- Revision History

- Overview

- Update Tasks

- Feature Summary

- Transportation Management

-

- Transportation and Global Trade Platform

- Transportation Management (Base)

- UI Configuration

-

- Contact Manager Moved to Manager Layout

- Power Unit - Grid Fatten Remark Field

- Packaged Item Description Visible After Running Add New Line Item Added

- Manager Layout Direct URL Link In Stylesheet to User's Configured Manager Layout

- Create Secondary Charge Action Moved to Manager Layout

- Work Assignment Screen Set - Results Add User Defined Images and Indicator

- Planning Actions

-

- Create Multi-Block Shipment - Shipment Action

- Create Work Assignment Shipment Sort Display Property

- Enhanced Split Shipment Action - Split by Delivery Stop

- Add Repack Ship Unit and Repack Equipment Action Menu Options to Sell Shipment

- Move Order to Shipment Action Supports Multi Order Select

- Change Equipment Action Recalculate Input Options

- Booking and Tendering

- Financials

- Shipment Group

- Dock Scheduling

- Performance and Metrics

- Rates and Rating

- Ocean Enhancements

- Usability Enhancements

-

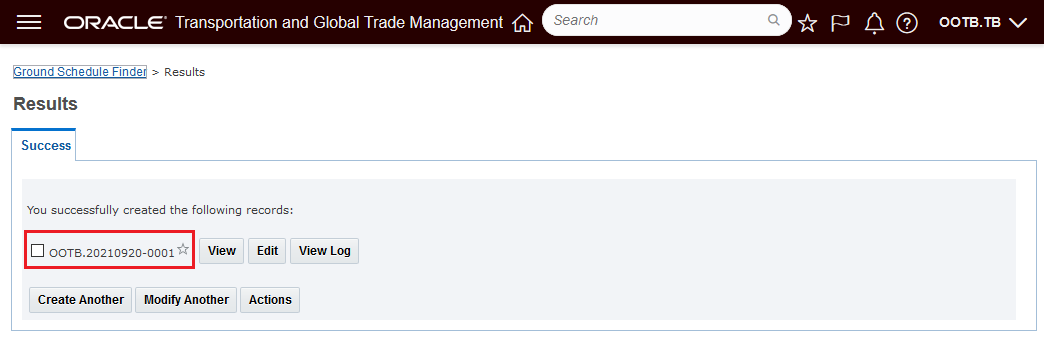

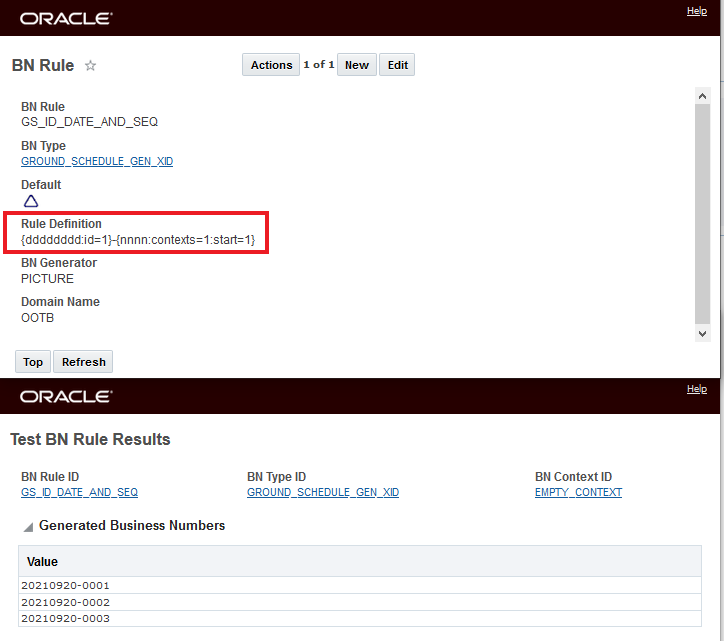

- Add Business Number Generator to Ground Schedules

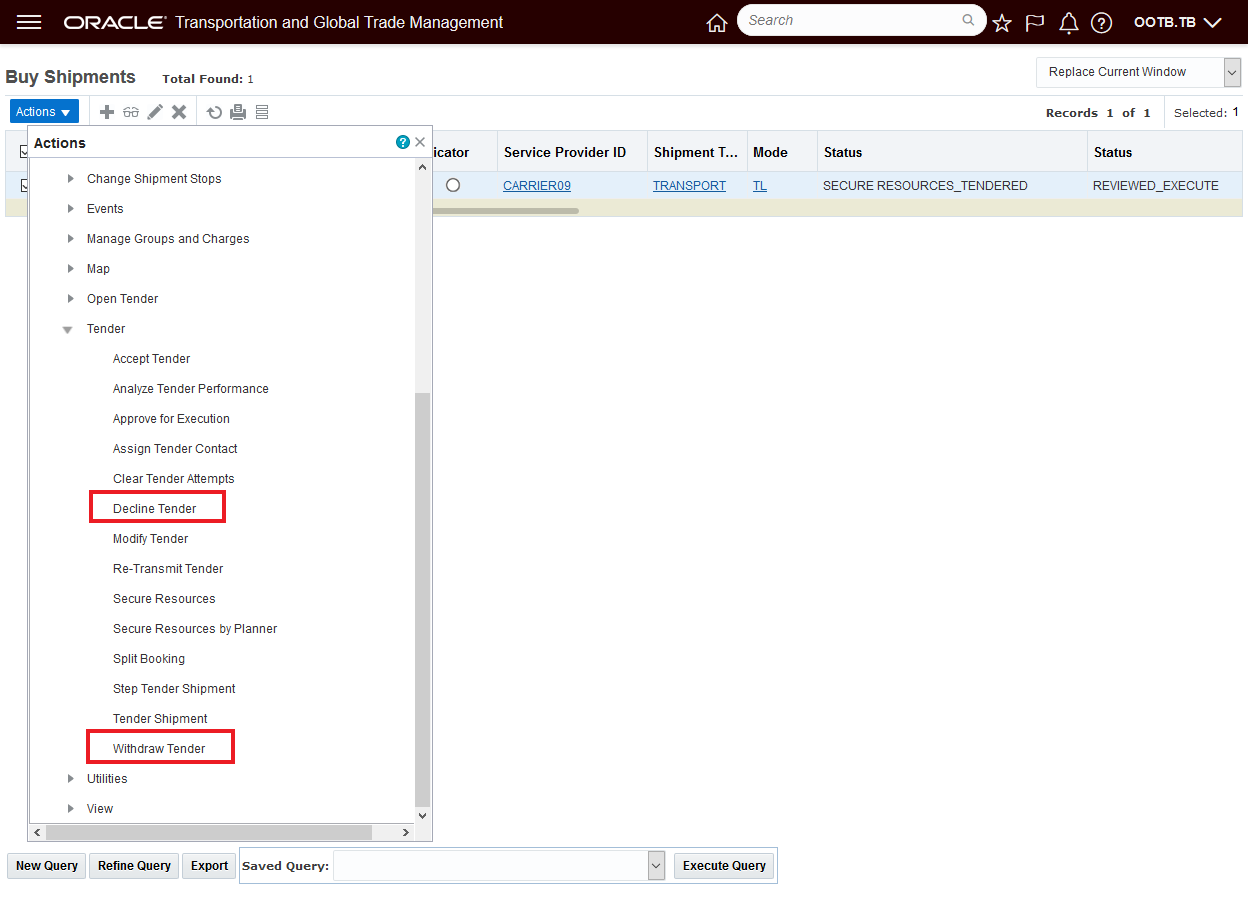

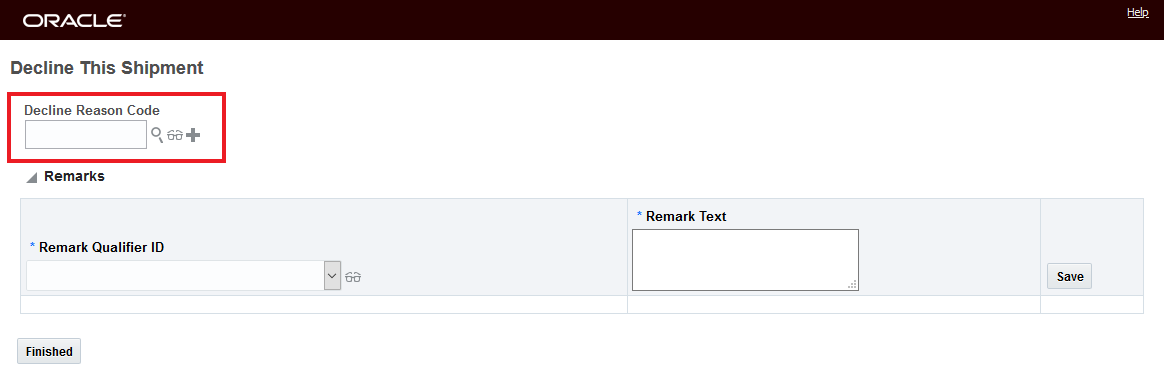

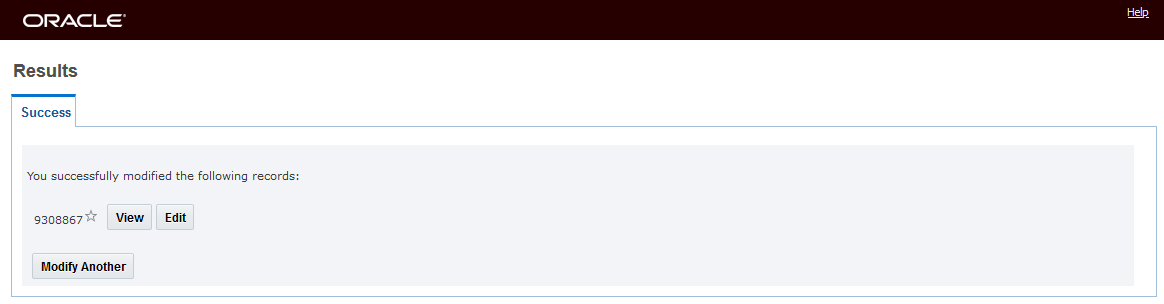

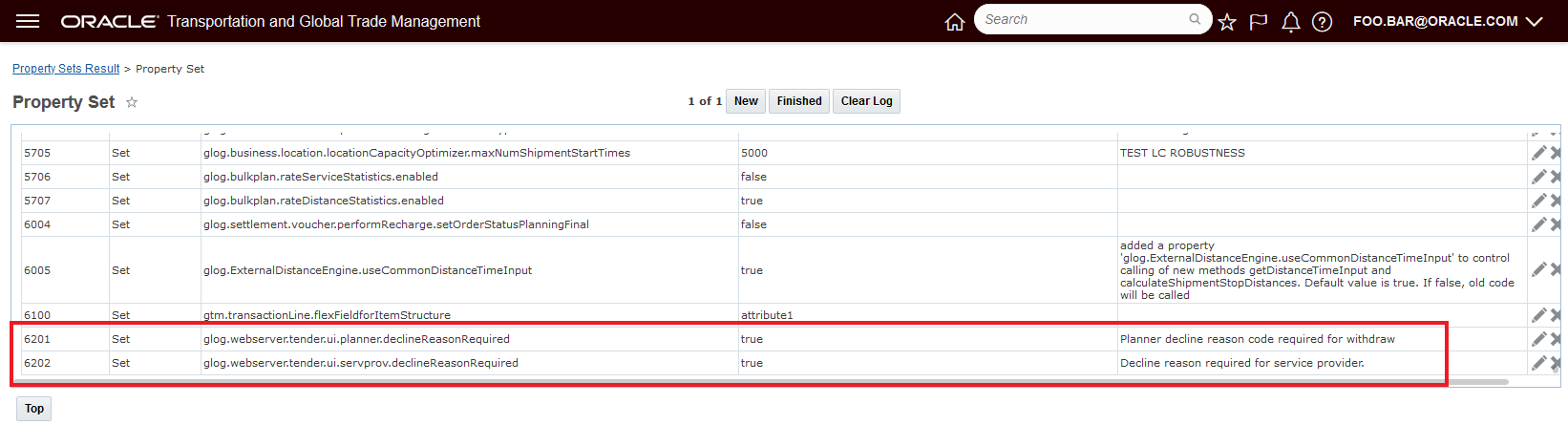

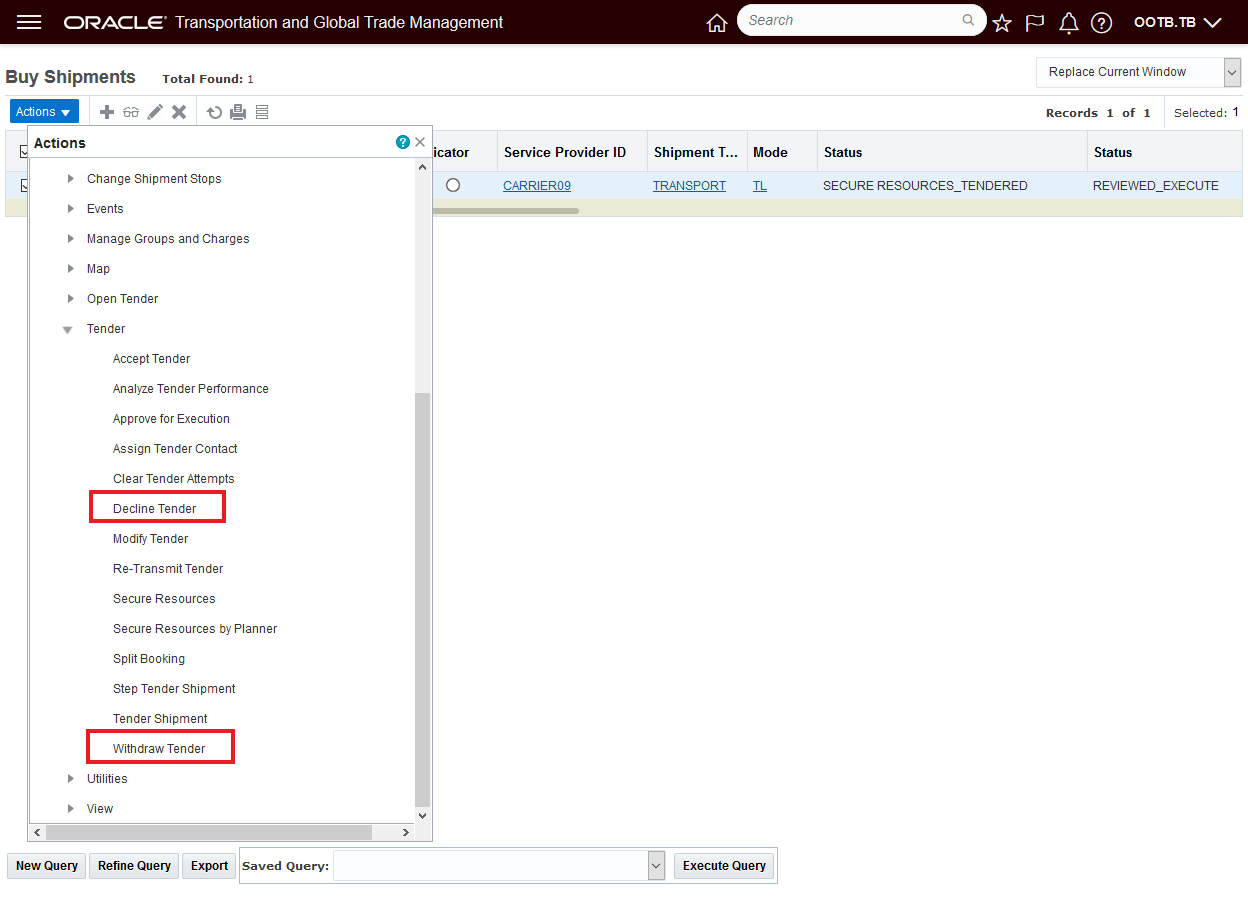

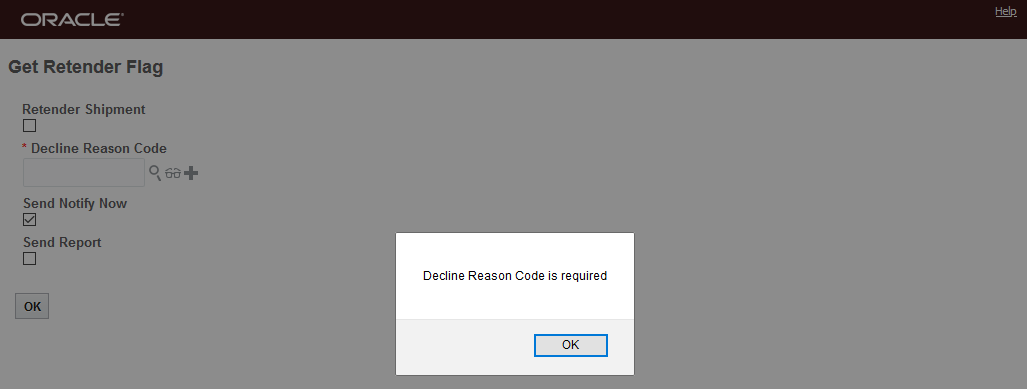

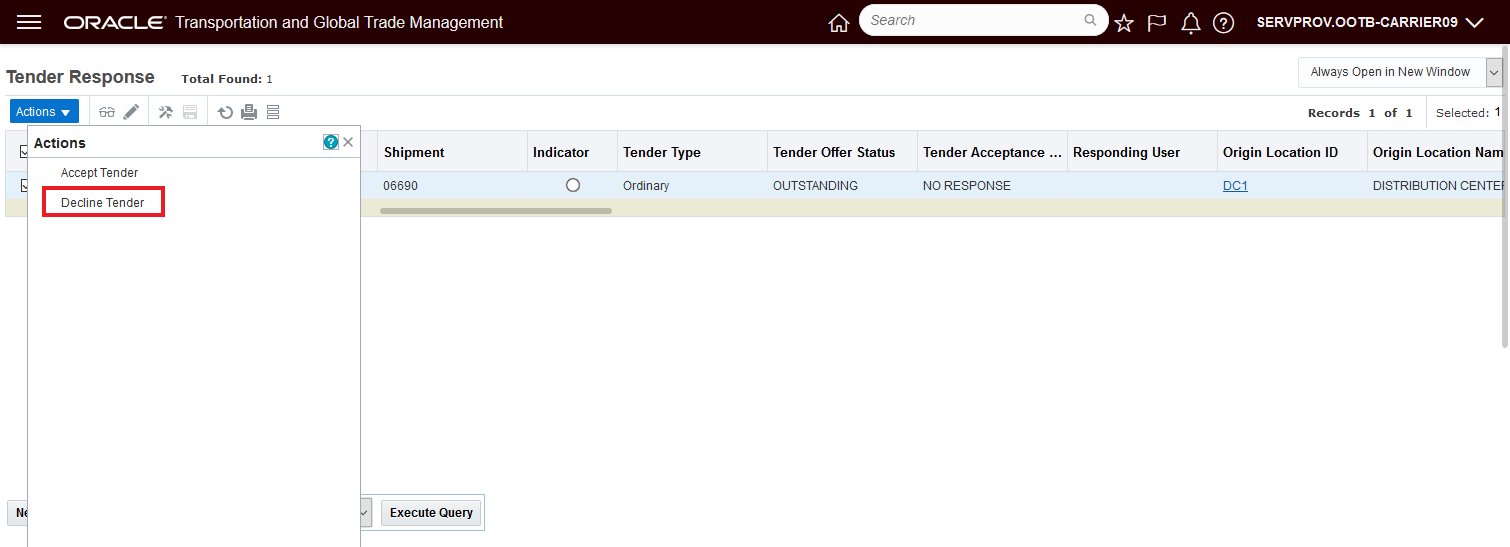

- Decline Reason Code Mandatory for Service Provider Decline and Planner Withdraw/Declines

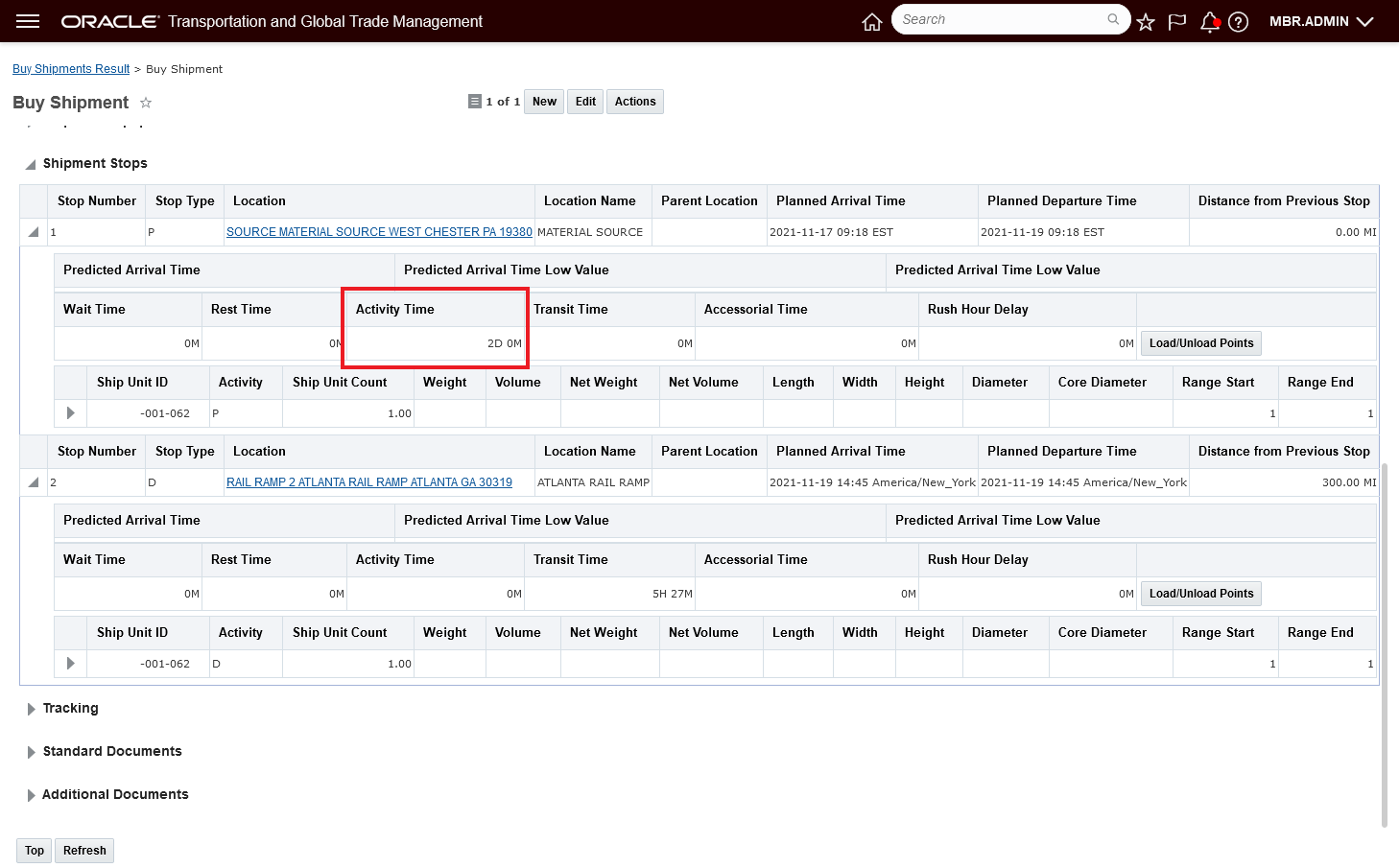

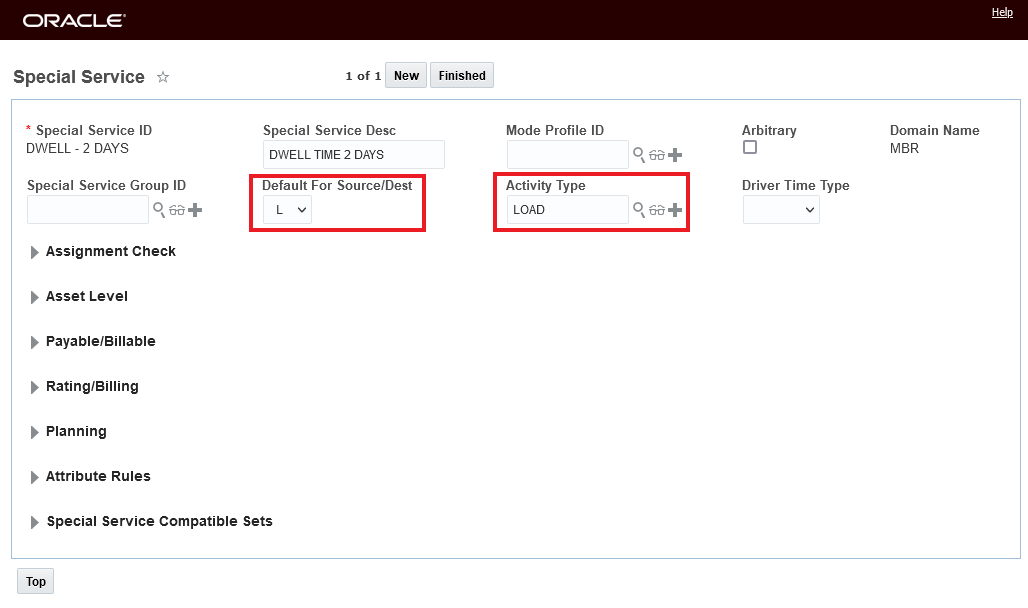

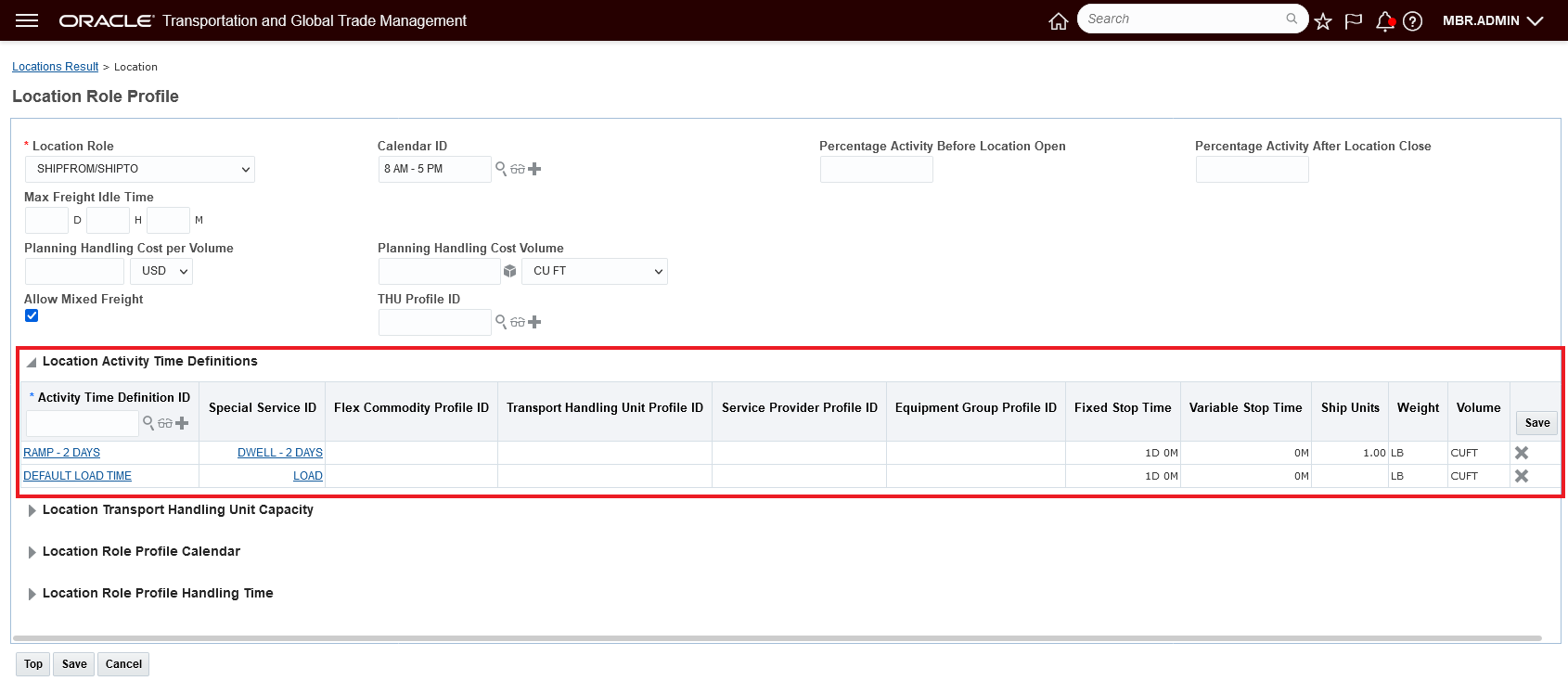

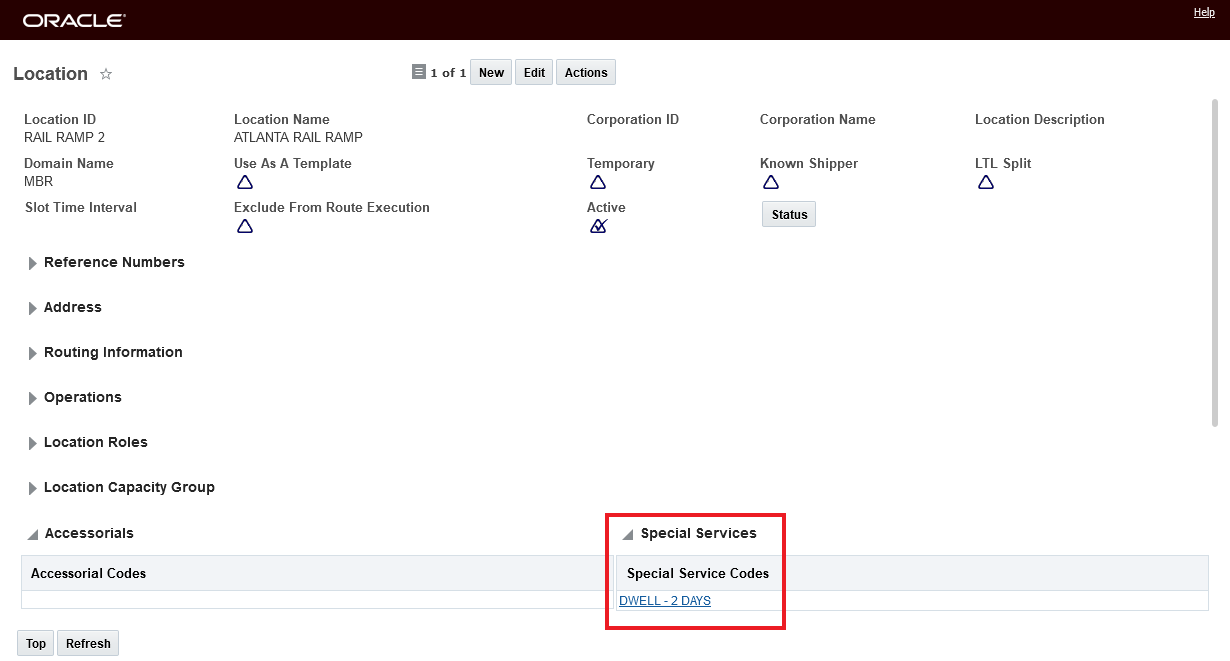

- Special Service Activity Time at Source Considering Shipment Destination

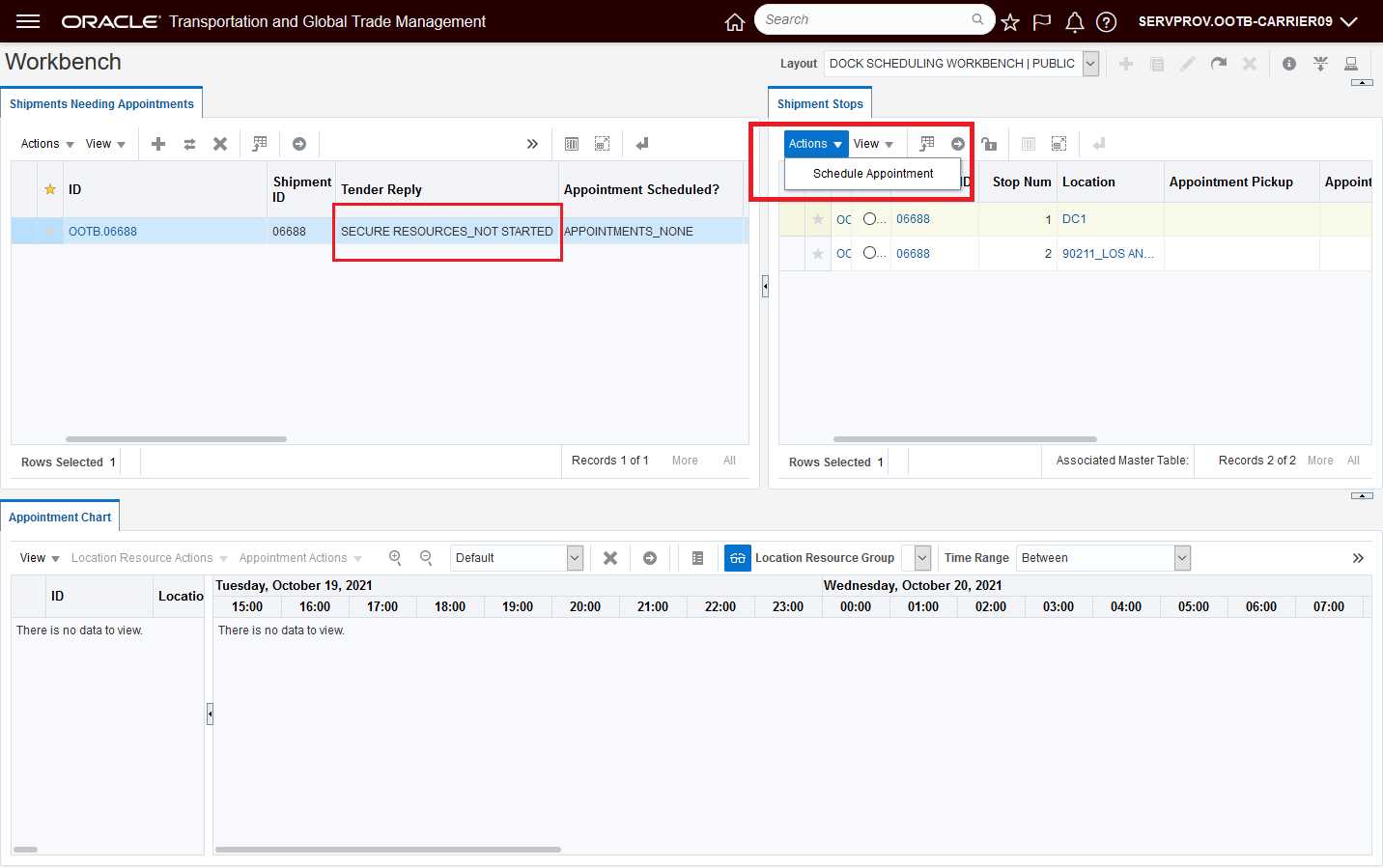

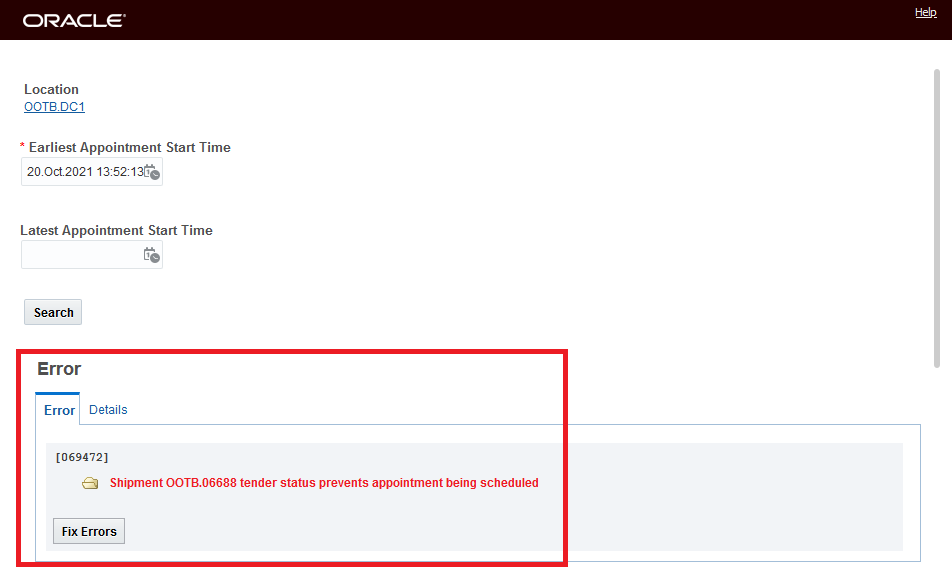

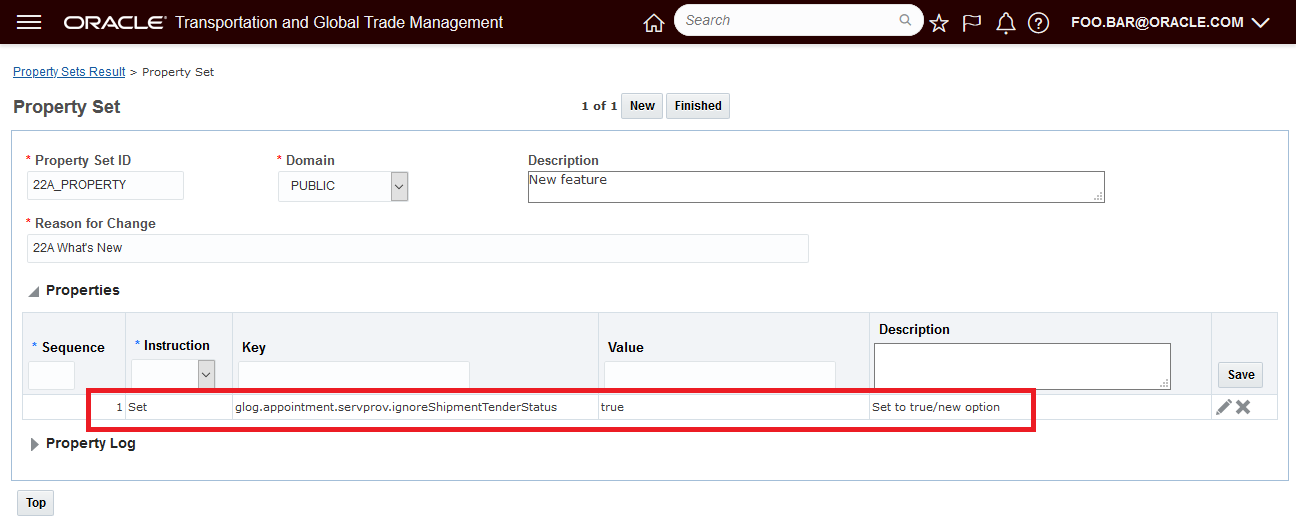

- Property to Ignore Shipment Tender Status for Service Provider Set Appointments

- Perform Recharge Action Order Release Sell Shipment Status to Allow Sell Shipment Delete

- Equipment Reference Units

- External Distance Engines

- Logistics Machine Learning

- Transportation Intelligence

This document will continue to evolve as existing sections change and new information is added. All updates appear in the following table:

| Date | Product | Feature | Notes |

|---|---|---|---|

| 11 FEB 2022 | Transportation and Global Trade Platform | Outbound REST | Updated document. Revised feature information. |

| 04 FEB 2022 | Transportation Management (Base) | HERE Technologies V8 for Distance and Service Time | Updated document. Revised feature information. |

| 17 DEC 2021 | Created initial document. |

This guide outlines the information you need to know about new or improved functionality in Oracle Transportation Management Cloud Update 22A. Each section includes a brief description of the feature, the steps you need to take to enable or begin using the feature, any tips or considerations that you should keep in mind, and the resources available to help you.

HAVE AN IDEA?

HAVE AN IDEA?

We’re here and we’re listening. If you have a suggestion on how to make our cloud services even better then go ahead and tell us. There are several ways to submit your ideas, for example, through the Ideas Lab on Oracle Customer Connect. Wherever you see this icon after the feature name it means we delivered one of your ideas.

GIVE US FEEDBACK

We welcome your comments and suggestions to improve the content. Please send us your feedback at otm-doc_us@oracle.com. Please indicate you are inquiring or providing feedback regarding the Oracle Transportation Management What’s New in Update 22A.

DISCLAIMER

The information contained in this document may include statements about Oracle’s product development plans. Many factors can materially affect Oracle’s product development plans and the nature and timing of future product releases. Accordingly, this Information is provided to you solely for information only, is not a commitment to deliver any material, code, or functionality, and should not be relied upon in making purchasing decisions. The development, release, and timing of any features or functionality described remains at the sole discretion of Oracle.

This information may not be incorporated into any contractual agreement with Oracle or its subsidiaries or affiliates. Oracle specifically disclaims any liability with respect to this information. Refer to the Legal Notices and Terms of Use for further information.

This section gives you information to help you plan, deploy, and validate your update. We make frequent additions to this document, so don’t forget to check back and get the latest information before your update starts.

Review the Release Notes.

- The release notes include fixes, special instructions, and resolutions related to the Oracle Transportation and Global Trade Management Cloud.

- Release Notes can be found here:

- https://support.oracle.com/epmos/faces/DocumentDisplay?id=2620583.1

Use the following resources to prepare for and validate your Oracle Engagement Cloud update.

On My Oracle Support Read:

- Doc ID 2095509.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Environment Refresh Policy

- Doc ID 2095528.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Quarterly Update Planning

- Doc ID 2096782.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Quarterly Update Planning FAQs

- Doc ID 2195580.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Get Started with Your Implementation

- Doc ID 2508854.1

- Oracle Cloud Applications - Transportation and Global Trade Management Cloud: Quarterly Updates - Preparation and Testing Recommendations

Column Definitions:

Report = New or modified, Oracle-delivered, ready to run reports.

UI or Process-Based: Small Scale = These UI or process-based features are typically comprised of minor field, validation, or program changes. Therefore, the potential impact to users is minimal.

UI or Process-Based: Larger Scale* = These UI or process-based features have more complex designs. Therefore, the potential impact to users is higher.

Features Delivered Disabled = Action is needed BEFORE these features can be used by END USERS. These features are delivered disabled and you choose if and when to enable them. For example, a) new or expanded BI subject areas need to first be incorporated into reports, b) Integration is required to utilize new web services, or c) features must be assigned to user roles before they can be accessed.

Transportation and Global Trade Platform

Next Generation Enhanced Workbench

This feature provides you with the first release of the Oracle JET based Enhanced Workbench. This first release of the Enhanced Workbench (Layouts and Designer) provides you with many of the same or equivalent features and functionality as the original Workbench (developed using ADF technology) while providing you with a long list of usability, functionality and performance improvements.

NOTE: While the first release of the Enhanced Workbench has many of the features and functions of the current Workbench, it is not yet fully functionally equivalent and should only be used for review, testing and evaluation purposes. The Enhanced Workbench should not be rolled out into production.

Both the Enhanced Workbench and the original Workbench will continue to coexist for several update cycles in order to provide you with ample time to migrate from the older technology to the new Enhanced Workbench technology. Your migration to the Enhanced Workbench will be supported by migration tools that will allow you to easily move your existing Workbench Layouts into the new Enhanced Workbench infrastructure.

