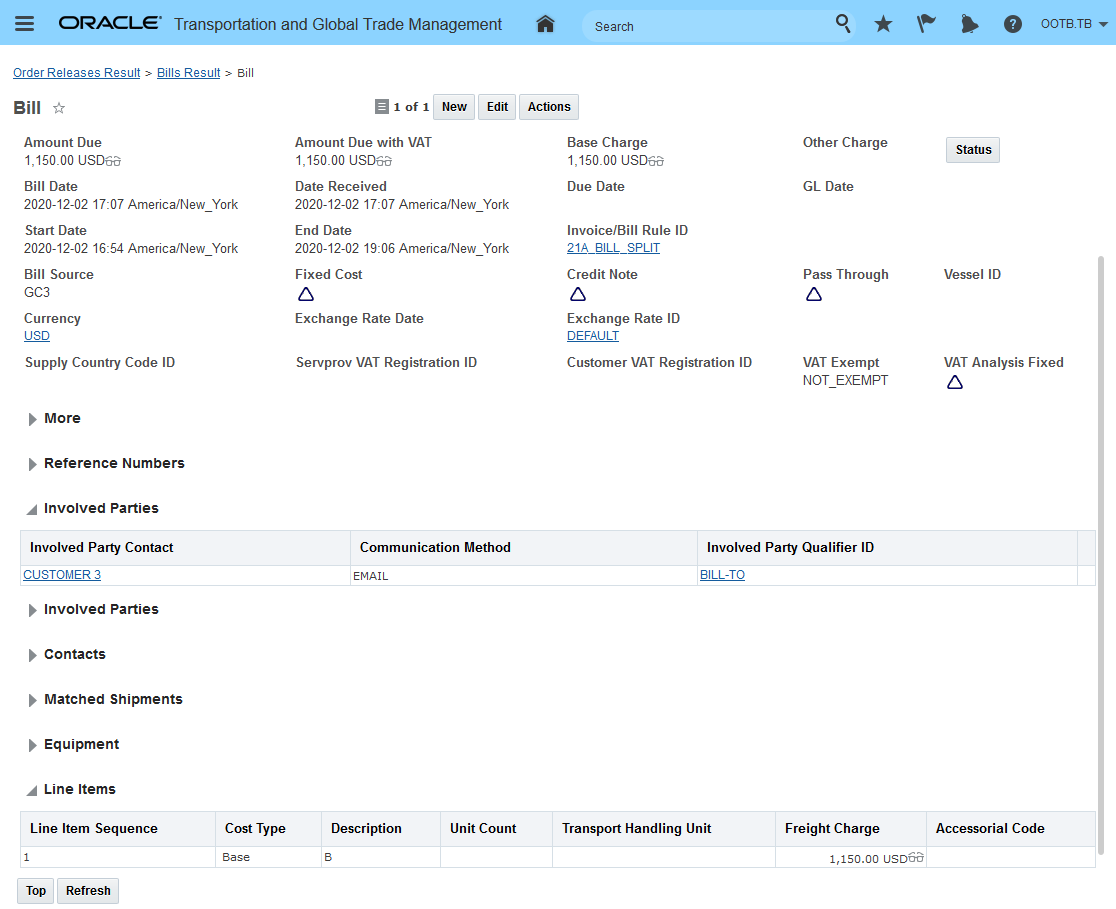

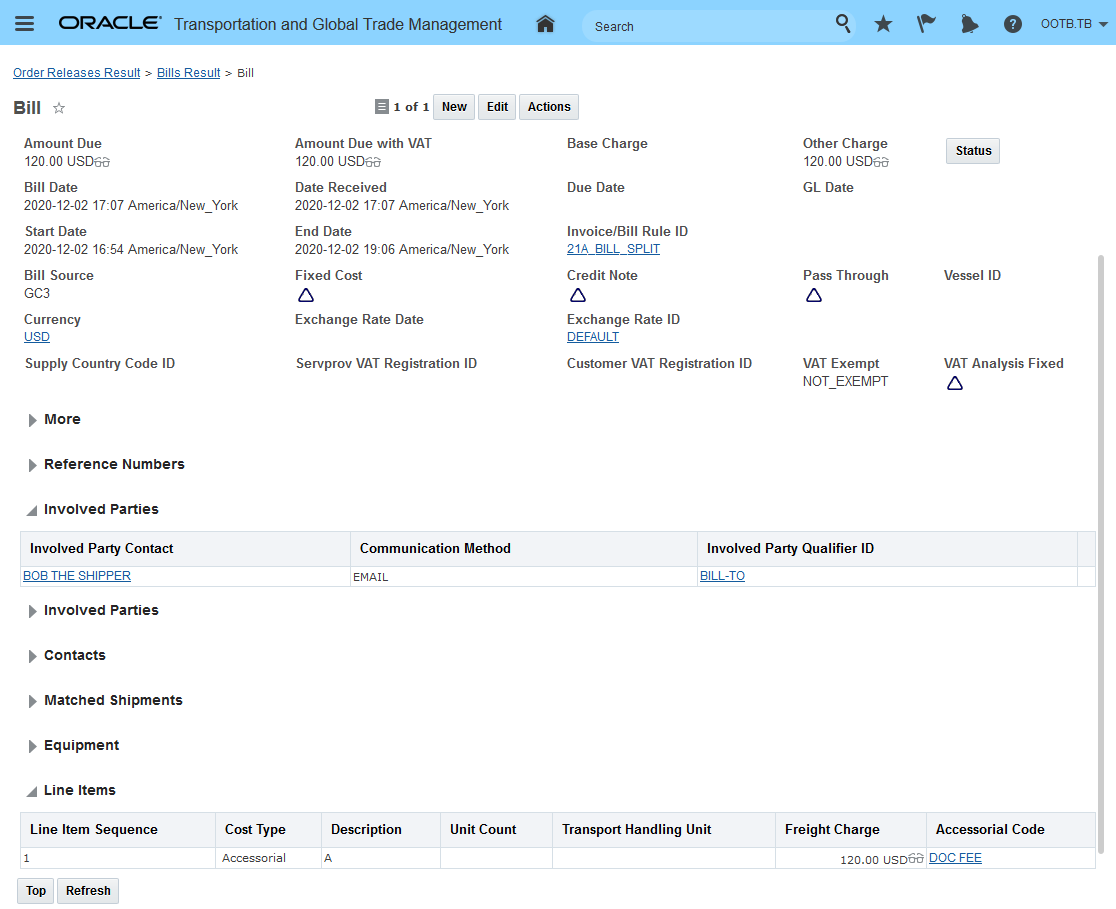