Some of the highlights of the Enhanced Workbench include:

- The Workbench Manager which supports migrating your existing Workbench Layouts to the Enhanced Workbench Format - and vice versa

- A collapsible menu for navigation that you can easily toggle on and off

- A new Analytics Dashboard Content Type which allows you to add BI content as a panel within the workbench

- A new Data Visualization Content Type which allows you to incorporate data visualization project content within the workbench

- A new Transactional Report Type which allows you to include an Oracle Analytics Publisher report within the workbench

- A new Shipment Gantt Content Type which provides you with a Gantt view of your shipments

- A new Overview Panel for your all your Gantts that provides you with an improved navigation experience within the available Gantts

- The ability to do multiple splits per region

- An enhanced type ahead with contains Workbench Layout ID dropdown search

- The ability to collapse tabs in a region to gain additional screen real estate

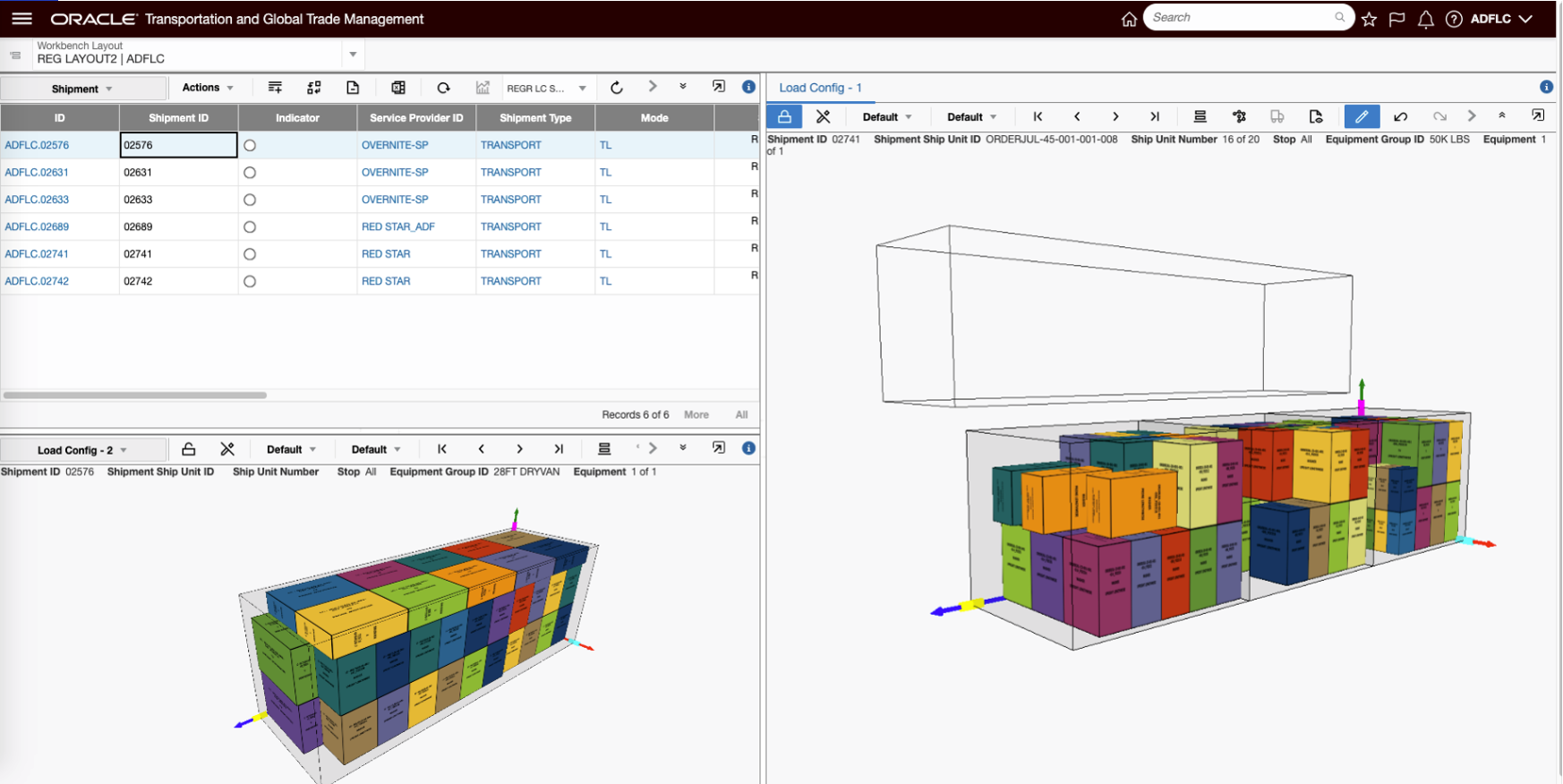

- Load Config Region now supports Edits within the Enhanced Workbench

- The ability to flip between the Region Content and the Region Details

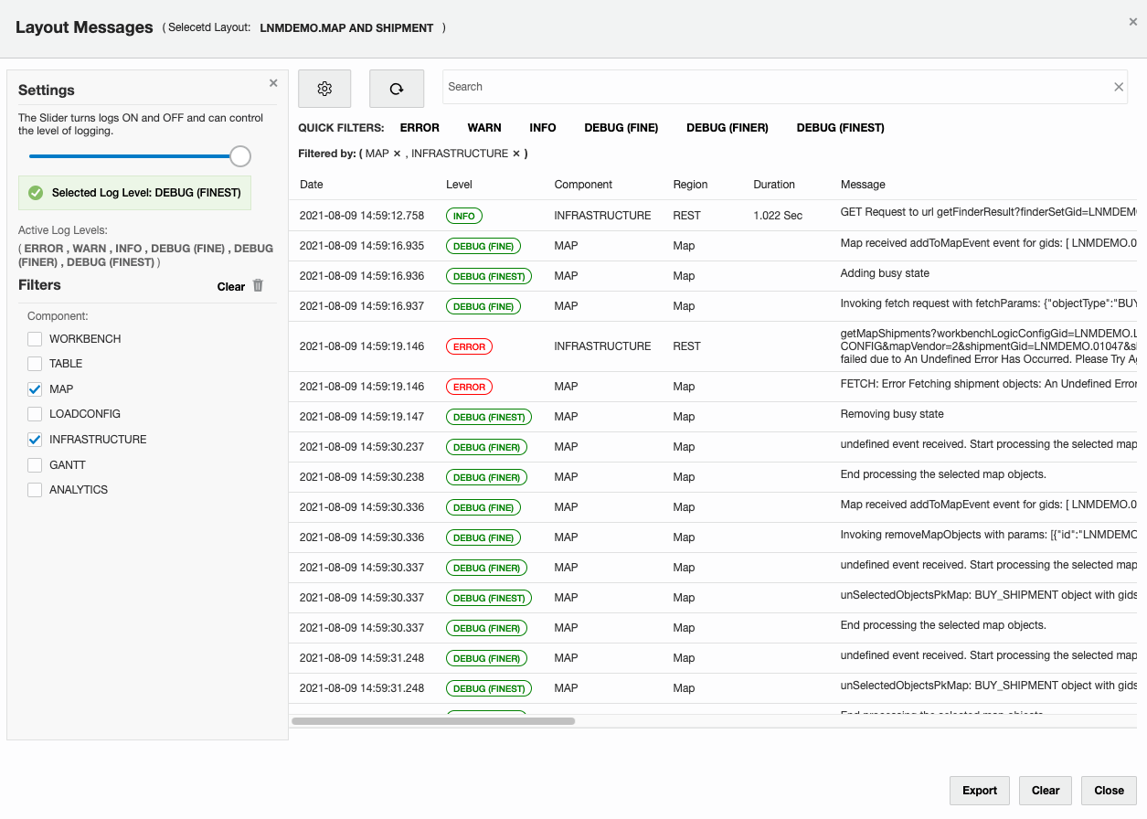

- Improved Logging

- More Informative - Progress Bar – in-process Logging and error messages all improved

- Configurable “on the fly”

- Duration as a metric

Below you will find an example of just some of the changes provided by the new Enhanced Workbench.

The Workbench Manager allows you to easily find and select one or more of your Workbench layouts and convert the Workbenches between a Legacy or Enhanced Workbench view using the actions - Enhanced View Enabled - which moves the Legacy Workbench to an Enhanced Workbench - or Legacy View Enabled - which moves an Enhanced Workbench to a Legacy Workbench view.

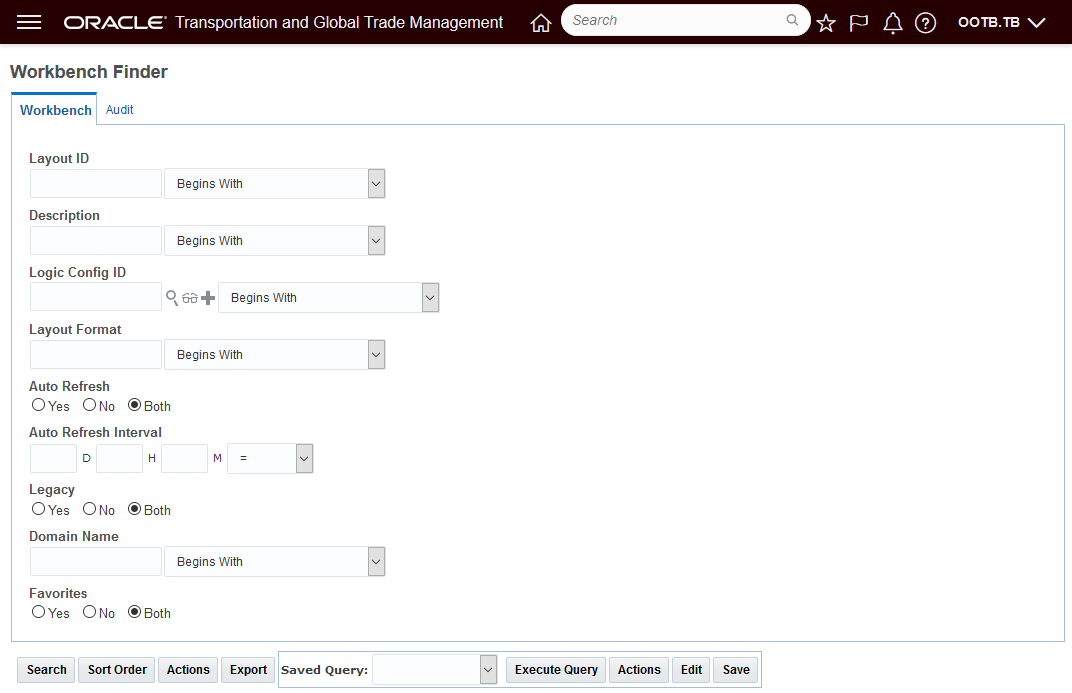

Workbench Manager Finder

Use the Workbench Manager to find all of your Legacy Workbenches.

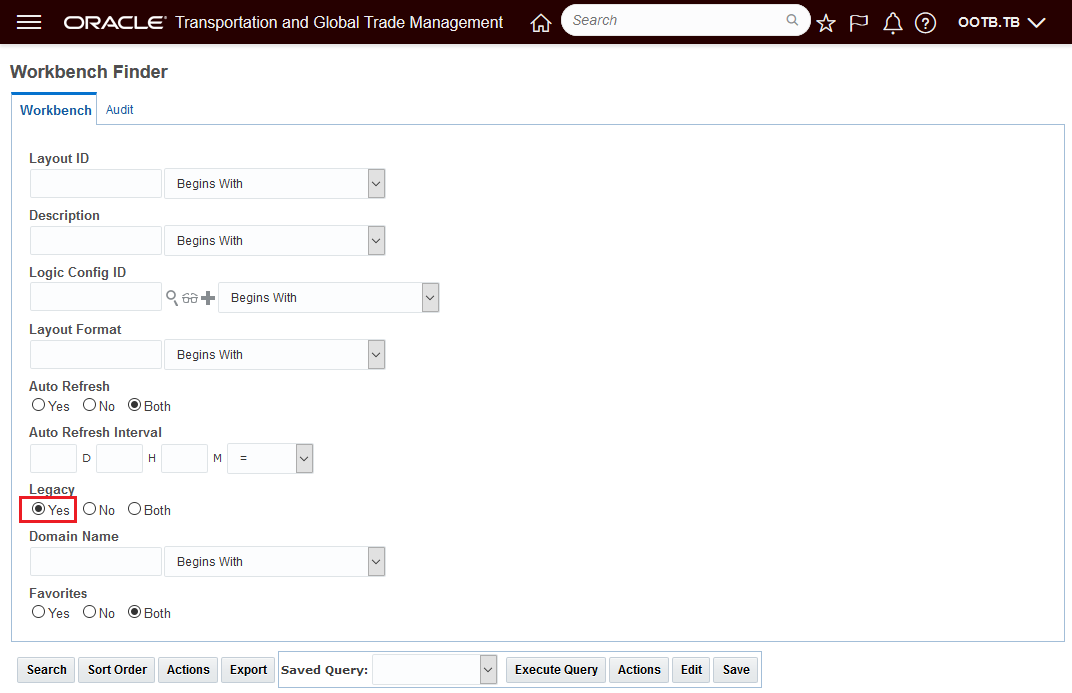

Workbench Manager Finder - Find Legacy Workbench Layouts

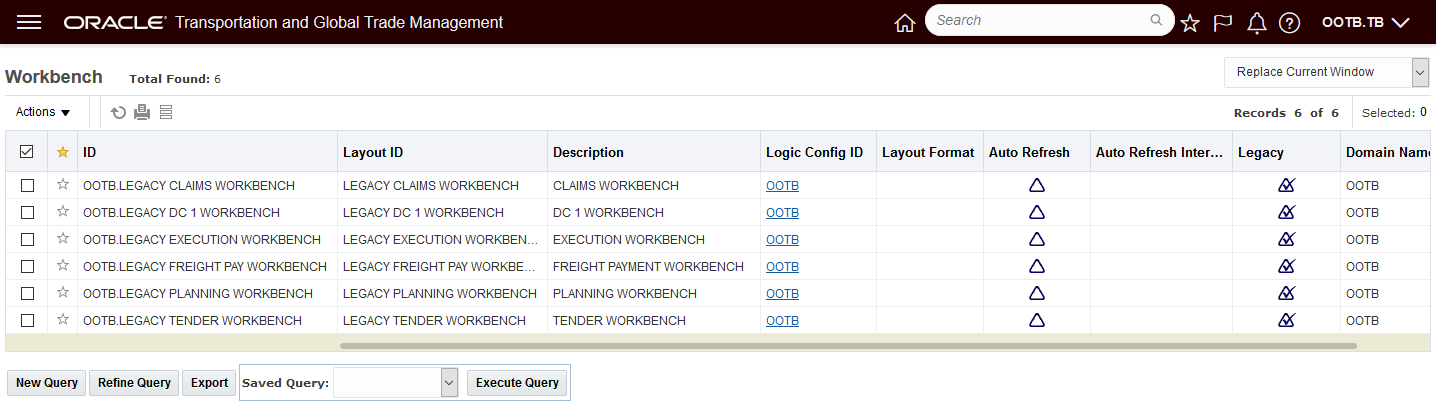

The results below show six Legacy Workbenches. Converting all six Workbenches from Legacy to Enhanced only requires you to select all six and run the action Enhanced View Enabled as shown below.

Legacy Workbench Finder Results

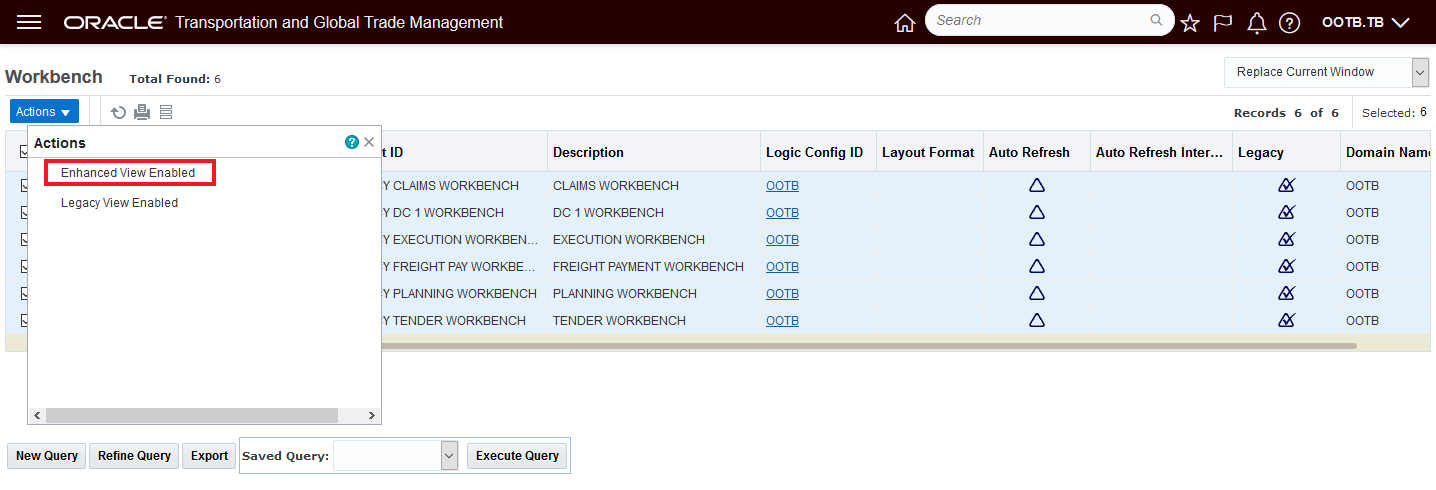

Select the set and convert them all to Enhanced using the action Enhanced View Enabled

Enhanced View Enabled Action

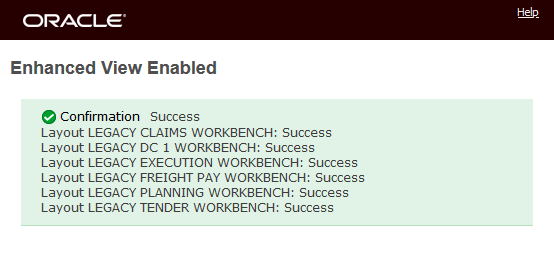

Results of running the action - each workbench is converted

Enhanced View Enabled - Workbench Conversion Message

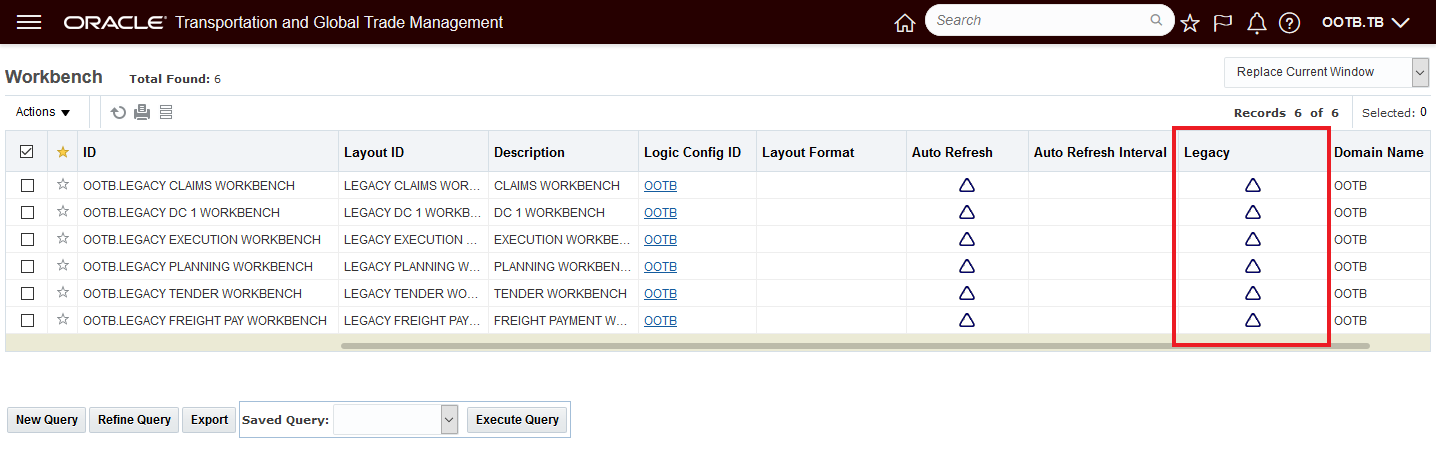

The six selected Workbenches that were in the Legacy format are no longer legacy workbenches. The converted Workbenches will now show up in the Enhanced Workbench designer and not in the Legacy Workbench Designer.

Legacy to Enhanced View Converted

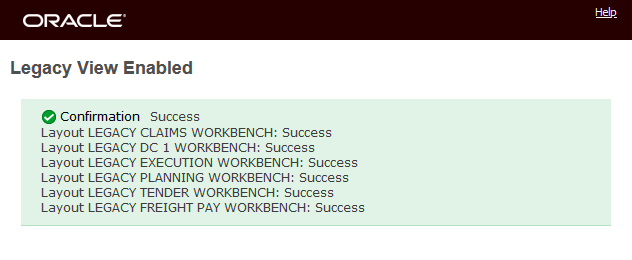

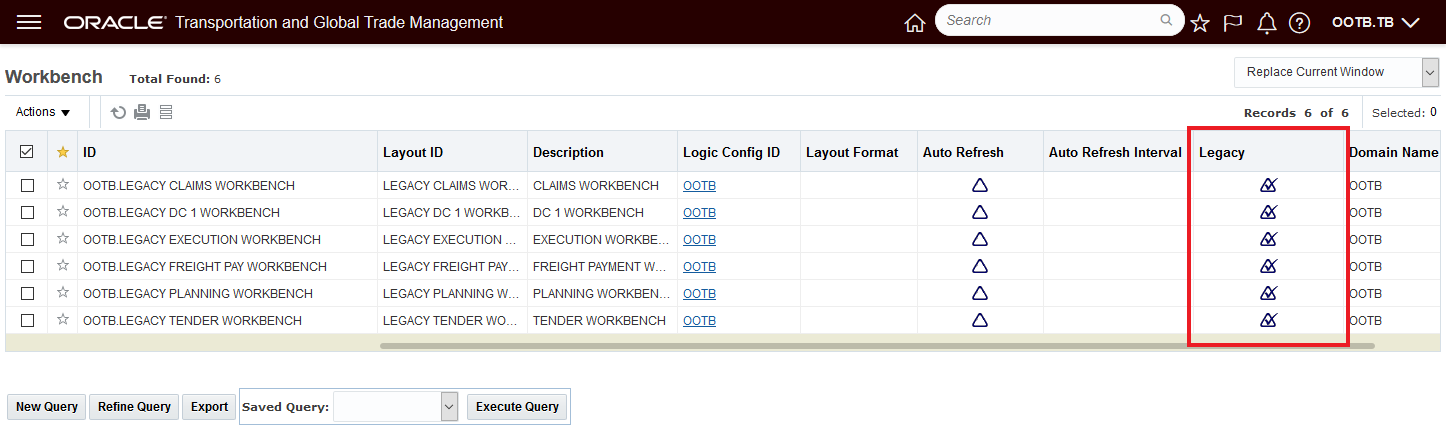

If, for some reason you need to convert the Workbenches back to the Legacy format - that can be done very easily by selecting the Workbenches and running the Legacy View Enabled action as shown below.

Enhanced back to Legacy

Convert Back to Legacy

Legacy Flag Visible

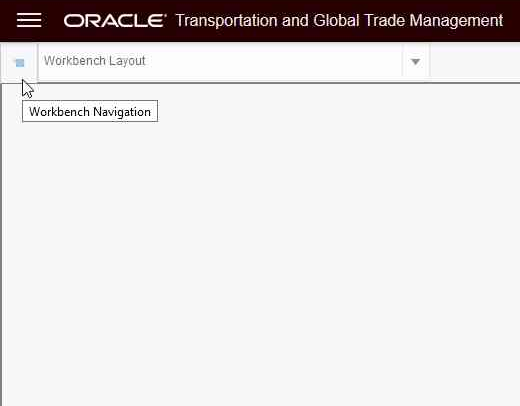

The Enhanced Workbench Menu and Navigation options can be easily toggled on and Off.

Enhanced Workbench Menu

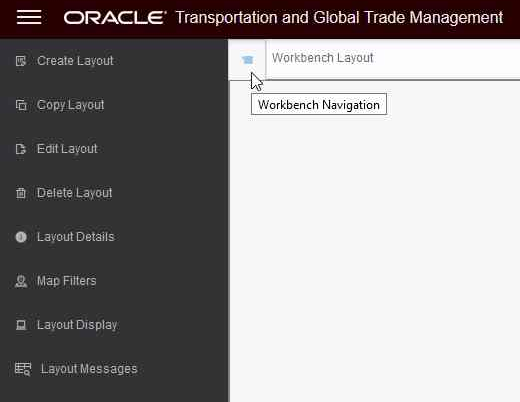

Additional Content Types

- New Analytics Dashboard Content Type which allows you to add BI content as a panel within the workbench

- New Data Visualization Content Type

- New Shipment Gantt Content Type which provides you with a Gantt view of your shipments over time

- New Transactional Report Type which allows you to include an Oracle Analytics Publisher report within the workbench

New Content Types Analytics and Shipment Gantt

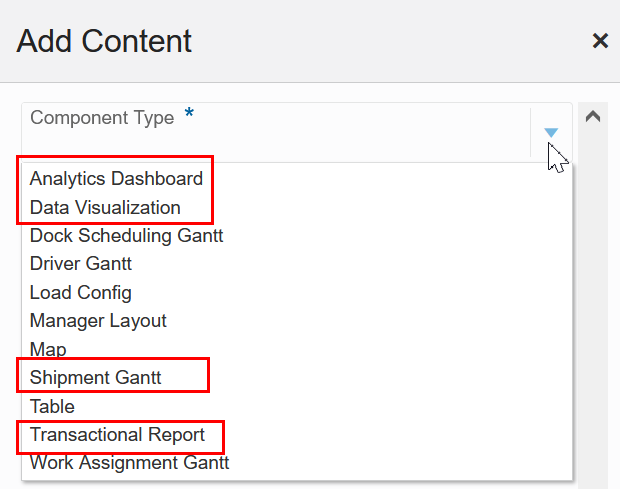

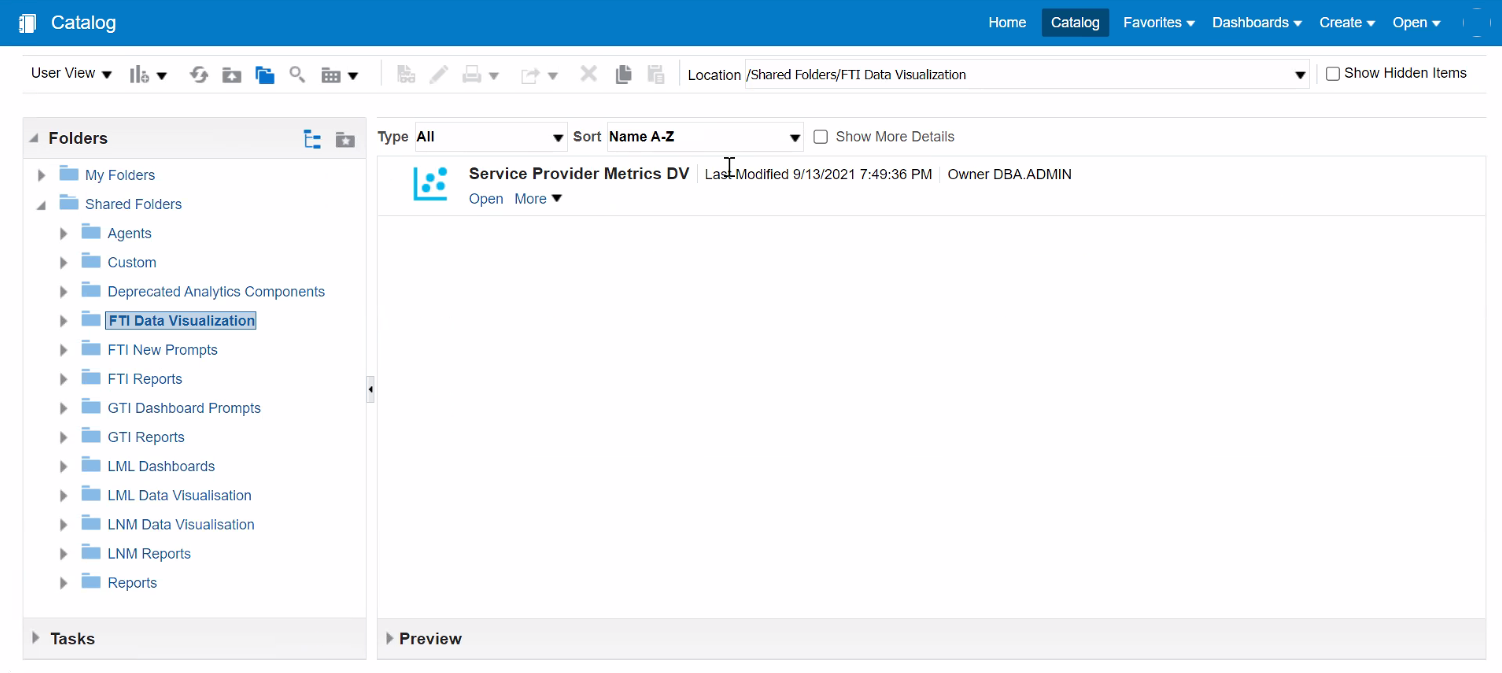

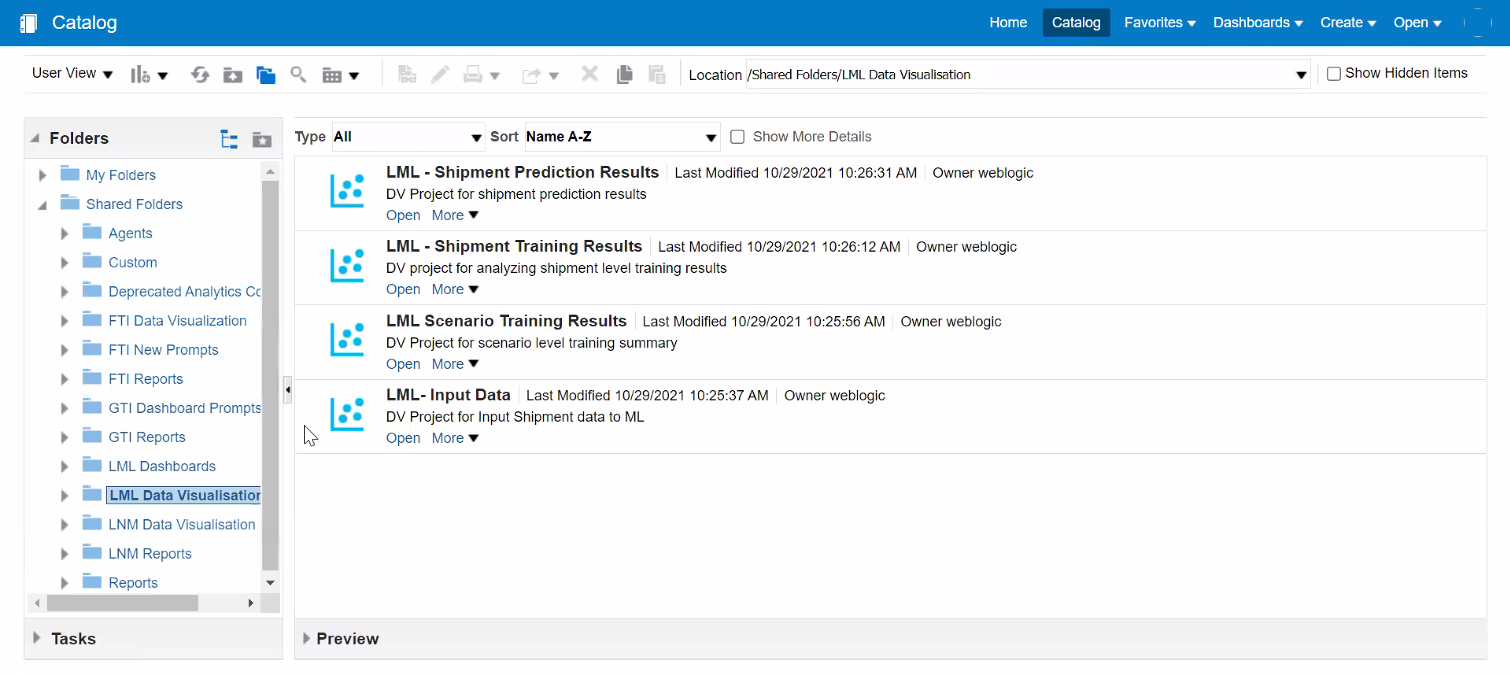

Below is an example of the Analytics Dashboard Content Type incorporated into the Enhanced Workbench Layout. In this example, the Service Provider Metrics Dashboard is incorporated.

Analytics Dashboard Component - Service Provider Metrics

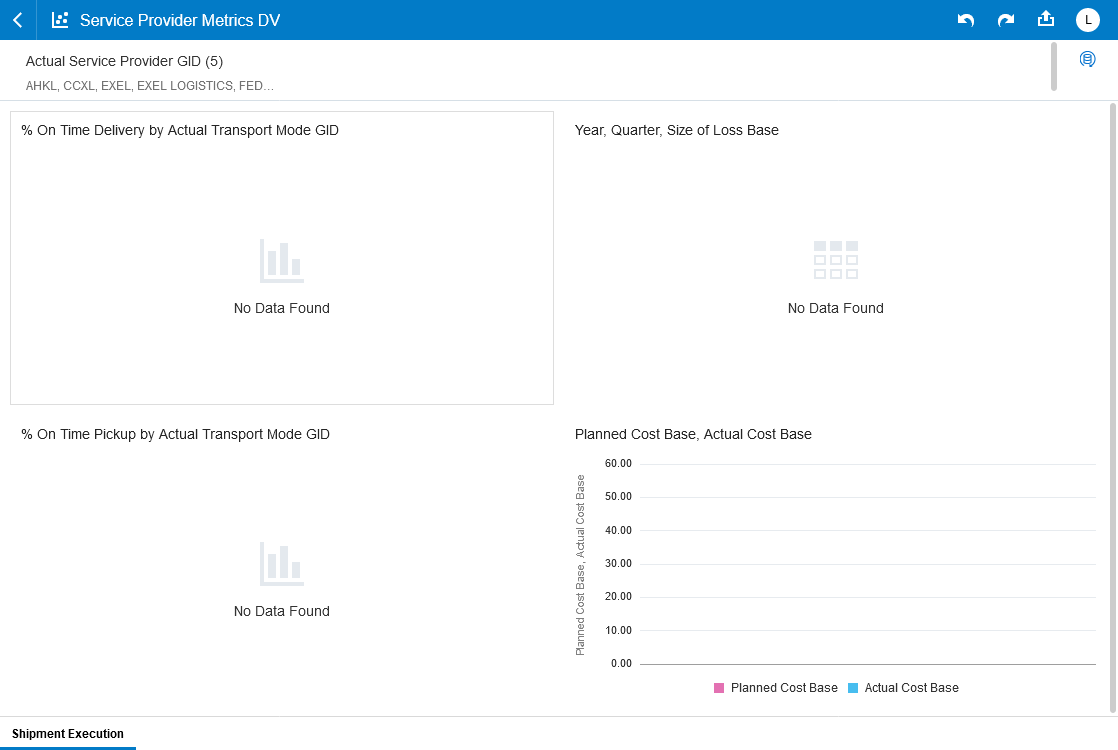

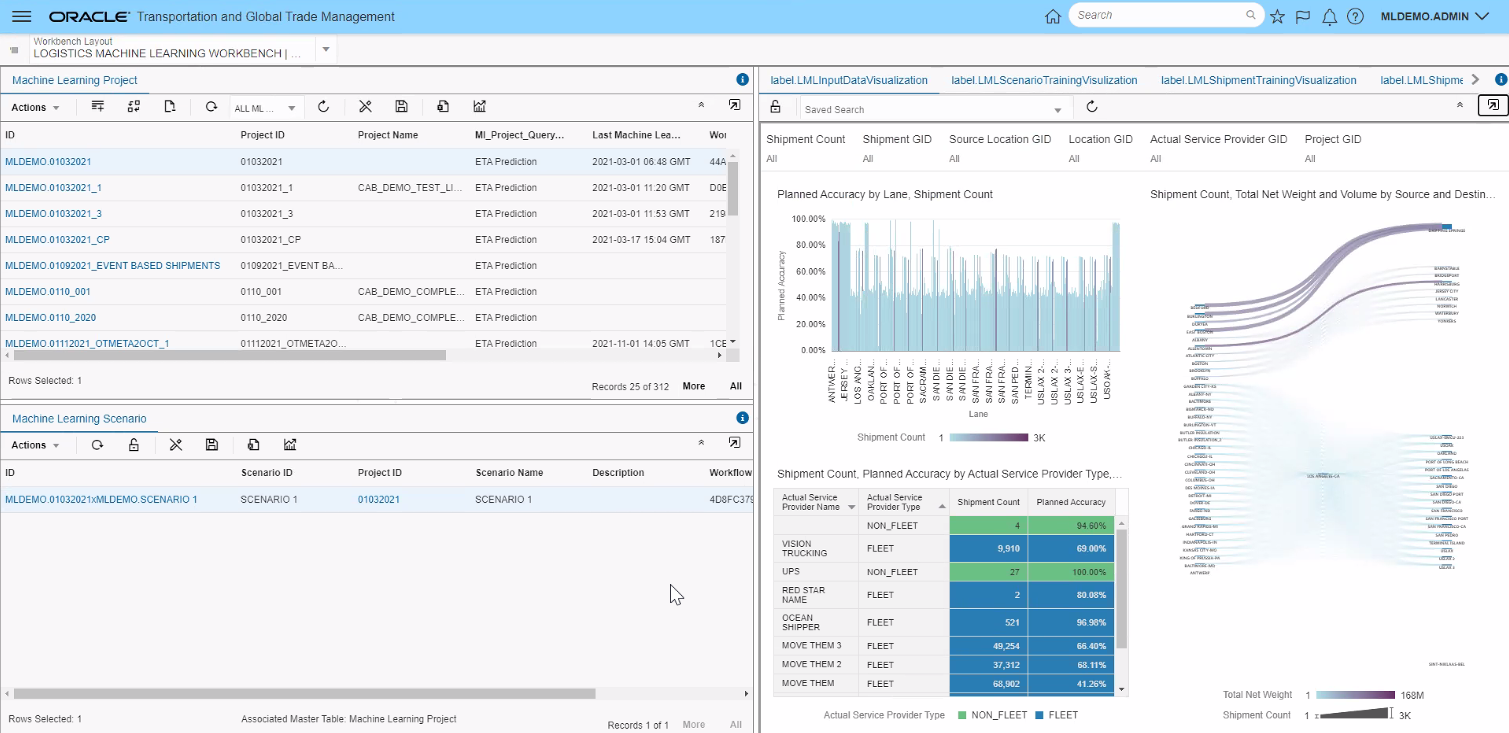

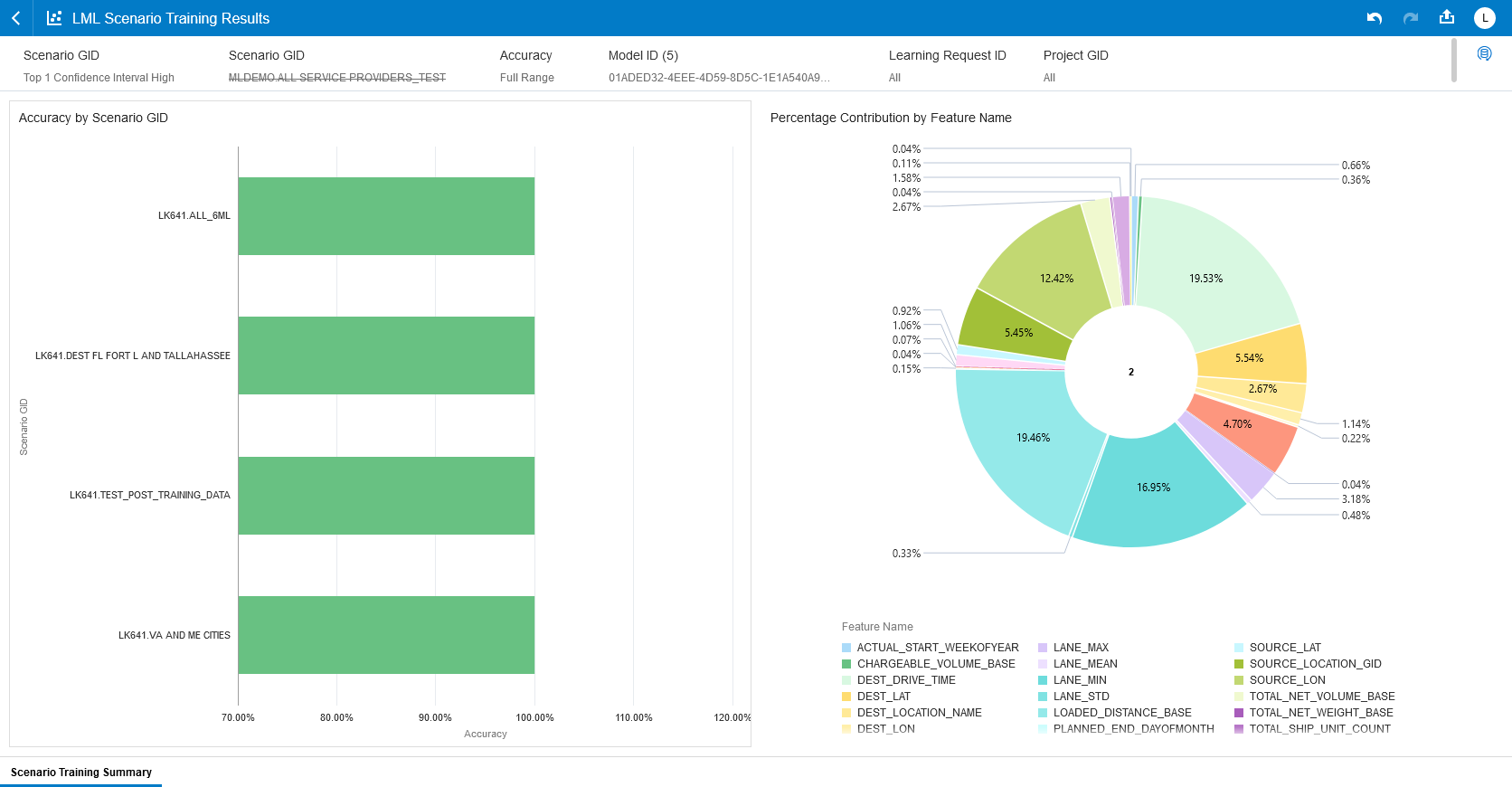

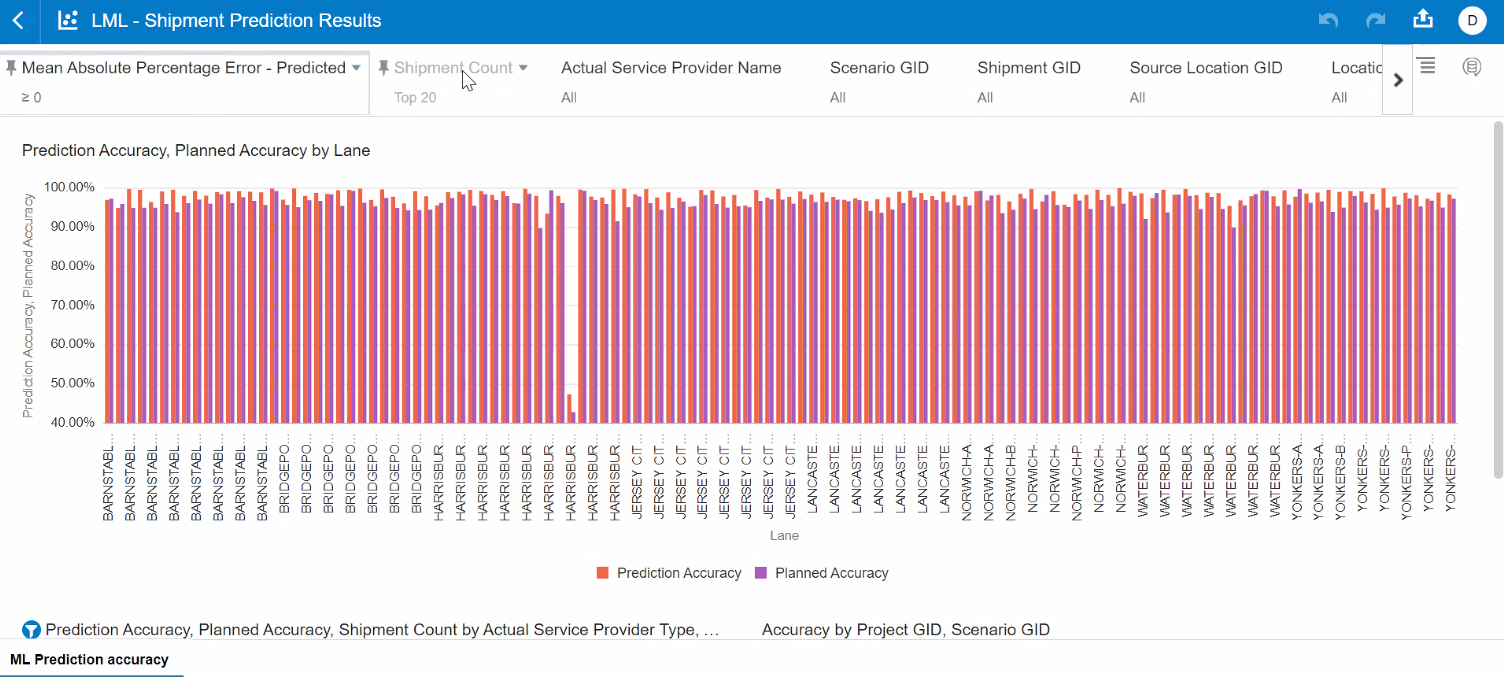

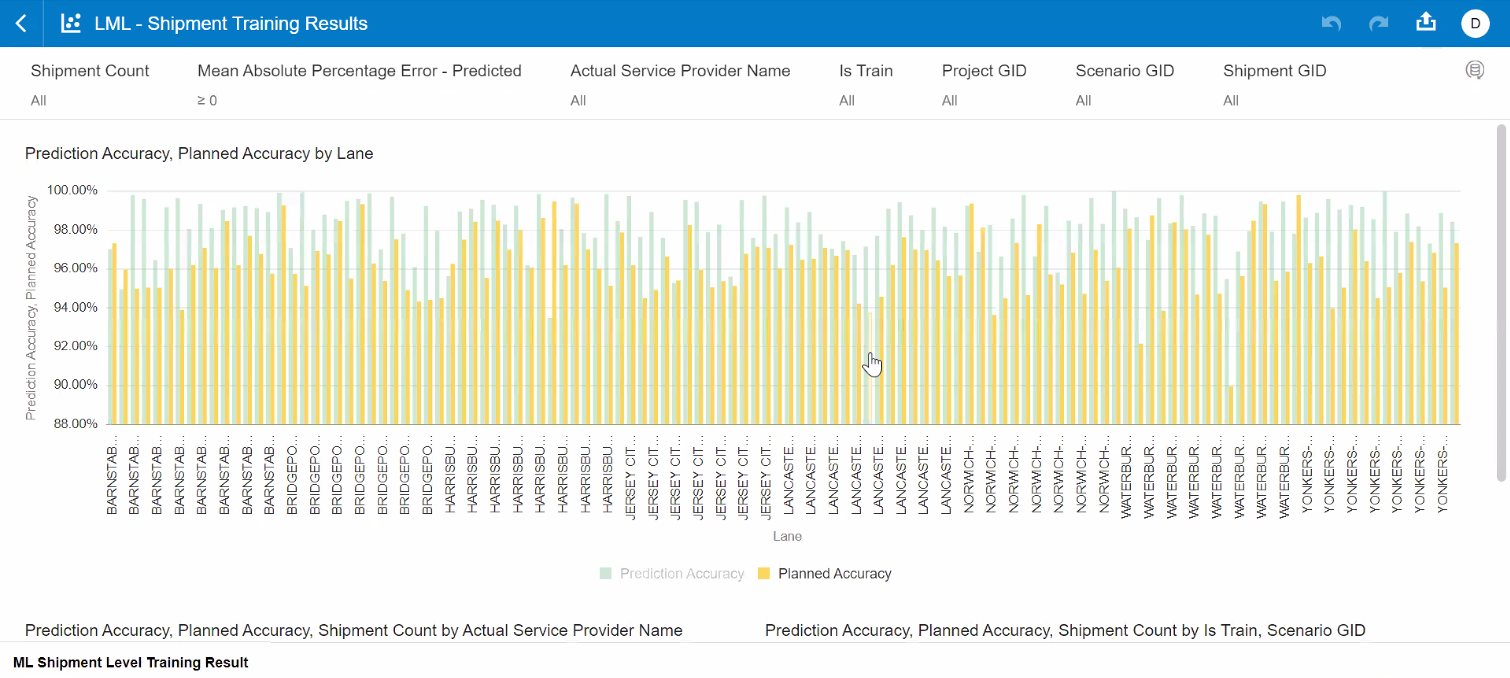

Below is an example of the new Data Visualization Content Type incorporated into the Enhanced Workbench Layout. In this example the analysis is for Logistics Machine Learning accuracy.

Data Visualization Content Type

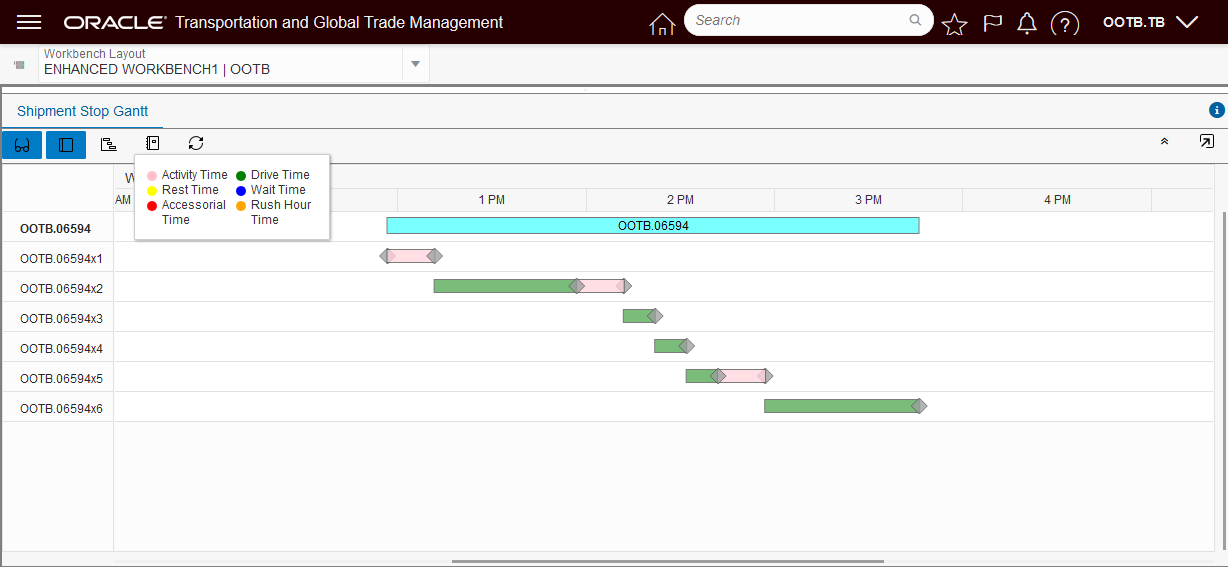

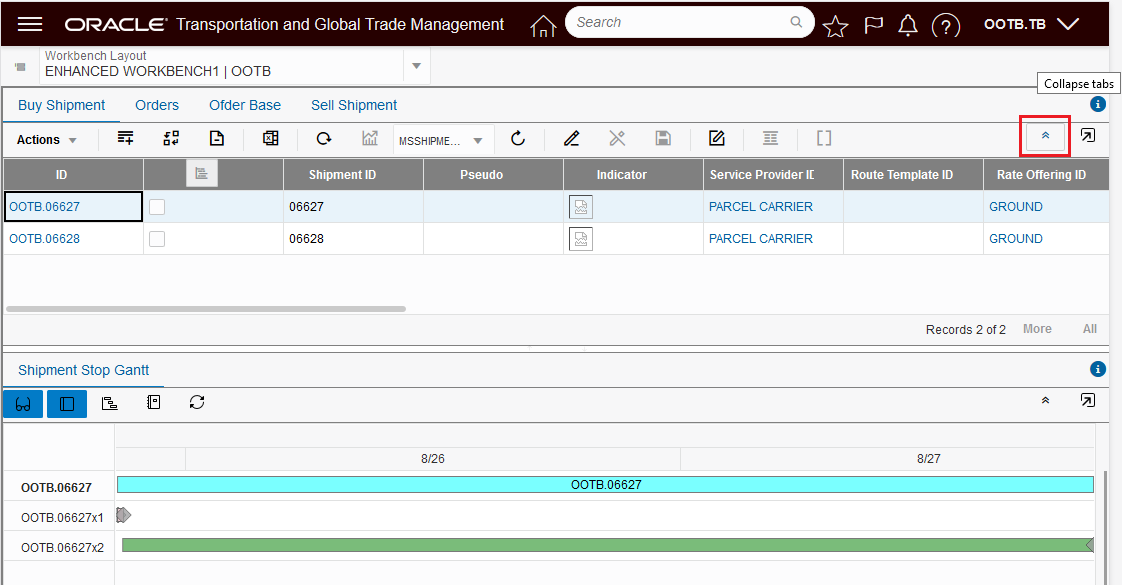

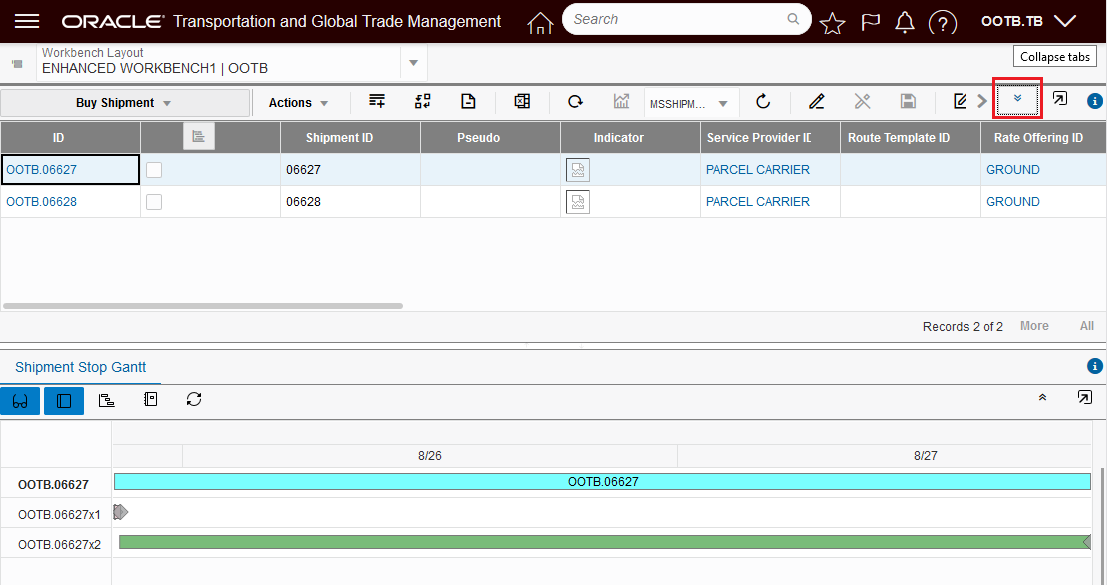

The example below shows the new Shipment Gantt which provides you with the opportunity to visualize your shipments in a Gantt format.

Shipment Stop Gantt

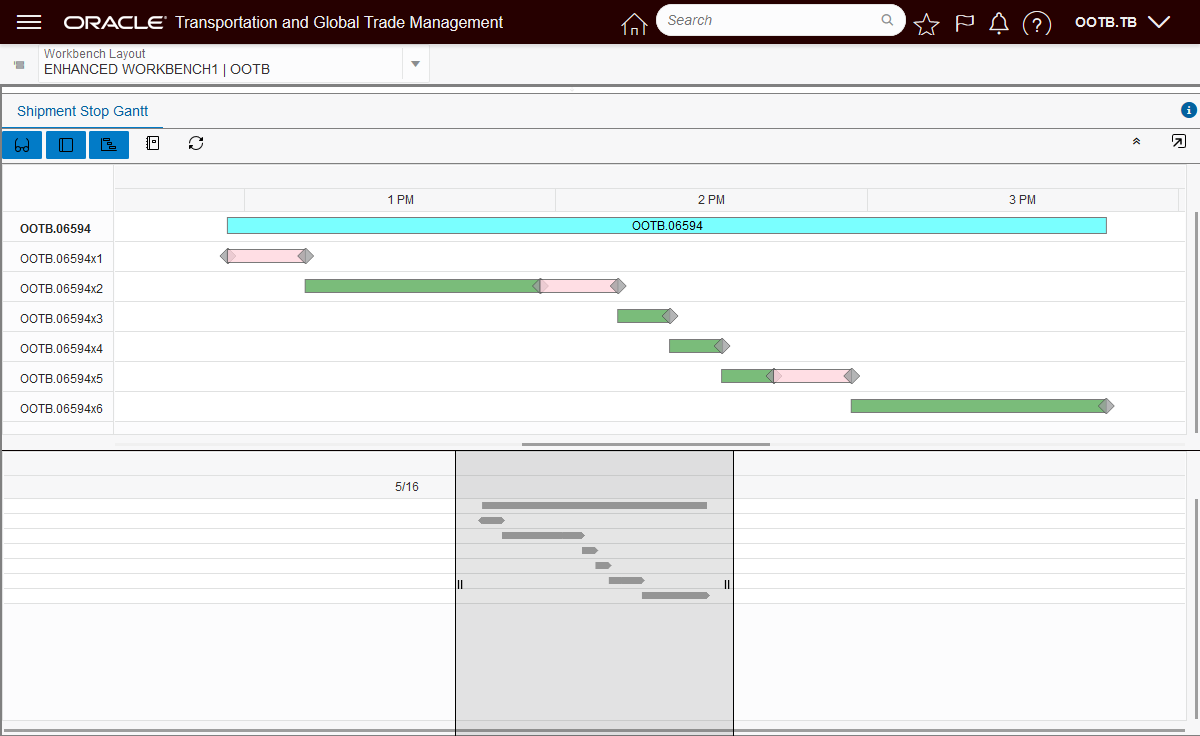

The Overview Panel has been added to all the Gantts (Dock Scheduling, Driver, Shipment, and Work Assignment) to allow for an improved Gantt navigation experience. The Overview allows you dynamically set the time window you wish to review the Gantt with, as well as allowing you to slide that window across time - either earlier or later.

In the example below, the Overview - by default - sets an overview window that covers the entire shipment timeline.

Gantt Overview

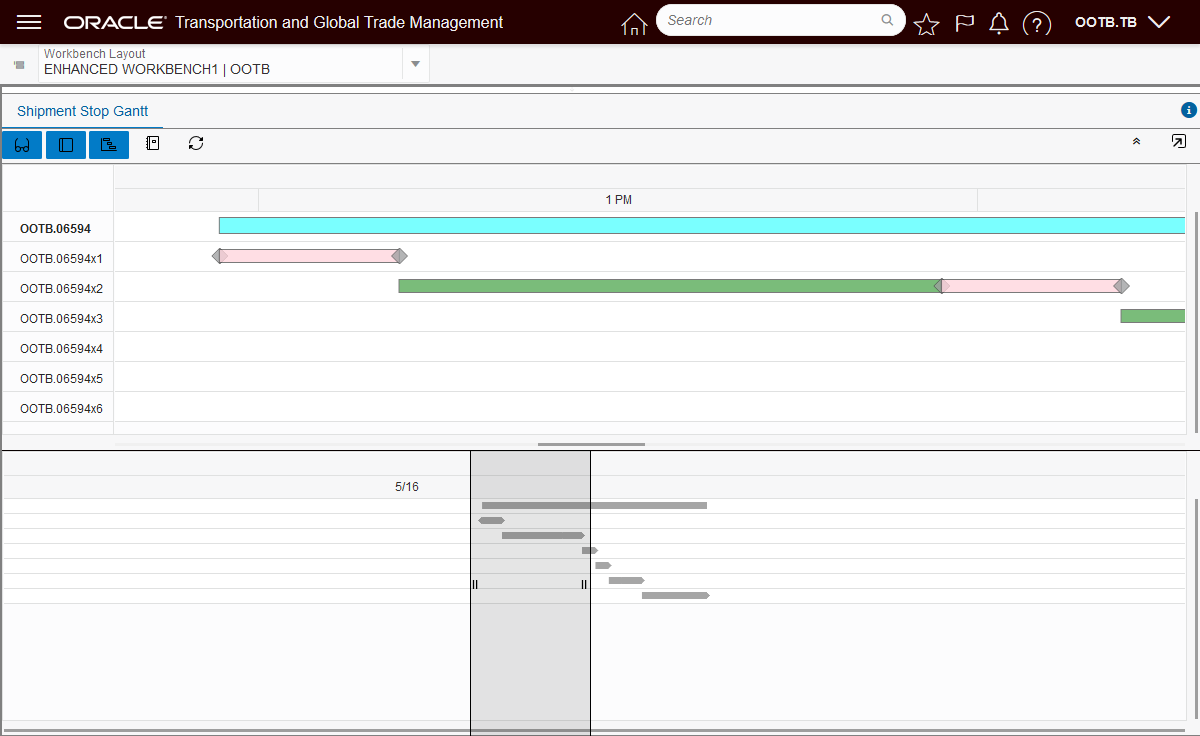

You can "zoom in" to a more specific time by simply reducing the size of the Overview window.

Narrow Overview Gantt Window

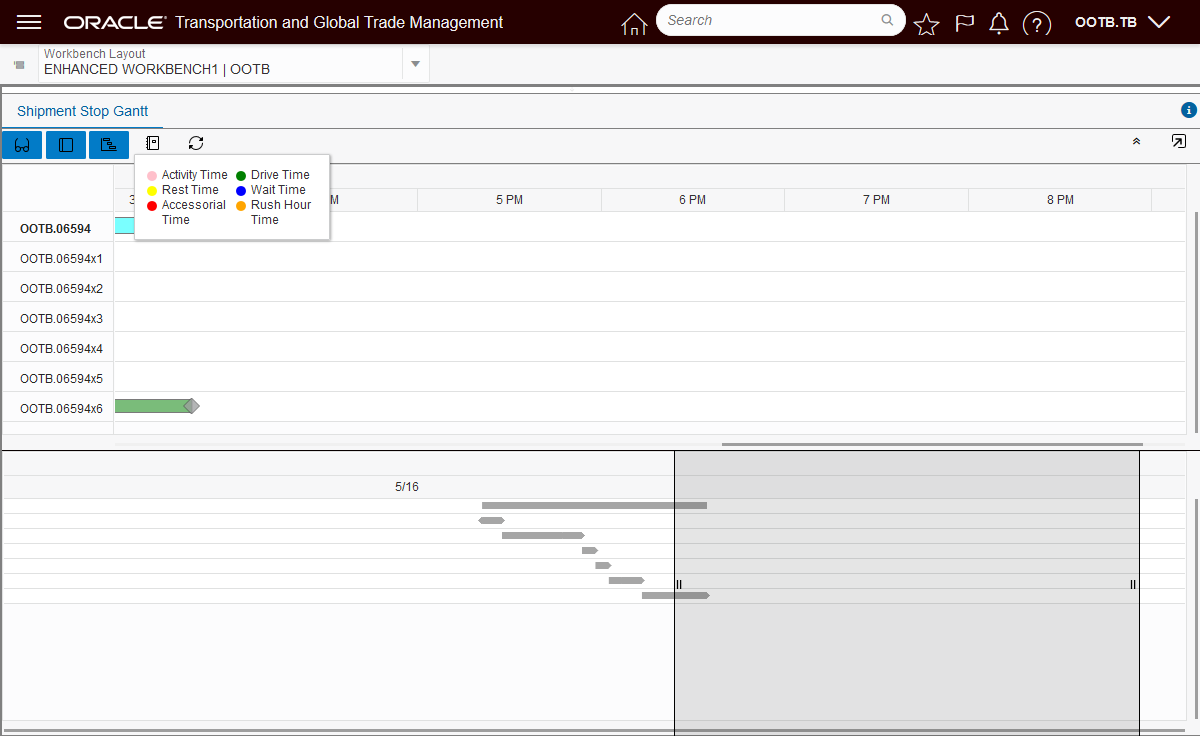

You can also use the Overview window to change your time frame - left (earlier), or right (later).

Overview Shifted to the Right

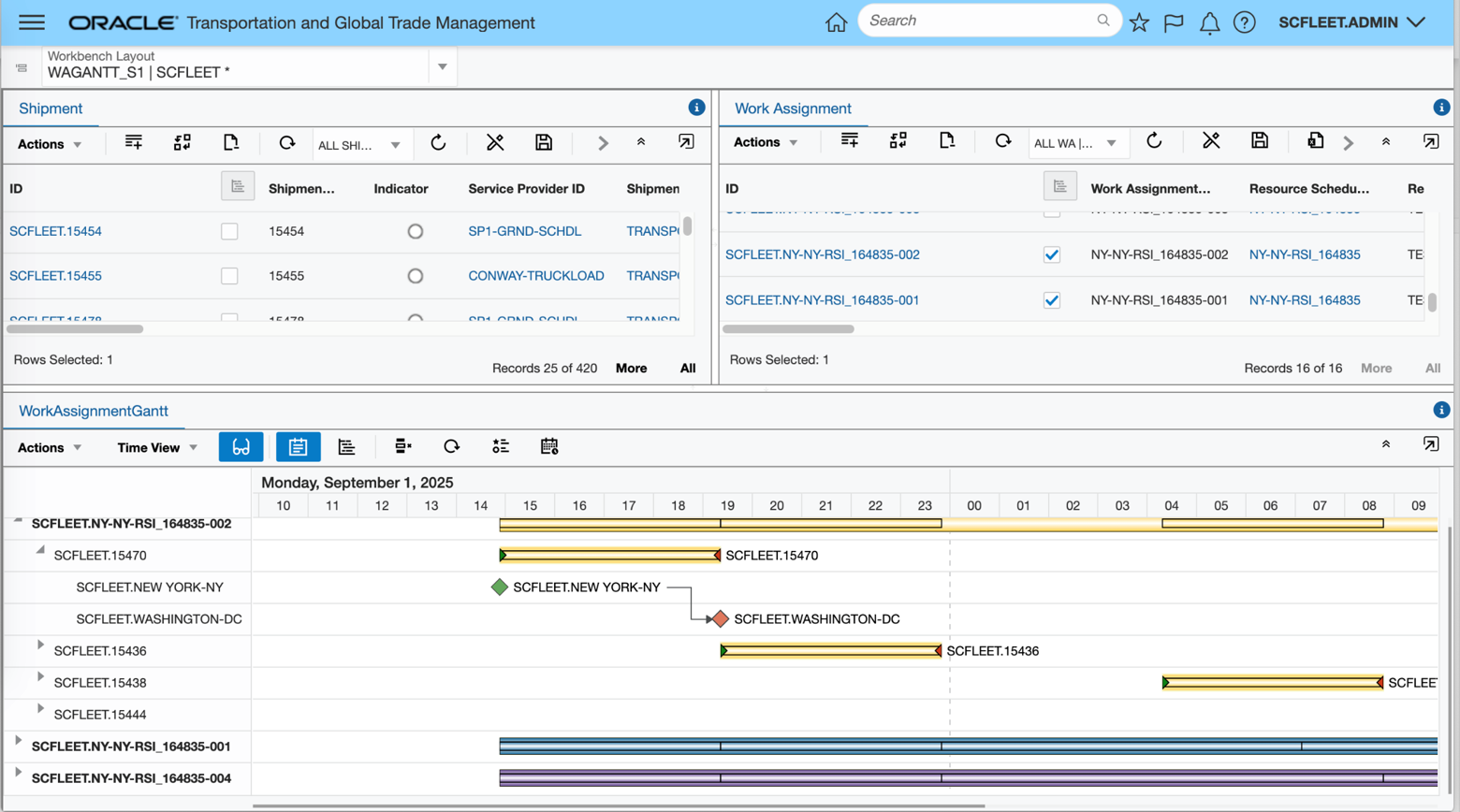

The new Work Assignment Gantt, below, has also been enhanced to provide a clean, modern and more information rich view into your work assignments..

Work Assignment Gantt

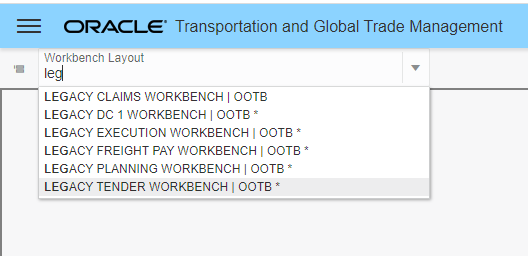

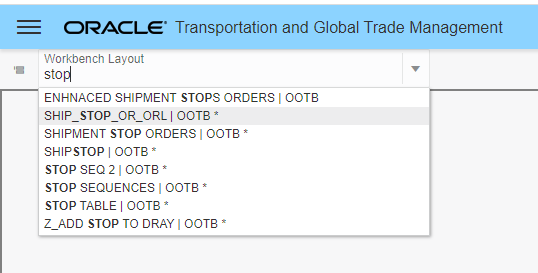

The Enhanced Workbench Drop Down provides you with an improved typeahead Search capability looking for Workbench Layouts in the dropdowns using a contains search for text entered.

Improved Search - All Enhanced Workbenches with "leg" in the ID

Improved Search - All Workbenches with "stop" in the ID

The example below shows the new capability available to you for collapsing your tabs.

Expanded Tabs View

Collapsed Tabs View

The Load Config region now supports the Edit Load Config view and manipulations.

Edit Load Config Available in Enhanced Workbench

The Enhanced Workbench also provides you with greatly improved logging for trouble shooting workbench issues. In addition to improved and expanded Errors, Warnings and Info related messages, logging now uses colors to denote different levels of logging - Errors (red), Debug and Info messages (green).

Improved Logging

Steps to Create a Basic Enhanced Workbench

The steps for creating a workbench using the new Enhanced Workbench Designer are equivalent to the steps you have used to create Workbenches previously. There are just a few differences in the navigation and icons displayed to access the functionality used to create and configure an Enhanced Workbench. The example below will be used to identify the steps required to create a simple Enhanced Workbench. The example will focus on the changes.

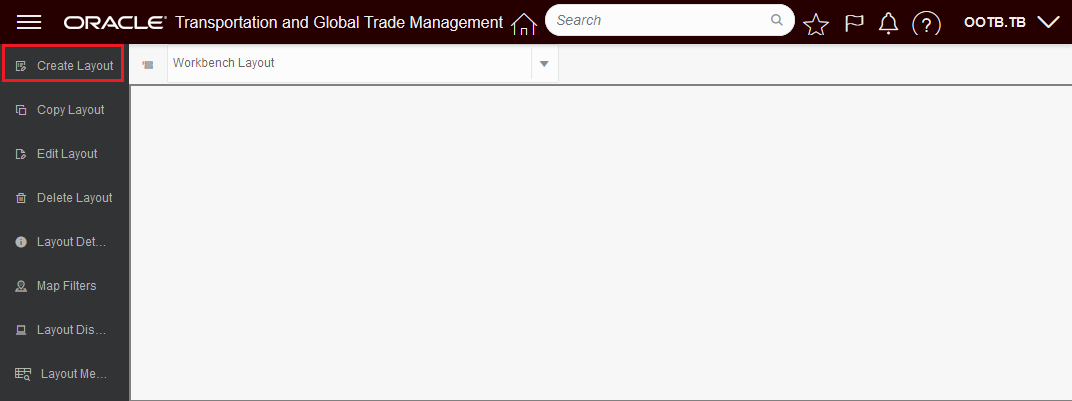

Step one is to navigate to the Enhanced Workbench Designer. Once there you will select the Create Layout option.

Bring up Enhanced Workbench Navigation menu.

Select Create Layout.

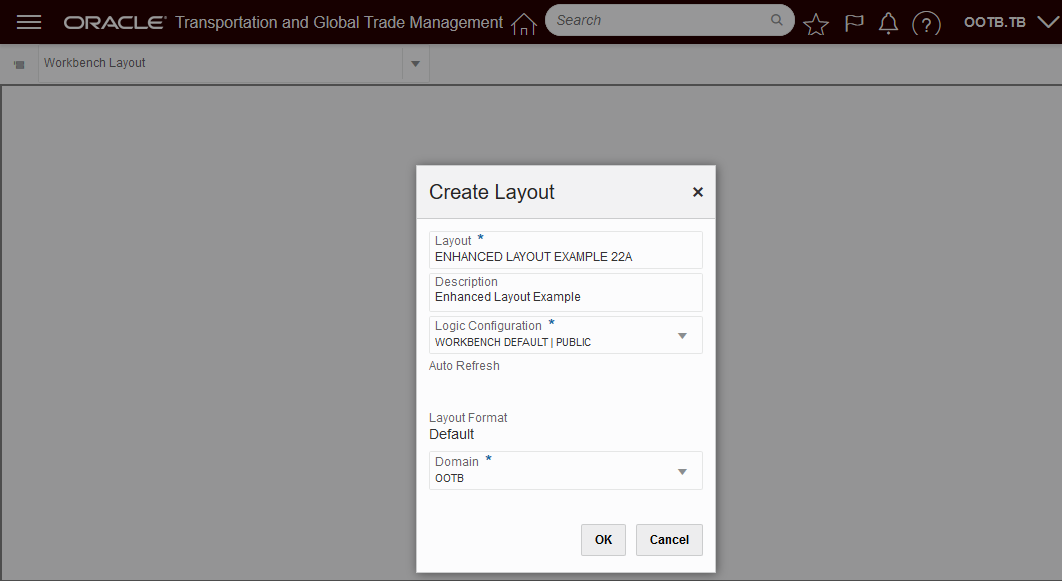

Enter info about your workbench.

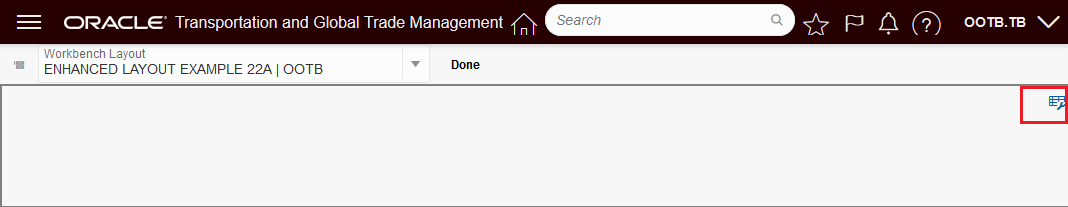

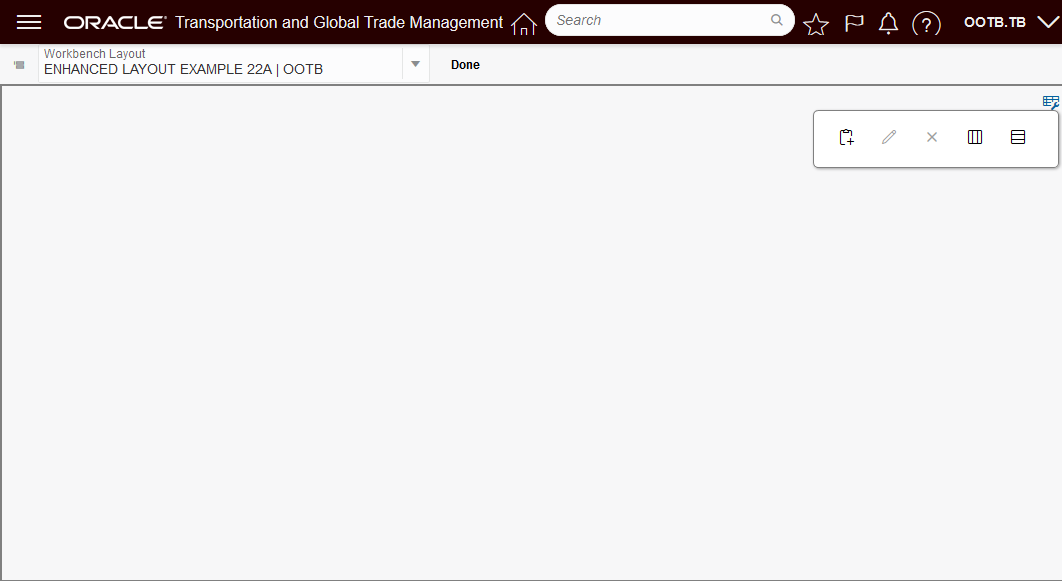

Select the Tool Icon to add, delete, and edit content and split vertically or horizontally.

Tool Icon

Add Content

Edit Content

Remove Content

Split Horizontally

Split Vertically

This feature resets the development platform for the Workbench Designer and Workbench Layouts providing you with many usability, functionality and performance improvements.

Steps to Enable

The Enhanced Workbench Designer can be made visible on your menu by doing the following:

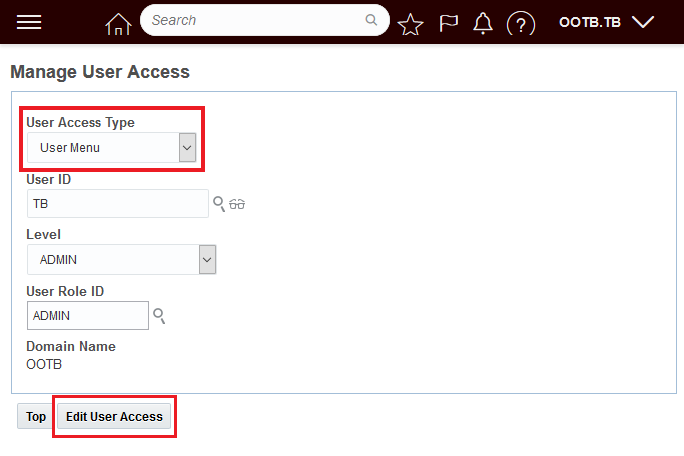

- Configuration and Administration > User Configuration > Manage User Access

- Select User Access Type of User Menu

- Fill in your user info - User ID, User Level, User Role etc.

- Select Edit User Access

Manage User Access

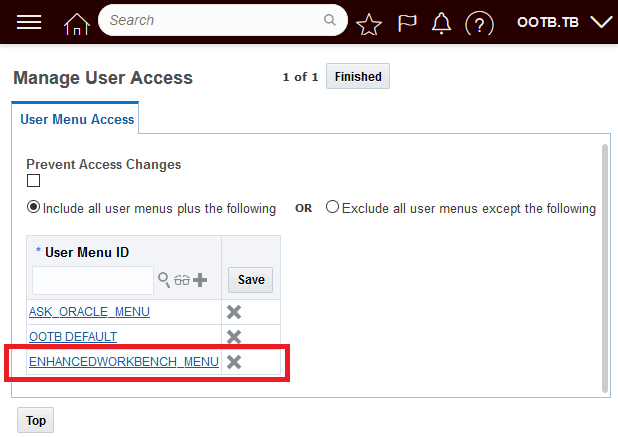

- Add the ENHANCEDWORKBENCH_MENU to the User Menus you have access to

Add Enhanced Workbench Menu

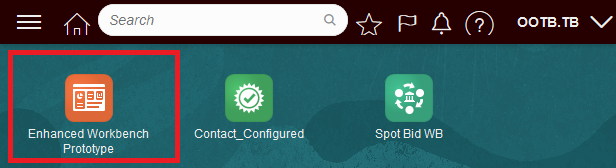

- When completed the Icon for the Enhanced Workbench Prototype should be visible.

Enhanced Workbench Access Provided

Tips And Considerations

NOTE: Important! The 22A Enhanced Workbench Prototype is provided for testing and evaluation purposes ONLY. The Enhanced Workbench Prototype is NOT intended to be used in your production environment. The Enhanced Workbench Prototype provides significant improvements and additional features - but does not yet have full functional equivalence with the legacy Workbench.

The Enhanced Workbench will ONLY work if the JET APPLICATION SHELL Optional Feature is Opted In.

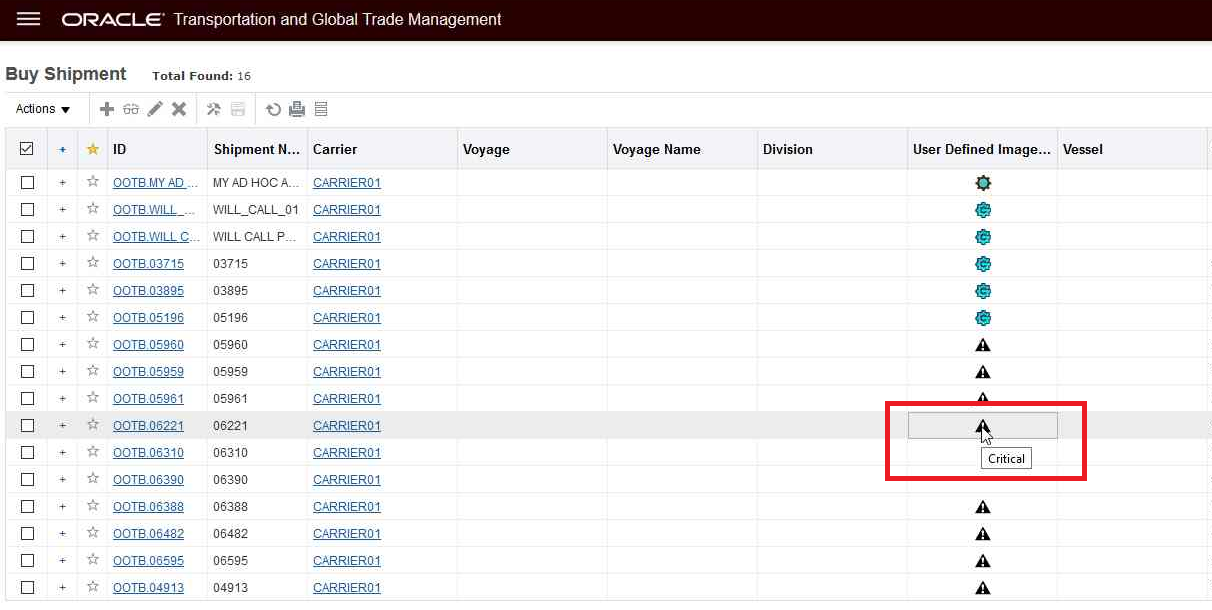

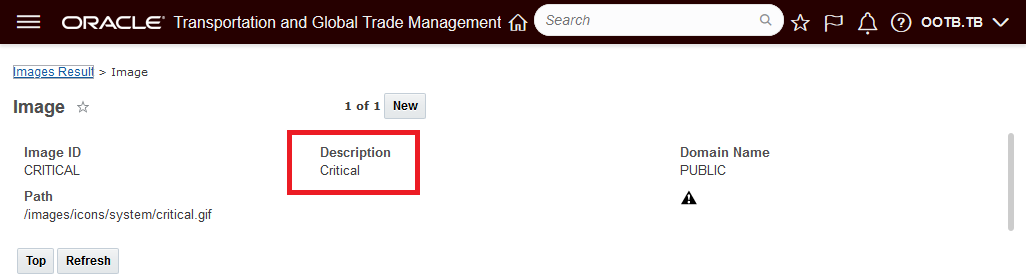

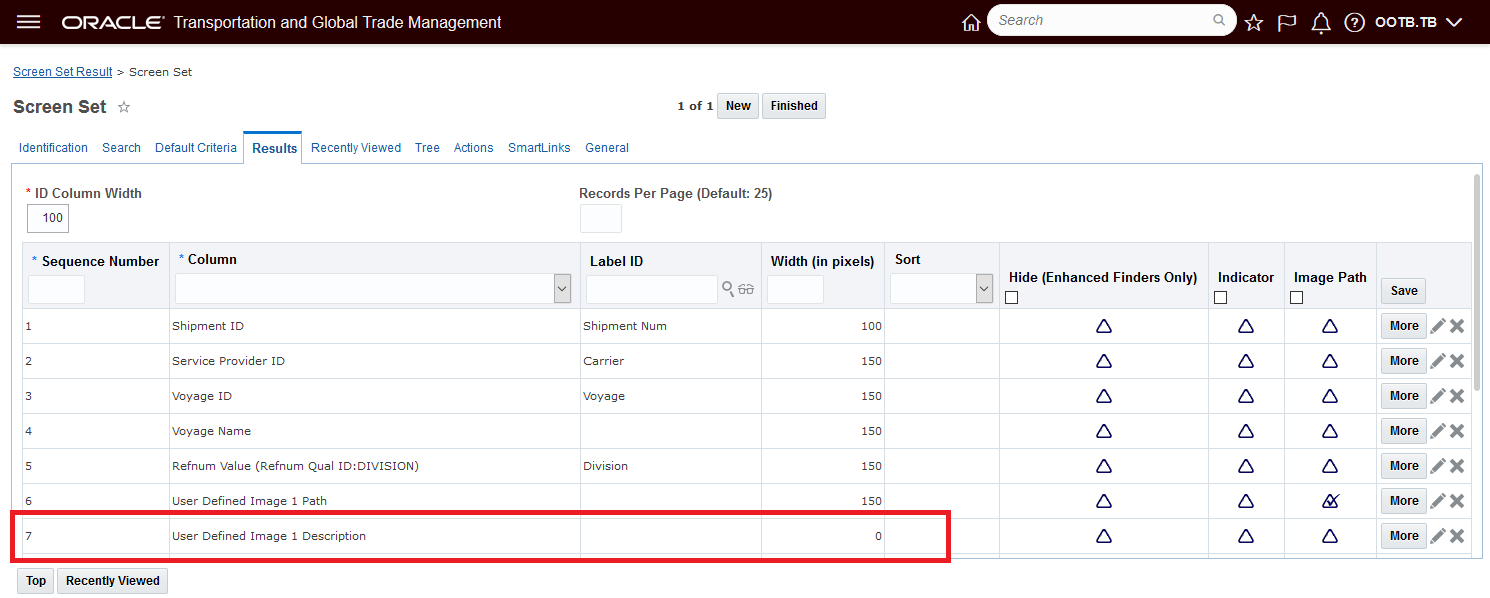

Display User Defined Image Description When Hovering

This feature uses the User Defined Image's Description field, when included in the screenset, as the hover text provided when you hover over your User Defined Image(s).

Previously - when you hovered over a User Defined Image in your finder results, the hover text provided was limited to the generic text "User Defined Image"..

Original User Defined Image Hover Text

With this enhancement, you can configure your screen sets to include the User Defined Image Description fields and when this field is included the hover text provided for the related User Defined Image image will be the User Defined Image Description field.

.

New Hover Text Behavior - User Defined Image Description Field Displayed

User Defined Image

This feature provides you with a quick way to confirm, via hover, what the various User Defined Image(s) represent on your finder results.

Steps to Enable

To enable this feature you will need to include the User Defined Image Description field in your finder results for all the User Defined Images included in your finder results. You can include the User Defined Description fields as a normal addition to the screen set - with a normal width so that the User Defined Description is fully displayed and visible - or - you have the option of adding the User Defined Description field with the width set to "0" which will enable the hover for the image, but will not add the description field to your finder results.

In the setup below - the User Defined Description field for the User Defined Image 1 was added to the screen set with the width set to "0". This enables the hover, without adding the Description field as a column in the finder results.

Setup - User Defined Image Description Field Added - Width = "0"

Screen Set Inline Edit and Mass Update Supports Flex Field Types

This feature provides Screen Set Inline Edit and Mass Update support for editing Flex Fields that have field types of:

- FlexPickList

- FlexDropList

- FixedDropList

Define a Flex Field with a field type of one of the above, add it as a column in the screen set results and set it as editable. When a user edits the field in the results they will be presented with the appropriate options.

This feature adds more editing capabilities in the screen set results.

Steps to Enable

You don't need to do anything to enable this feature.

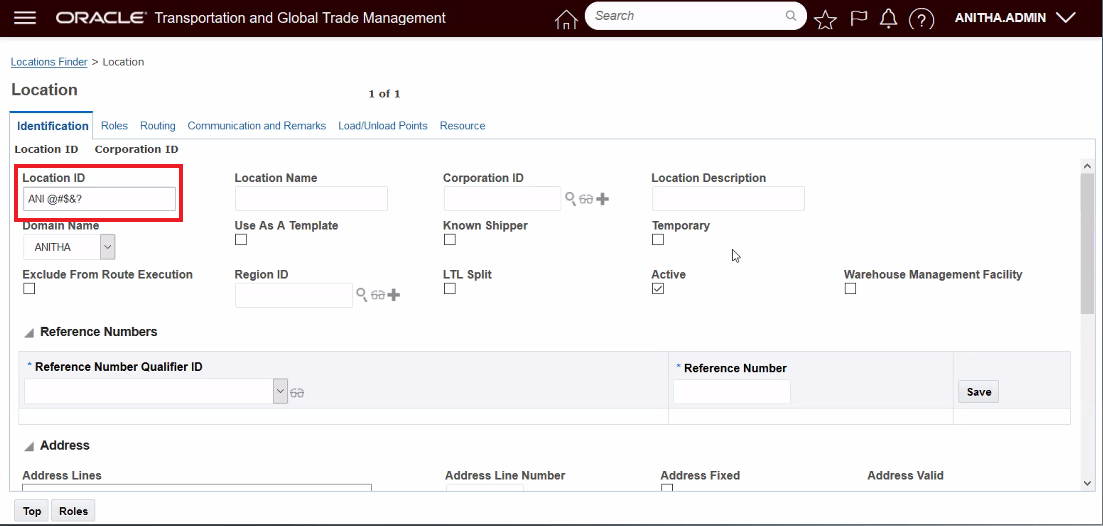

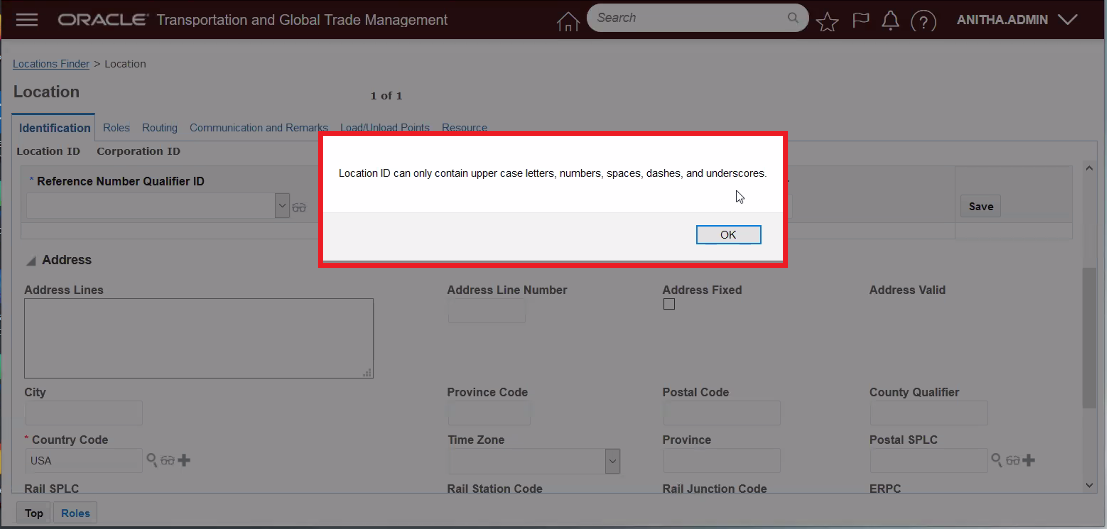

New Property to Configure the Tables to Not Validate XID Characters

This feature provides you with a new property - glog.ui.validateXid.suppress.<table>=true - that you can use to select the table or tables you do not wish to have your XIDs validated for restricted characters: , x > < = / & ? ; # $ ' " \r \n ( ) when the Optional Feature Validate ID (released in 21A) is enabled.

The Validate ID feature, when enabled, will validate newly created records in OTM to insure that the external IDs (XIDs) entered do not contain restricted characters. The goal is to restrict the creation of XIDs to containing only numbers, upper-case letters, spaces, underscores and dashes. This feature allows you to select the tables you would like to have this logic suppressed.

If a potential XID for a new record contains a restricted character, and the Validate ID logic is enabled, the transaction will fail.

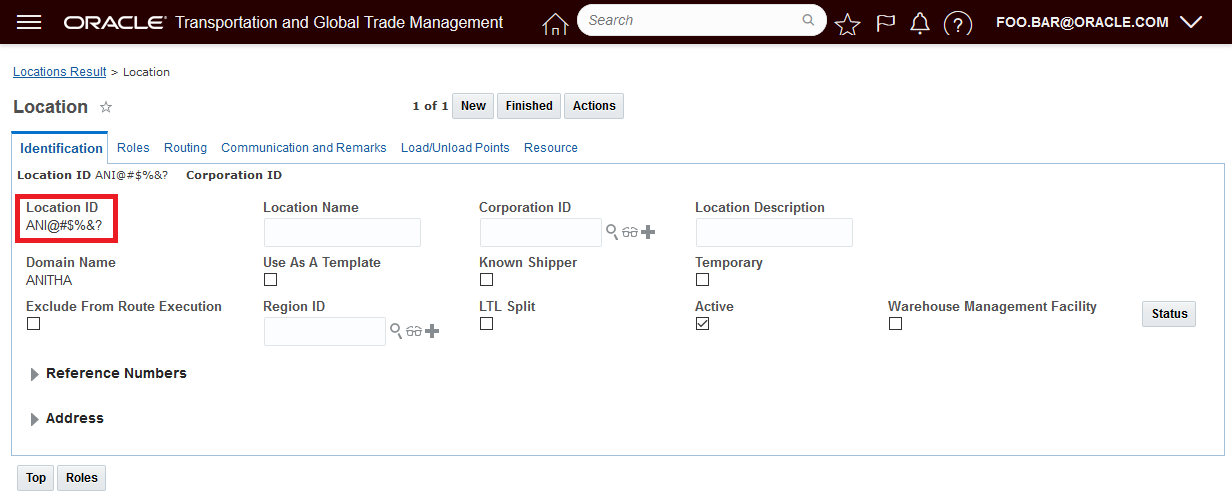

In the example below, the Validate ID logic is enabled and the attempt to enter the location with a location id that contains restricted characters fails.

Location with Restricted Characters in the XID

When you attempt to save this location record with an ID that contains restricted characters you receive the following message.

Error Message Received for Restricted Characters in an ID

Setting the property glog.ui.validateXid.suppress.location = true will suppress the Validate ID logic and will allow the location to be saved even with restricted characters in the ID.

With Property Set to Allow Special Characters for the Location Table

The set of restricted characters is: , x > < = / & ? ; # $ ' " \r \n ( )

The Validate ID logic validates the XID if they are sent in via XML, REST or via the UI - the new property - glog.ui.validateXid.suppress - will suppress the XID validation logic for the same set of entry points i.e., XML, REST and UI.

Provides you with the option - if necessary - on a table by table basis to override the Validate ID features logic to disallow the entry of XIDs with restricted characters.

Steps to Enable

To use this feature, you will need to set the property for all the table(s) you wish to have the Validate ID restricted character logic ignored.

Either create or select the Property Set to configure. Configuration and Administration > Property Management > Property Sets.

NOTE: Only the DBA.ADMIN user can access and use the Property Sets page.

Set the property glog.ui.validateXid.suppress for the desired table or tables. The format is glog.ui.validateXid.suppress.<table name>= true

In the example below the Location table and Item table have been configured so that the Validate ID logic regarding restricted characters is suppressed.