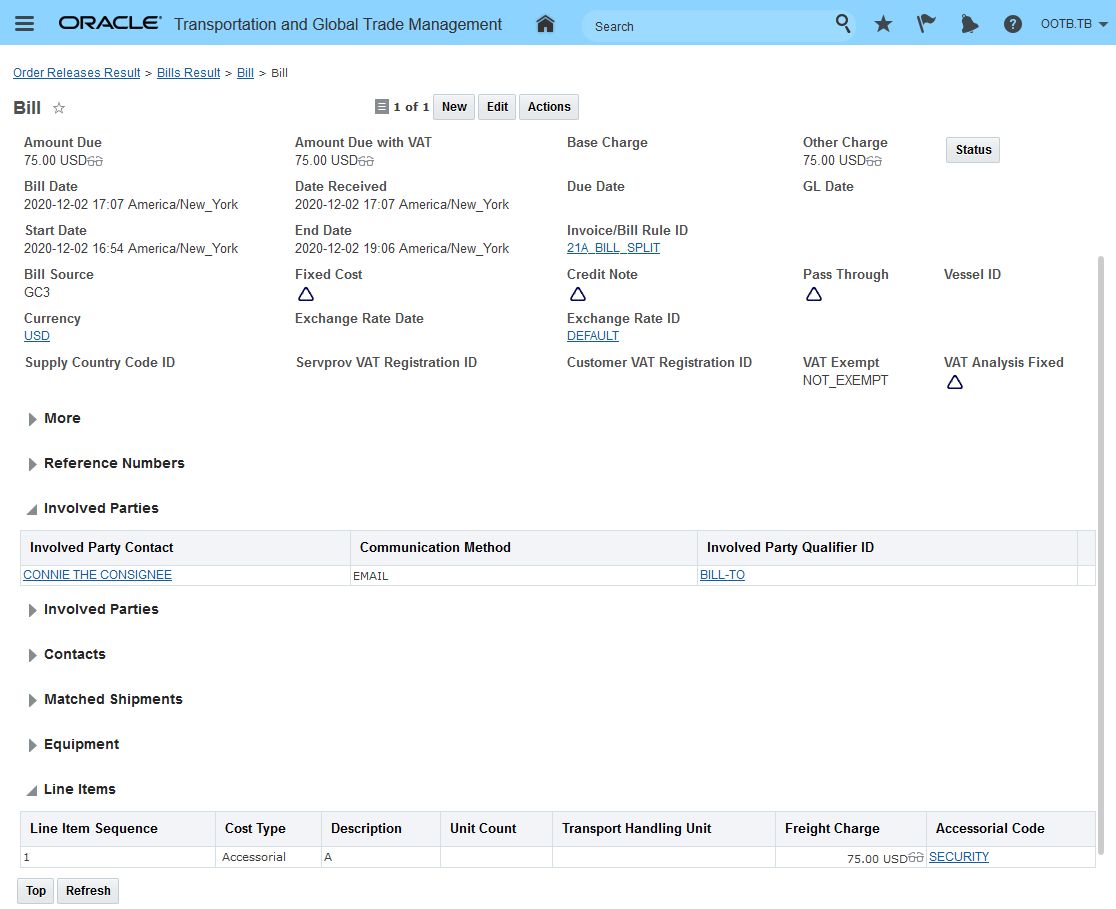