Property Set Example for Location and Item

UI Logic Configuration Parameter - Show Domain Name for Duplicate Values

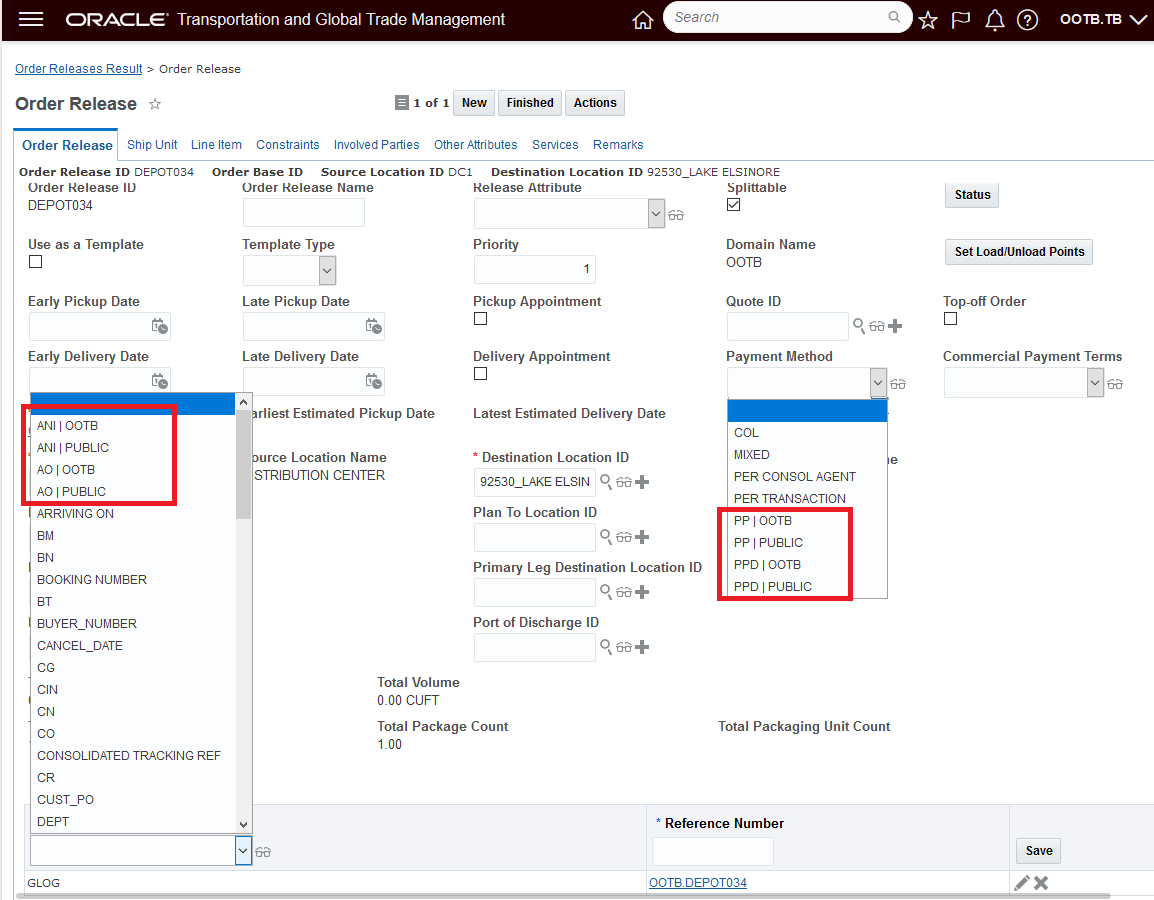

This feature provides you with a new UI Logic Configuration parameter SHOW DOMAIN NAME FOR DUPLICATE VALUES that will, when configured, in situations where duplicate drop down values are found, display the domain name next to the drop down list value so you can select the right value based on the domain.

In the example below, the parameter Show Domain Name For Duplicates Values is set to True and drop downs, with duplicate values, show the domain names next to the duplicate values. In this case, the Reference Number Qualifiers ANI and AO are duplicates and the related domain names OOTB and PUBLIC are shown next to the duplicate values. For the Payment Method Codes dropdown the values of PP and PPD are also duplicates and are found in the OOTB and PUBLIC domains. Note that only the duplicate values have the | Domain Name addition provided - this makes it easy for you to identify the duplicate values.

Example Drop Down with Duplicate Name with Domain Names Provided

Allows you in situations where duplicate values for a drop down reside in multiple domains, to easily pick the correct value from the correct domain.

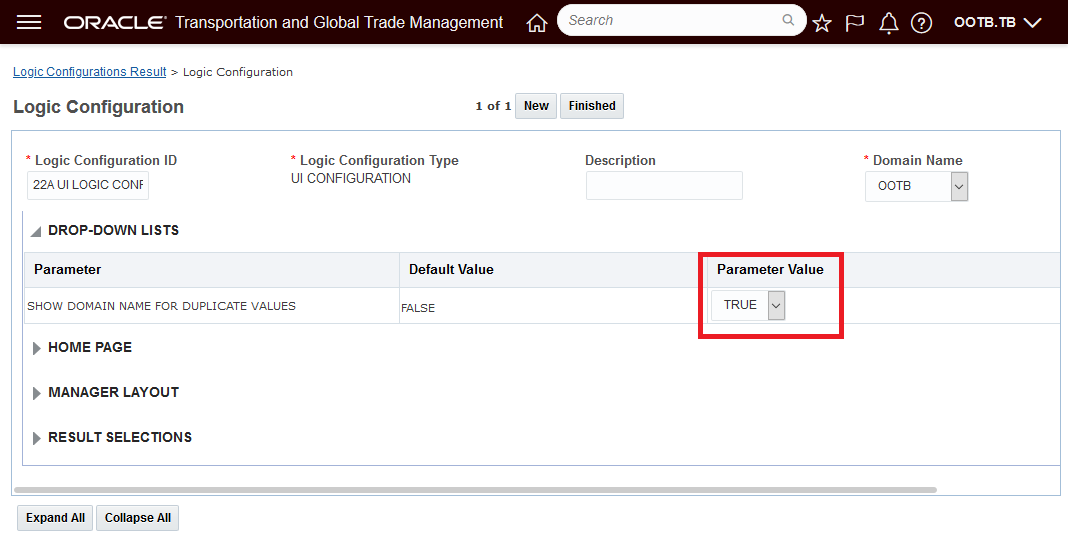

Steps to Enable

To enable the new Display Domain Name when Duplicates are found functionality, your UI Logic Configuration must be configured so that the Show Domain Name For Duplicate Values parameter is TRUE. Then the related logic config must be assigned so that it used in your User Preference.

Display Domain Name When Duplicates Found Setup

Tips And Considerations

This doesn't include the finder Saved Query Droplist, Flex Field Droplists, Droplists on ADF screens, or Droplists on JET screens.

SharePoint Online Content Management System Integration Using MS Graph API

This feature extends the content management system options available for managing documents inside of OTM/GTM to include integration to SharePoint Online using the Microsoft Graph (MS Graph) API. Once configured, the integration provides the ability to add, view, modify and delete documents stored in the SharePoint Online content management system from within OTM/GTM.

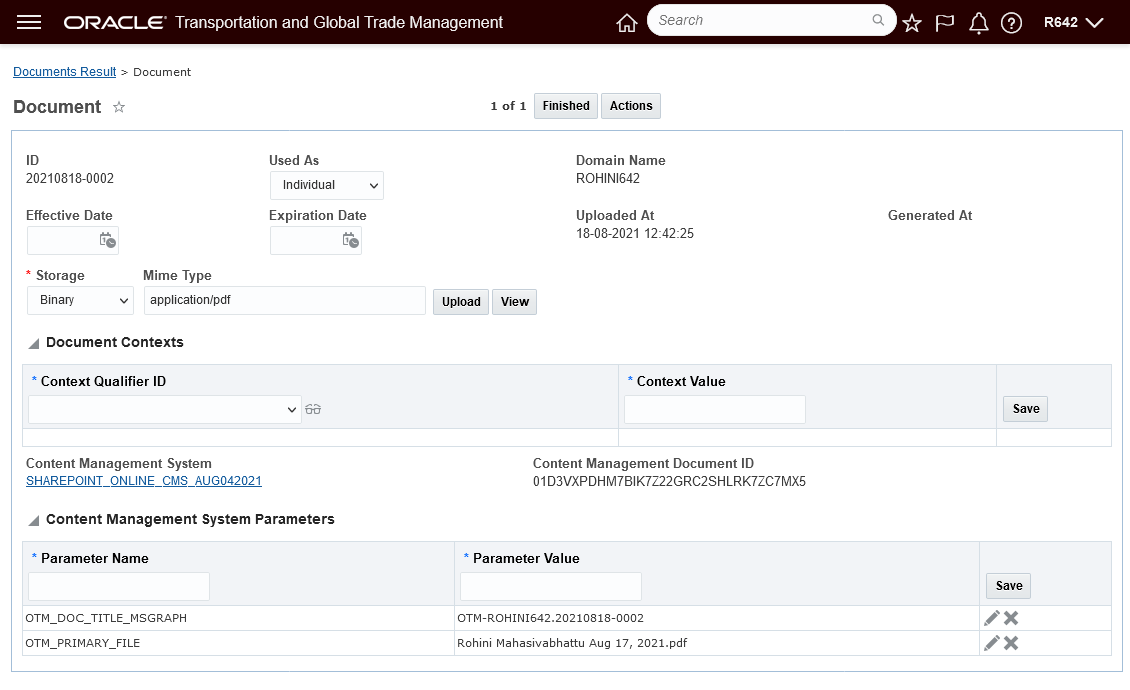

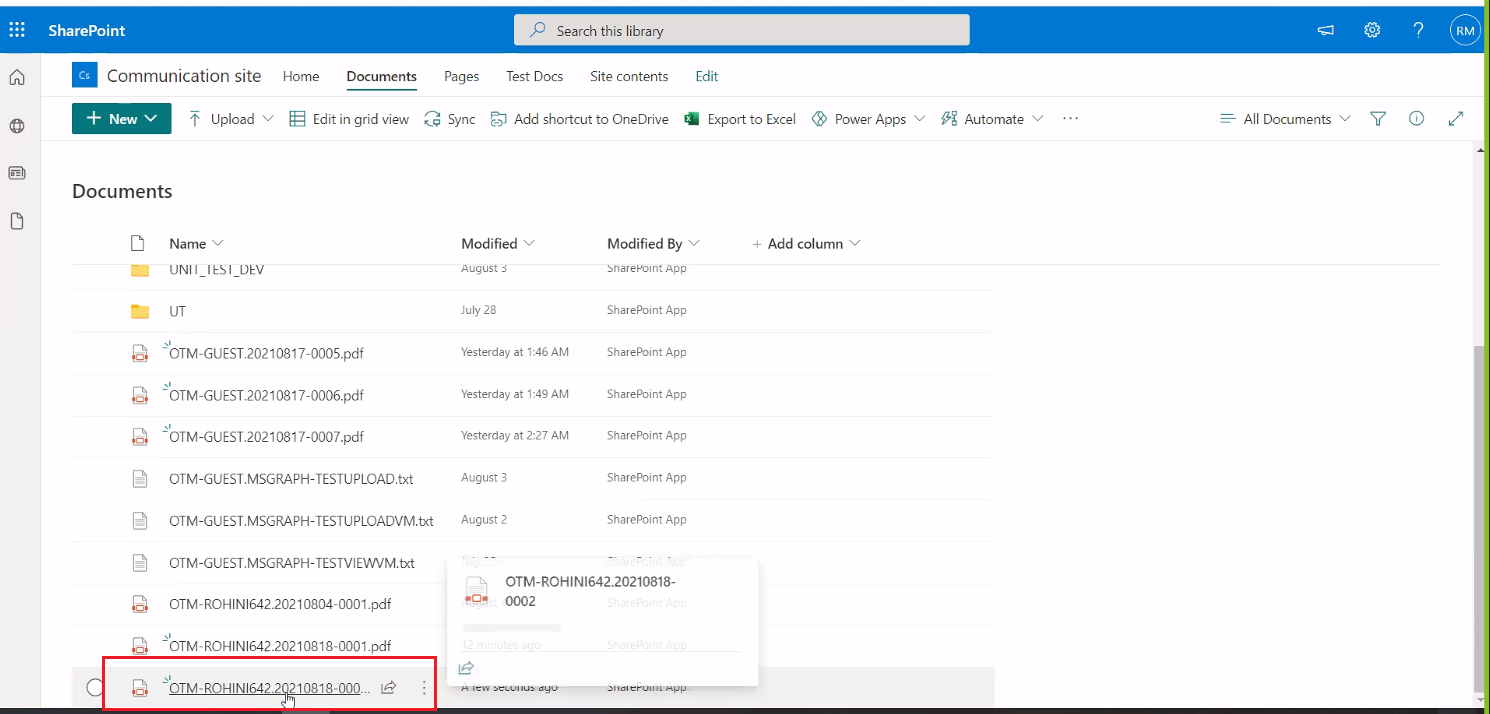

In the example below - the document 20210818-0002 is saved to SharePoint online as OTM-ROHINI642.20210818-0002.

OTM Document Created - Storage In SharePoint Online

Document Stored in SharePoint Online

Extends the available CMS options in OTM/GTM to include the popular SharePoint Online content management system.

Steps to Enable

Setup for Using SharePoint with OTM/GTM

SharePoint Online Setup

SharePoint Online Setup

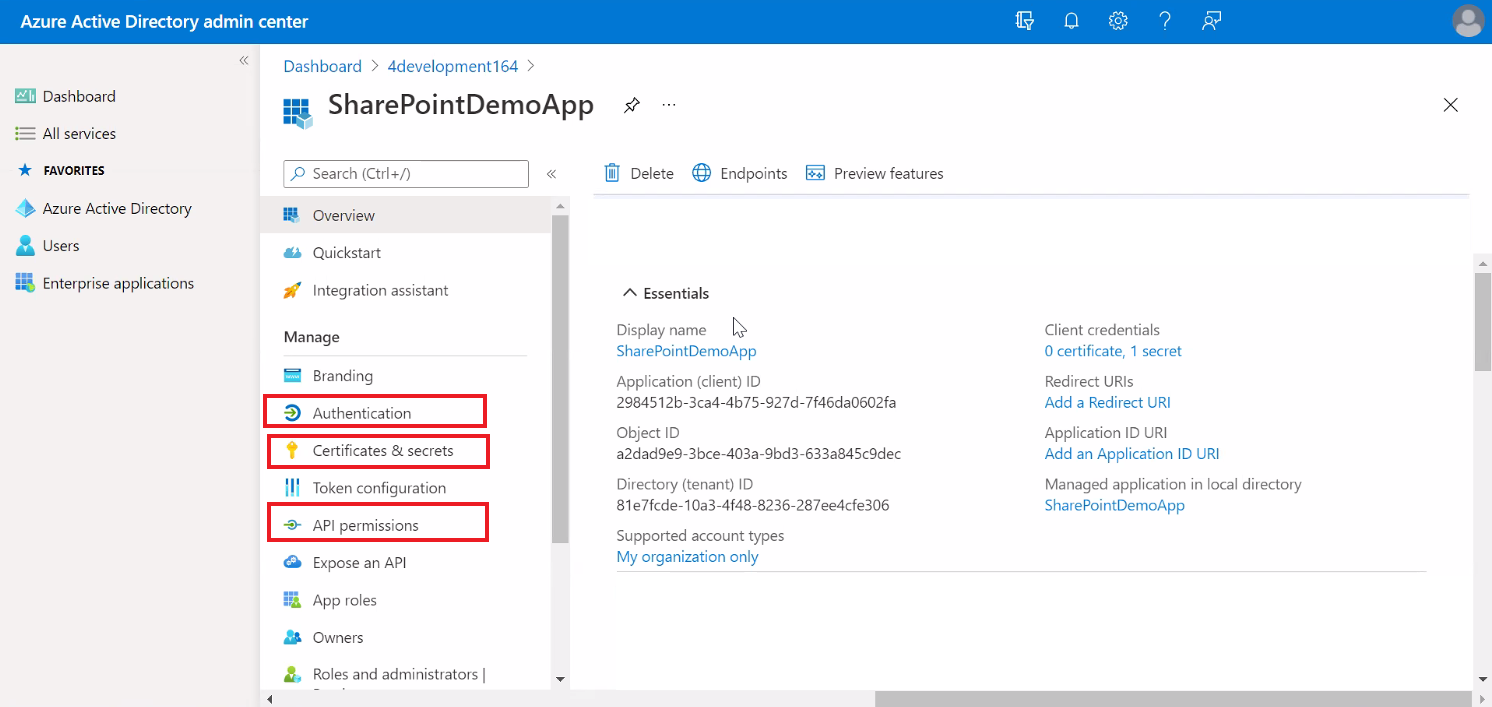

- Register the OTM/GTM application in the Azure Active Directory (AAD) portal. OTM will communicate with SharePoint by means of this application.

- Configure a Client Secret for the application which will be used for authentication purposes. This can be achieved by creating a new Client Secret under "Certificates and Secrets".

- Provide adequate permissions to the newly registered application so that the Microsoft Graph API calls work. This can be achieved by via API Permissions > Add a Permission > Microsoft Graph, and then selecting the required permissions from "Delegated Permissions" and "Application Permissions".

Once the permissions are granted, the application is ready for use. You will have the following details generated once the application is registered:

- Application (client) ID

- Directory (tenant) ID

- Secret Value (obtained while creating the Client Secret)

These will be required for the next steps where you will configure OTM to work with SharePoint.

Setting Up an External System In OTM

You will be required to configure an external system in OTM that will enable you to authenticate/interact with SharePoint.

The input fields should be set as follows:

- Authentication Type: OAuth 2.0 - Client Credentials

- Authorization Service Authentication Type: Microsoft Graph API

- Client ID: Provide the Application (client) ID value generated after registering the application

- Client Secret: Provide the Secret Value generated after registering the application

- Authorization Service URL: https://login.microsoftonline.com/{Directory (tenant) ID}/oauth2/v2.0/token (replace {Directory (tenant) ID} with the actual value)

- Application Scope: https://graph.microsoft.com/.default

- URL: https://graph.microsoft.com/v1.0/drives (acts as a base URL for all API requests)

Setting Up Content Management System In OTM

You have to configure a Content Management System (CMS) in OTM for SharePoint.

The input fields should be set as follows:

- System Type: SharePoint Online

- External System: Select the External System created in the above section

- Drive ID: This represents the location where the documents will be stored . The drive ID to be used can be obtained by means of an API call. Microsoft Graph provides certain ways to obtain the drive ID. You can refer to Microsoft documentation for Microsoft Graph APIs (Microsoft Graph > v1.0 reference > Files > Drives > Get drive) to check for the various ways to obtain the drive ID.

See On-Line Help Topic - Setup for Using SharePoint with OTM OTM/GTM - for more information.

Tips And Considerations

The integration to SharePoint requires that your SharePoint service must support the Microsoft Graph API.

Key Resources

- The Overview of Microsoft Graph API can be found here-> https://docs.microsoft.com/en-us/graph/overview?view=graph-rest-1.0

Expand Document Actions and Features to Additional Objects

This feature extends the document actions and features to include many objects that previously did not have document actions and capabilities enabled. Listed below - by action - are the new objects where this action has been added.

Upload Document Action added to the following Business Objects:

OTM

- Demurrage Transaction

- Rate Record

- Rate Offering

- Work Assignment

- Driver Work Invoice

GTM

- Campaign

- Campaign Lines

- Declaration Lines

- Item Qualification

- Item Classification

- Trade Transaction Lines

Add Document Action has been added to the following Business Objects:

OTM

- Item

- Sell Shipment

GTM

- Declarations

- Trade Transaction

Attach Document Action has been added to the following Business Objects:

OTM

- Demurrage

- Rate Record

- Rate Offering

- Work Assignment

- Driver Work Invoice

GTM

- GTM Shipment Line

- GTM Item Classification

This feature allows you to assign documents to objects where the uploading or adding of documents was not previously supported. Providing direct document Add or Upload capabilities simplifies the process of assigning documents to these objects.

Steps to Enable

You don't need to do anything to enable this feature.

Upload Document Action with Document Type Assignment

This feature provides you with an easy way to specify your Document Types when you use the Upload Document Action. You can specify the Document Type in situations where you are uploading one or many documents.

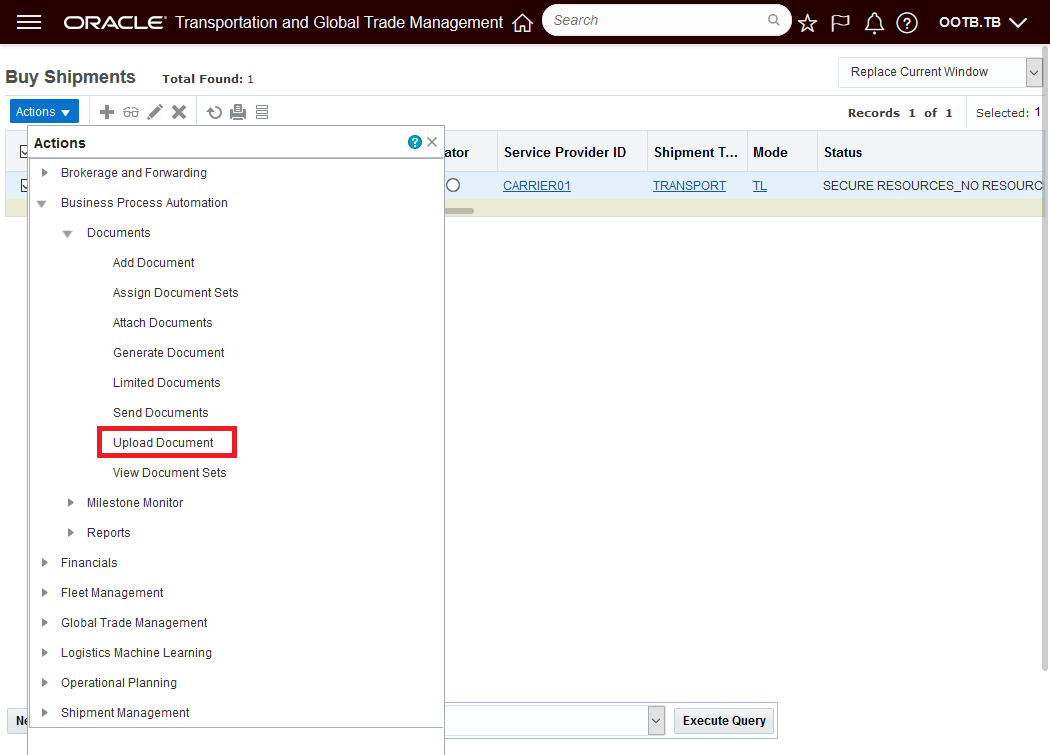

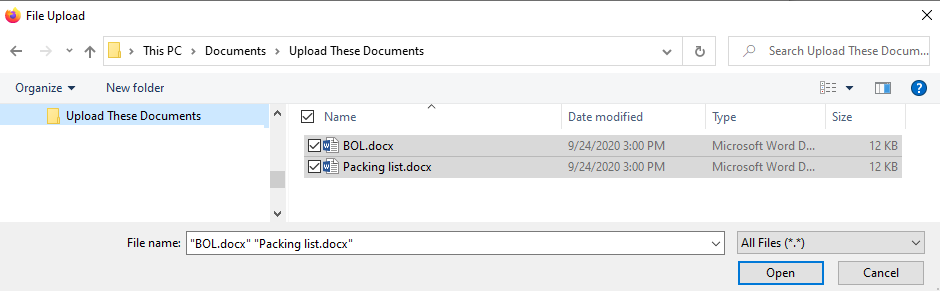

In the example below - two document types (BOL and Packing List) are being uploaded in one multi-select run of the Upload Document Action and will be assigned to the desired Document Type.

In this case the Upload Document action is being run against a Buy Shipment.

Run Upload Document Action

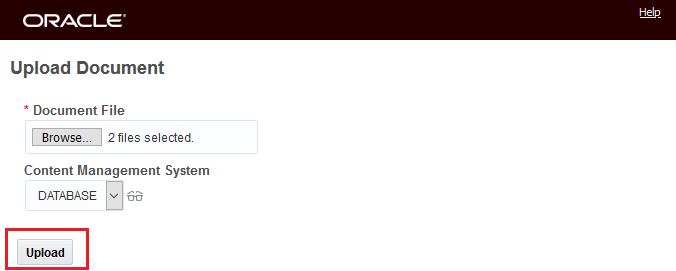

Browse and select the documents you wish to upload. In this case two documents are selected to be uploaded.

Browse and Select the Documents to Upload

Once the documents have been selected then select Upload.

Select Upload

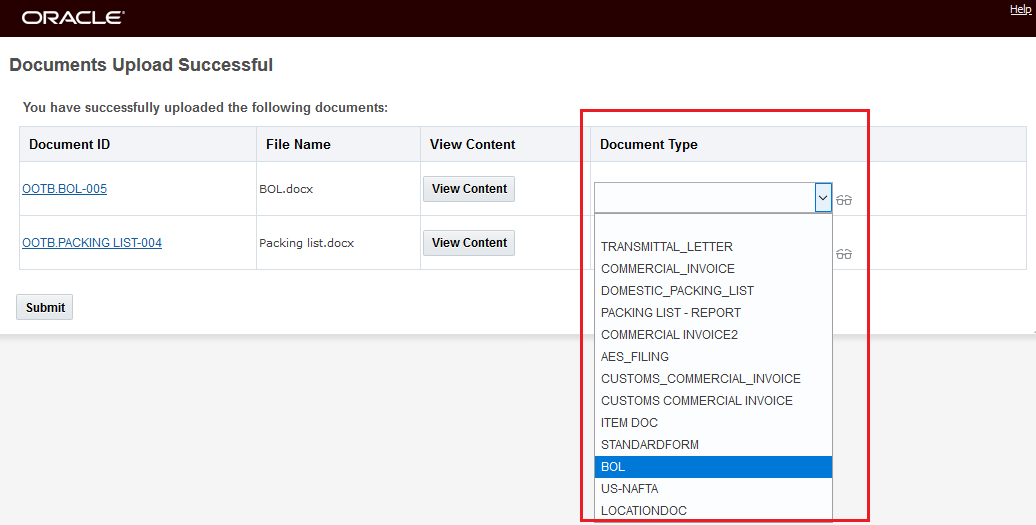

In the dialog box below - after the Upload has been initiated - you are given the opportunity to specify the Document Type using the Document Type Dropdown next to each of the documents being uploaded.

Select Document Type

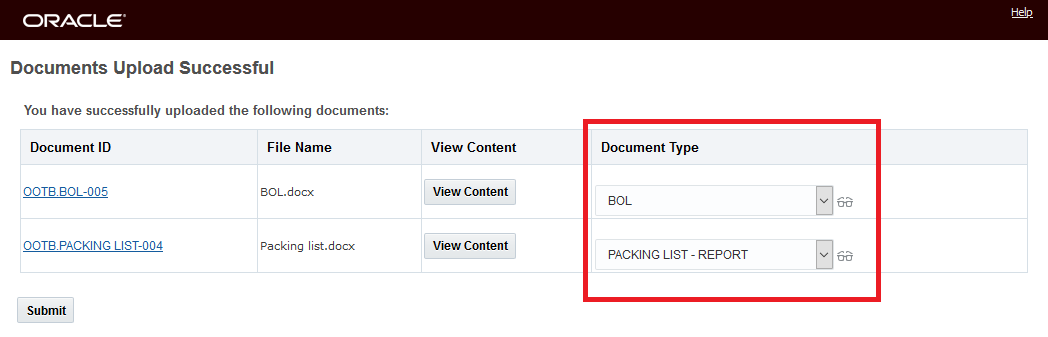

Selected Document Types

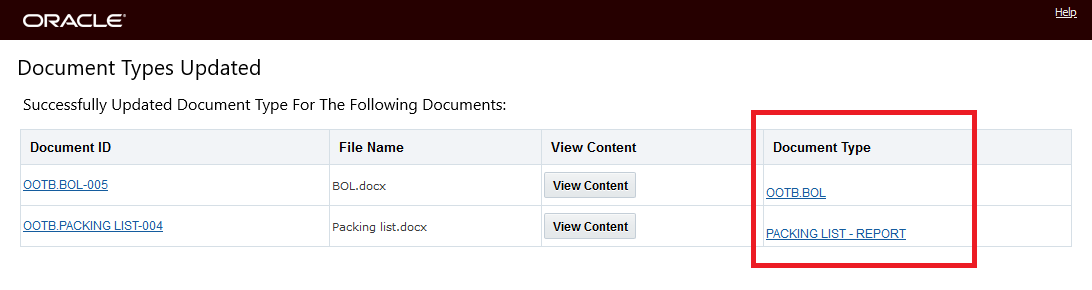

When you run Submit - after selecting your Document Types a verification is provided for the selections made.

Document Type Update Verification

You will find this feature beneficial in any scenario where you wise to upload ad hoc documents - and as part of that upload - you wise to specify the uploaded documents Document Types.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

NOTE: These Upload is used to Upload Ad Hoc documents.

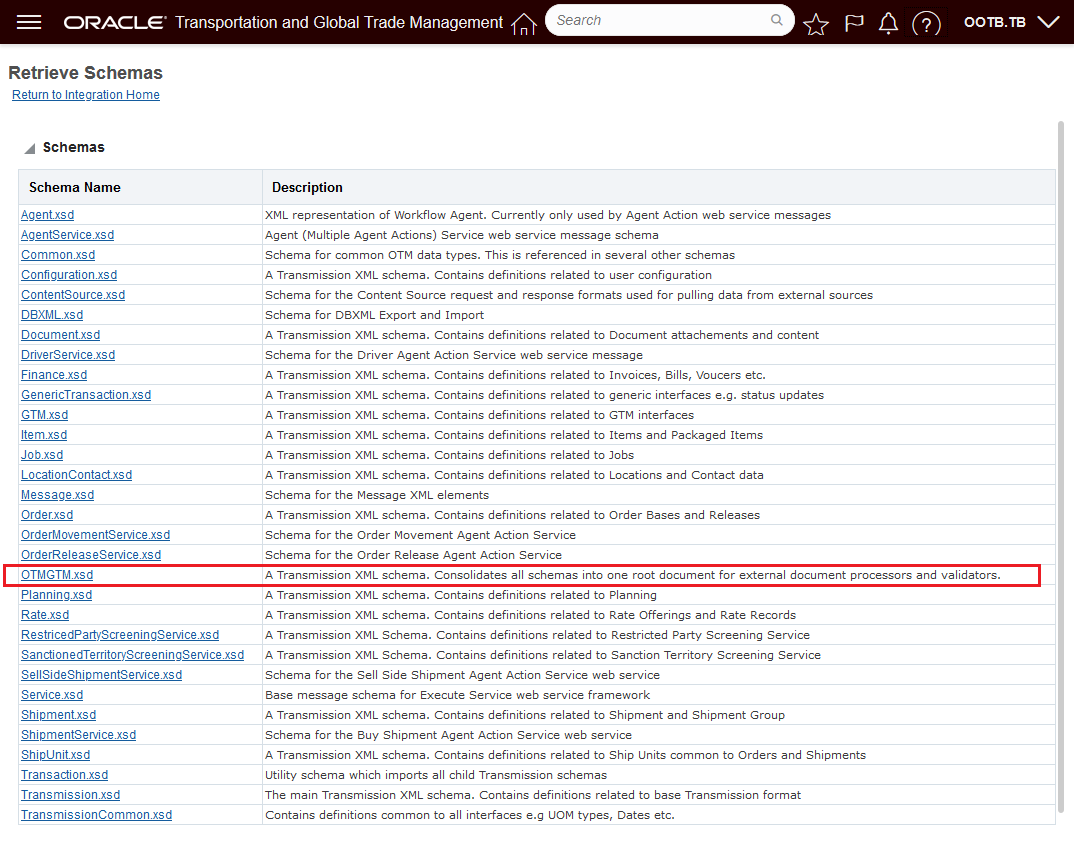

This feature provides you with a consolidated XML Schema definition - OTMGTM.xsd - that consolidates all of the separate XML schema files into a single schema.

The OTMGTM.xsd file can be downloaded from Business Process Automation > Integration > Integration Manager > Retrieve Schemas.

OTMGTM.xsd File

The OTMGTM.xsd consolidated schema provides you with more flexibility when using third party tools to do schema validation or the processing of messages.

Steps to Enable

You don't need to do anything to enable this feature.

DBXML Maximum Message Size Increased to 10MB

This feature increases the default DBXML export and import maximum message size from 5MB to 10 MB (mega bytes). The maximum message size was introduced in the 21A DBXML MAXIMUM EXPORT SIZE RESTRICTED optional feature. The maximum message size was originally set to 5MB, this feature doubles the maximum allowed.

Provides you with the option to import/export DBXML messages up to 10MB.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

Increase default DBXML export and import maximum message size to 10 MB (mega bytes).

Inbound Integration Acknowledgement Pre-Staging

This feature provides improvements in the processing of transmissions that contain a large number of transactions. This feature breaks the processing of these transmissions into two steps:

- Step 1 - Saves the transmission setting the status to New and then sends back the acknowledgment (ACK).

- Step 2 - Stages/parses the transactions in the transmission.

The default/current behavior is for all the transactions in an inbound transmissions to be staged/parsed first before sending back the transmission ACK - which, in some cases, can be longer than the time allowed by the sending system for receiving the transmission ACK. With this feature enabled, the ACK will be transmitted back before (pre) the staging/parsing of the transactions in the transmission.

This feature will reduce the time required to return an acknowledgement (ACK) to the sending system when the transmission being processed contains a large number of transactions.

Steps to Enable

To take advantage of the new processing behavior you will need to set the property- glog.integration.transmission.enableInboundPreStaging - to true.

To change the property:

- Navigate to Configuration and Administration > Property Management > Property Sets

- Select the Property set to modify.

- Set set the property glog.integration.transmission.enableInboundPreStaging to true.

NOTE: Only the DBA.ADMIN user can access and use the Property Sets page.

The optional feature, OVERRIDE DATAQUEUE PARAMETER - when enabled, overrides any parameter settings so that inbound transmissions always use integration data queues.

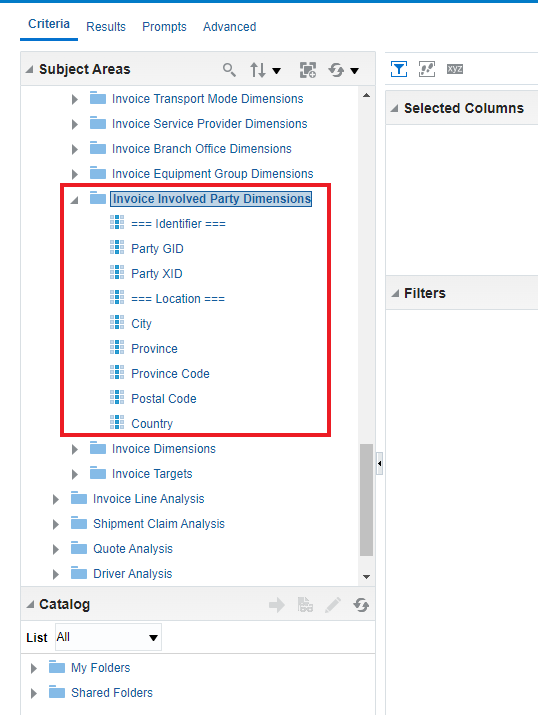

Extends you analysis and reporting abilities to include analysis of your Invoice Facts by Involved Party.

Steps to Enable

You don't need to do anything to enable this feature.

Add Event Date to Order Release XML

This feature adds the Event Date to the Tracking Event data provided within the Order Release XML.

Extends information provided about the order release.

Steps to Enable

You don't need to do anything to enable this feature.

This feature provides you with the next set of enhancements to the Historical Metrics capabilities. The Historical Metrics platform allows you to proactively monitor the health and performance of your OTM/GTM instances. In this latest enhancement iteration, you will find enhancements across the Historical Metric platform, including improvements in your ability to define and automate the collection of metrics and the ability to automatically send notifications when your performance metrics exceed defined thresholds.

Areas enhanced or added in this update include:

- How to Configure Metric Collection

- The new How To provides directions on metric collection, threshold definition, metric notification and viewing metrics

- Metric Cumulative Criterion

-

A cumulative criterion allows you to compare one or two historical bases to trigger a cumulative threshold. For example, you want to see if your bulk plans are taking longer to run now than they have historically, you can compare a recent value basis against an historical one. Cumulative criteria only trigger hourly, when they are recalculated based on the invocation of Persist Metrics, and they are used to trigger performance trends as opposed to critical events.

-

- Metric Current Criterion

-

A Metric Current Criterion provides a way to watch performance in real time and can generate notifications in real time. You would use a current criterion to capture diagnostic information as it happens.

-

- Metric Historical Basis

-

Metric Historical Basis is a definition of a historical value and is used by both the cumulate and current thresholds. You could use an historical basis to define the average value over the last 5 days, the maximum value over the last 3 weeks, the total count over the last two hours, or the average over the last four days of the week. The Metric Historical Bases used by cumulative and current thresholds are updated hourly when Persist Metrics is automatically run.

-

- Metric Threshold

-

You use a Metric Thresholds to establish when a metric notification will be triggered. You can create thresholds based on Metric Cumulative Criterion and Metric Current Criterion.

-

In a Cumulative threshold, you compare one historical value to another (or to a fixed value). Historical values are updated hourly by the Persist Metrics recurring process and all cumulative thresholds are checked.

-

In a Current threshold, you compare current values to a historical or fixed value. They hold the current hour's average, maximum, and count along with any new value to accumulate into statistics. When a current threshold compares to a historical value, it uses the historical calculations last calculated by Persist Metrics.

-

-

Provides improved monitoring and proactive notification regarding the performance of your OTM/GTM instances.

Steps to Enable

Depending on the area you wish to monitor, there are a number of setup steps required. See the Help Topic - How to Configure Metric Collection - for guidance.

Tips And Considerations

NOTE: You must be a DBA to access this page.

The optional feature, PROTECT SECURITY CACHE - when enabled, disallows any cache clears from impacting security caches. Clearing security caches via a Clear or Clear All can impact system performance and lead to race conditions and outages.

This feature improves up time and system performance by guarding against the clearing of security caches via a Clear or Clear All which can impact system performance and lead to outages.

Steps to Enable

You don't need to do anything to enable this feature.

The optional feature, TIMEOUT PROPERTY ACCESS - timeouts on property retrieval allow properties to be retrieved, even though the data may be out-of-date. Timeouts on property updates will force an error.

This feature provides a more graceful approach for managing timeouts on property retrieval.

Steps to Enable

You don't need to do anything to enable this feature.

DBXML Security Updates with Auto Cache Handling

The DBXML SECURITY UPDATES WITH AUTO CACHE HANDLING optional feature allows for the DBXML import of various security records without the need for any manual cache refresh. Specifically, this feature provides special handling for the following records to properly synchronize caches:

- GL_USER, USER_ROLE, USER_ROLE_ACR_ROLE,

- GL_USER_ACR_ROLE, ACR_ROLE,

- ACR_ROLE_ROLE, ACR_ENTRY_POINT,

- ACR_ROLE_ENTRY_POINT.

When this feature is enabled, data inserts, updates and deletes will be sent through custom security code, automatically updating security caches. No additional cache clears are necessary.

For the selected set of records, this feature eliminates the need to manually perform a cache refresh when these records are imported via DBXML.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

This page is accessed via Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

Transportation and Global Trade Management UI Automation Sample Selenium Scripts

A set of sample Selenium scripts with documentation is now available for you to review and consider using as a basis for creating your own Selenium scripts to help with your OTM/GTM UI testing efforts. The scripts and documentation are found under MOS Note 2822896.1.

This feature provides you with sample Selenium scripts that you can consider reviewing and using as a basis for creating your own Selenium scripts to test your Transportation and Global Trade Management UIs. The objective of the samples is to facilitate your use of Selenium (Selenium web driver and Oracle JET web driver) for UI test automation.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

The scripts are provided "as-is" and will require configuration/customization to work in your instance of OTM/GTM.

Automatic Indexing Enabled for Archive Schema

This feature enables Automatic Indexing on the archive schema to facilitate queries on archived data to support your audit reporting requirements. Before this enhancement, attempts to run reports against the Archive Schema for specific date ranges could result in unacceptable amount of run-time. The enabled automatic indexing provided in this enhancement improves query retrieval run-time to support your archive reporting requirements.

Provides improved run-time for reports run against the Archive Schema.

Steps to Enable

You don't need to do anything to enable this feature.

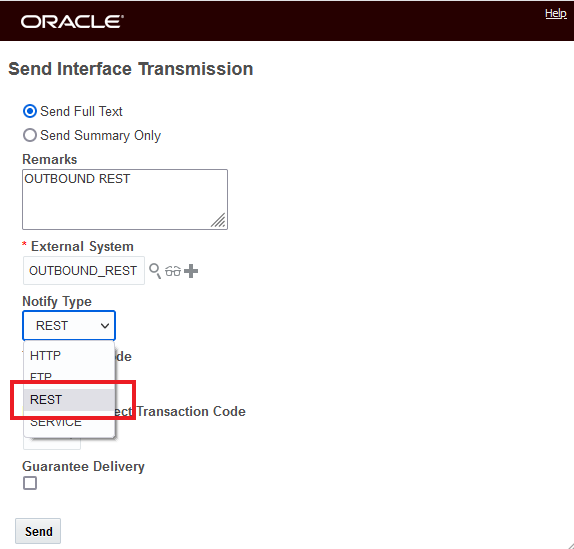

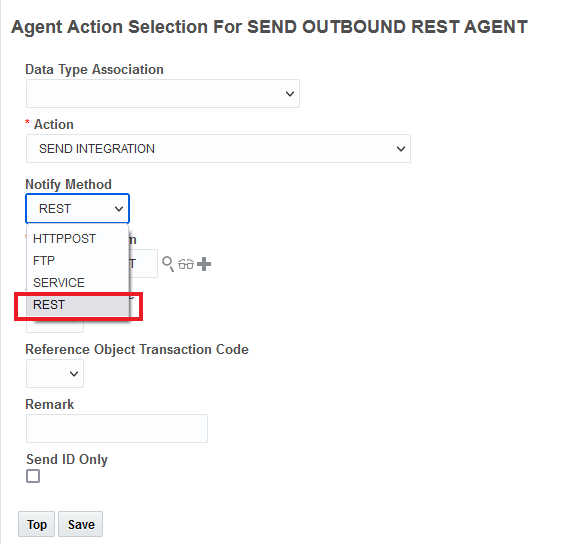

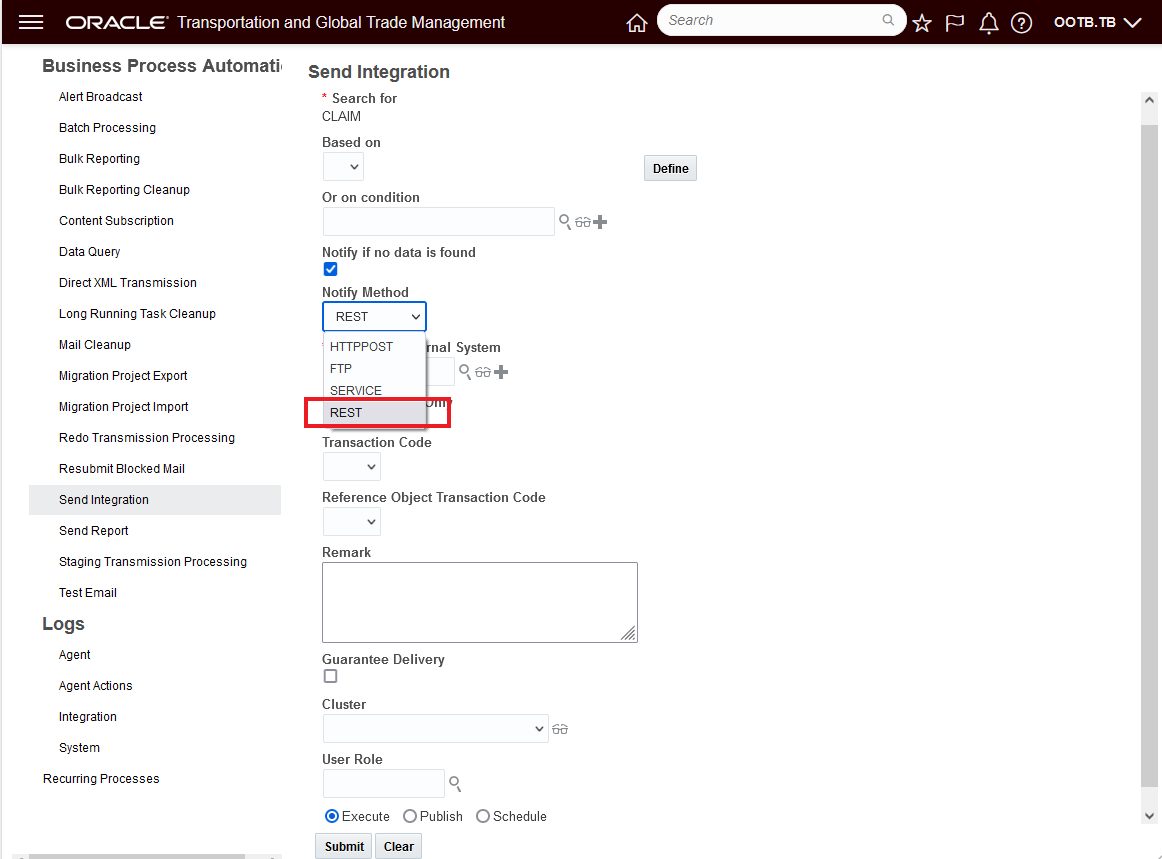

This feature extends the REST API capabilities to include sending outbound business objects following the same REST resource formats available for processing your inbound messages.

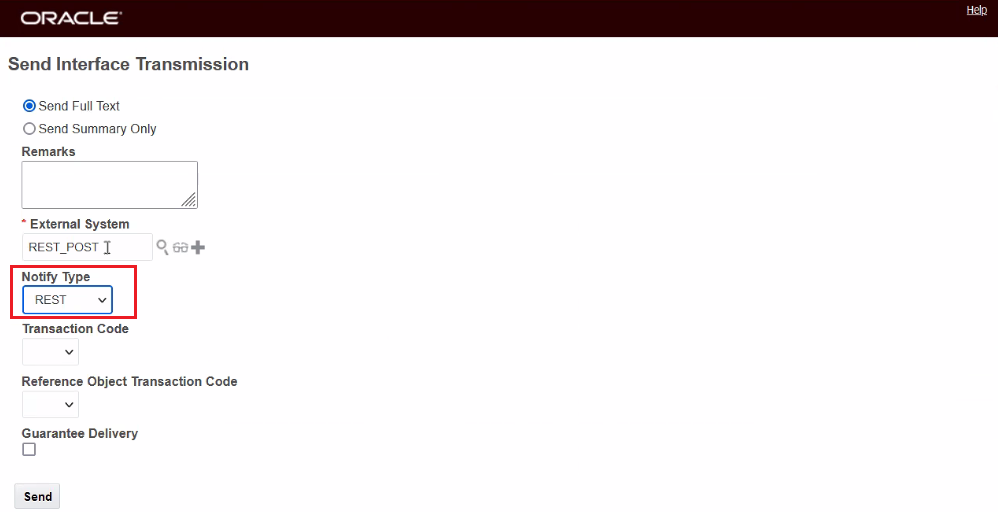

This feature provides you with the option to select the REST notify communication method in the following actions:

Send Interface Transmission

Send Interface Transmission

Send Integration Agent Action

Send Integration Agent Action

Send Integration process

Send Integration

In the example below, the Send Interface Transmission action for an order release is demonstrated.

The Notify Type of REST needs to be selected and the External System Content Type must be 'application/json'.

Send Interface Transmission - Order Release

The transmission Result for this Transmission is below. One Transmission with one Transaction.

Transmission Result

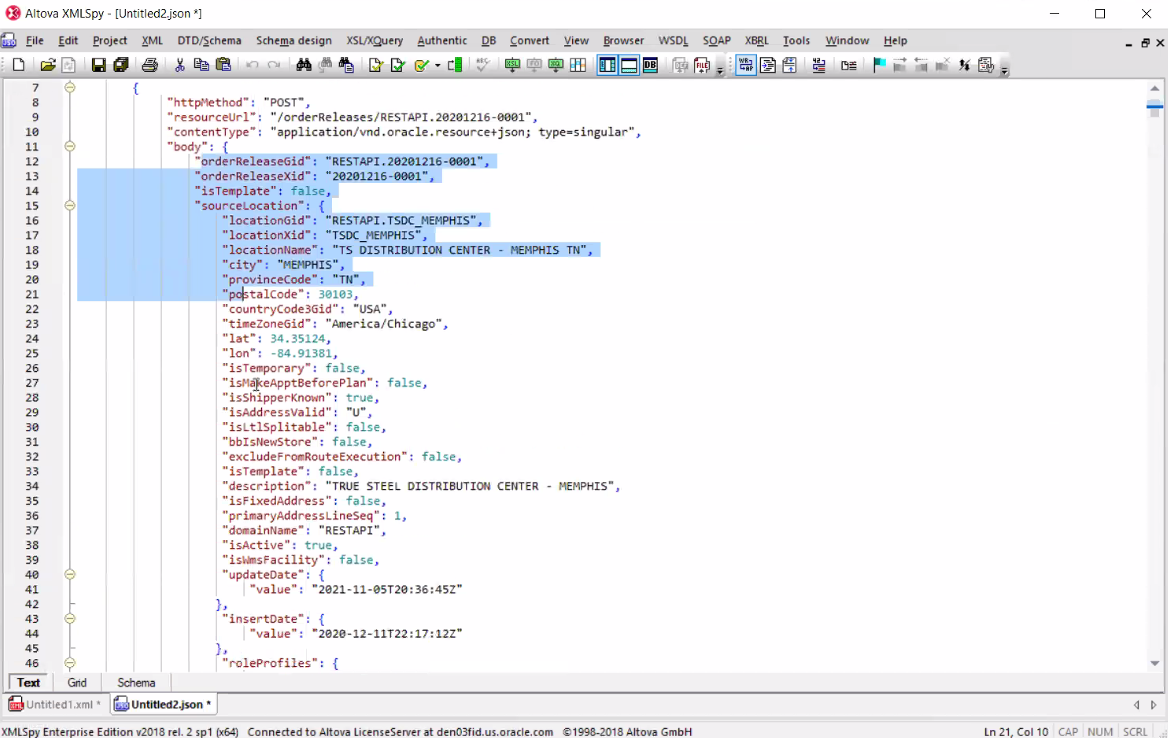

And the outbound POST transmission for the Order Release is below.

Outbound POST

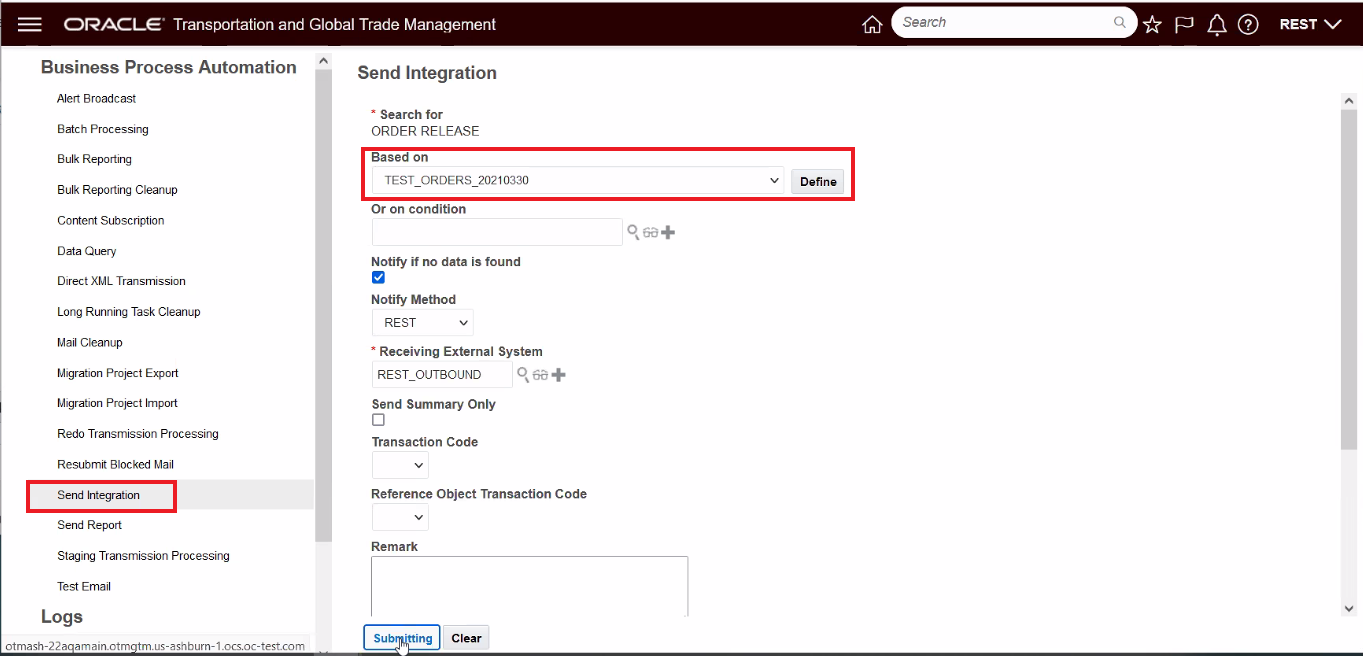

You can send multiple outbound transactions in a transmission using REST by using Send Integration and specifying a saved query. In the example below, the specified saved query will create a transaction for six order releases.

Send Integration with Saved Query

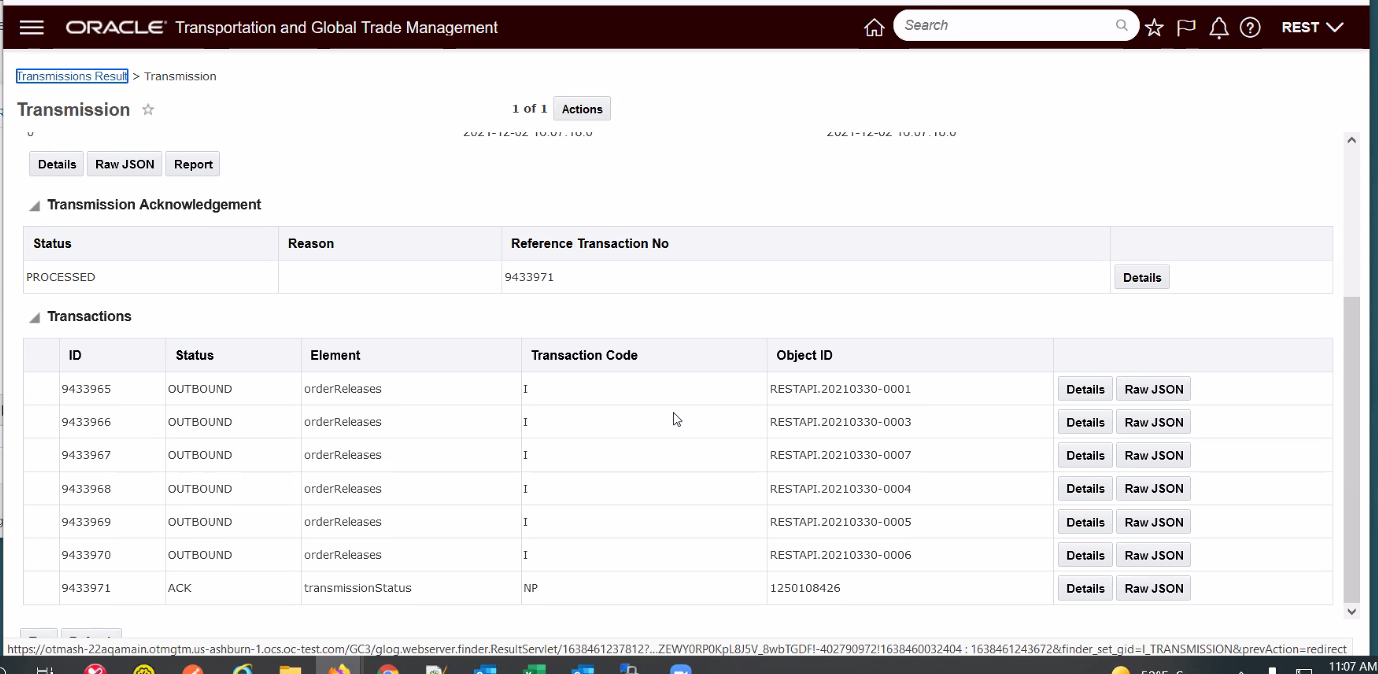

The Send Integration above results in the following Transmission Result - one Transmission with six Transactions - one for each of the order releases returned by the specified saved query.

Transmission Result - Multiple Transactions

This feature provides you with the opportunity to take advantage of the lightweight, easier to work with REST JSON format to support your outbound integration requirements.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

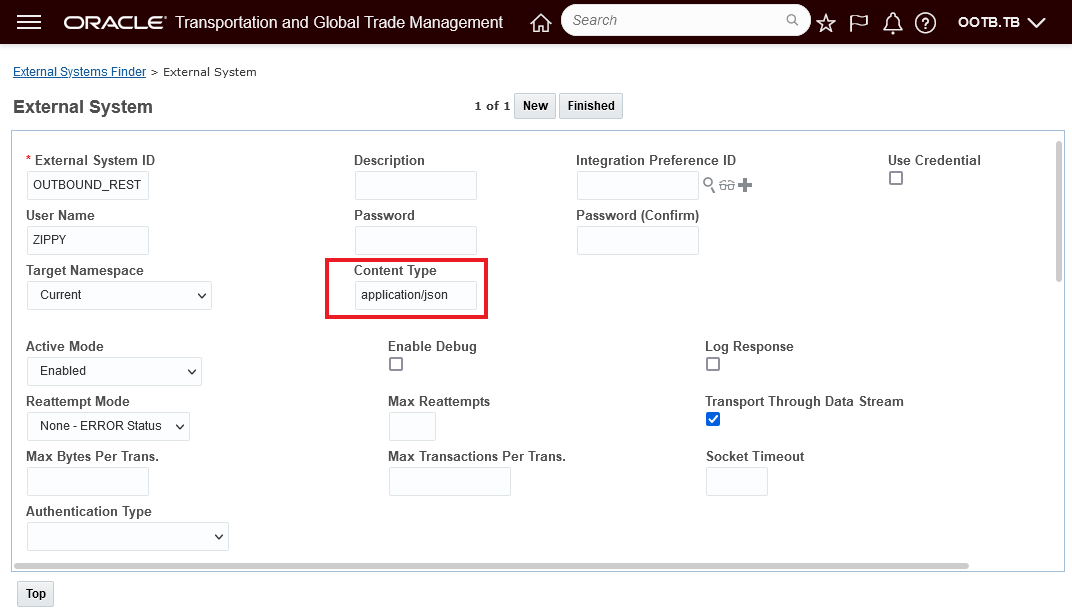

The target External System must have the Content Type specified as "application/json".

External System Content Type - is "application/json"

This is the same Content Type and format used by the inbound BATCH API "transmissions" resource.

Both messages will adhere to the Open API schema described by the OTM/GTM online REST API documentation on docs.oracle.com.

Outbound REST is limited to sending the full resource content which is equivalent to the response for a 'GET' on the same resource with 'expand=all' query parameter.

STAGING capability is not yet supported.

Send REST Event Notification Agent Action

This feature provides you with the ability to configure an agent using the new agent action - SEND REST EVENT, that, when configured, will send a small message notification to the specified external system that a lifetime event has occurred against the object. The event information received can then be used to initiate a GET for the related object. With the send event notify and GET approach, you have the option to either GET the complete object or you can parse down your GET request to just the elements of interests.

The SEND REST EVENT action will accepts the following parameters:

- External System - required

- Reference Value

- Should be the choice between a static value entered as an input field or as the result of a single valued Saved Query.

- Override Resource Name

- Send Reason

Sent REST Event

The outbound message will contain the following information:

- External Reference (from reference value above)

- Send Reason (from above)

- Triggering event (i.e. lifetime event)

- Root resource URL

The SEND REST EVENT agent action is available for these Agent Types:

| BILL |

| CONSOL |

| CONTACT |

| CLAIM |

| DOCUMENT |

| DRIVER |

| EQUIPMENT |

| INVOICE |

| ITEM |

| LOCATION |

| ORDER BASE |

| ORDER MOVEMENT |

| ORDER RELEASE LINE |

| ORDER RELEASE |

| PARTNER ITEM |

| POWER UNIT |

| QUOTE |

| RATE OFFERING |

| SELL SIDE SHIPMENT |

| SERVICE PROVIDER |

| SHIPMENT SHIP UNIT |

| SHIPMENT |

| TRACKING EVENT |

| VOUCHER |

| VOYAGE |

| WORK INVOICE |

| GTM CAMPAIGN |

Simplifies the setup required for notifying external systems that a lifetime event has occurred against an object and supports an integration pattern where the external system is notified of an event and then the GET for the object can be tailored to retuning just the elements of interest.

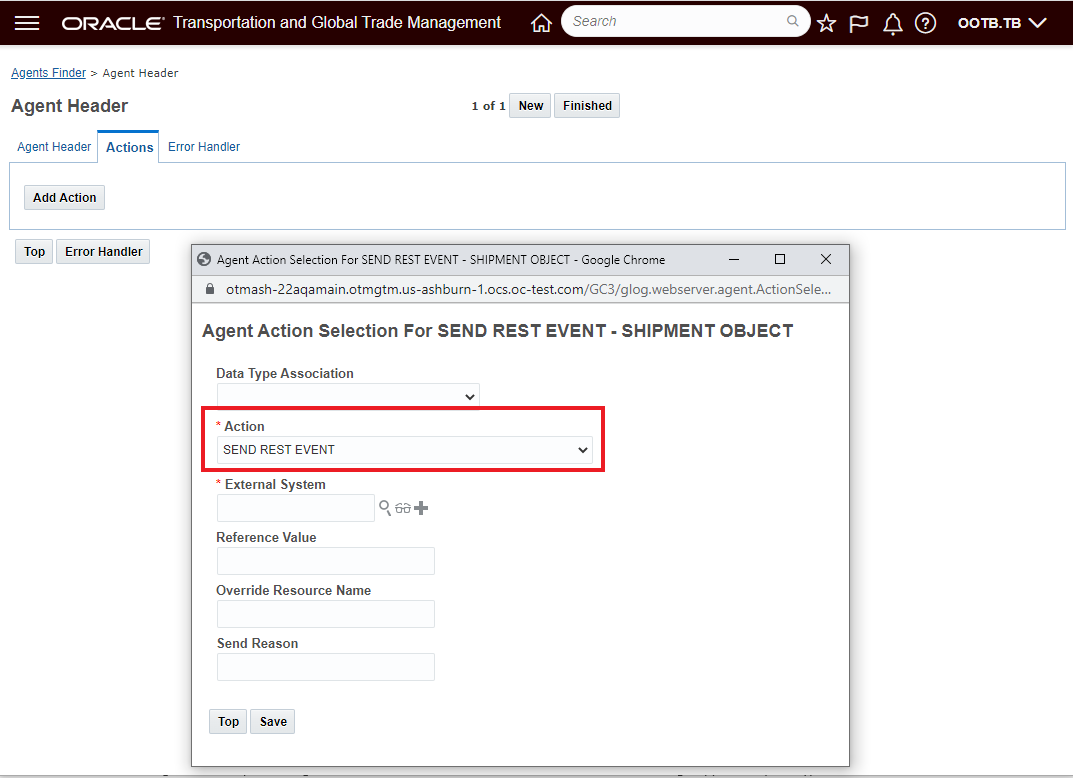

Steps to Enable

You will need to either create a new Automation Agent or modify an existing agent to use this feature.

Go to Business Process Automation > Agents and Milestones > Automation Agent.

The Agent Manager allows you to construct agents that are key components of configurable Oracle Transportation Management processing. An agent listens for an Oracle Transportation Management event, verifies a user-defined condition, and executes one or more actions that you choose from an action library.

Create an agent using the following tabs that you must follow sequentially:

- Agent Header defines basic information such as ID, agent type, and whether the agent is active as well as the events and event conditions that trigger the agent to process actions.

- Actions defines the actions that are executed when specific events are met - in this case you will want to select the SEND REST EVENT agent action for the selected object.

- Error Handling defines the actions to take when errors occur during the processing of an agent.

Read Only Shipment Group Resource Added to REST API

The feature extends the available REST Resources to include the Shipment Group along with the Shipment Group's Secondary Charge details. The Shipment Group REST Resource supports a GET (read only) request.

Provides you with read access to your shipment group(s) using the REST API.

Steps to Enable

Review the REST service definition in the REST API guides, available from the Oracle Help Center > your apps service area of interest > REST API. If you're new to Oracle's REST services you may want to begin with the Quick Start section.

Batch Asynchronous Support for Power Data Resources

This feature enables the Power Data REST resources to use the batch framework for loading.

Provides you with the option to load Power Data in batch using REST Services.

Steps to Enable

Review the REST service definition in the REST API guides, available from the Oracle Help Center > your apps service area of interest > REST API. If you're new to Oracle's REST services you may want to begin with the Quick Start section.

Transportation Management (Base)

Contact Manager Moved to Manager Layout

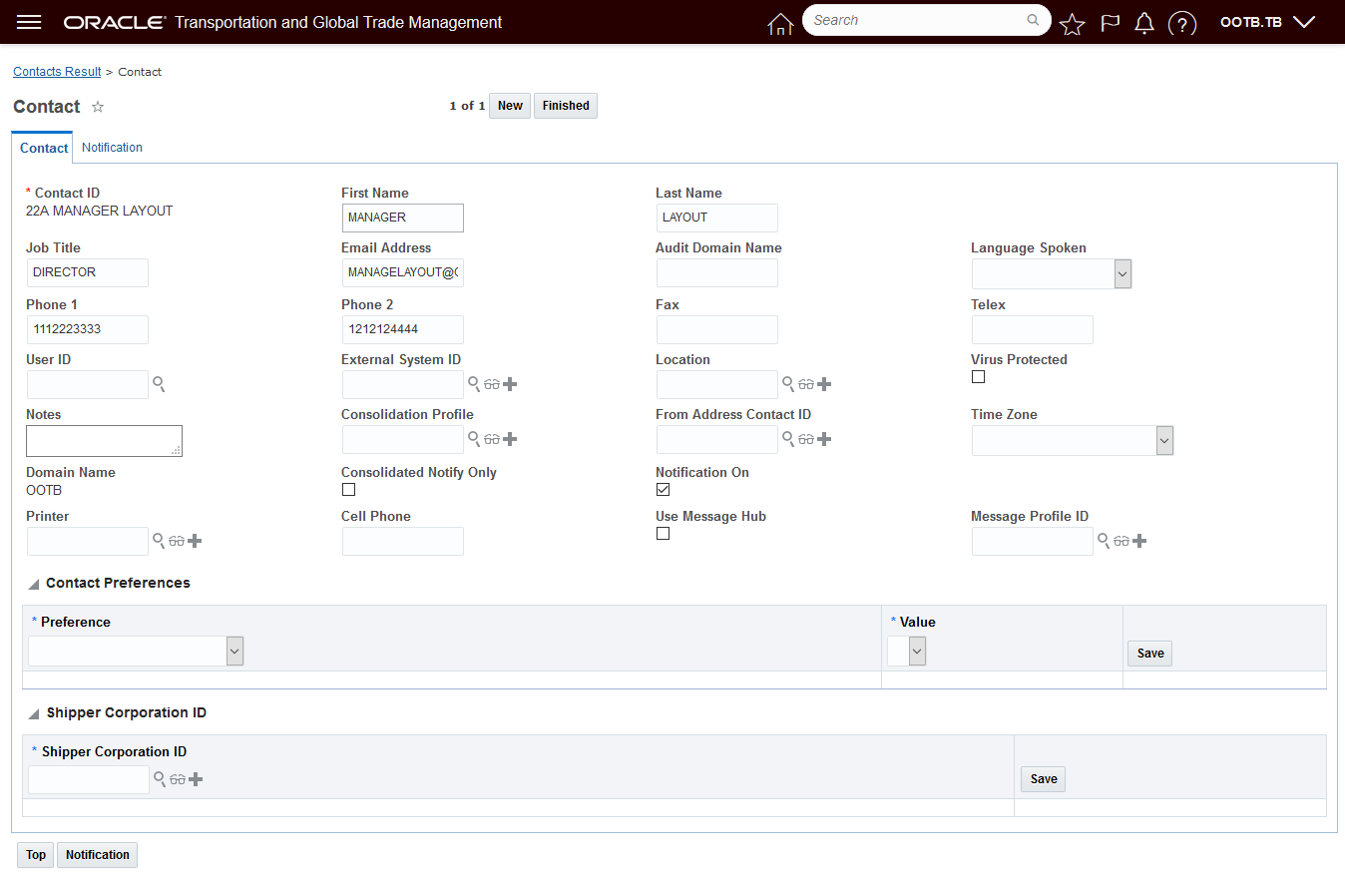

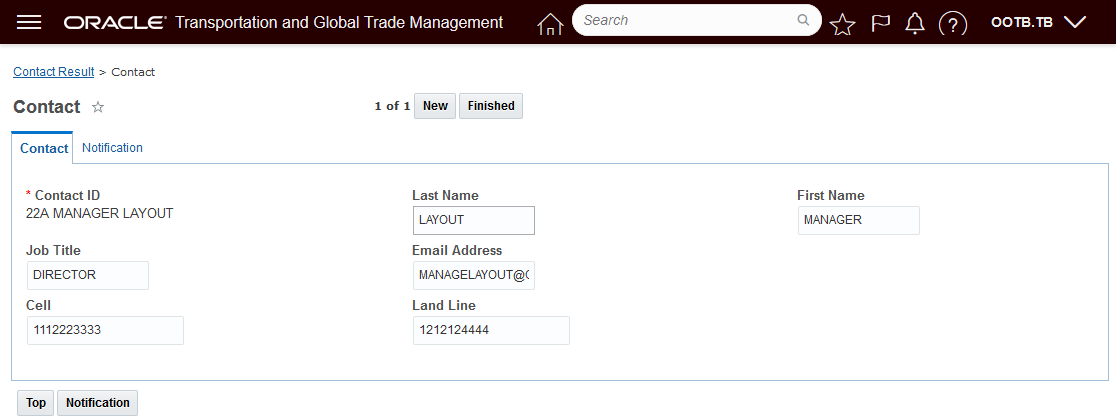

This feature provides with the ability to configure your contact manager for both view and edit using manager layout functionality.

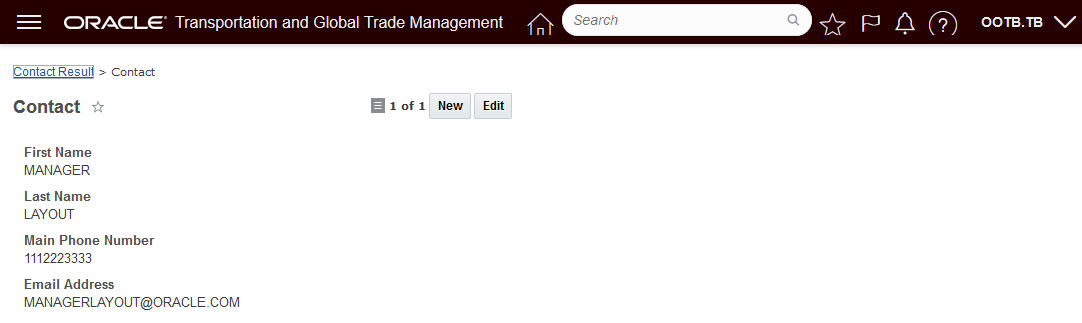

Below is an example of the Public Contact Manager Layout for Edit (and New), and an example of the Contact Manager configured using the Manager Layout capabilities - where fields have been removed, moved and re-labeled.

Public Contact Manager Layout - Edit

Below is the Contact Manager configured using the Manager Layout capabilities. Fields have been removed and relabeled.

Contact Manager Configured - Edit

Below is an example of the Public Contact Manager layout for View and a configured version of the Contact Manager View.

Public Contact Manager Layout - View

Below is the configured Contact Manager view with fields removed, rearranged and relabeled.

Manager Layout Configured Contact Manager Layout - Edit

Allows you to configure your Contact Manager - for both view and edit - so that the layout is simplified (unused features and fields removed) and labeled and organized to improve both navigation and general usability.

Steps to Enable

To take advantage of this feature you will need to:

- Copy the public Contact Manager Layouts to create new Contact Manager Layouts for view and edit.

- Copy and configure a new Contact Manager Screen Set (or modify an existing one) and point to the newly configured Contact Manager layouts for edit and view.

- Add the new Contact Manager Screen Set to your Menu using the Menu Manager.

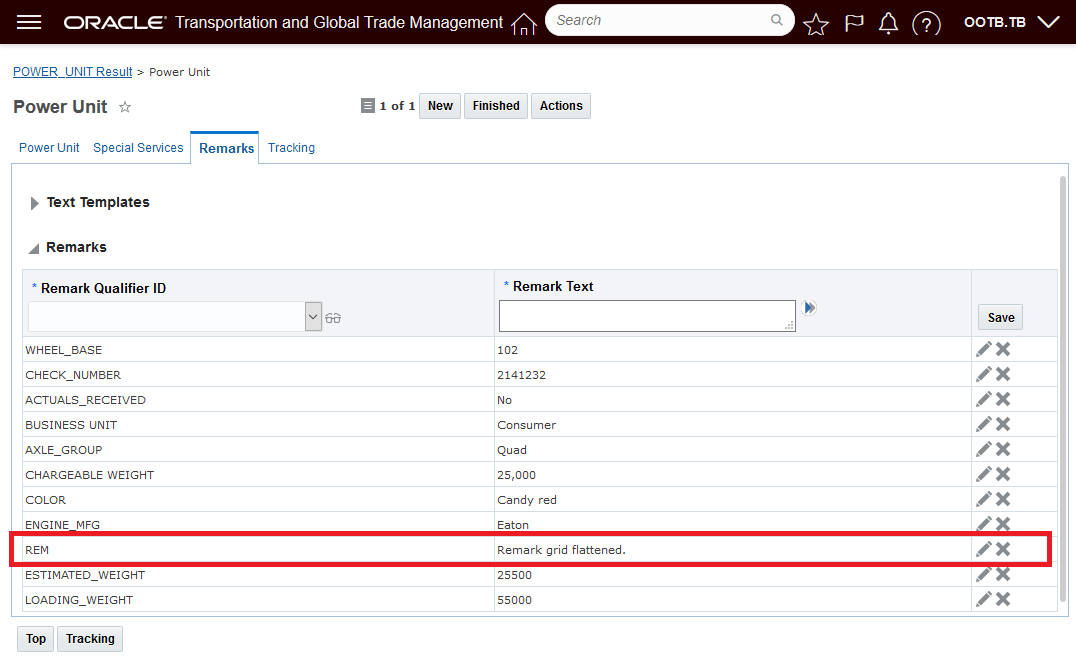

Power Unit - Grid Fatten Remark Field

This feature provides you with the ability to grid flatten the Remark field on the Power Unit screen set.

In the example below the Remark field has been grid flattened for the Remark Qualifier Value "REM".

Grid Flattened Remark Field Example

In the example below - without Grid Flattening - the REM qualifier and value do not stand out.

Without Grid Flattening

Allows you to promote selected Remark Qualifiers so they appear as "real" fields simplifying the management and improving the visibility of the configured Remark Qualifier and the values entered.

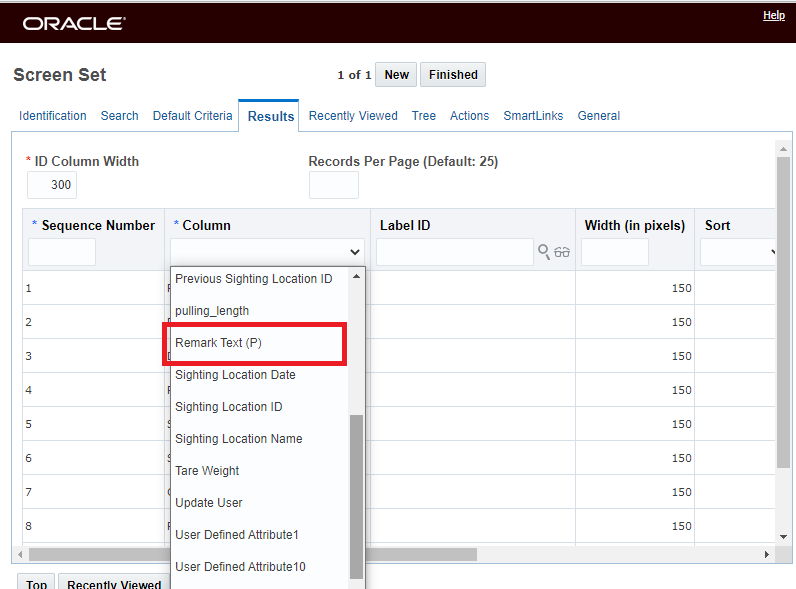

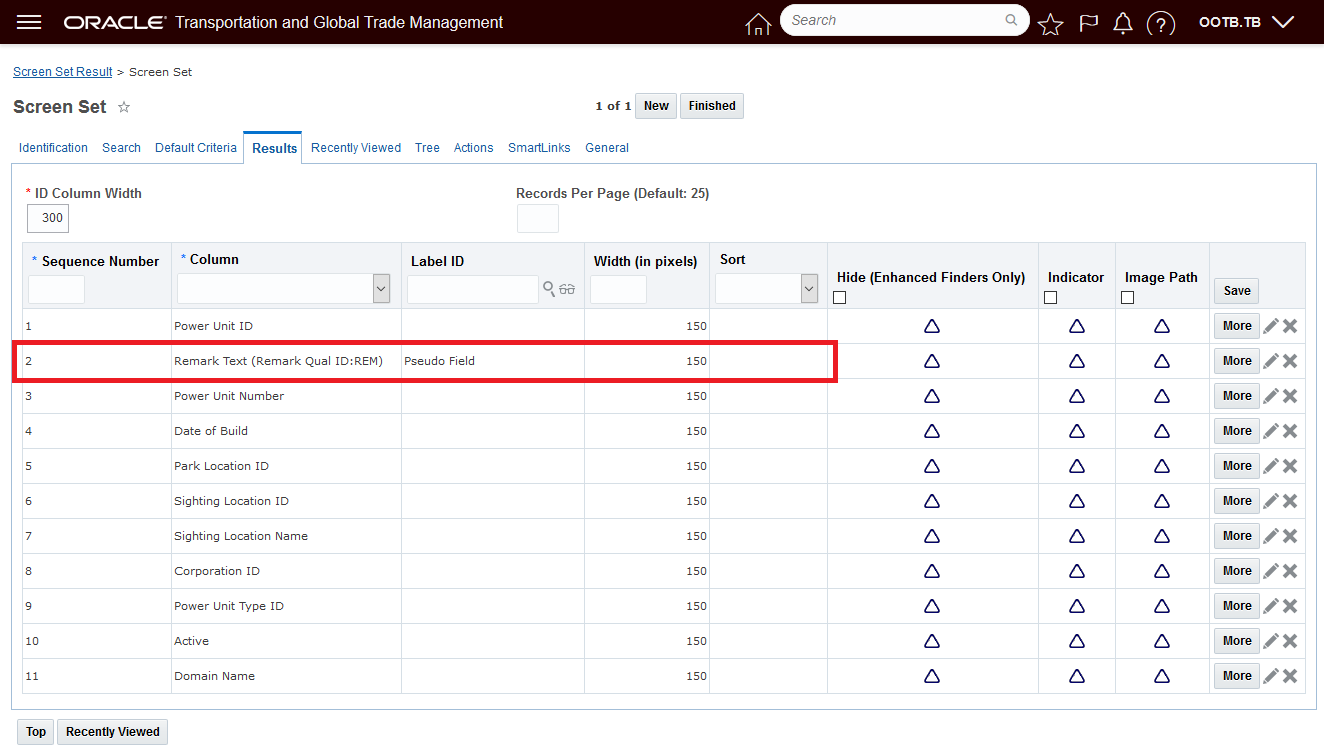

Steps to Enable

To enable this feature you will need to do the steps required to configure a pseudo or grid flattened field.

- Create a new screen sent for you Power Unit object or modify your existing screen set.

- Add the Remark(P) field to the finder results for your Power Unit screen set.

Add Remark Text (P) Pseudo Field to Finder Results

- Select the qualifier you want to grid flatten.

Select the Remark Qualifier - REM in this case

Screen Set Setup

Packaged Item Description Visible After Running Add New Line Item Added

This feature provides visibility to the Packaged Item Description on the Ship Unit Form immediately after you run add a New Line Item and Save. Previously, you would have had to save the order release and then edit the order release to see the Packaged Item Description.

The set of screen shots below illustrate the benefits of this feature.

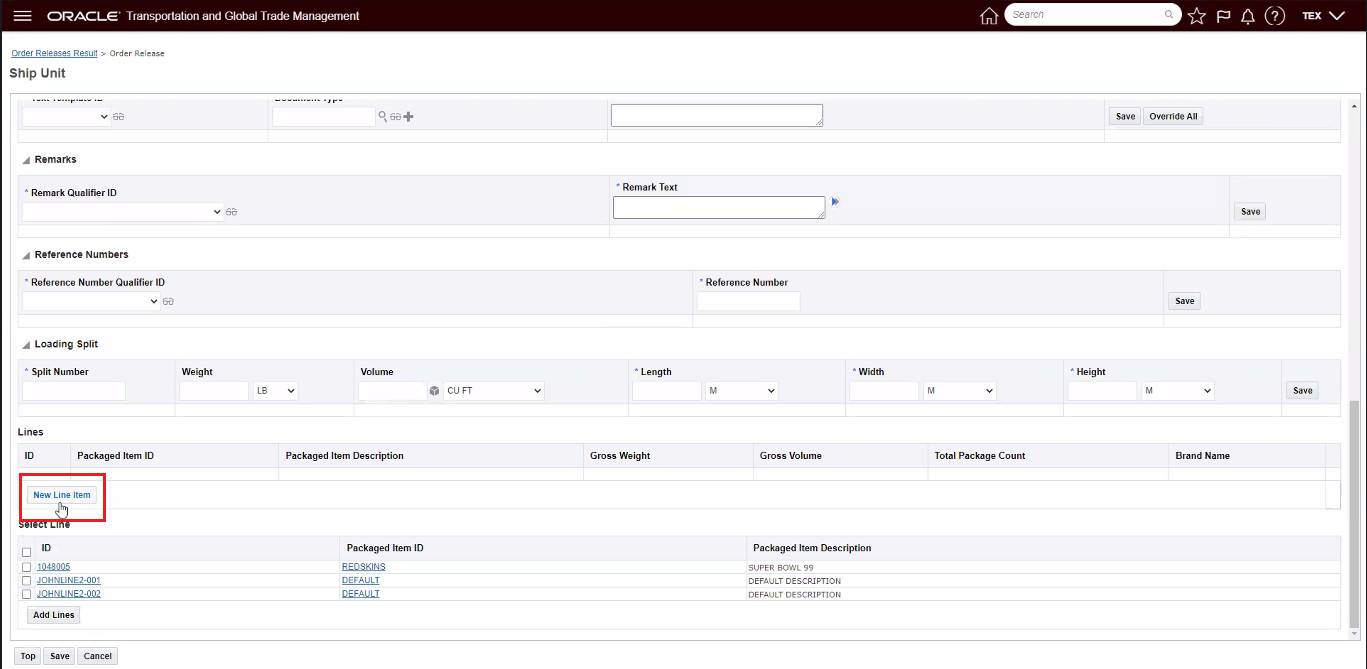

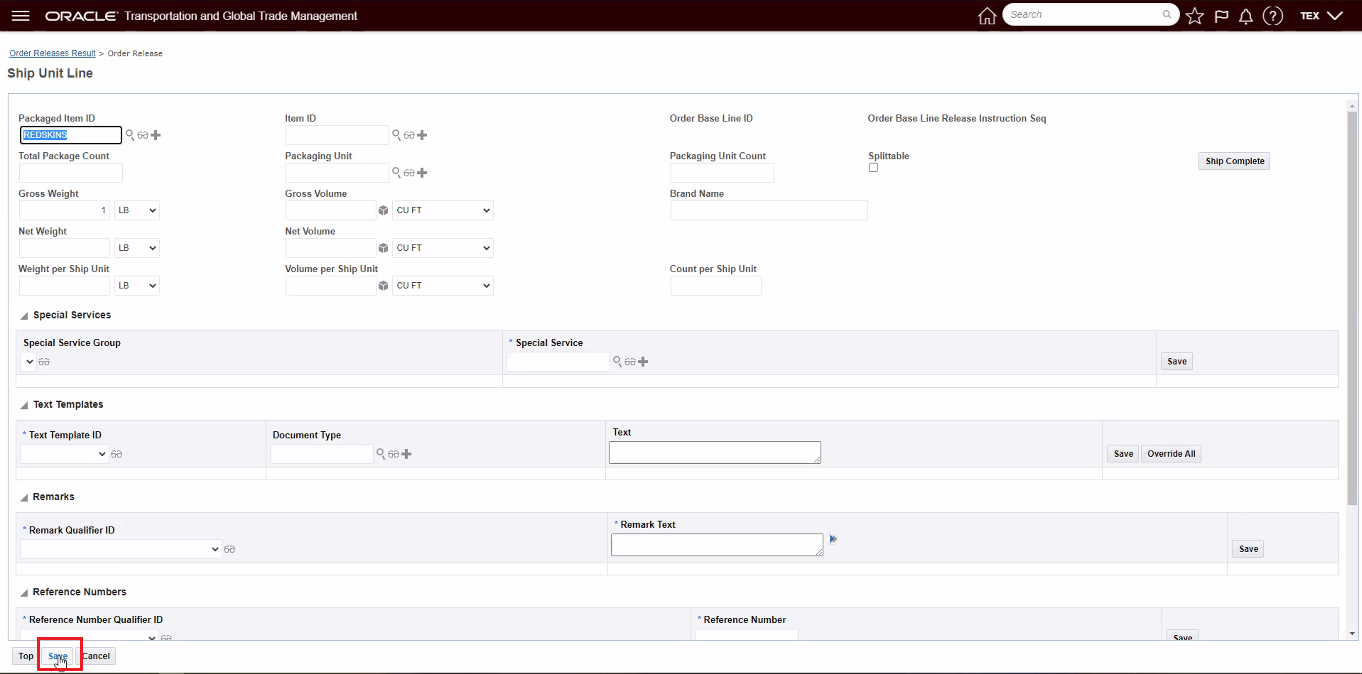

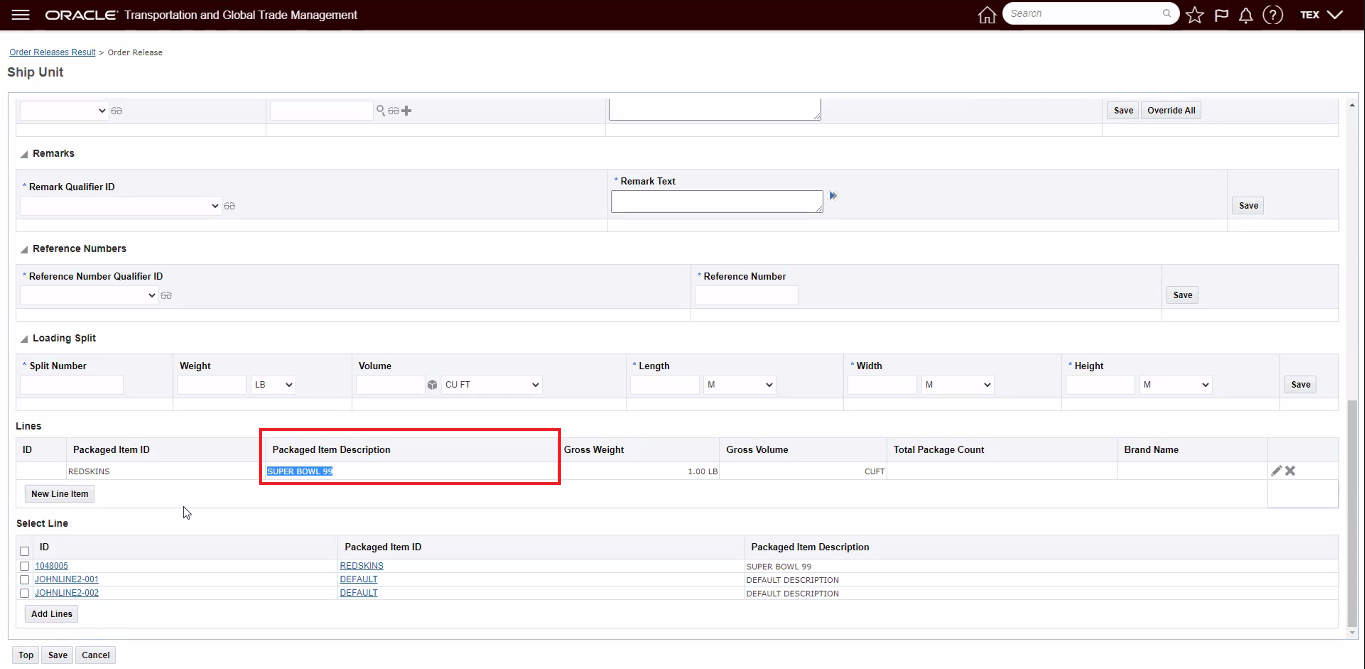

In the first step, you select the New Line Item button on the Ship Unit.

On Order Release Ship Unit - New Line Item

In the second step - you add the new line item and Save.

Add New Line Item

In the screen below, you will not see the Packaged Item Description populated for the newly added line item.

Package Item Description Populated

Provides you with more information about the packaged items beyond just the Packaged Item Id.

Steps to Enable

You don't need to do anything to enable this feature.

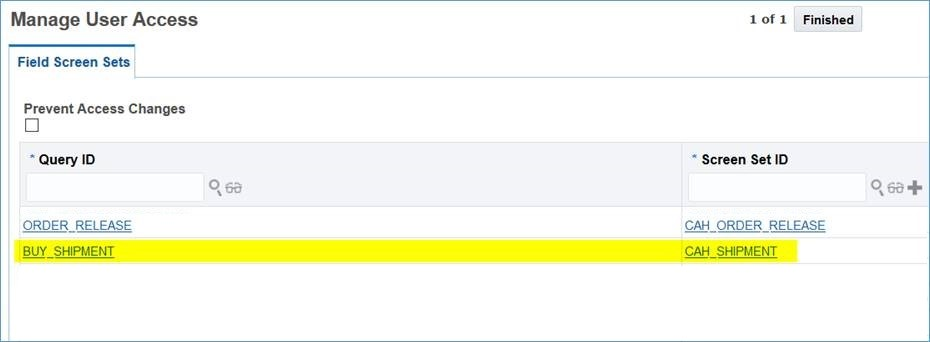

Manager Layout Direct URL Link In Stylesheet to User's Configured Manager Layout

This feature supports, for the Buy Shipment Manager Layout, Order Release Manager Layout and Invoice Manager Layout, the ability to have your direct OTM URL link link into the user’s configured Manager Layout instead of the PUBLIC Manager Layout.

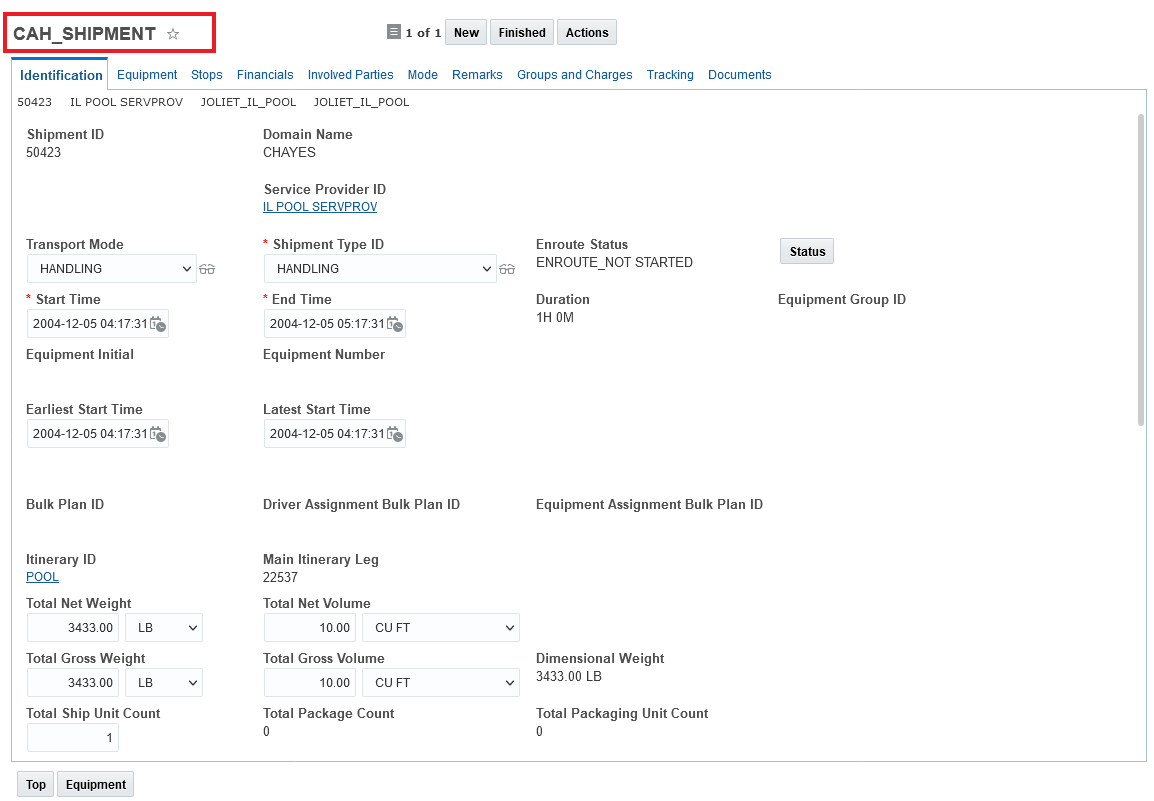

Finder Screen Set Setup for CAH Shipment - Configured Buy_Shipment Manager Layout

With the Finder Screen Sets setup above for , following the direct URL link https://otmash-22aqamain.otmgtm.us-system-1.ocs.oc-test.com//GC3/ShipmentEditRouter?pk=CHAYES.50423 links to the specified shipment using the the Screen Set CAH_SHIPMENT and related manager Layout - as shown below.

Direct Link Links to User Access Specified Screen Set and Manager Layout

Provides you with improved control over the information users see for the Buy Shipment, Order Release and Invoice, as well as providing a more consistent manager layout experience for the user.

Steps to Enable

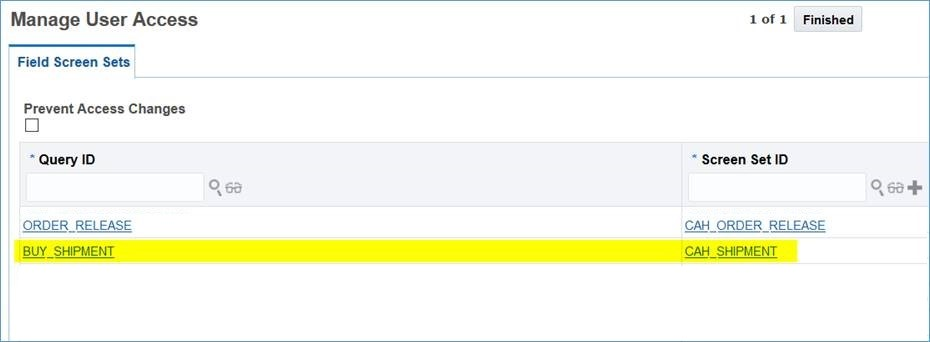

The Manage User Access Type of Field Screen Sets is used to set the layout used for the user for the Buy Shipment Layout, Order Release Layout and Invoice Layout.