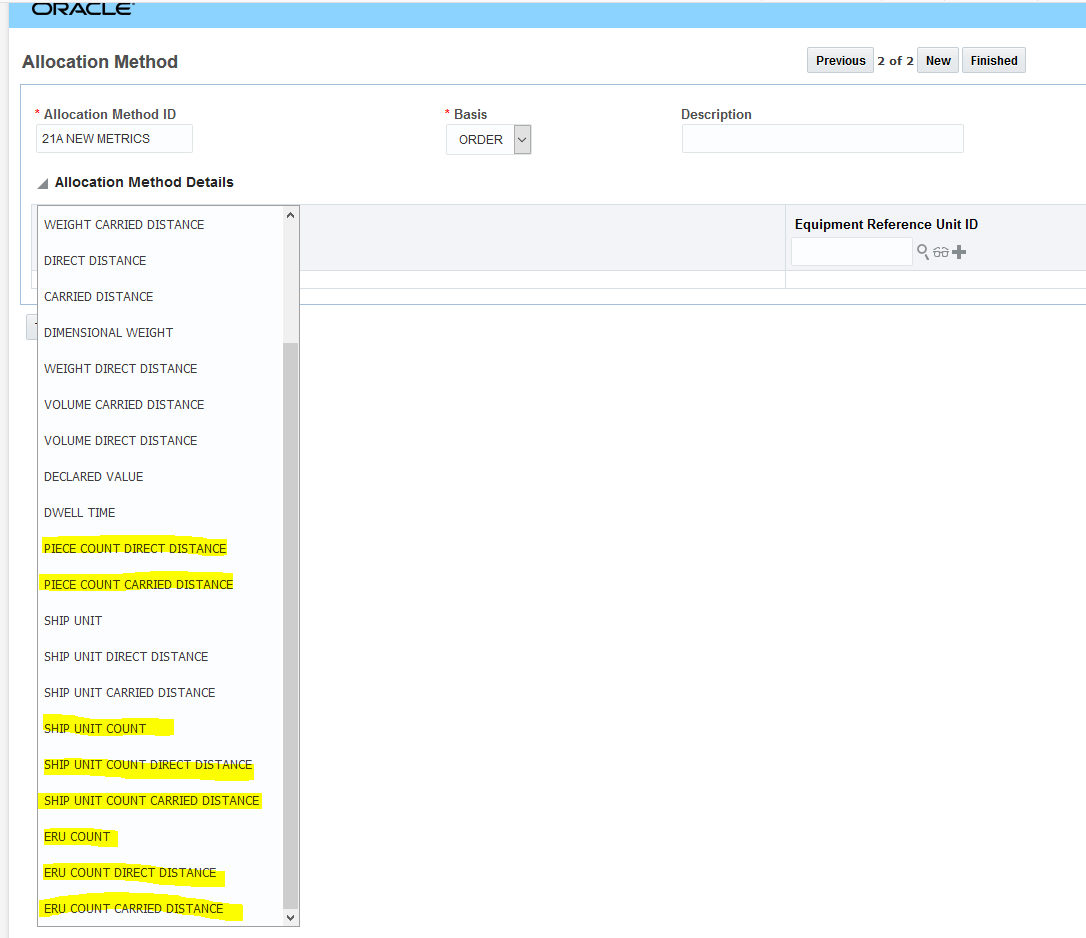

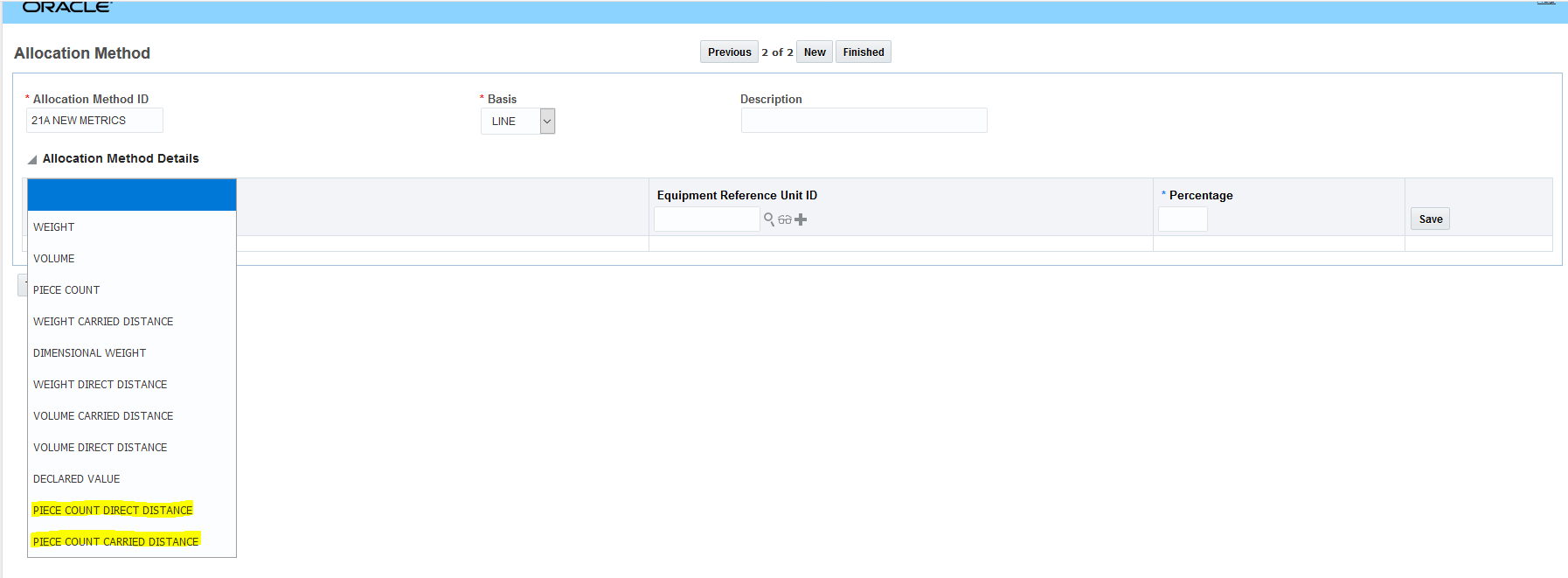