Access this page via Configuration and Administration > User Configuration > Manage User Access.

NOTE: You must have DBA.ADMIN access to Manage User Access.

In the User Access Type field, select the option Field Screen Sets. Click Edit User Access. The Field Screen Sets page opens.

Use this page to configure the default screen set that is used for the Buy Shipment, Order Release or Invoice.

:

Configuration Example - Buy_Shipment and Order Release

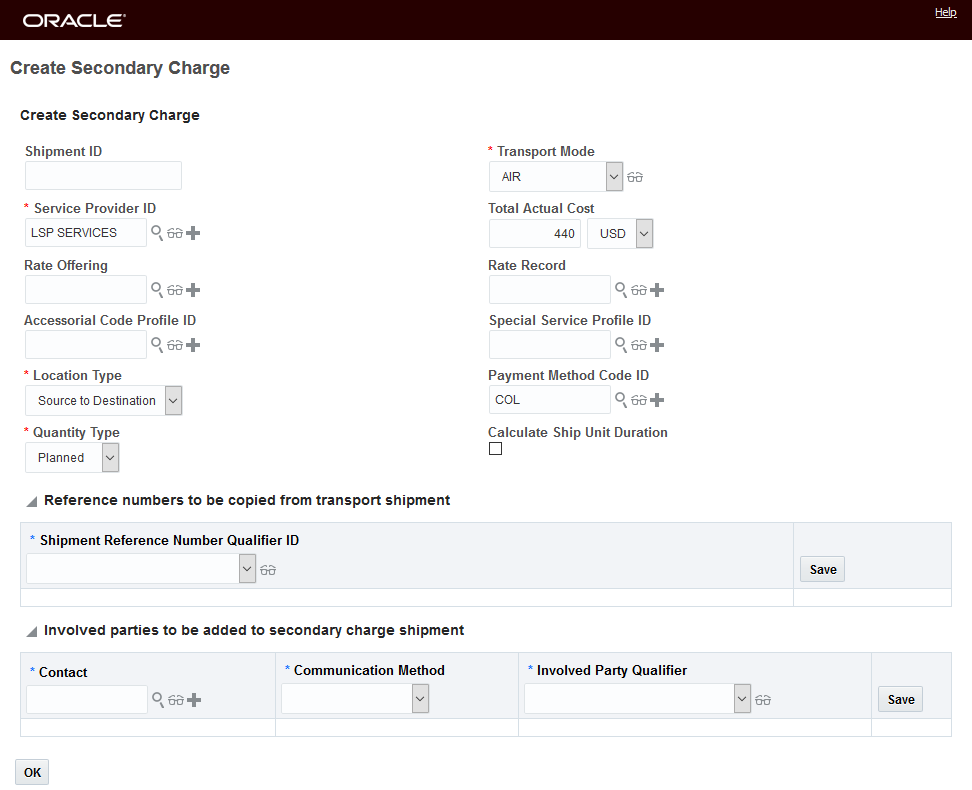

Create Secondary Charge Action Moved to Manager Layout

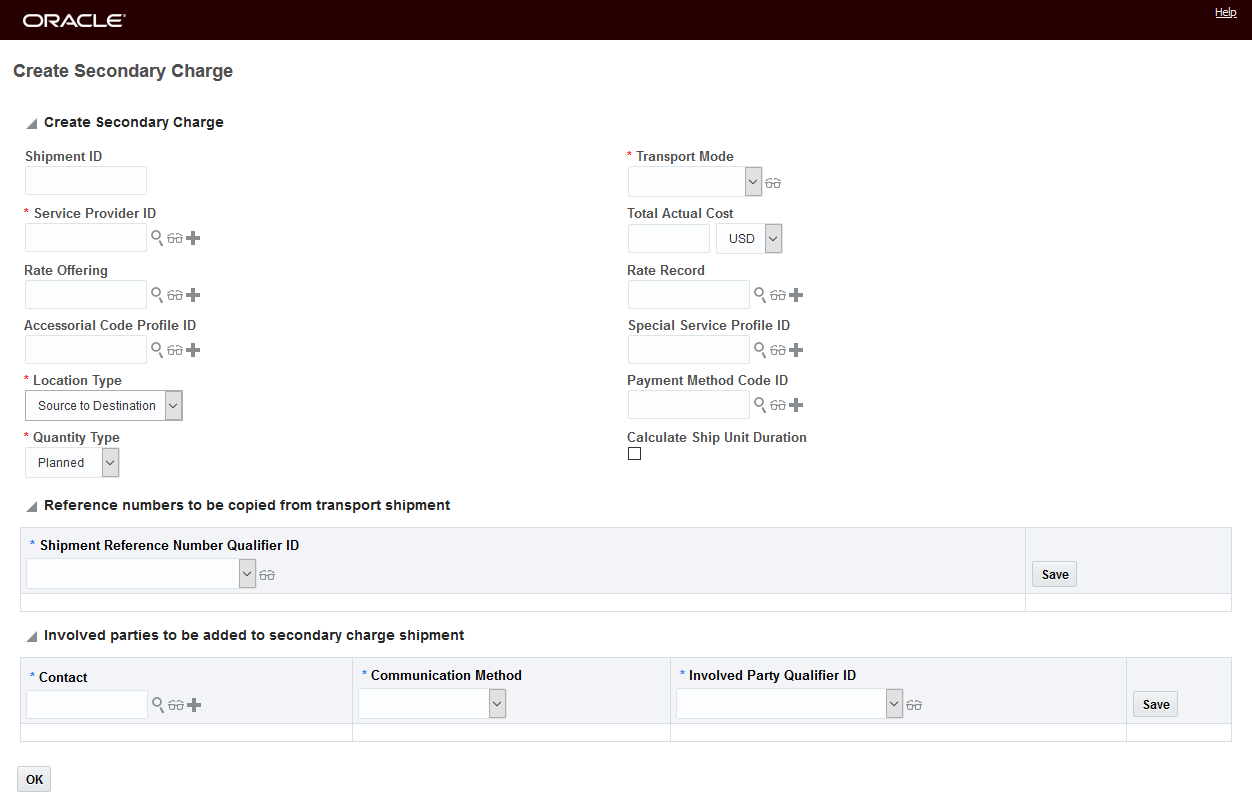

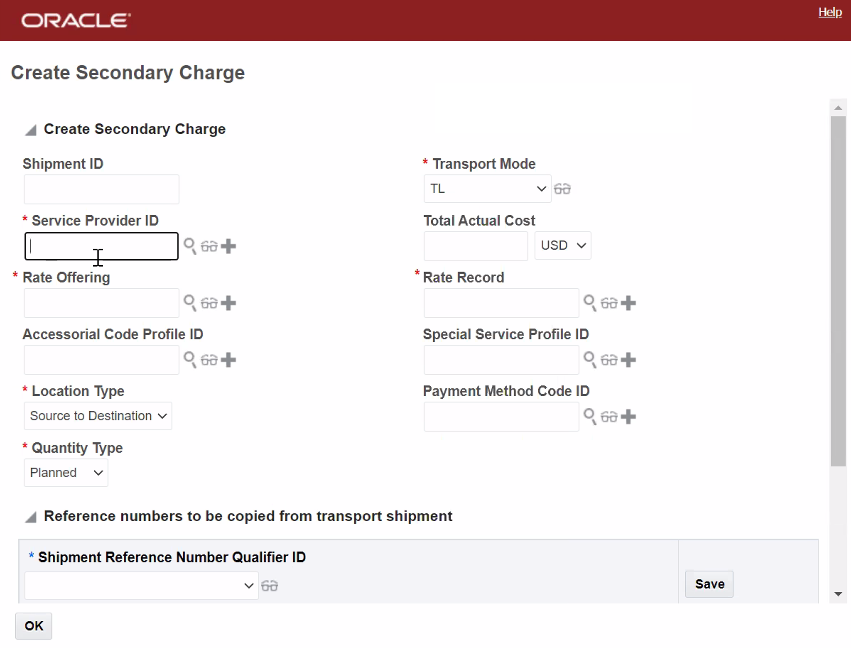

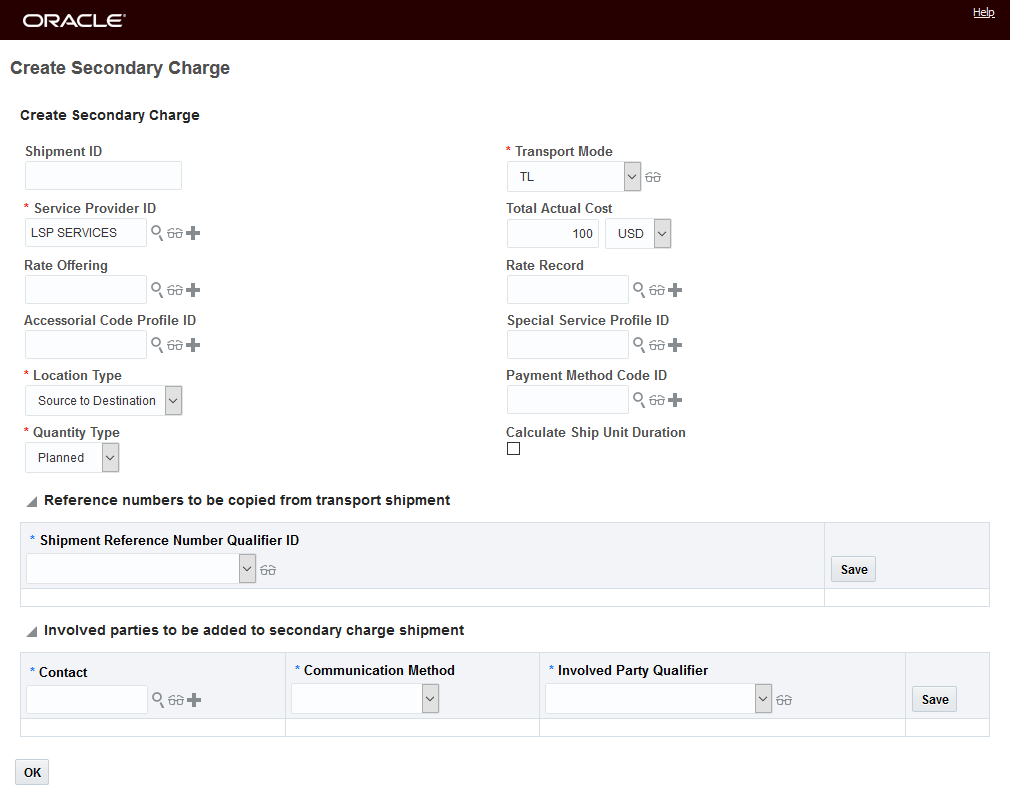

This feature adds manager layout capabilities to the Create Secondary Charge action which allows you to configure the action input. With this enhancement, you can hide unnecessary fields or as necessary, make other fields mandatory.

Create Secondary Charge - Standard Action Input

In the example below, Transport Mode defaults to TL, both the Rate Offering ID and Rate Record have been made Mandatory, and the Involved Party grid and the Calculate Ship Unit Duration Check Box have been removed.

Create Secondary Charge - Configured Action Input

Allows you to configure the Create Secondary Charge action to meet the needs of your implementation, improving usability and adoption of the application.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

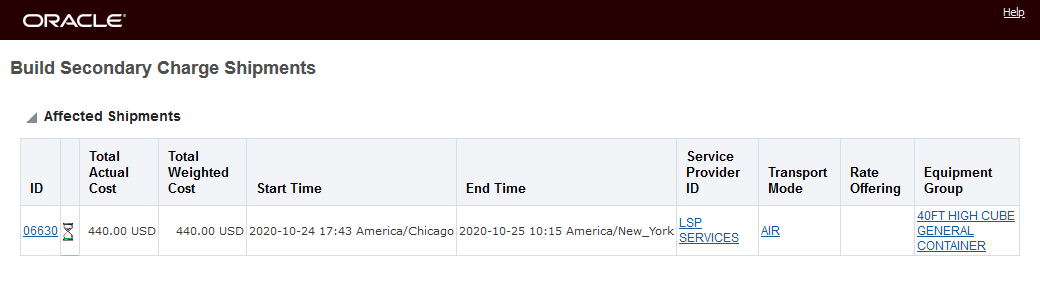

Note, the previous Shipment Create Secondary Charge action supported a multi-select action input. When the action was run against multiple shipments, the Create Secondary Charge input page would be displayed for each selected shipment, one at a time, and a secondary charge shipment would be created for each of the shipments after each input step. Unfortunately, the old Create Secondary Charge action did not provide any information about which of the selected shipments the secondary charge was being created for as it stepped through the selected set of shipments and created secondary charge shipments. See example below. The inability to understand which shipment was being processed in the multi-select shipment running of the Create Secondary Charge action was considered confusing by most users.

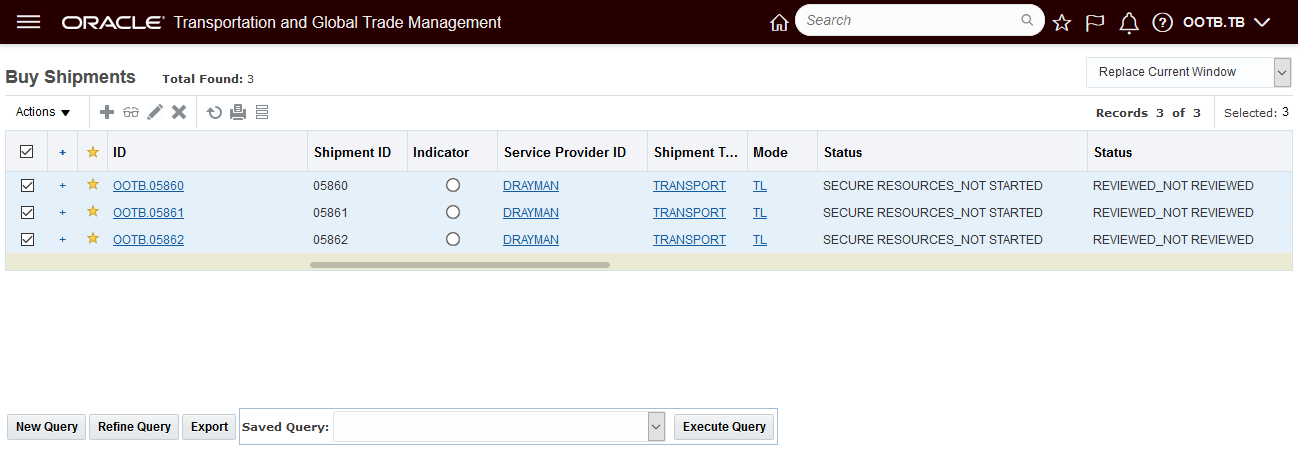

For example, using the previous Create Secondary Charge, you are able to select multiple shipments and run the action.

Old Multi-Select Create Secondary Charge Action Behavior

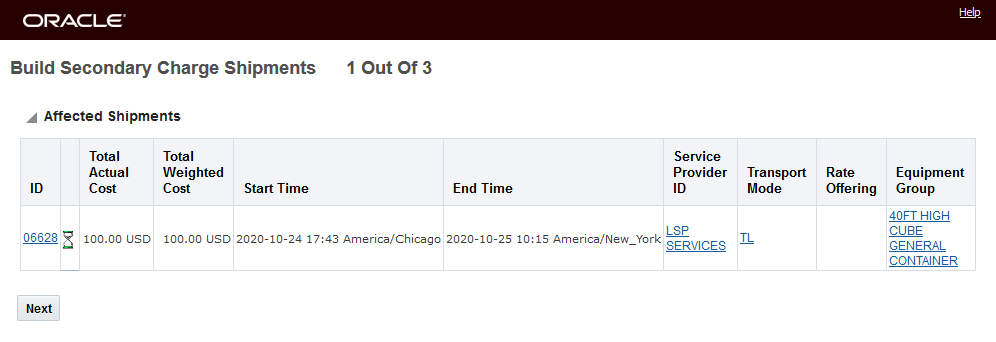

For each of the shipments selected you are given an action input screen and then shown the resulting secondary charge shipment - but you have no way of knowing which shipment you are creating the secondary charge shipment for.

Input Screen 1

Secondary Charge Shipment 1

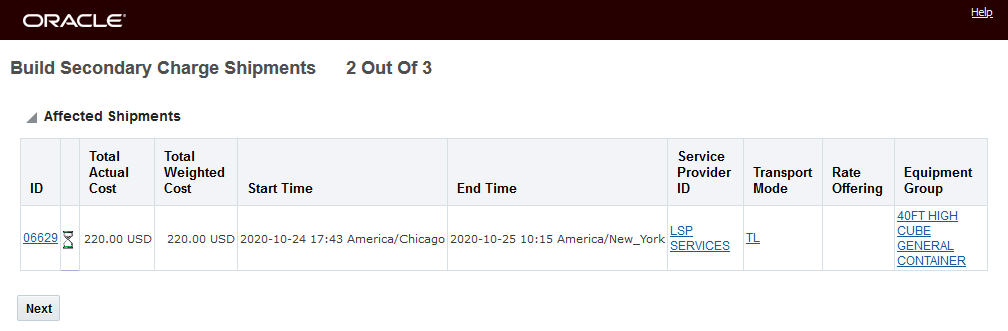

Input Screen 2

Secondary Charge Shipment 2

Input Screen 3

Secondary Charge Shipment 3

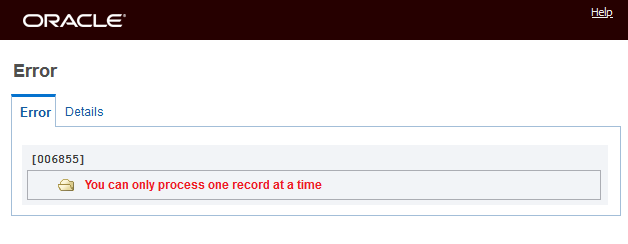

The new manager layout enabled Create Secondary Charge action avoids the multi-select issue by dis-allowing a multi-select shipment input. With the new Create Secondary Charge action, if you select multiple shipments and run the action you will receive this message.

Create Secondary Charge - Multi-Shipment Select Error Message

NOTE: The new Create Secondary Charge action and behavior (multi-select not supported) are now the default for this action, however, if for some reason the previous Create Secondary Charge action's behavior is required, you have the ability to revert to the previous version of the action by replacing the new Create Secondary Charge action with the previous action - now called Create Secondary Charge (Deprecated) in your Buy Shipment and Shipment Group screen sets.

Configuration and Administration > User Configuration > Screen Set Manager. Actions tab.

Revert to Old Behavior - Replace Create Secondary Charge action with Create Secondary Charge (Deprecated)

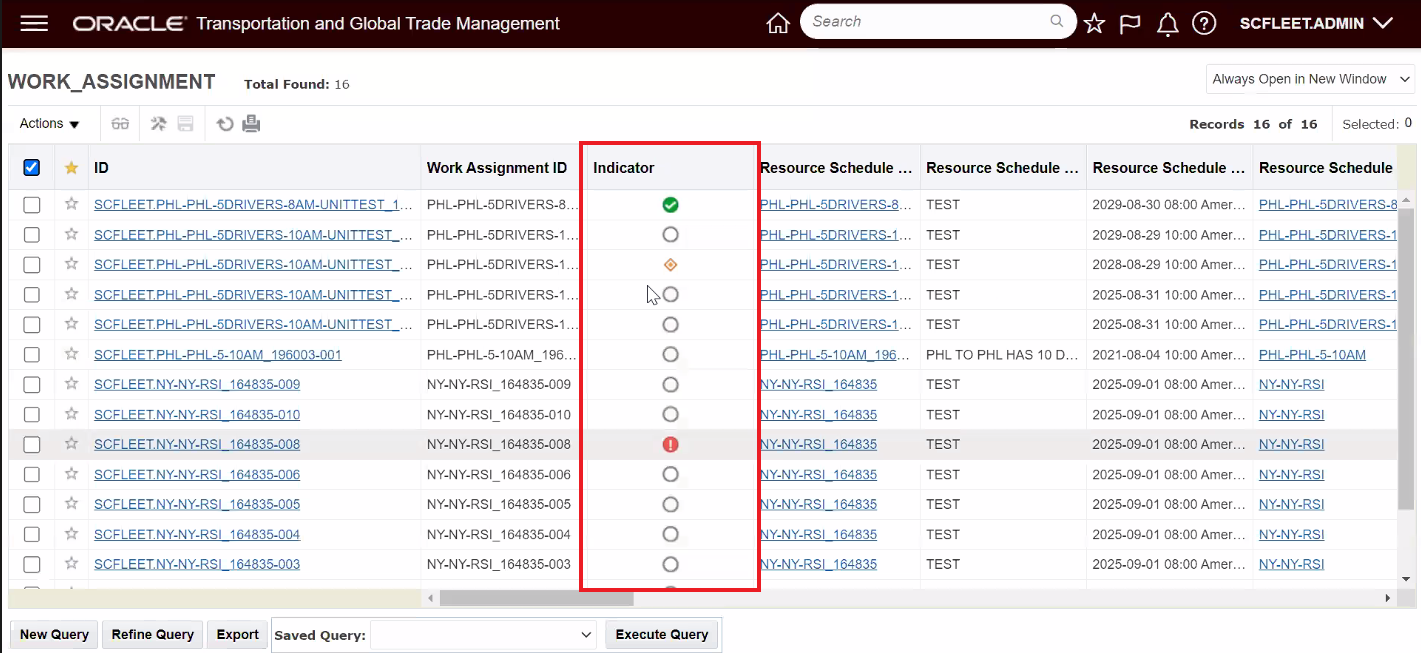

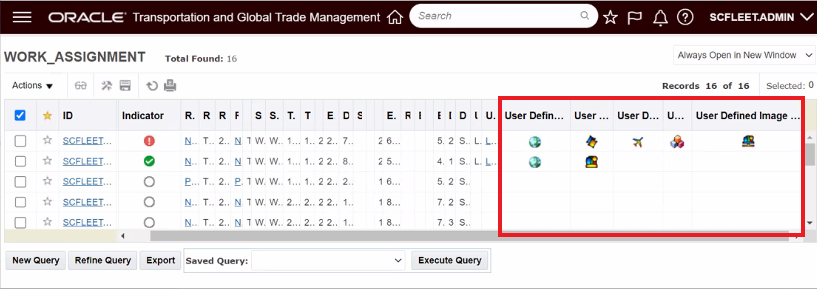

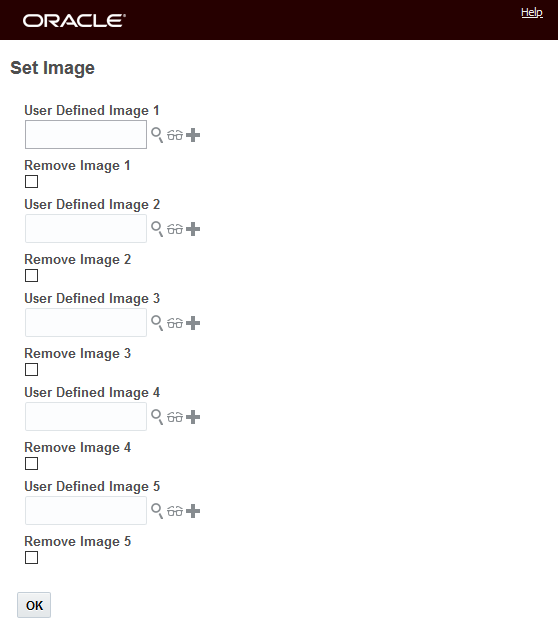

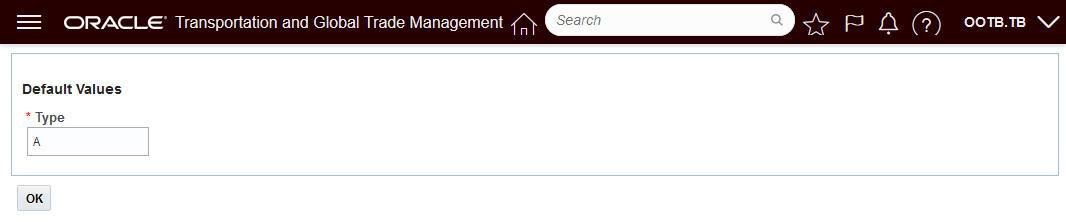

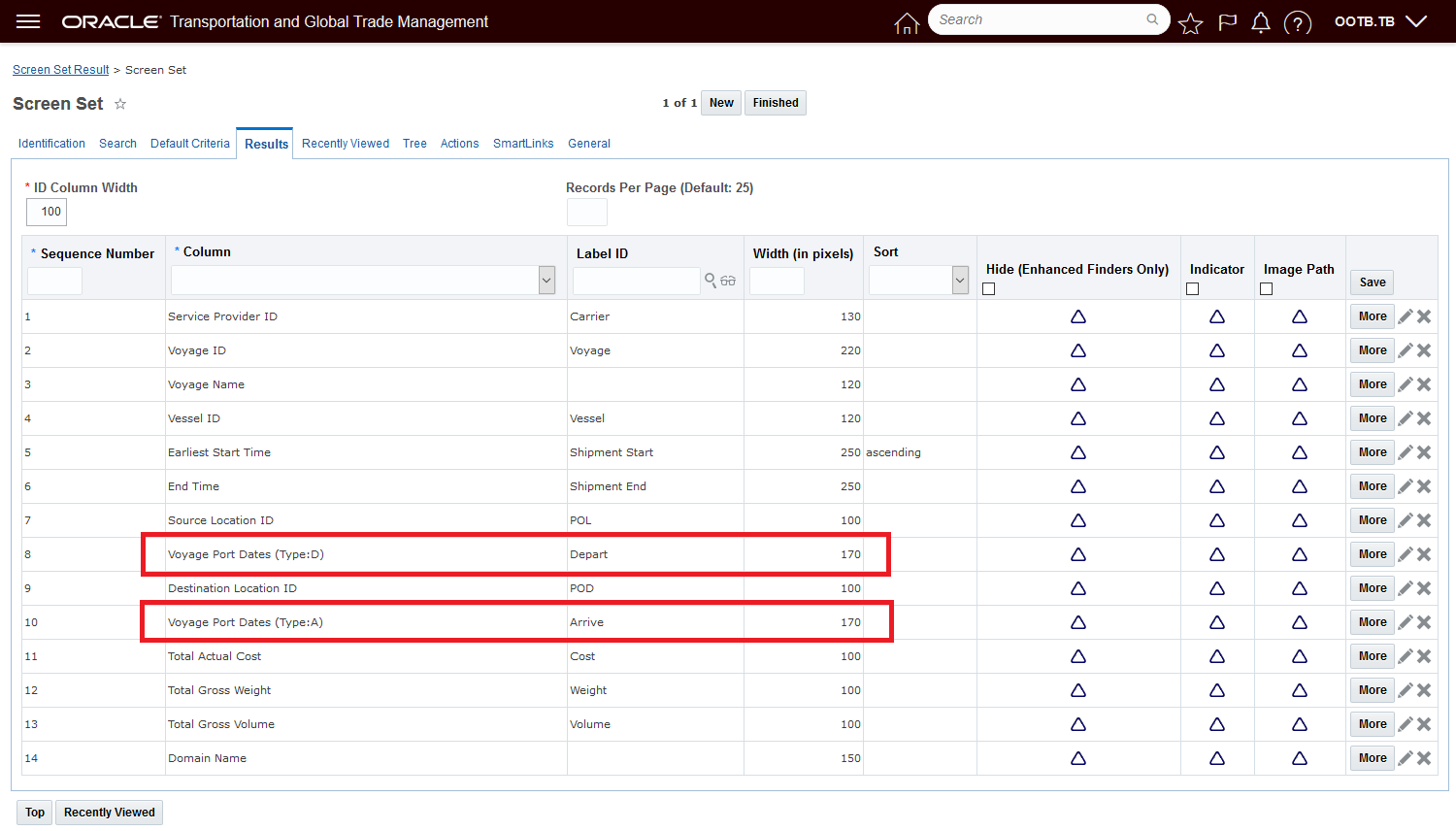

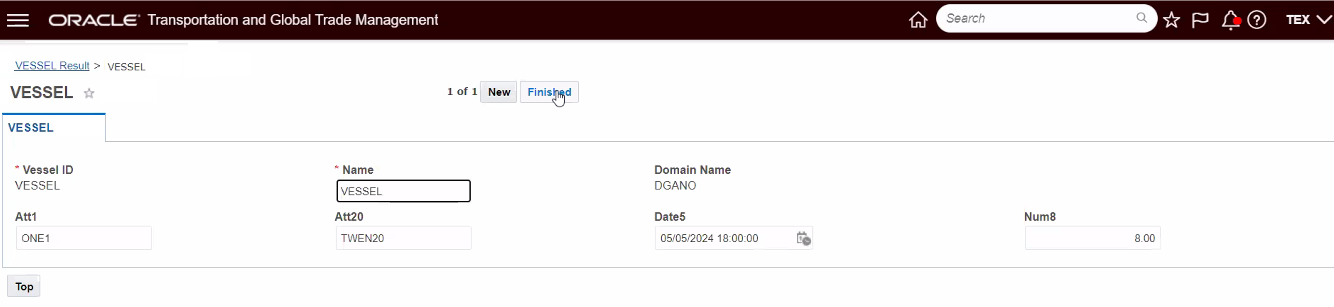

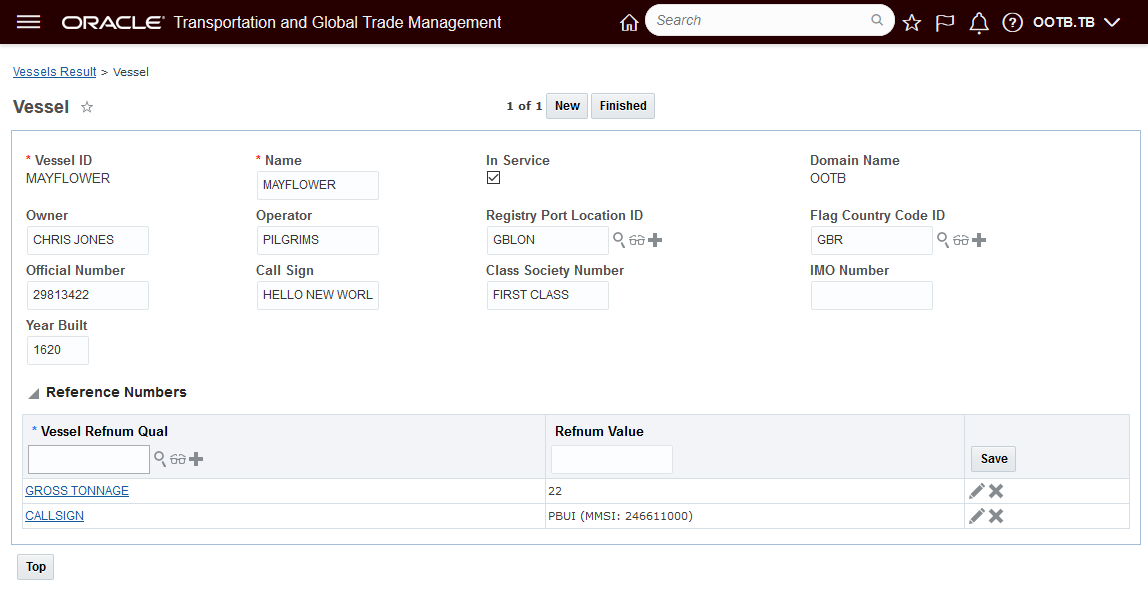

Work Assignment Screen Set - Results Add User Defined Images and Indicator

This feature enhances the Work Assignment Screen Set to include User Defined Images (1-5) and an Indicator. You can set the Image(s) and Indicator using the actions Set Image and Set Indicator on the Work Assignment or via an agent action.

Work Assignment Screen Set Results - Indicator Added

Work Assignment Screen Set Result - User Defined Images Added

Provides you with the option of setting User Defined Images (1-5) and/or an Indicator on your Work Assignments to provide visual queues to the current condition and status of your Work Assignments.

Steps to Enable

To take advantage of this feature you will need to add the User Defined Image(s) and Indicator to an existing or new Work Assignment Screen Set.

Screen Set Setup - Indicator and User Defined Images 1-5

Once configured - you can use the Set Image and/or Set Indicator to set the image(s) and indicator to your Work Assignments.

Set Image Action - Set or Remove Image(s)

Set Indicator Action Selection

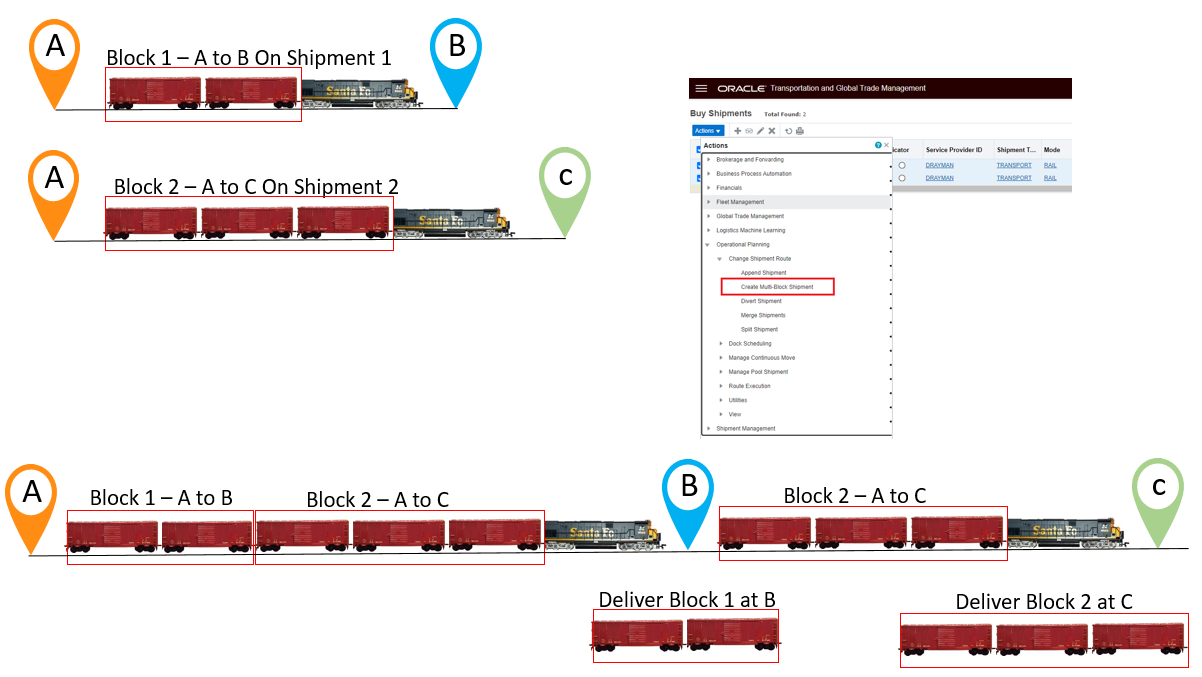

Create Multi-Block Shipment - Shipment Action

This feature provides you with a new Create Multi-Block Shipment action, that will create a multi-stop shipment from a selected set of direct shipments where the stops in this scenario assume a "delivery" of shipment equipment at the stops. You will find this feature useful in all your European Unit Train rail scenarios where the unit train involves delivering one or more rail cars at different junctions on the route. The usage assumption for this feature is that the creation of the Multi-Block Shipment will occur after the details related to the individual Block Shipments have been finalized - i.e., Equipment Initial and Number are added, shipment actuals have been processed etc.

In the example below, there are two individual block shipments - Shipment 1 going from A to B with two rail cars and Shipment 2 going from A to C with three rail cars. The Create Multi-Block Shipment action allows you to select your single block shipments (which share the same Reservation Number) and then create one Multi-Block shipment with - in this case, five rail cars with two delivery stops - one stop at location B delivery two rail cars and a second stop at location C delivering three rail cars..

The process for building the desired Multi-Block shipment - once the prerequisite have been completed - involves first building the individual Block Shipments (in this case Shipment 1 going from A to B and Shipment 2 going from A to C) which can be accomplished by selecting all the orders for the desired blocks and running a Bulk Plan where the Planning Parameters have been configured so that each rail car in the individual Block Shipments are loaded as desired. Once the individual Block Shipments are created, then you create the Multi-Block Shipment by selecting the two individual Block Shipments and running the action Create Multi-Block Shipment. The Create Multi-Block Shipment action will take the two individual Block Shipments and create one Multi-Block Shipment by consolidating the individual Block Shipments into one of the selected Individual Block Shipments.

Block to Multi-Block Example

Create Multi-Block Shipment

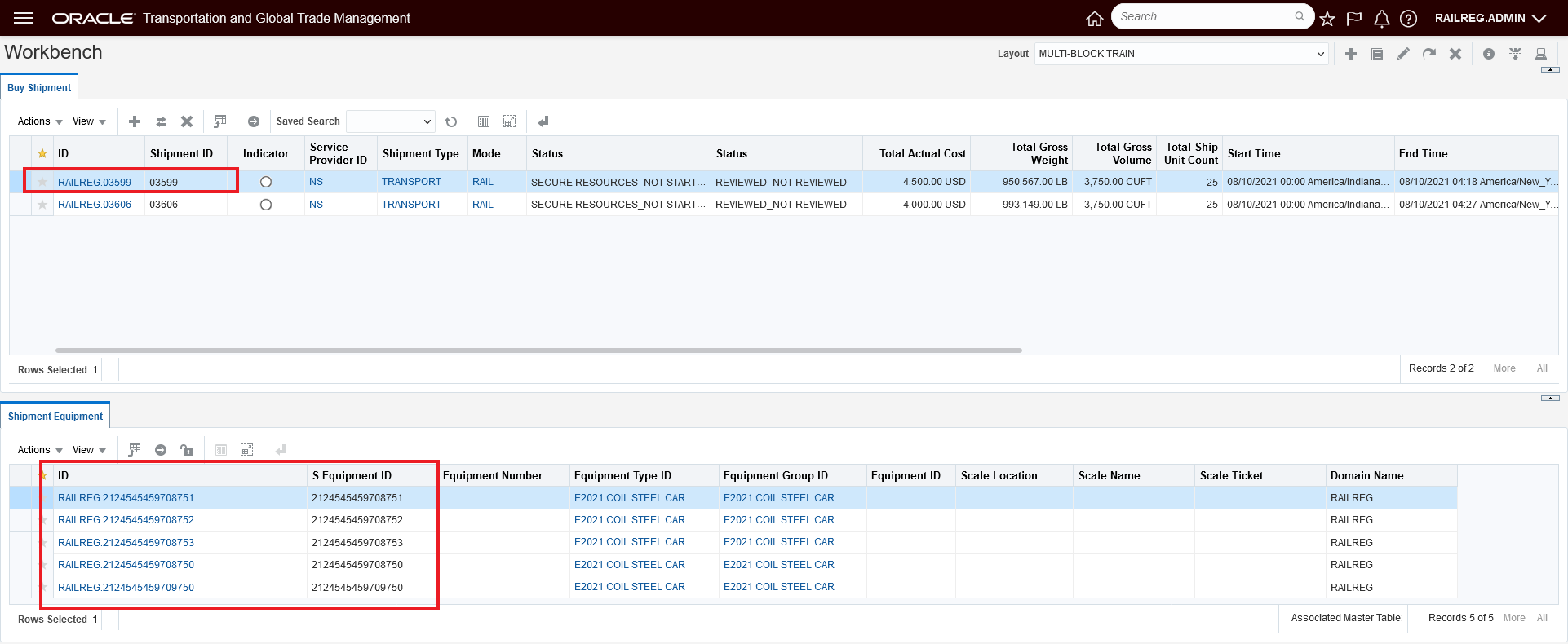

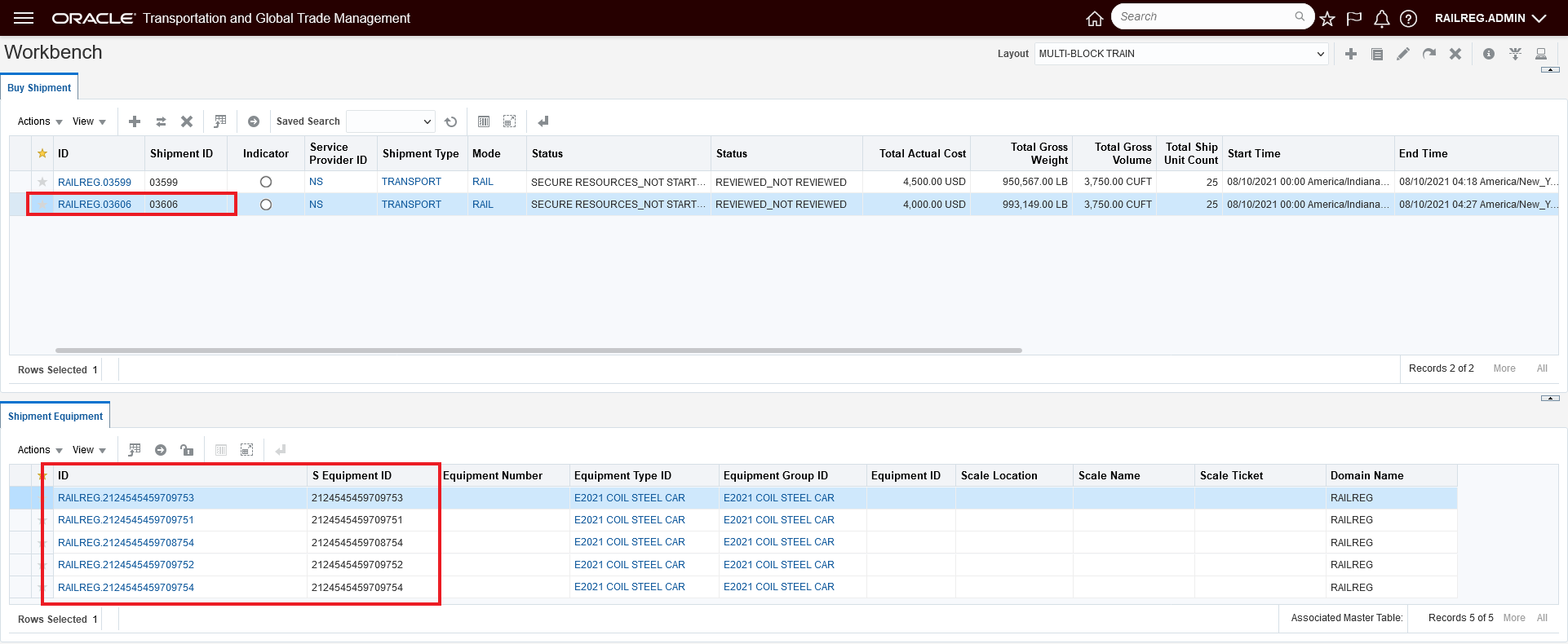

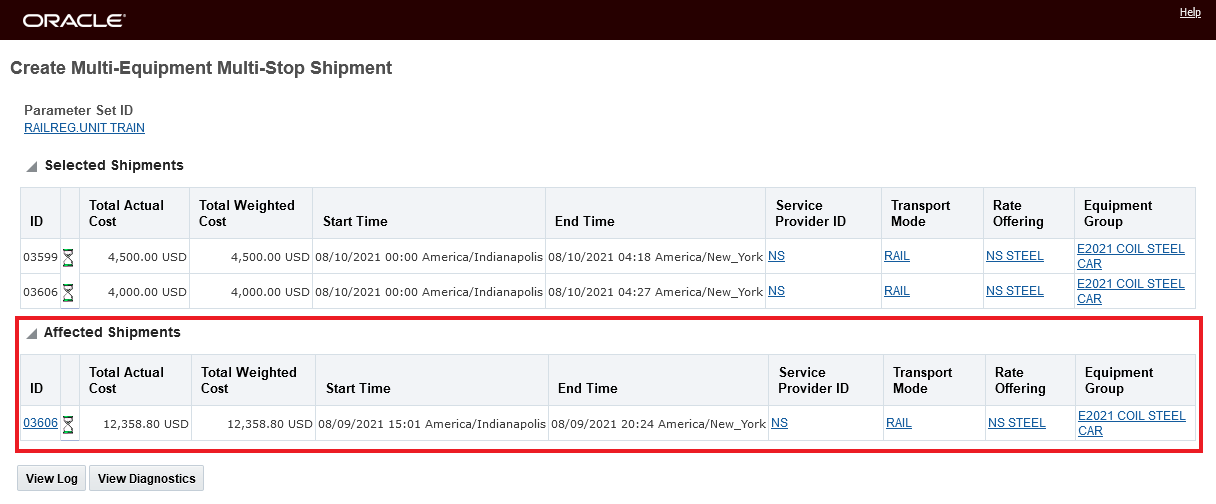

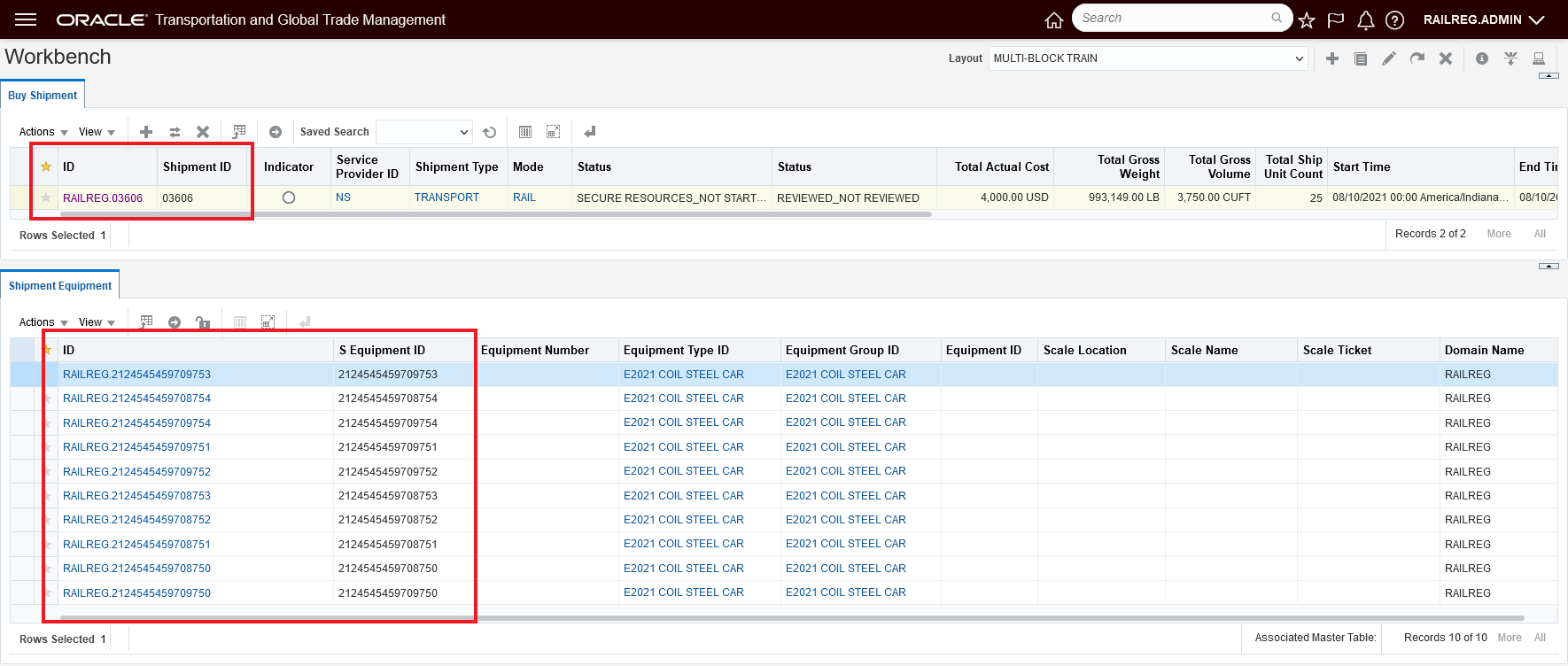

In the example below, there are two individual Block Shipments - 03599 and 03606, each of these shipments contains five shipment equipments as shown in the Workbench below. Block Shipment 03599 goes from Burns Harbor IN to Flint MI, Block Shipment 03606 goes from Burns Harbor IN to Pontic MI.