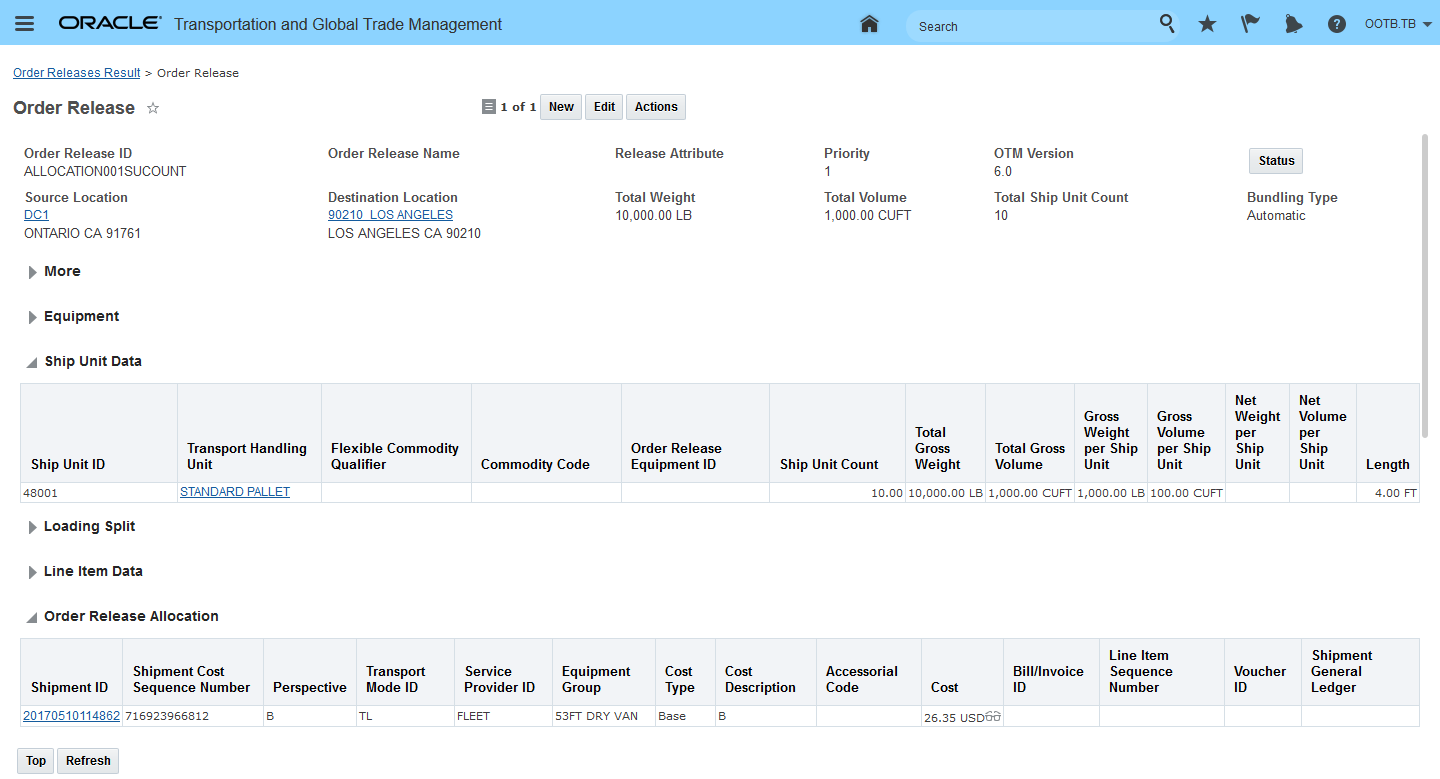

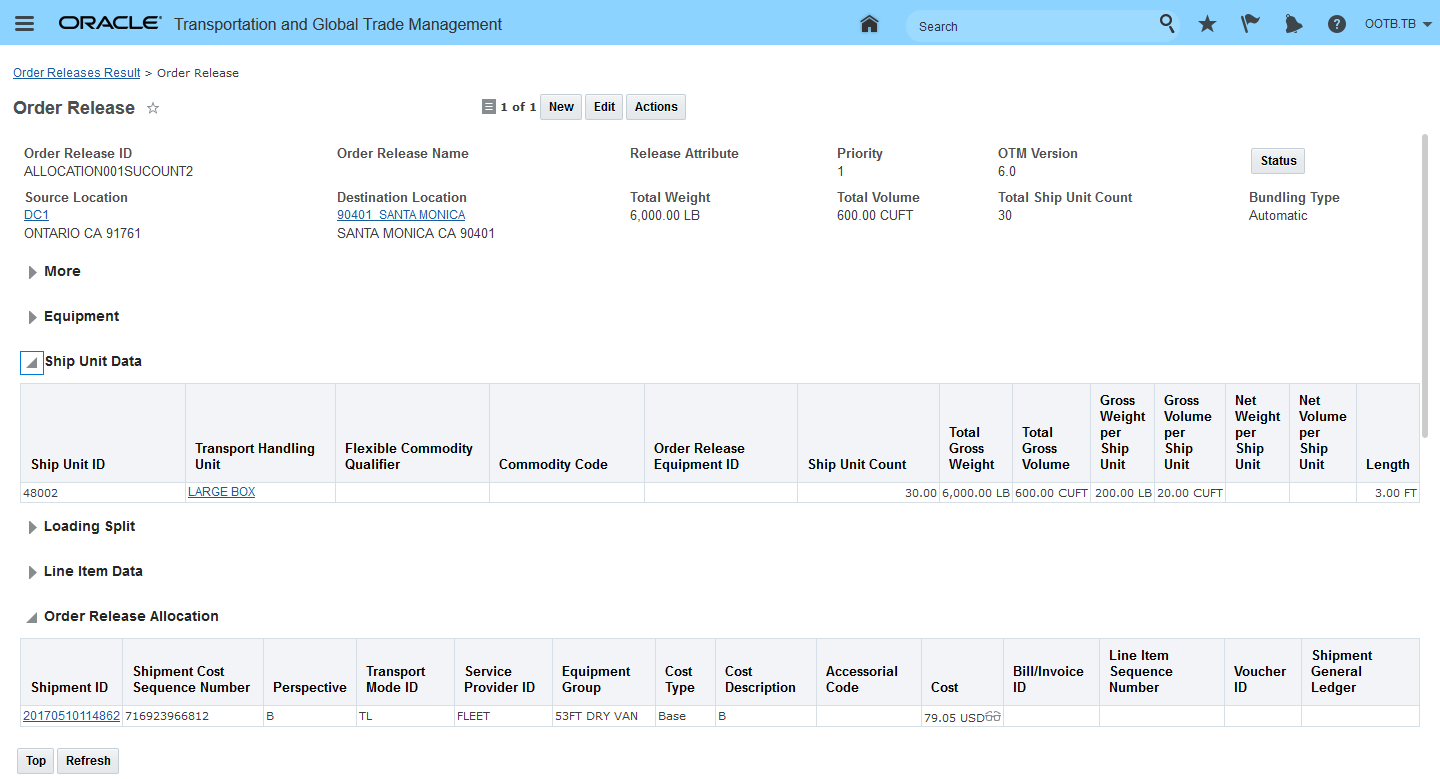

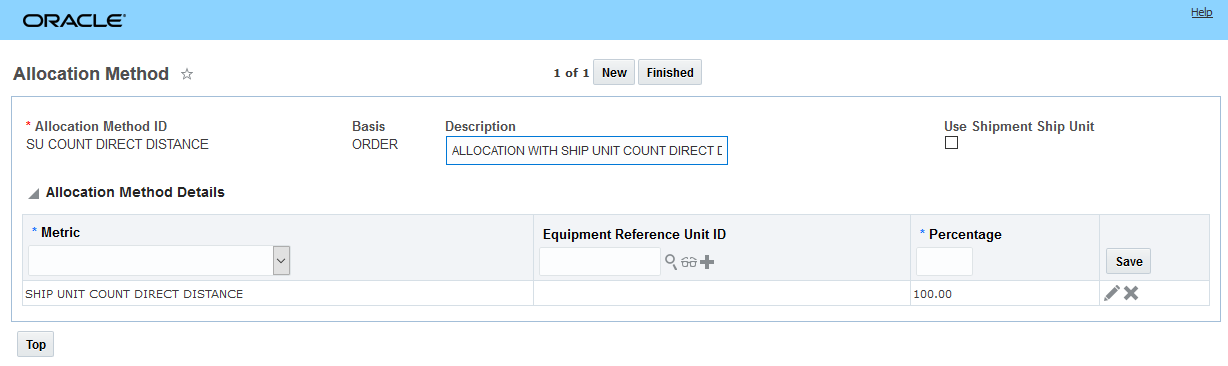