Block Shipment 03599

Block Shipment 03606

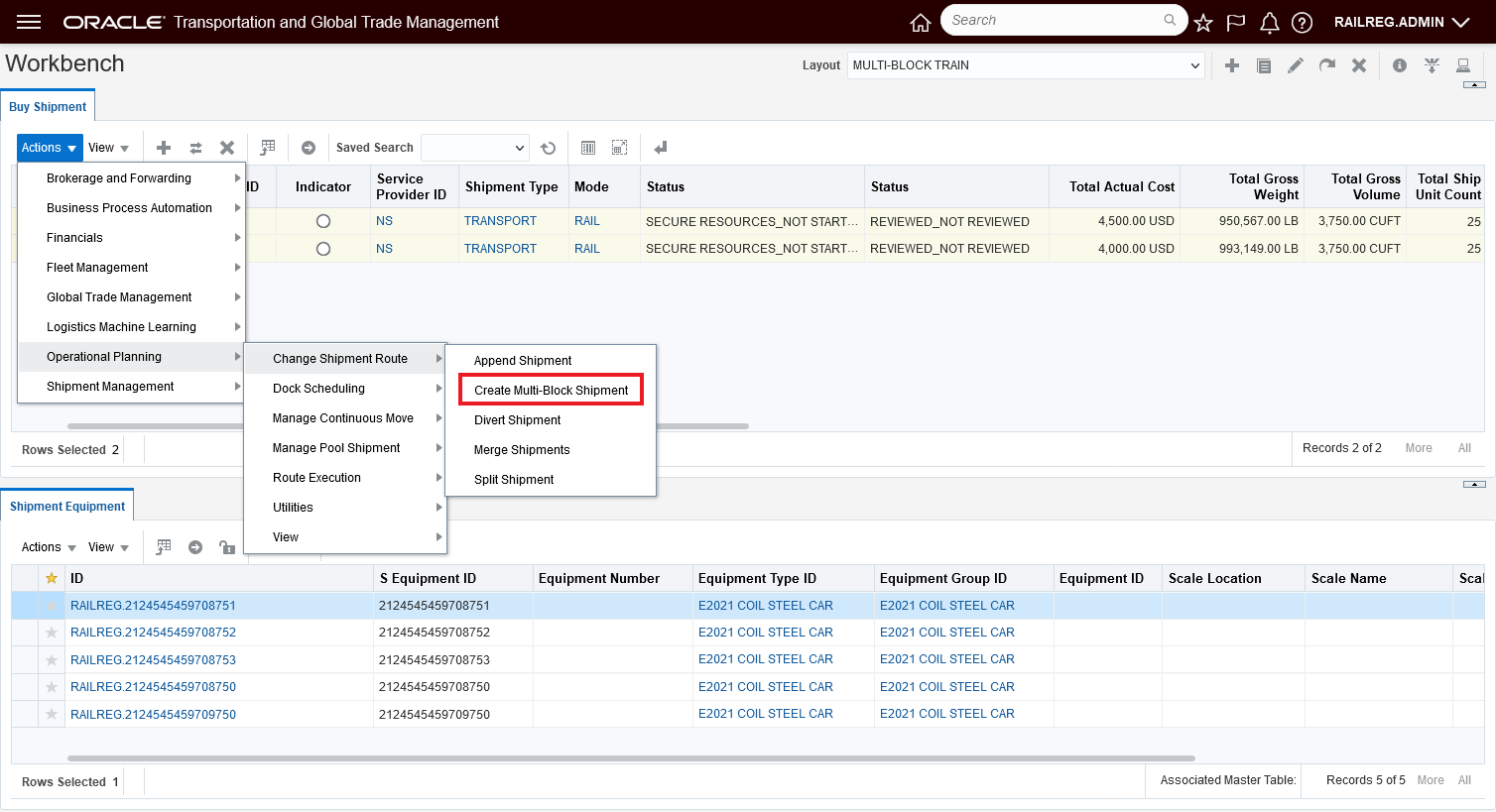

Assuming - as noted above - all the actuals have been reported against the two independent Block Shipments- - then you can run the action - Create Multi-Block Shipment - as shown below to create a single Multi-Block Shipment from the two Block Shipments.

Create Multi-Block Shipment Action

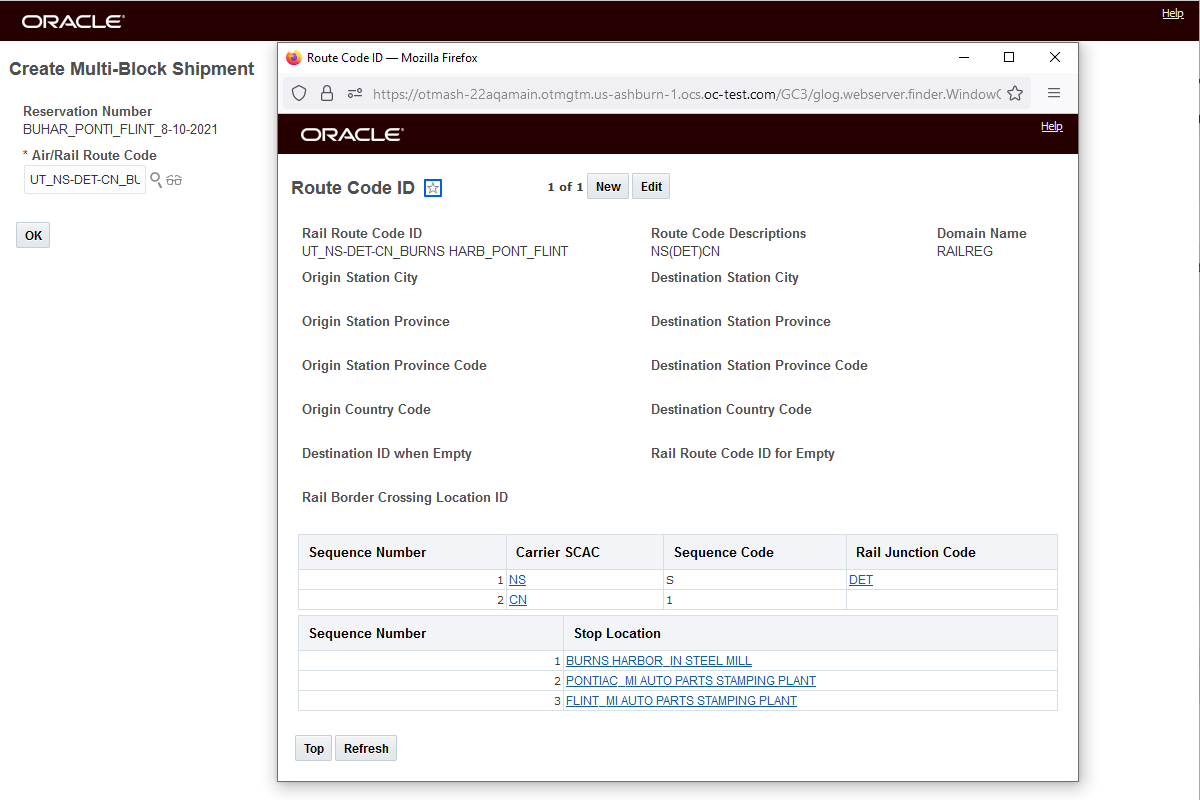

The action input for the Create Multi-Block Shipment action highlights some of the setup required to properly generate the Multi-Block Shipment. Specifically, the Reservation Number and Air/Rail Route Code are key to the successful setup for this action to run. The individual two-stop Block Shipments selected for this action must all have the same Reservation Number. You can enter the appropriate Air/Rail Route Code or - as shown below - the Air/Rail Route Code will be displayed if it is already assigned to all the shipments selected. The Air/Rail Route Code is used to determine the appropriate rate record to use for the combined shipment, and to determine the stop sequence for the combined shipment.

Action Input

View into Route Code Details

Result - Block Shipment 03599 Merged into Shipment 03606 to Create the Multi-Block Shipment

As you can see in the workbench below the Create Multi-Block Shipment has created one Multi-Block shipment 03606 with ten shipment equipments - from the two Block Shipments selected.

Resulting Multi-Block Shipment 03606

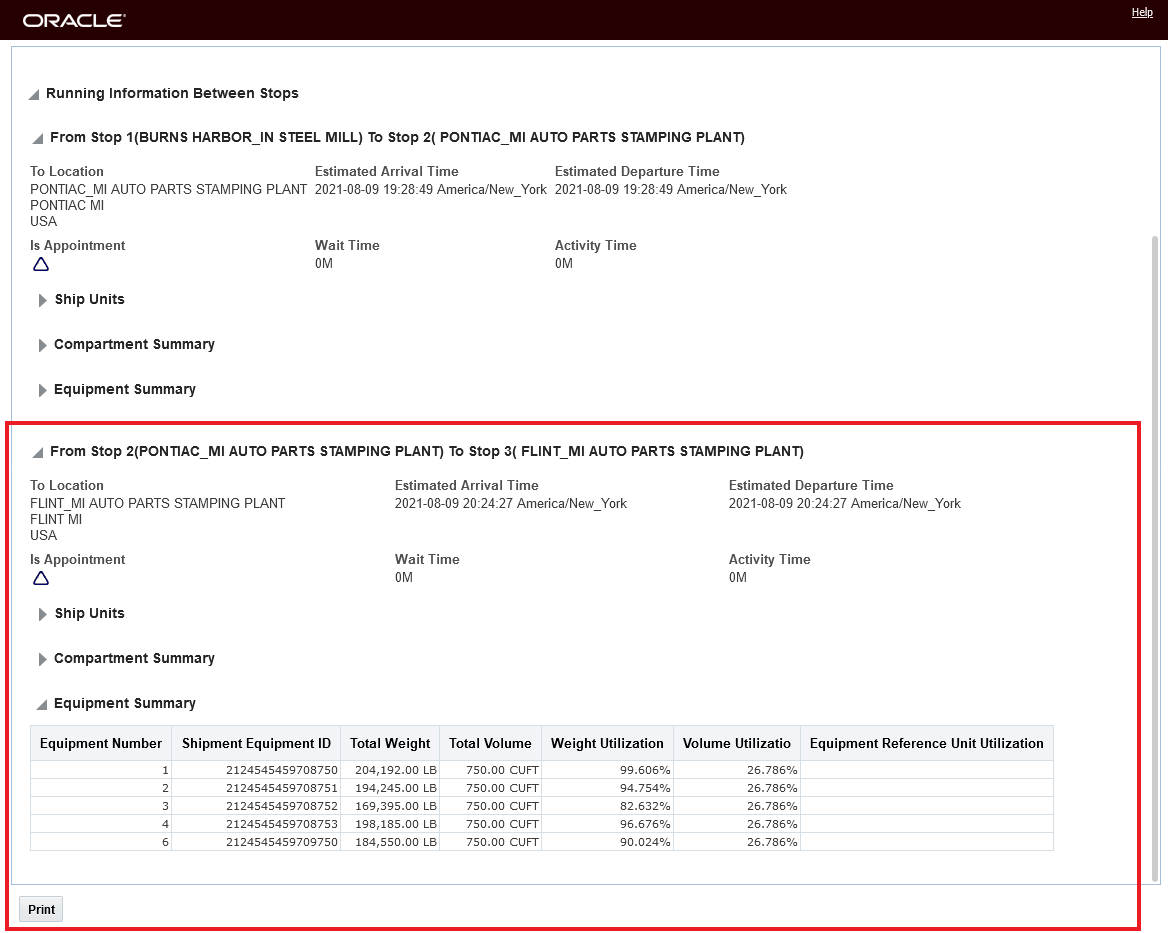

While the Shipment to Shipment Equipment provided above is an excellent way to visualize the shipment equipment on the Multi-Block Shipment, you will find the Running Manifest to be very helpful in determining the equipment being delivered at the stops on the Multi-Block Shipment. The Manifest report provides you a clear view into the activity occurring between stops. The Running Manifest is available here-> Shipment Management > Shipment Management > Buy Shipments > Actions > Shipment Management > View > Running Manifest.

Shipment Manifest View Equipment Summary from Stop 2 Pontiac to Stop 3 Flint

This new action is accessed via Shipment Management > Shipment Management > Buy Shipments > Actions > Operational Planning > Change Shipment Route > Create Multi-Block Shipment.

You will find this feature useful in solving all your European Unit Train rail scenarios where the unit train involves delivering sets rail cars at different junction points along the route.

Steps to Enable

A Multi-Block Shipment is created for a particular Rail Route Code and Reservation Number. The successful creation of a Multi-Block Shipment depends upon the correct set-up of Capacity Limits, Rail Route Codes and Reservation data.

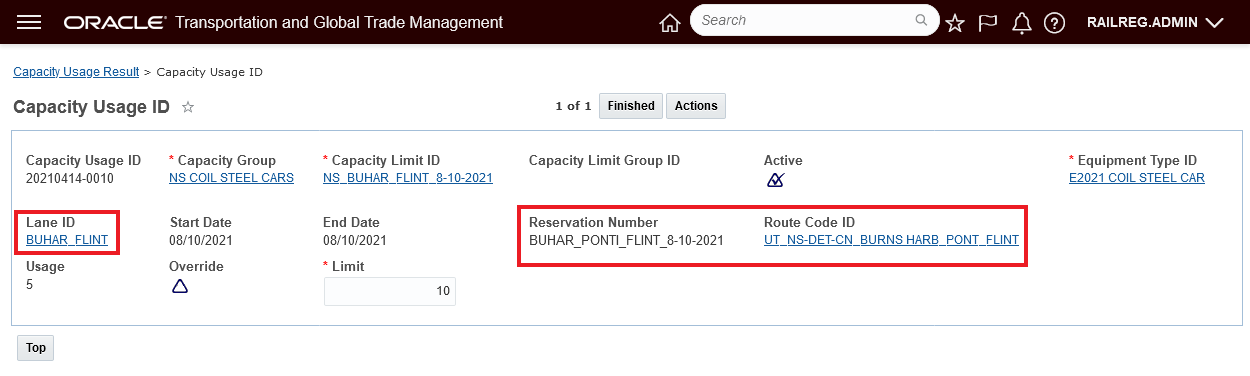

As shown below, the relevant Capacity Limit records used to create the Block Shipments should specify the Route Code ID and Reservation Number. A Capacity Limit is required for each of the individual Block Shipments - but Capacity Limits are not part of the Multi-Block Shipment process - in this business scenario your capacity limit management is handled by lane for each of the individual Block Shipments not for the final Multi-Block Shipment..

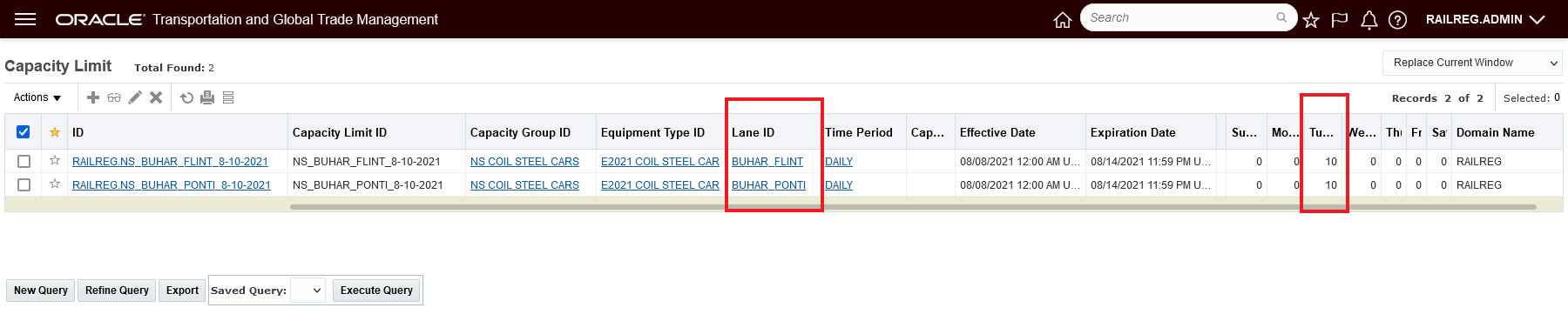

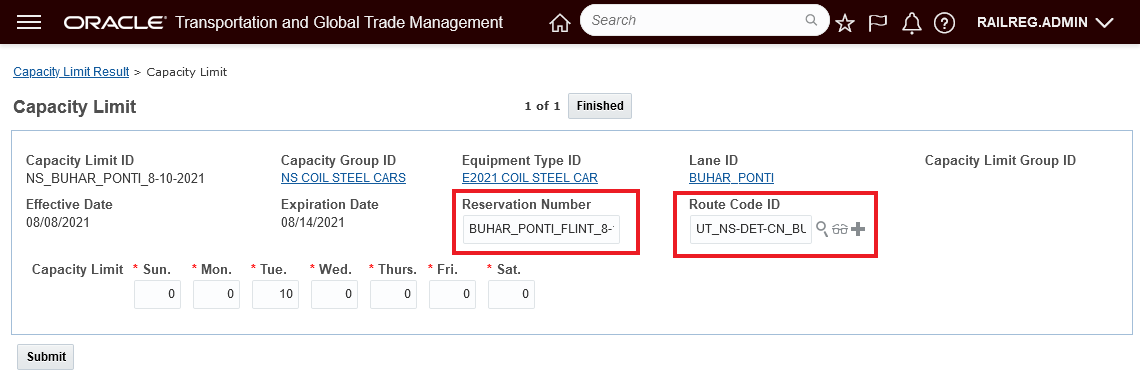

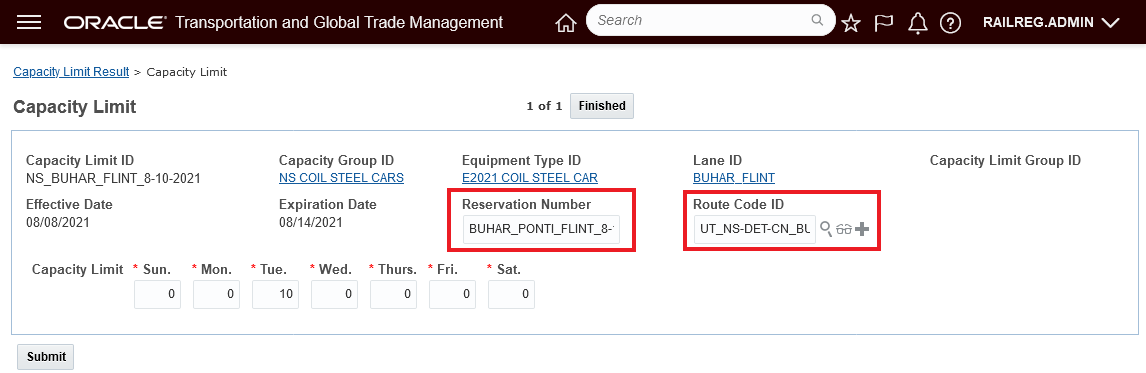

In the example above - where there are two Block Shipments - one from Burns Harbor to Flint and one from Burns Harbor to Pontiac - there are two Capacity Limit records defined as shown below.

Capacity Limits

Notice that both of the Capacity Limit Records, for both of the lanes involved have the same Reservation Number and Route Code assigned. Route Code: UT_NS-DET-CN_BURNS HARB_PONT_FLINT and Reservation Number: BUHAR_PONTI_FLINT_8-10-2021

Capacity Limit Burns Harbor to Pontiac

Capacity Limit Burns Harbor to Flint

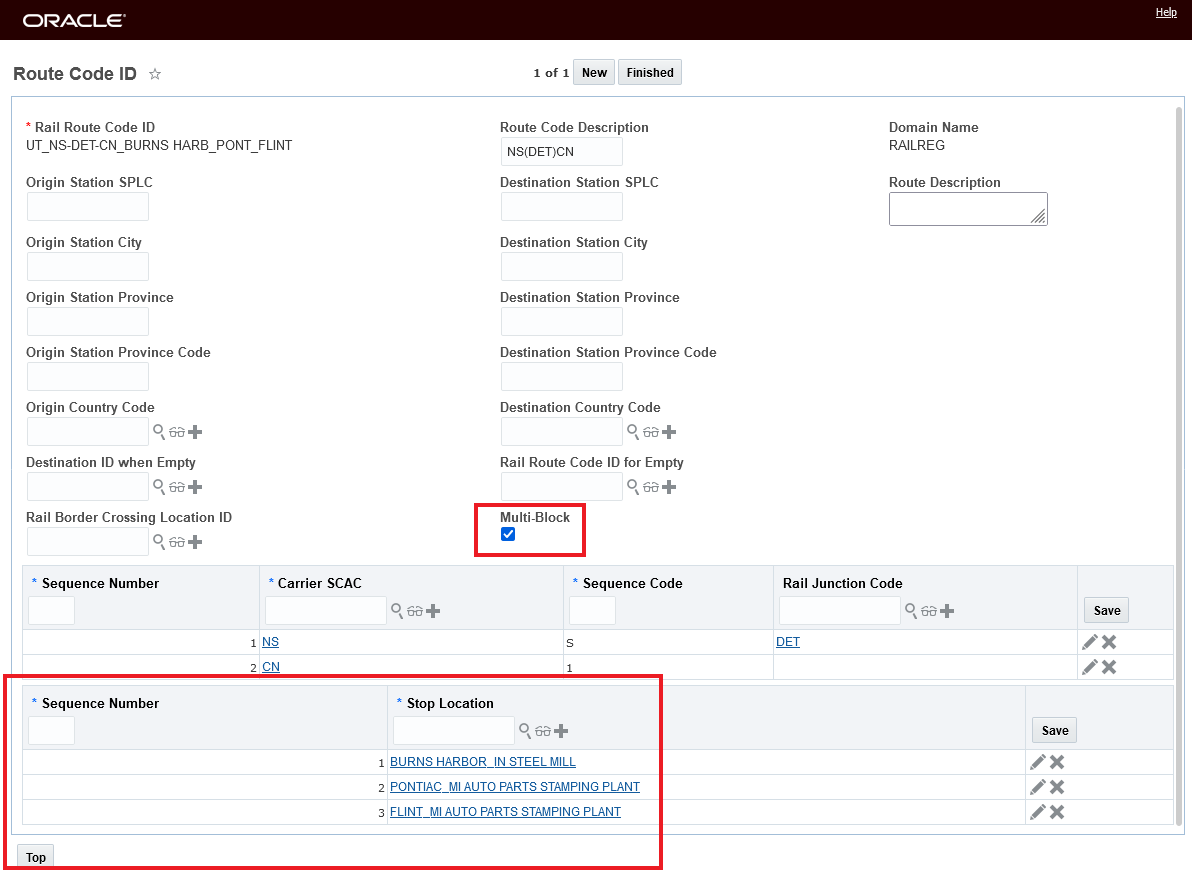

The Route Code Configuration is below.

The Multi-Block check box indicates that this route code will be used for creating a Multi-Block train. Selecting this check box will enable you to specify the sequence and the stop locations of the Multi-Block train. When the Multi-Block check box is selected, you will need to enter a Sequence Number to order the stop locations of the Multi-Block train as well as entering the Location IDs for the Multi-Block stops in the Stop Location field.

There are some regional variations on what is required - in the United States, where many customers use PC*MILER RAIL, additional details are required in the top grid - Carrier SCAC, Sequence Code and possibly Rail Junction Code, while in Europe, only the lower Sequence table is needed

Route Code Detail

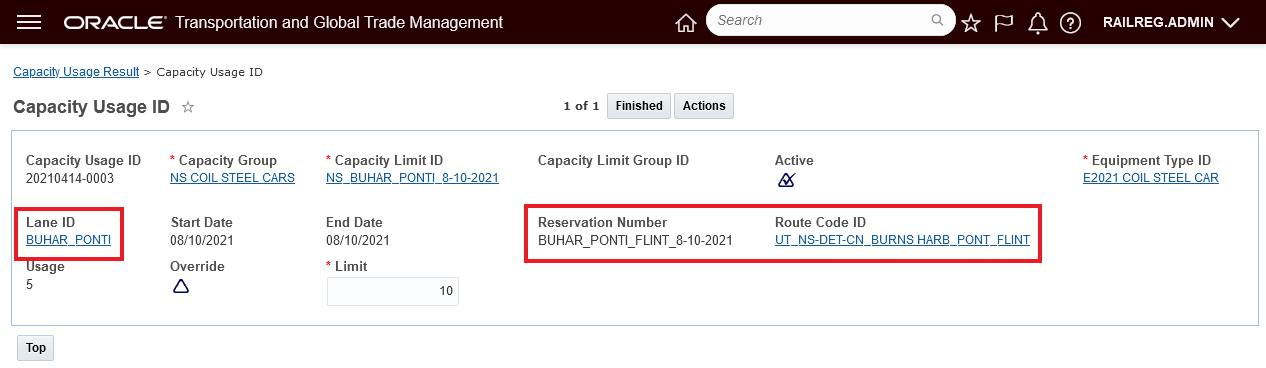

Below are the two Capacity Usage records used in planning the two Block Shipments - note the Capacity Usage records contain the required Reservation Number and Route Code information - this information is populated on each of the Bulk Shipments when they are planned.

Capacity Usage Burns Harbor to Pontiac

Capacity Usage Burns Harbor to Flint

This feature provides support for unit train rail activities that involve splitting off rail cars at different junctions along the route.

- Different Capacity Limit records with the same Reservation Number can be used for block shipments that will ultimately be combined into a multi-block shipment.

The relevant Rail Route Code records will have the "Multi-Block" flag checked.

- Each of the Rail Route Code records should specify the complete stop sequence for multiple stops for the multi-block shipment.

- Rail Route Code

NOTE: In ordinary truckload scenarios, a Capacity Limit record represents recurring capacity, that is, capacity that is available each day or each week, etc. However, in the multi-block scenario, a Capacity Limit record represents capacity available for a particular day and reservation, not recurring capacity that will also be available in future days.

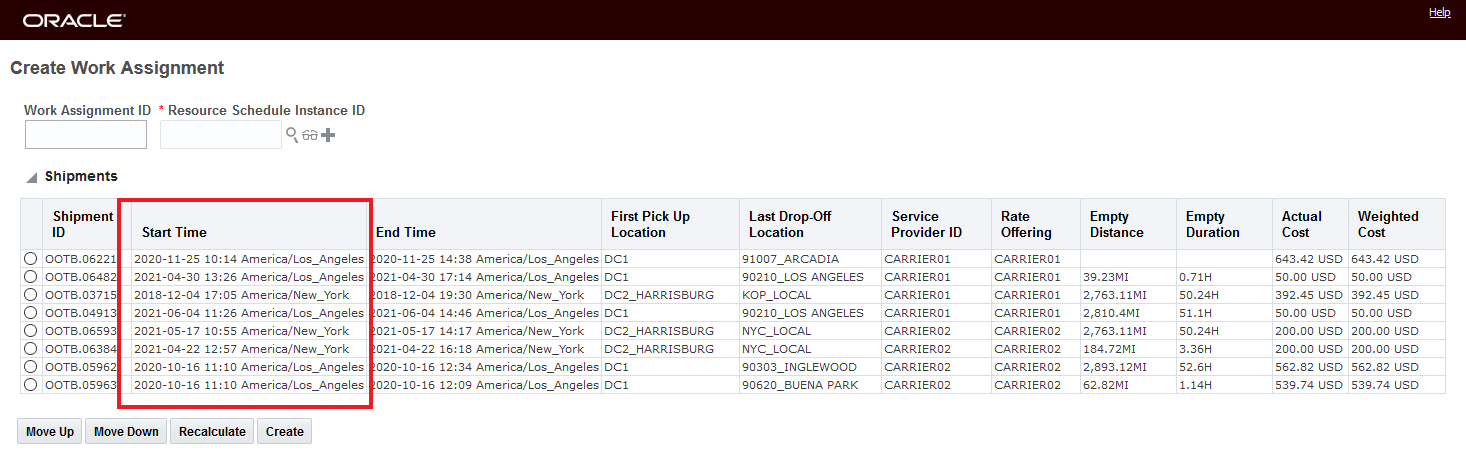

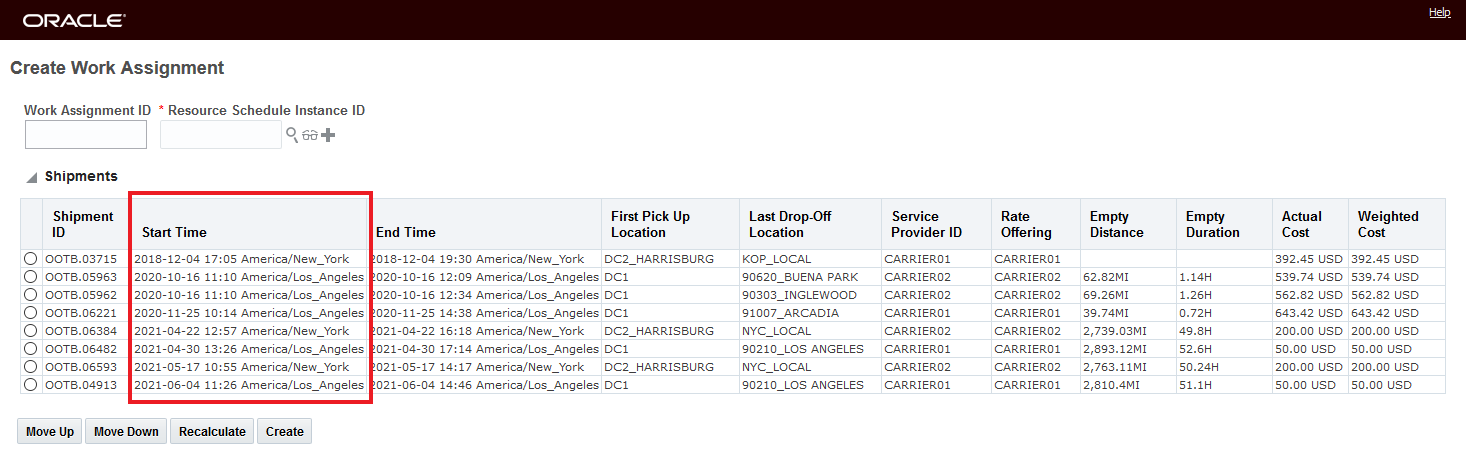

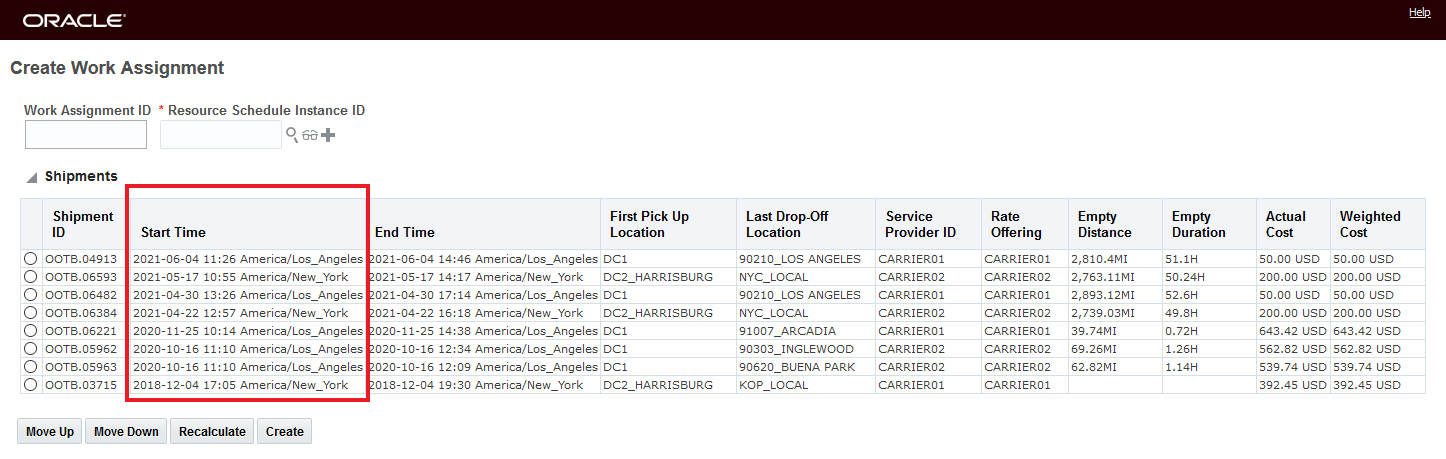

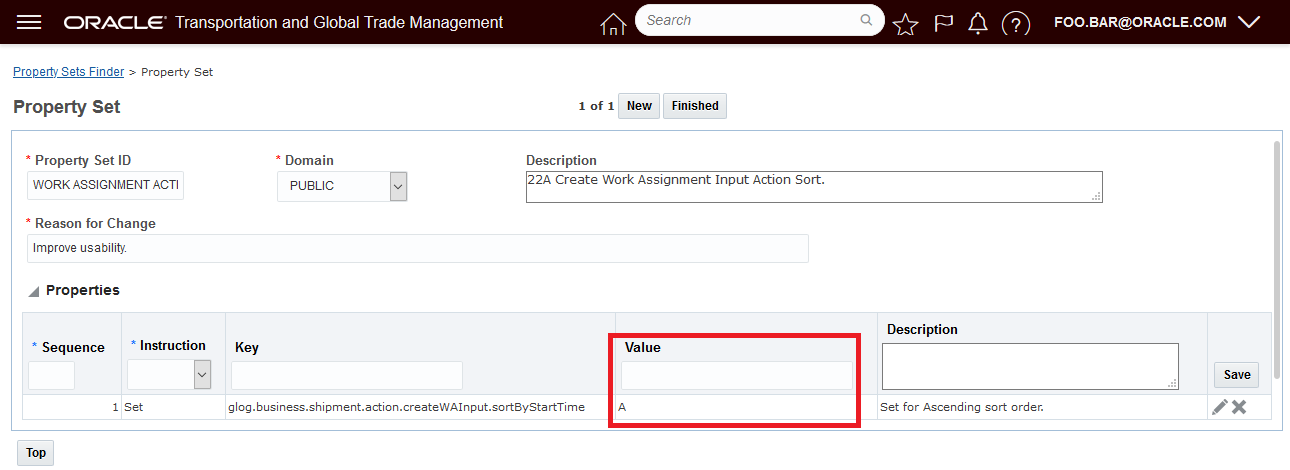

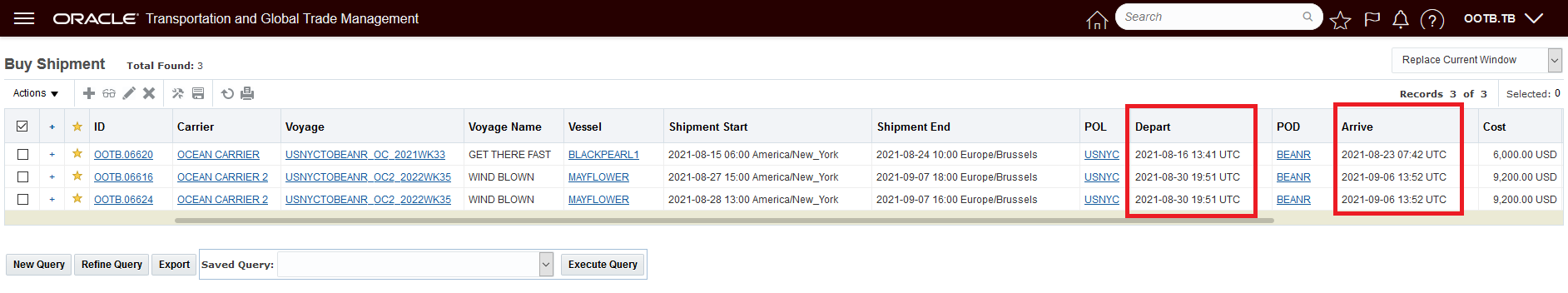

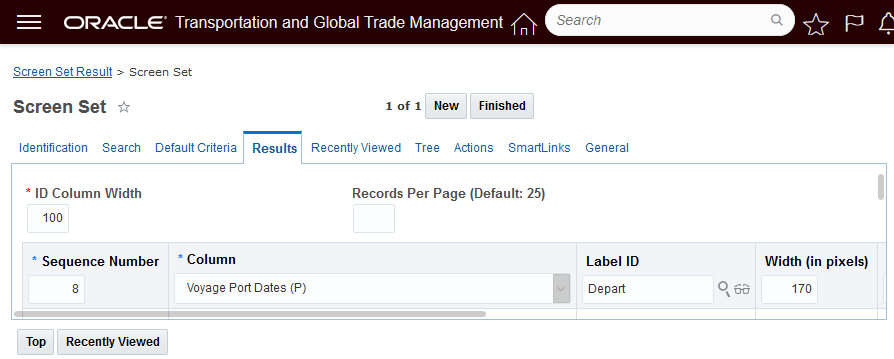

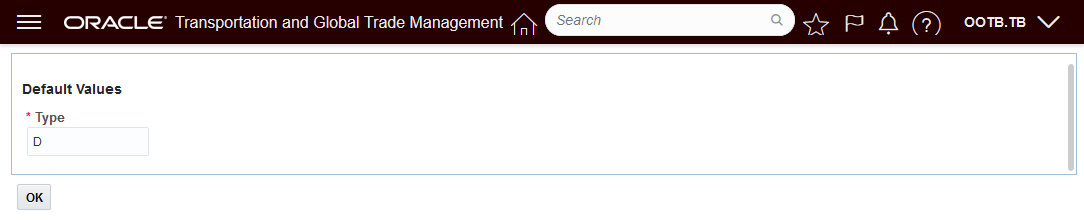

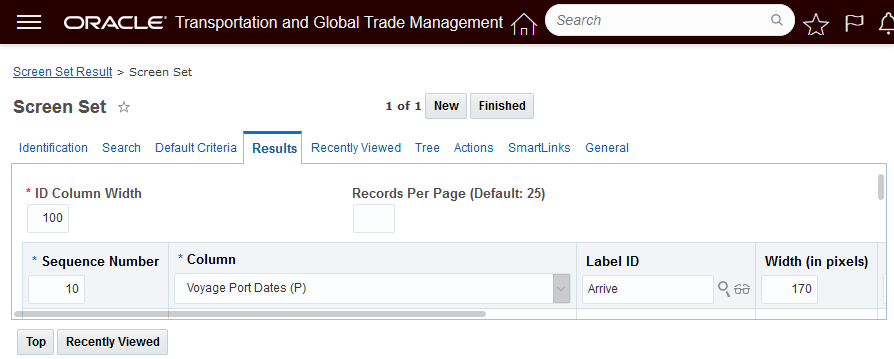

Create Work Assignment Shipment Sort Display Property

This feature provides you with a new property - glog.business.shipment.action.createWAInput.sortByStartTime - that allows you to set the sort order of the shipments selected when running the Create Work Assignment action. You can set the property to sort the selected shipments by the shipment Start Time either in Ascending (A) or Descending (D) order.

Below is an example of the default sort order for a set of eight shipments provided as input to the Create Work Assignment action. Note that the sort order is hard to determine and if your desired work assignment was to be created in an ascending order starting with the earliest shipment - you would need to manually re-sequence the shipments to accomplish this desired outcome.

Create Work Assignment Action Default Shipment Sort

Below is the same set of shipments, but in this case the property glog.business.shipment.action.createWAInput.sortByStartTime has been set to "A" so that the shipments are now sorted by Start Time in ascending order. In this case - if your goal was to create a work assignment with the shipments in ascending start time order - with the new property set to "A", there's no longer a need to manually move the shipments up/or down in the list - it's done automatically.

Create Work Assignment Action with Property Set to Sort Shipments in an Ascending Start Time Order

Create Work Assignment Action Property Set to Sort Shipments in a Descending Start Time Order

This feature improves the usability of the Create Work Assignment action by providing a consistent and intuitive ordering of the set of shipments selected to create the work assignment.

Steps to Enable

The property glog.business.shipment.action.createWAInput.sortByStartTime needs to be set to use this feature.

To set the sort order to ascending the property value should be set to "A" as shown below.

Ascending Option

To set the sort order to descending the property value should be set to "D" as shown below.

Descending Option

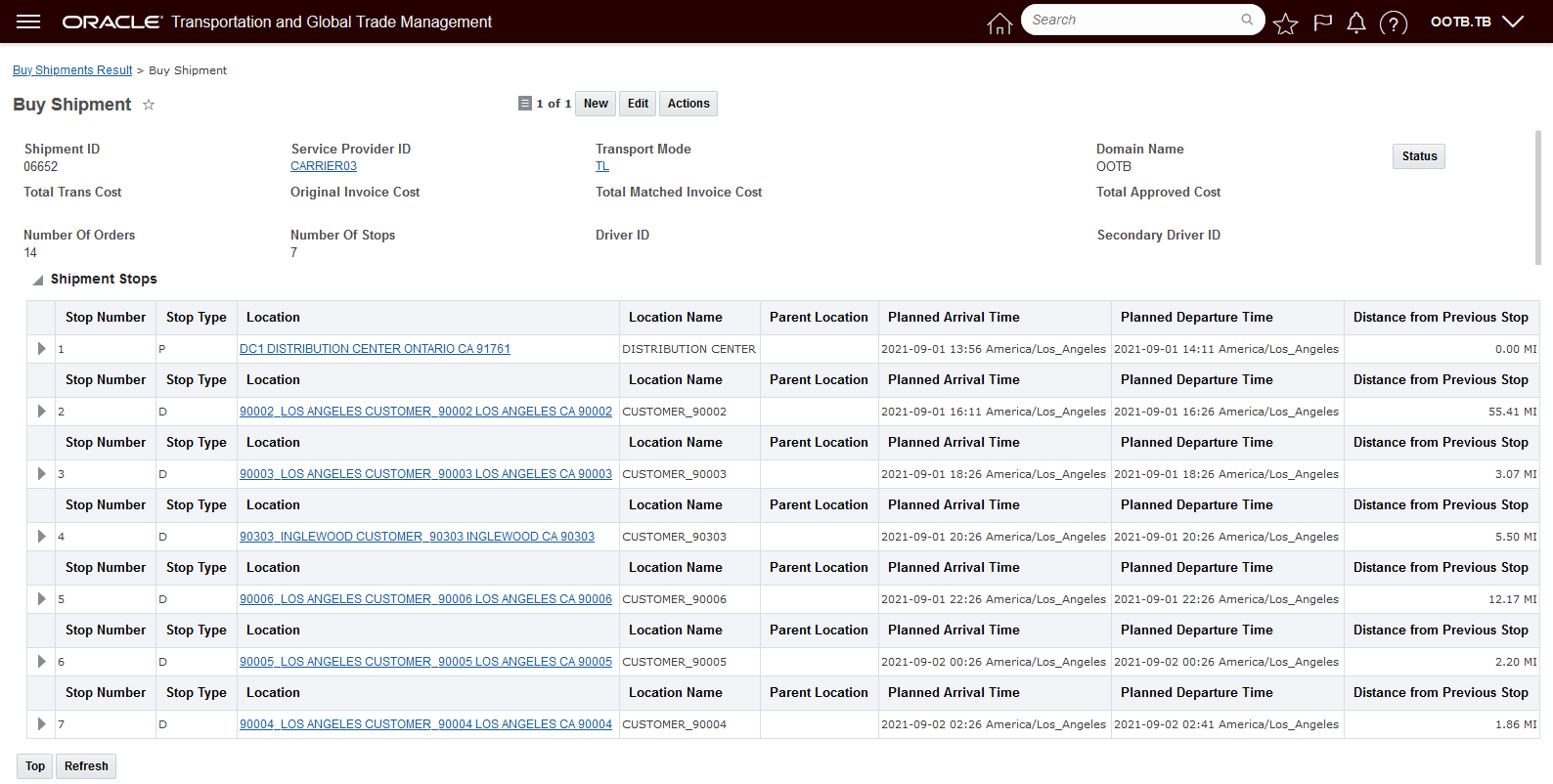

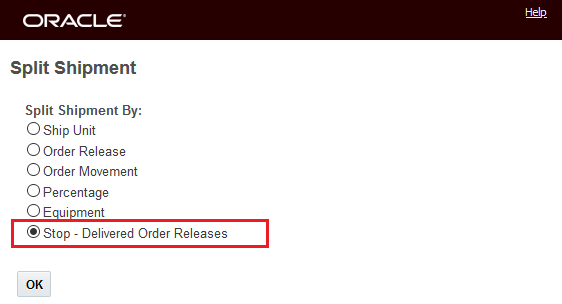

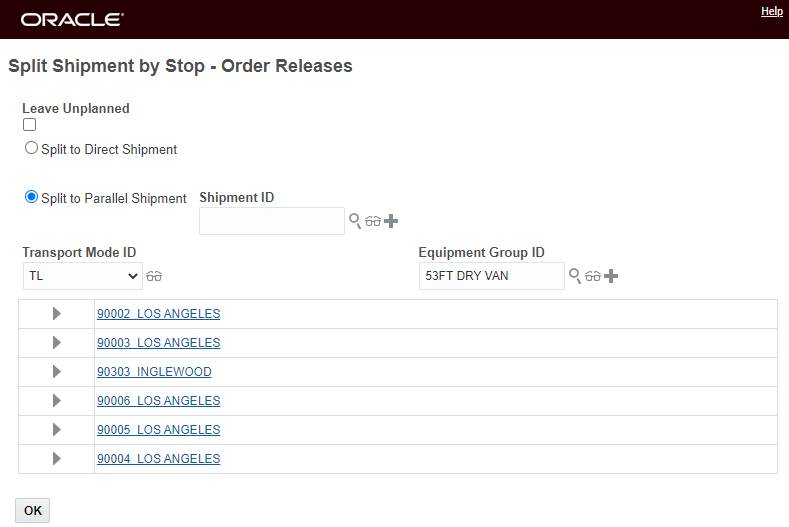

Enhanced Split Shipment Action - Split by Delivery Stop

This feature provides you with an additional Split Shipment action option - Stop - Delivered Order Releases that allows you to easily split your shipment by delivery stop (for all order releases delivered at the stop) or by a selected set of order release(s) delivered at the selected stop.