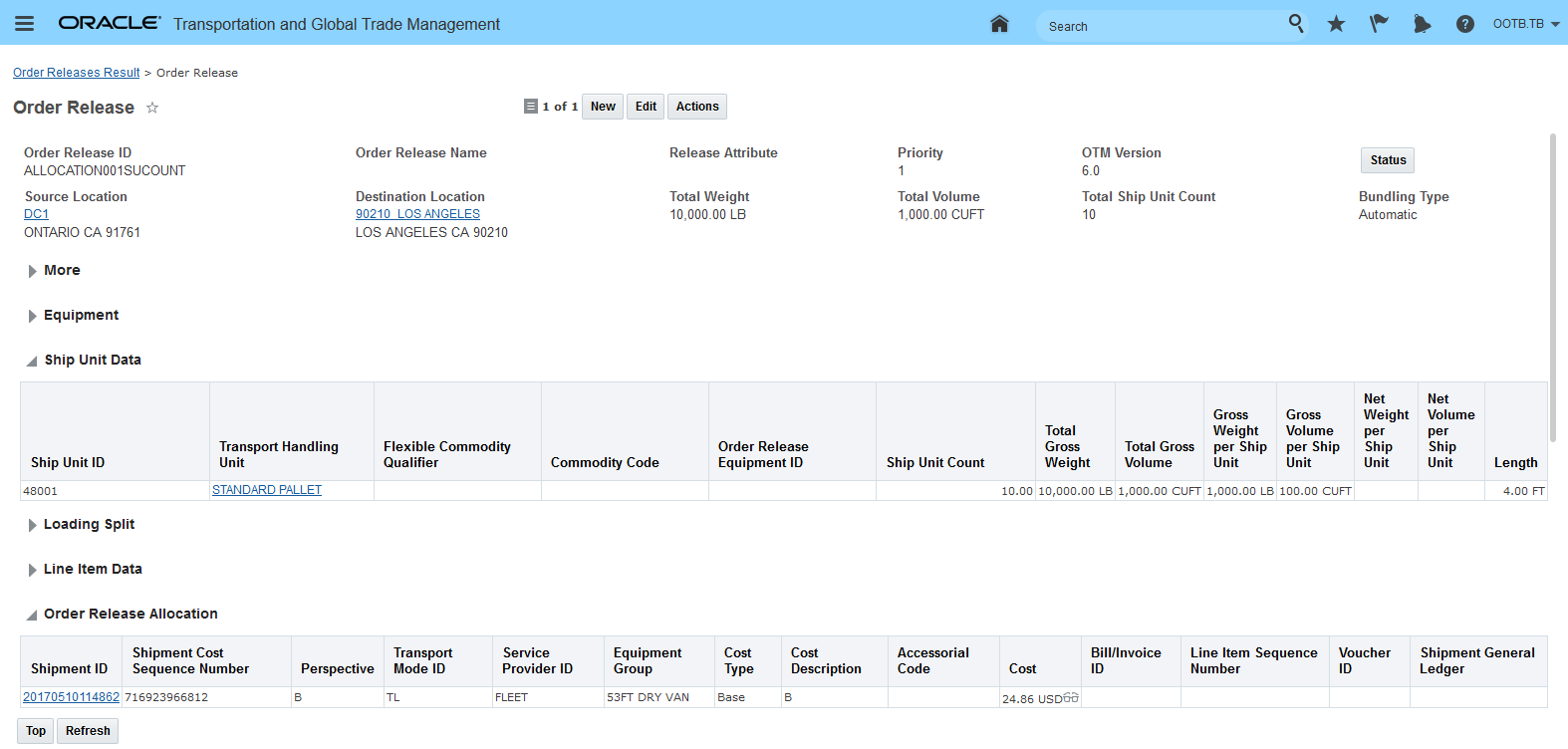

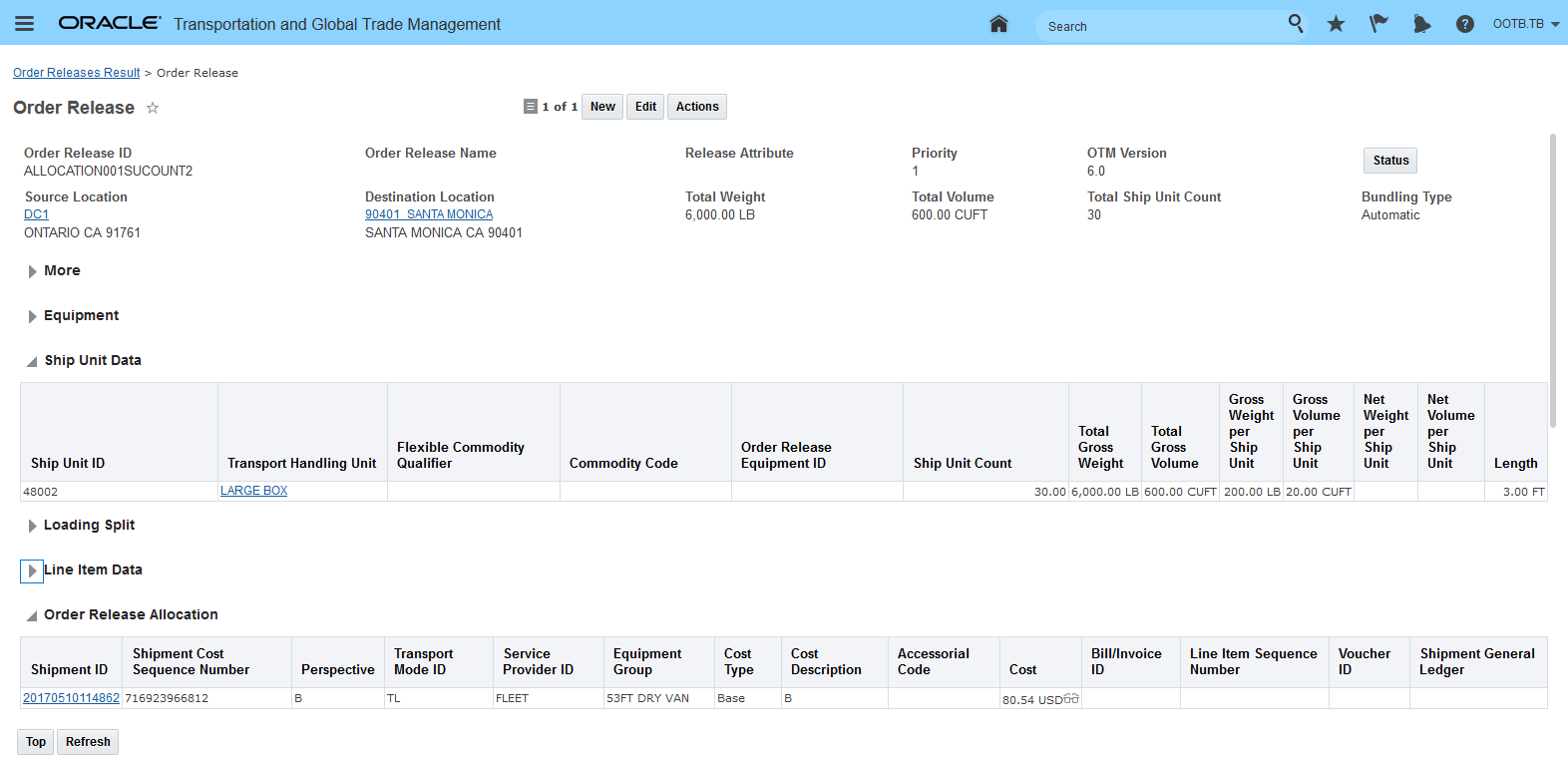

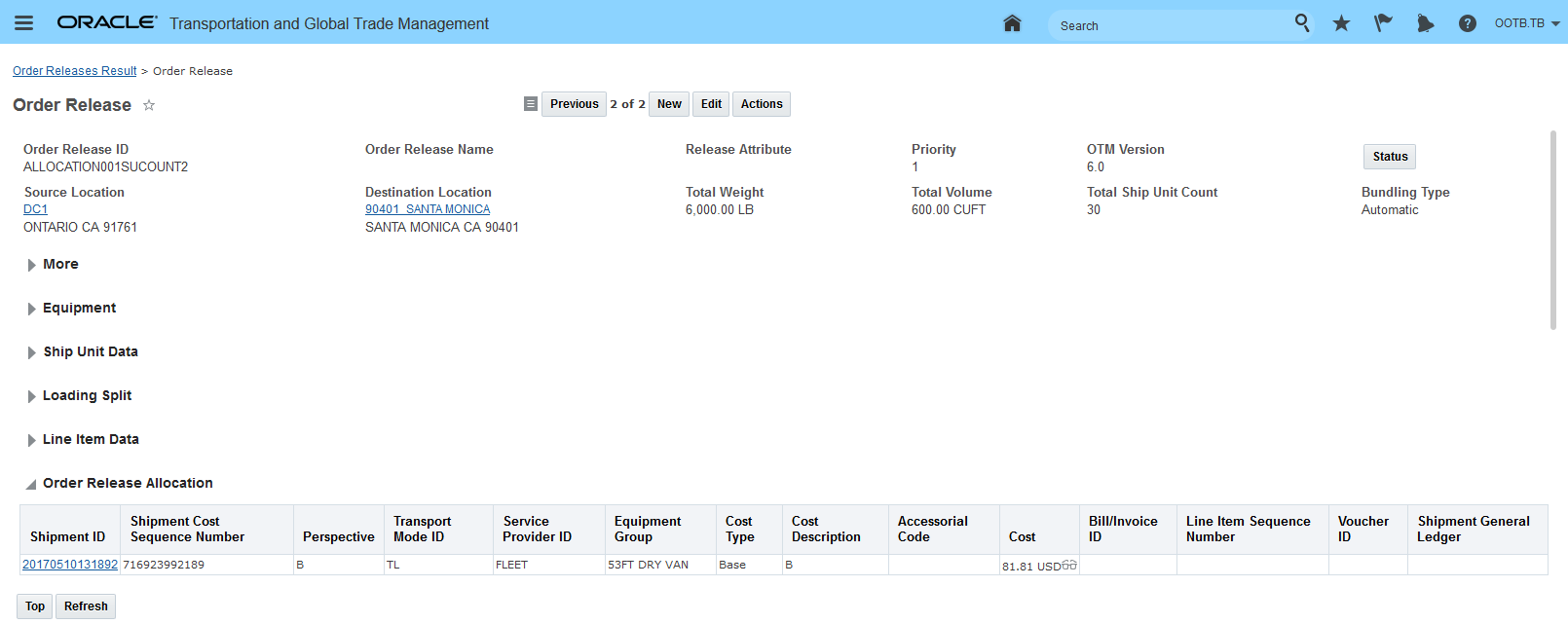

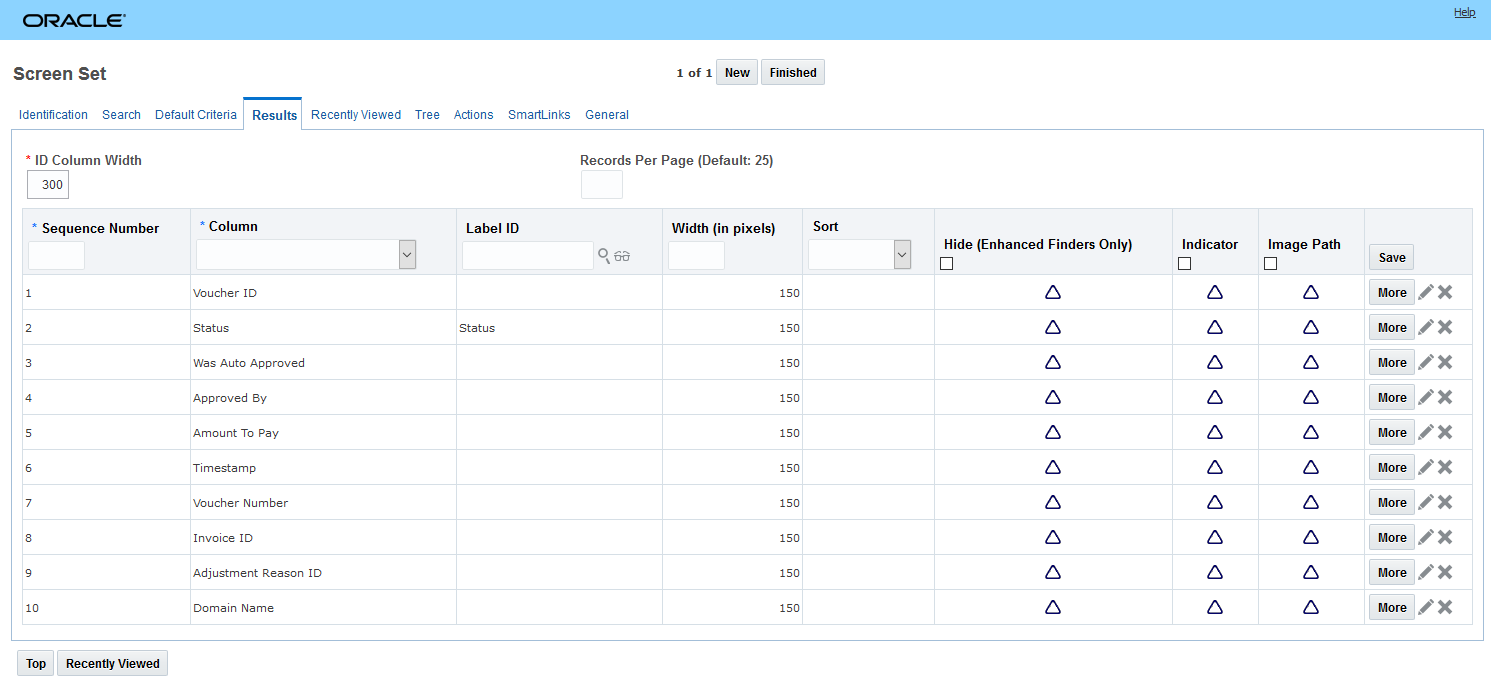

Manager Layout Enabled Action - Split Shipment Group