In the example below - the shipment contains six delivery stops (seven stops in total) and 14 orders. Several of the delivery stops contain multiple orders. The new Split Shipment By action option Stop - Delivered Order Releases when selected will display all the delivery stops on the shipment and then allows you to expand the view by delivery stop to review and select the order(s) to split by.

Example Shipment - Many Delivery Stops with Multiple Order Releases Per Delivery Stop

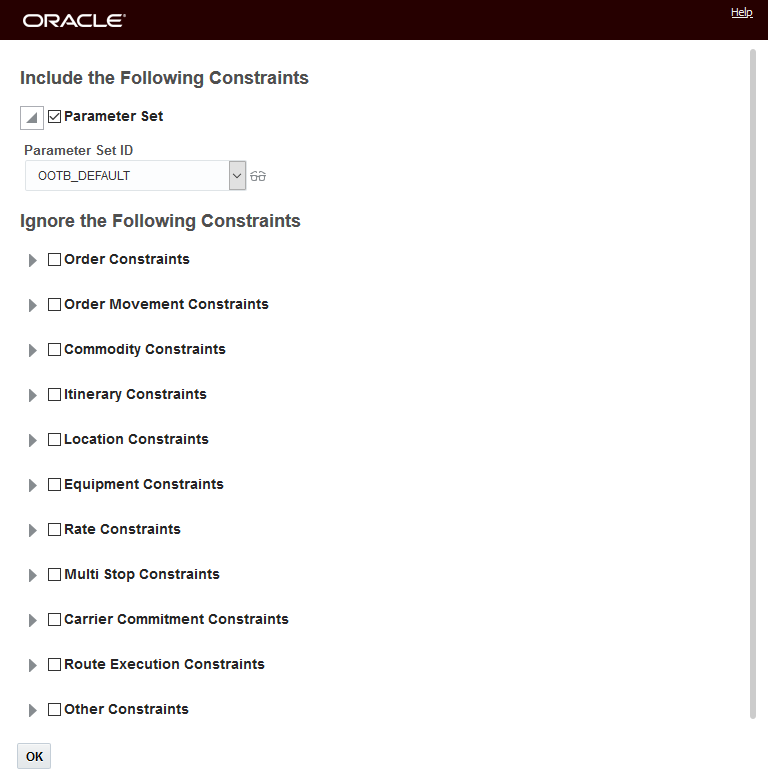

Two split the shipment using the new option, you fist need to select the shipment and run the Split Shipment action.

Split Shipment Action

After running the action, the next screen that is shown is the Ignore the Following Constraints screen.

Ignore the Following Constraints

The new Split Shipment option Split Shipment By: Stop-Delivered Order Releases has been added to the list of Split Shipment action options available previously.

Split Shipment Action Split Shipment By Stop - Delivered Order Releases

The Stop - Delivered Order Releases Split Shipment By selection presents you with the Split Shipment opportunities for the selected shipment by deliver stop and then by order within each delivery stop. Like all the other Split Shipment By options, you have the standard options to Leave Unplanned, Split to Direct Shipment, Split to Parallel Shipment etc.

Deliver Stops Collapsed

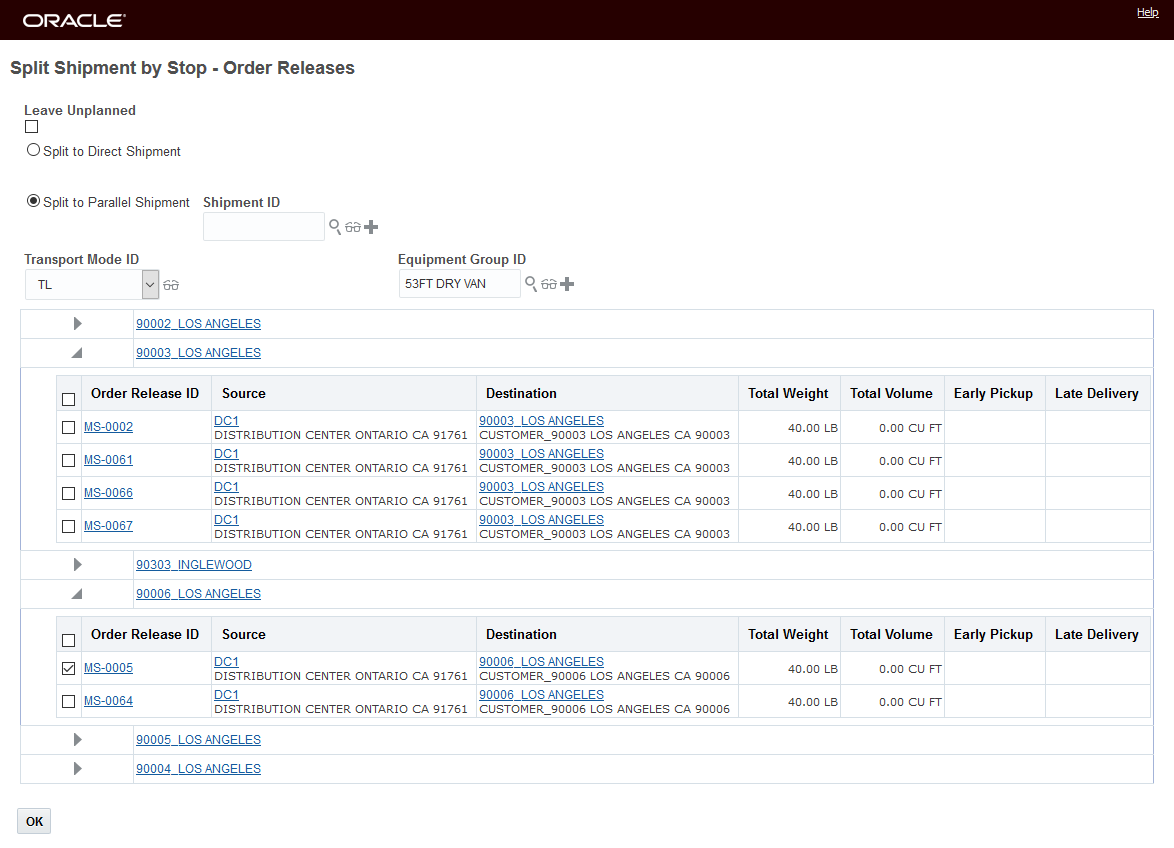

In this example - one order (MS-0005) from the 4th delivery stop will be spit to a parallel shipment.

Split Shipment By action option Stop - Delivered Order Releases display

Given the input provided above, the result (below) is to create a new parallel shipment 06653, with the one selected order MS-0005 that was on delivery stop 4 at the 90006 LOS ANGELES location.

Result

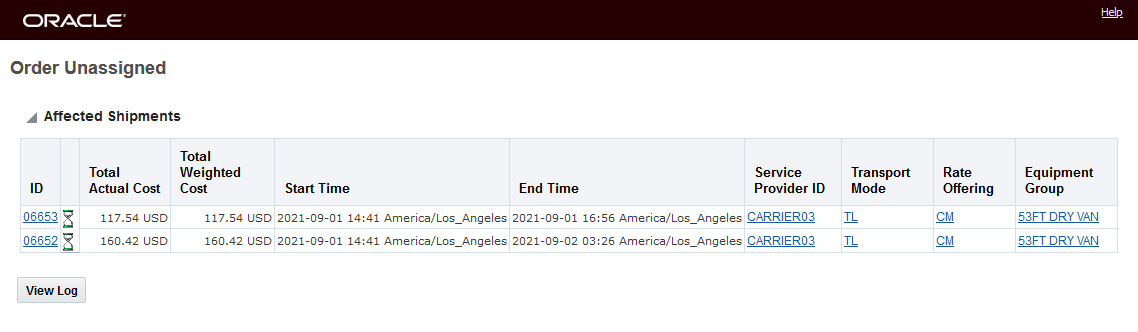

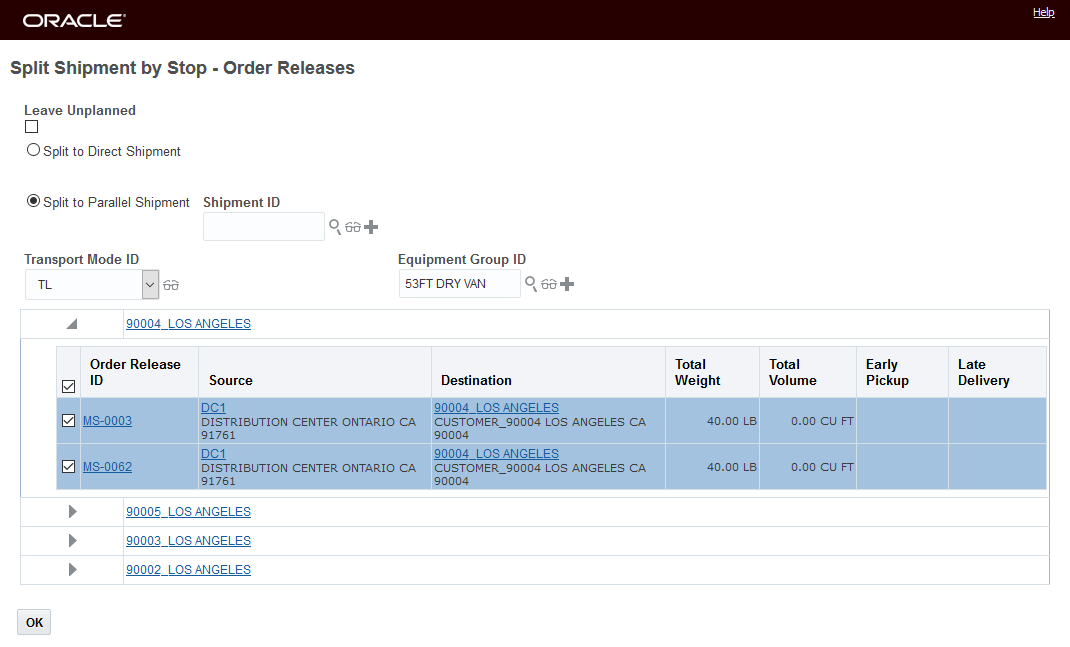

In the example below - all of the order releases for the first delivery stop (location 90004 Los Angeles) on the shipment 06658 will be split off to a new parallel shipment..

Split Delivery Stop Action Delivery Stop Order Release Selection

The first stop on the shipment is expanded and all the order releases are selected - then OK is selected.

All Order Releases for Stop Selected

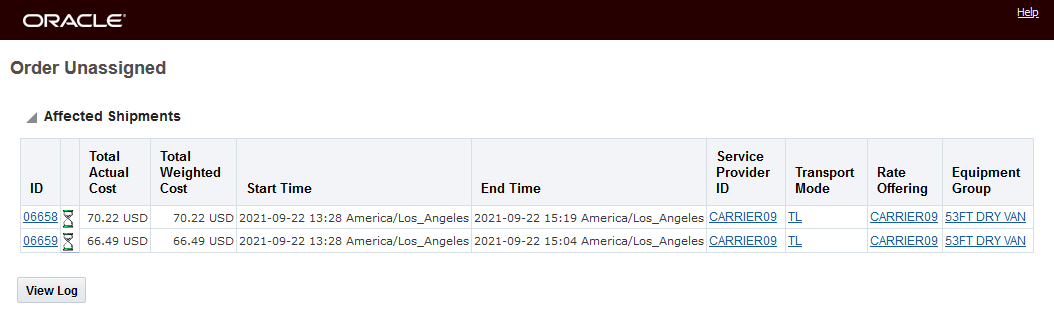

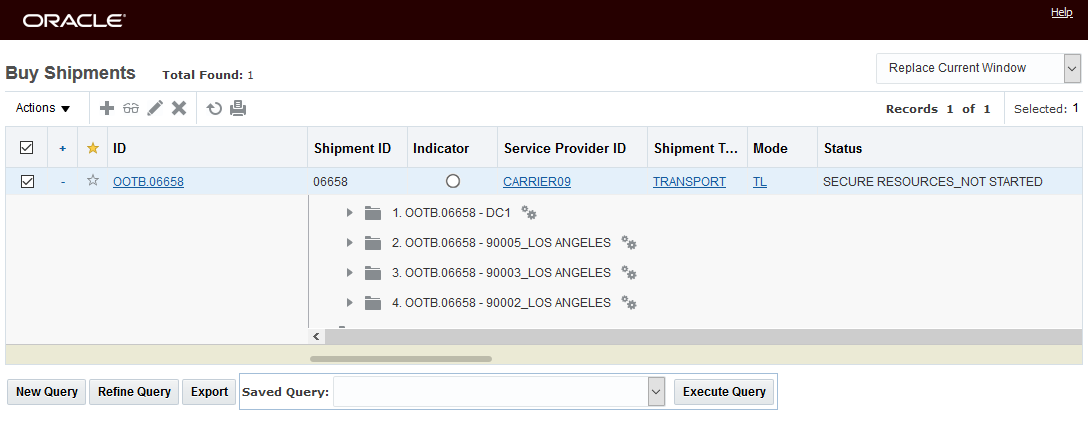

The result is two shipments - the original shipment 06658 - with the delivery stop and order releases split off and the new shipment 06659- created for the split off order releases from the first delivery stop.

Result

Below is the stop level view of the shipments.

Split From Shipment With Four Delivery Stops

New Shipment Created From the Split Off Order Releases from the First Delivery Stop

You will find the shipment split option beneficial in any outbound shipping situation that involves many delivery stops with each stop, potentially, containing many order releases.

Steps to Enable

You don't need to do anything to enable this feature.

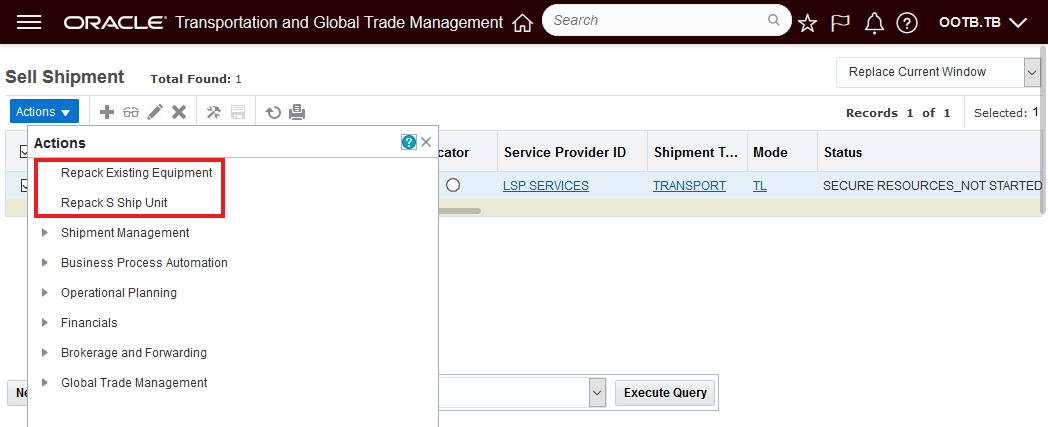

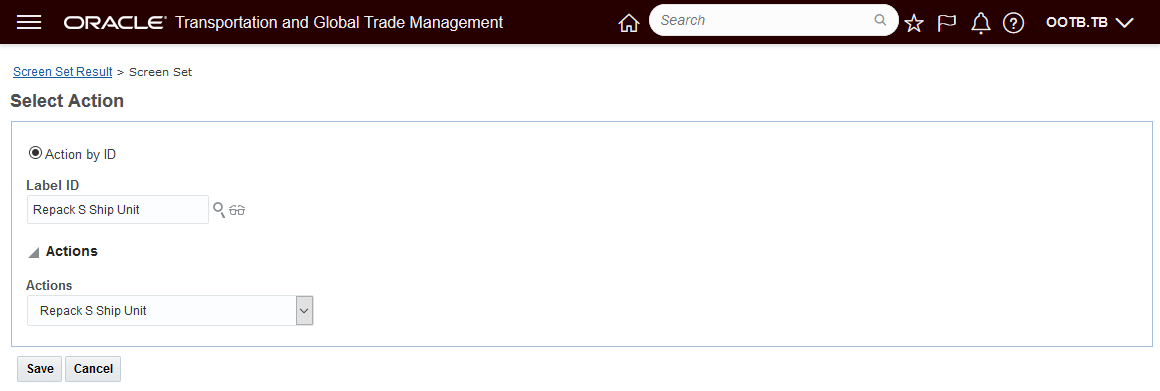

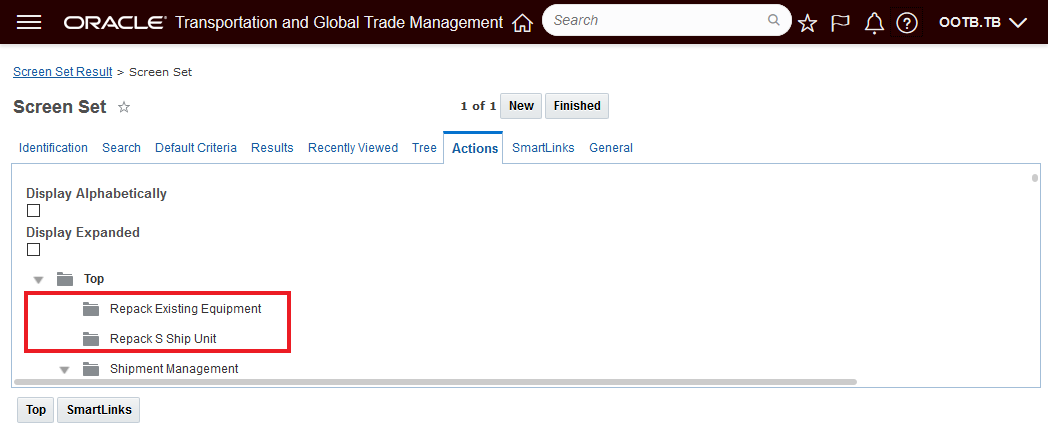

Add Repack Ship Unit and Repack Equipment Action Menu Options to Sell Shipment

This feature provides you with the ability to add the action menu options, Repack Existing Equipment, Repack S Ship Unit to your Sell Side Shipment Screen Set.

Repack Existing Equipment and Repack S Ship Unit Actions Added

This feature provides additional equivalence capabilities between the Buy and Sell side shipments allowing you to perform more operational changes to your Sell Side shipments.

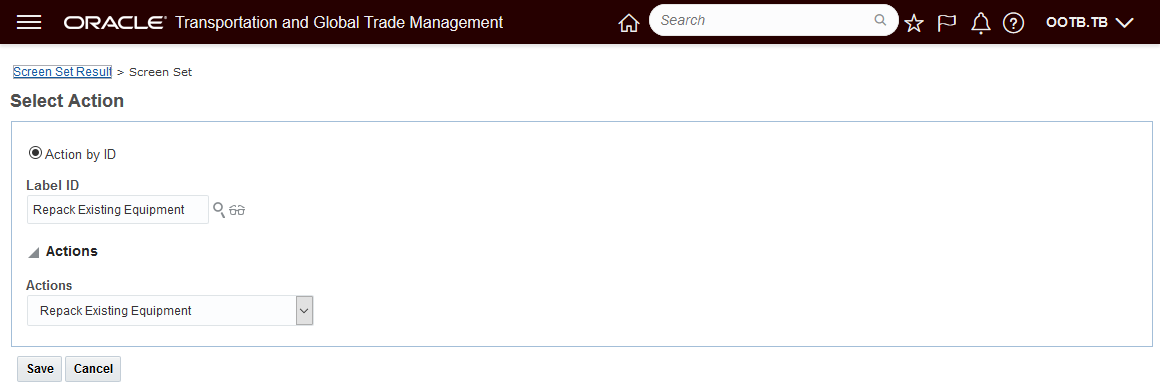

Steps to Enable

The additional actions are not provided as default actions for the Sell Side Shipment Screen Set - you will need to add the additional actions to a new and/or existing Sell Side Shipment screen set.

To add the new action menu options to your Sell Side Shipment Screen Set go to Configuration and Administration > User Configuration > Screen Set Manager. Then go to the Actions tab.

Add Repack Exiting Equipment Action

Add Repack S Ship Unit

Position the newly add actions on the Sell Side Shipment Actions Menu.

Action Menu Location

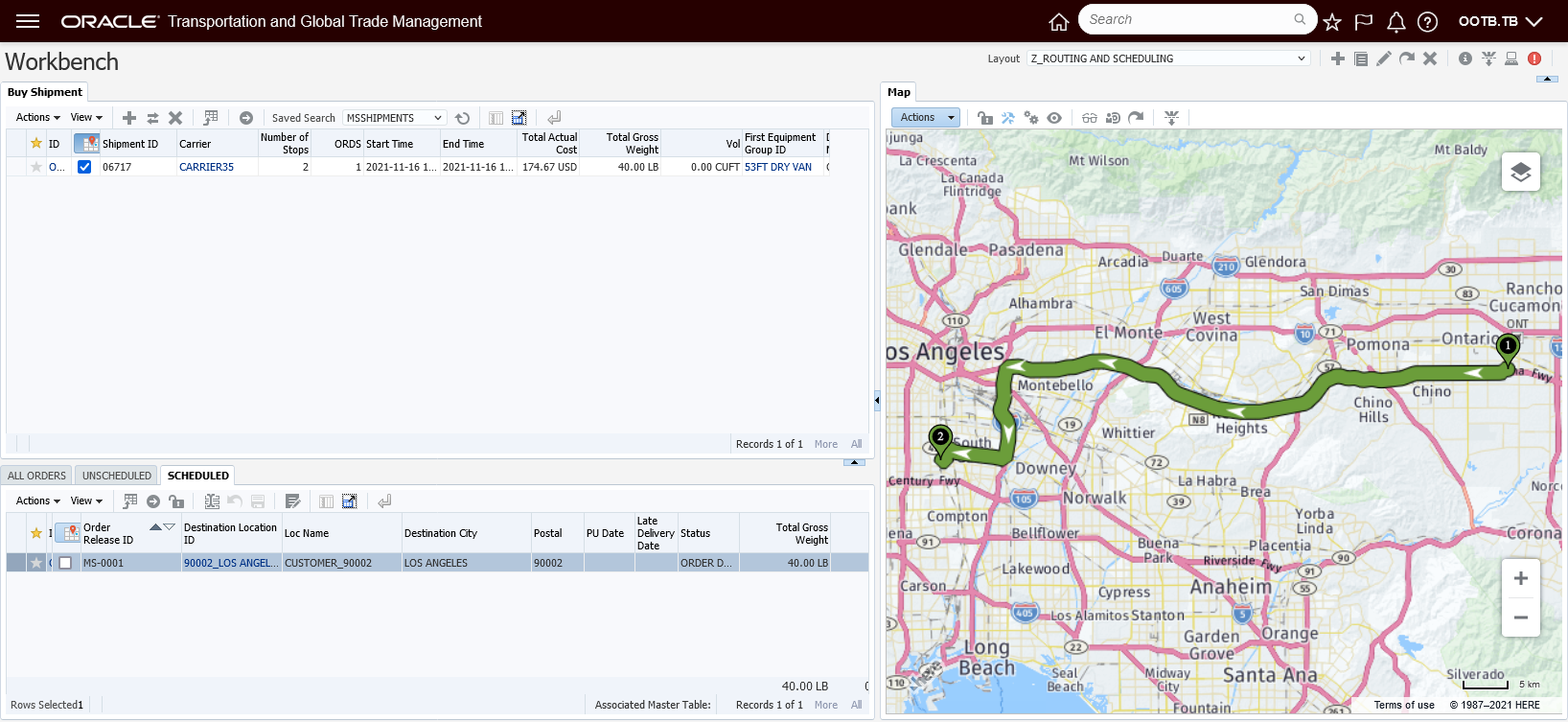

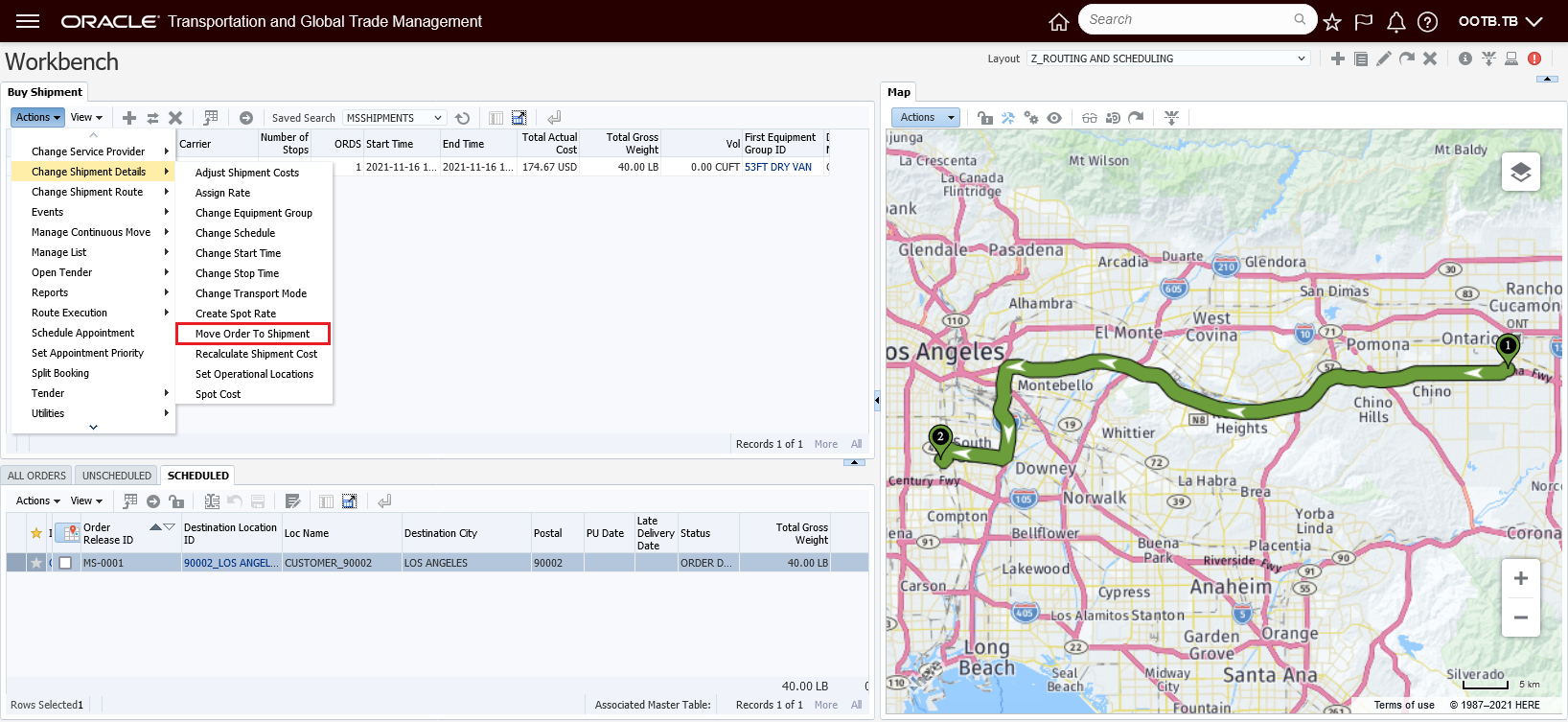

Move Order to Shipment Action Supports Multi Order Select

This feature enhances the Move Order To Shipment action to allow you to select and move multiple orders to the shipment in a single run of the action. You will find this feature useful in any situation where you have the need to quickly select and move multiple orders to a shipment.

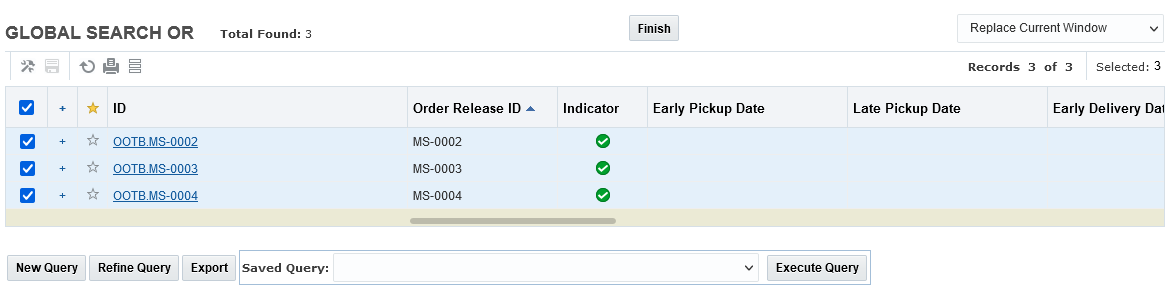

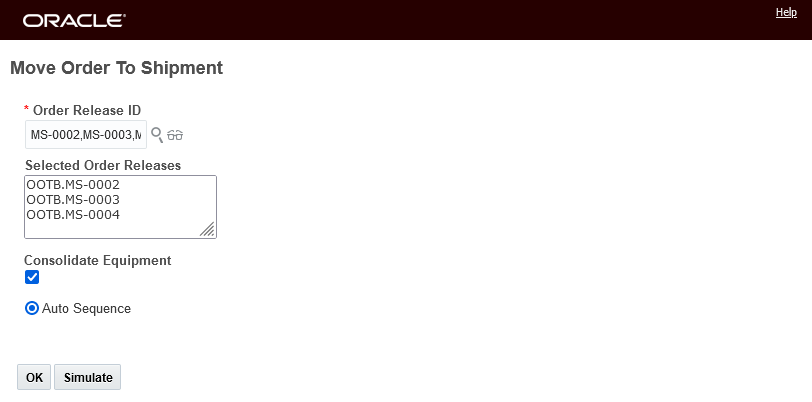

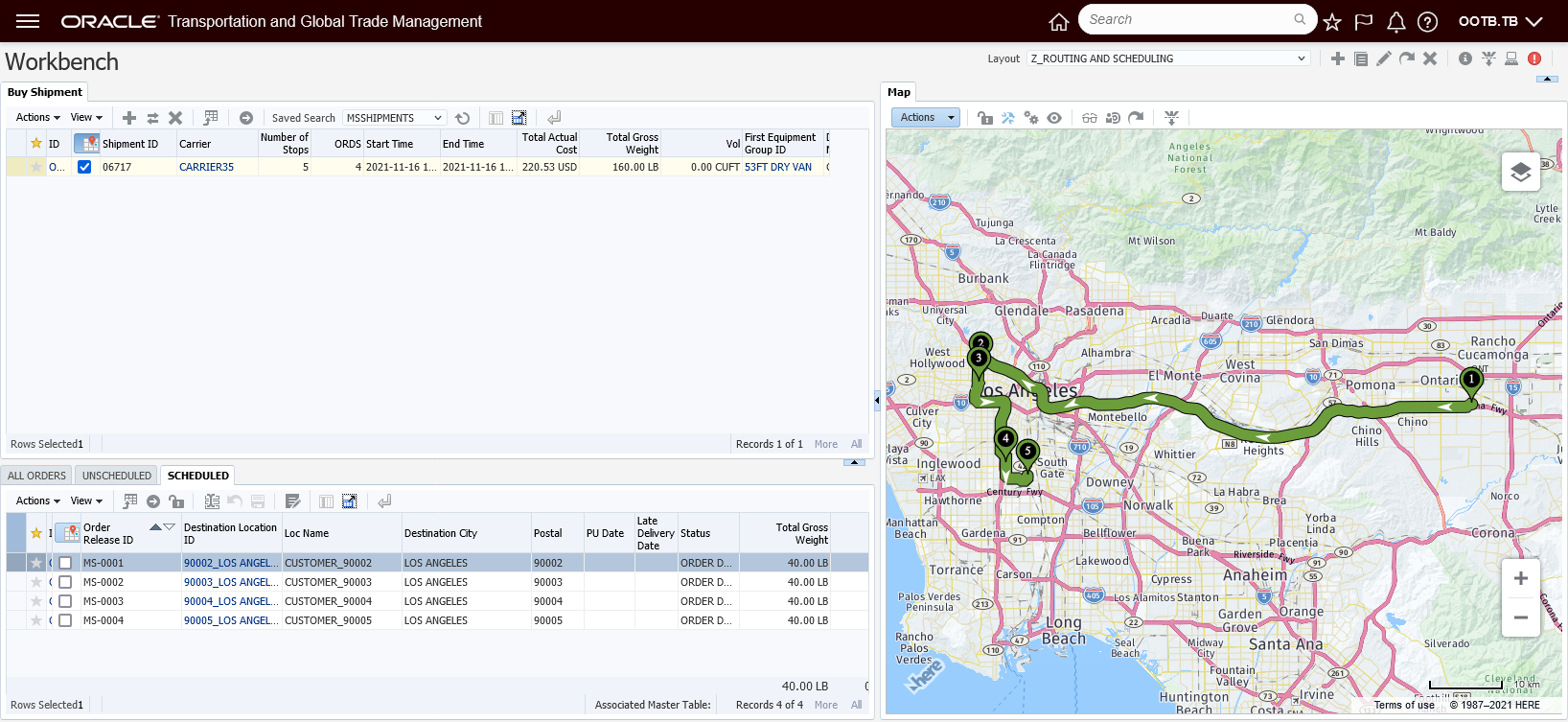

In the example below, the shipment 6717 has just 1 order on it. With this feature - adding 3 more orders to this shipment can be accomplished by running the Move Order To Shipment action once.

Original Shipment

Move Order to Shipment Action

Input screen = select 3 orders to add to shipment.

Move Order to Shipment Input Screen

Move Order to Shipment Multi-Select Supported

Selected Orders

Hit Okay and refresh and the result is the three additional orders moved to the shipment.

Result of Action

Simplifies the time required to move orders to an existing shipment by allowing for multiple orders to be moved in one run of the action.

Steps to Enable

You don't need to do anything to enable this feature.

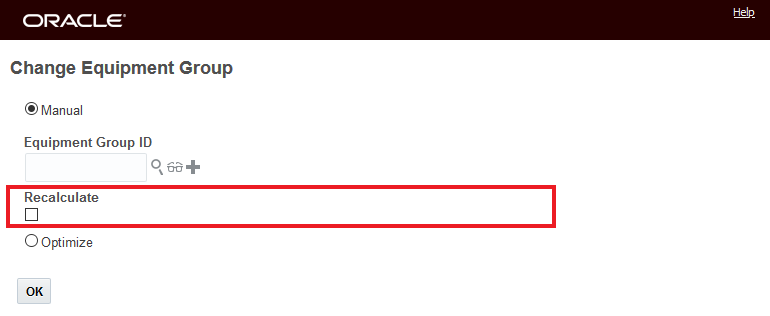

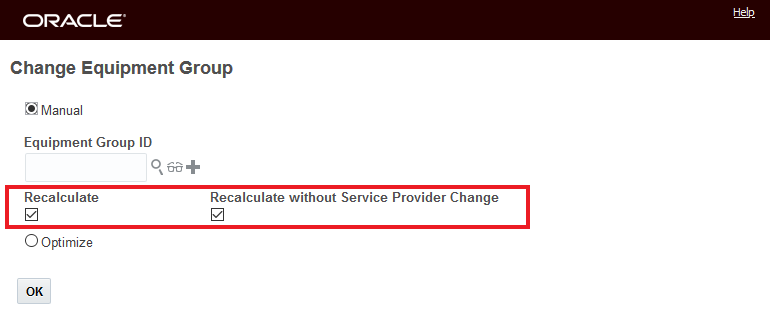

Change Equipment Action Recalculate Input Options

This feature provides you with a new property - glog.webserver.changeEG.ChangeEquipmentGroupRecalcFlag - that allows you to configure the Recalculate and Recalculate without Service Provider Change check boxes on the Change Equipment Group action input screen. The new property supports the default option, where the Recalculate and Recalculate without Service Provider Change are not selected - you also have the option to select just the Recalculate option or you can have both the Recalculate and Recalculate without Service Provider Change selected.

Below is the default Change Equipment Group action input screen. The Recalculate option is, by default, not selected.

Default - Recalculate Check Box Not Selected

Below is the Change Equipment Group action input screen with the property glog.webserver.changeEG.ChangeEquipmentGroupRecalcFlag set to On. With this setting, only the Recalculate option is selected.

Property Set to On

Below is the Change Equipment Group action input screen with the property glog.webserver.changeEG.ChangeEquipmentGroupRecalcFlag set to OnWithoutSPChange. With this value set, both the Recalculate and Recalculate without Service Provider Change are selected.

Property Set to OnWithoutSPChange

In situations where the usage of the Change Equipment Group action should, by default, involve a recalculation, this feature helps enforce that requirement by selecting the desired recalculation option by default.

Steps to Enable

To take advantage of the new behavior, you will need to set the property glog.webserver.changeEG.ChangeEquipmentGroupRecalcFlag to the desired value.

- Navigate to Configuration and Administration > Property Management > Property Sets

- Select the Property set to modify.

- Setting the property glog.webserver.changeEG.ChangeEquipmentGroupRecalcFlag to On will select the Recalculate option.

or

- Setting the property glog.webserver.changeEG.ChangeEquipmentGroupRecalcFlag set to OnWithoutSPChange which will select both the Recalculate and Recalculate without Service Provider Change options

NOTE: Only the DBA.ADMIN user can access and use the Property Sets page.

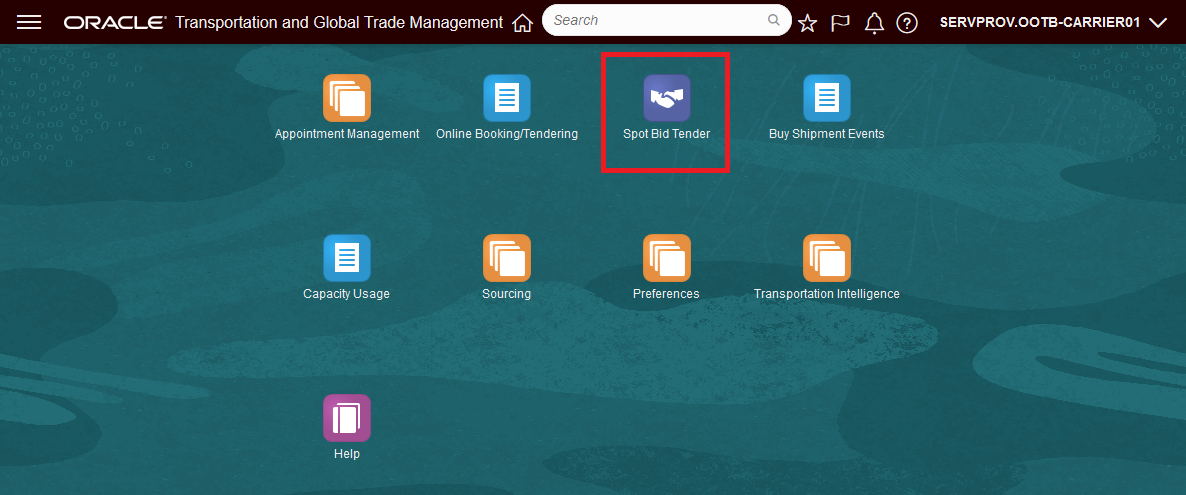

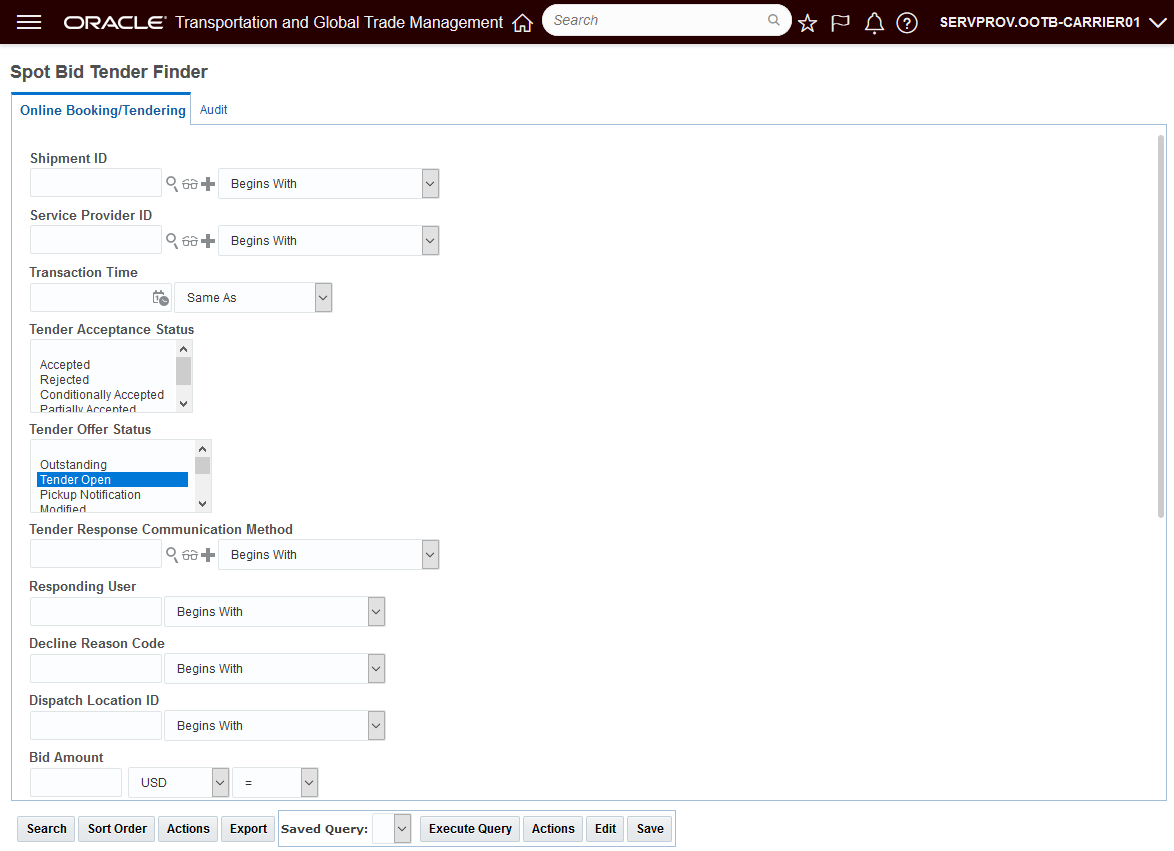

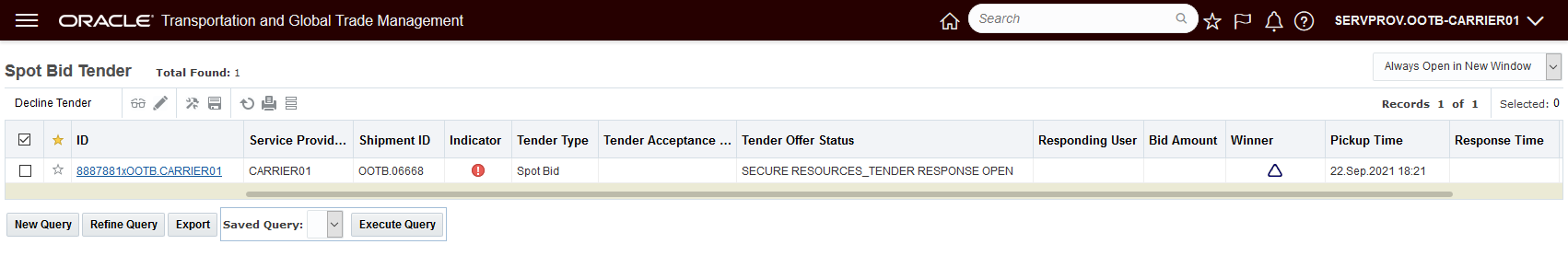

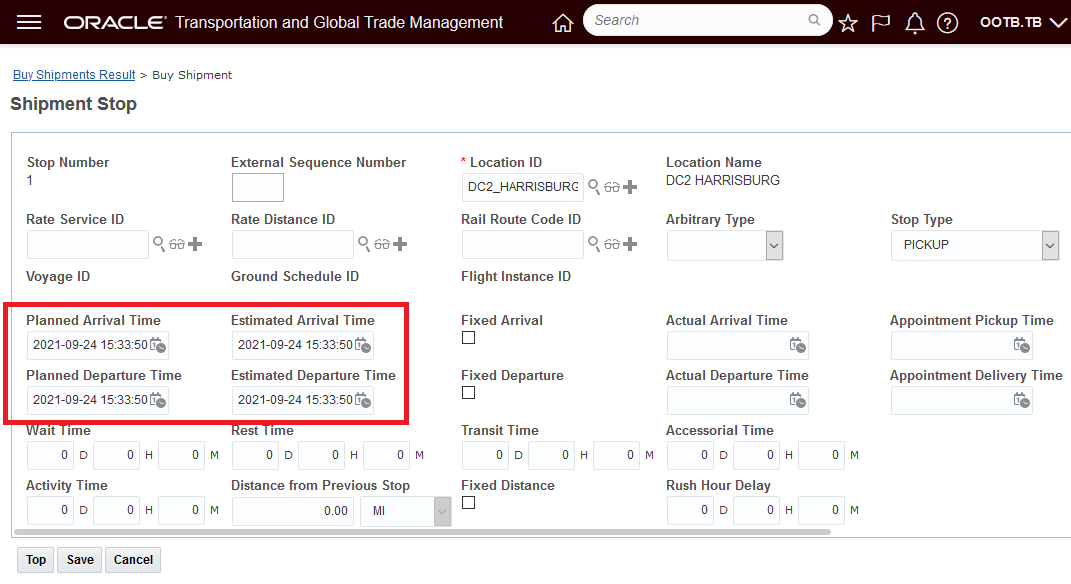

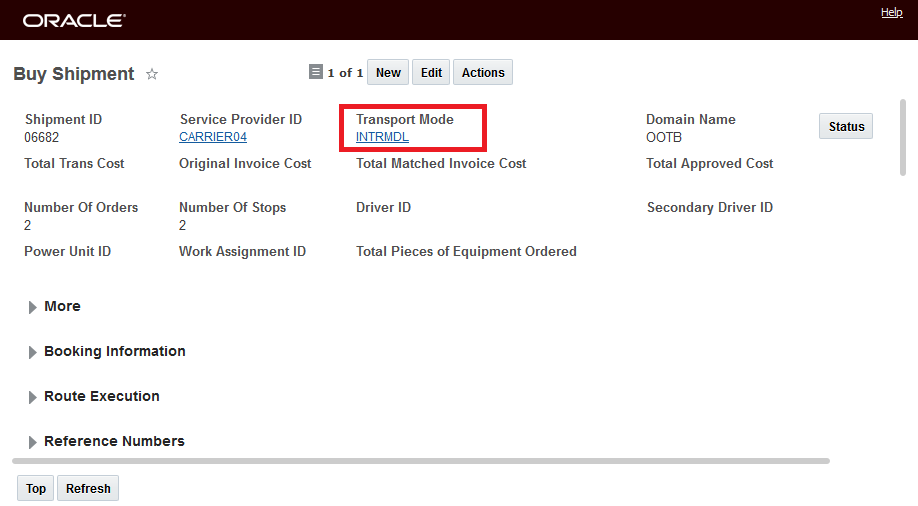

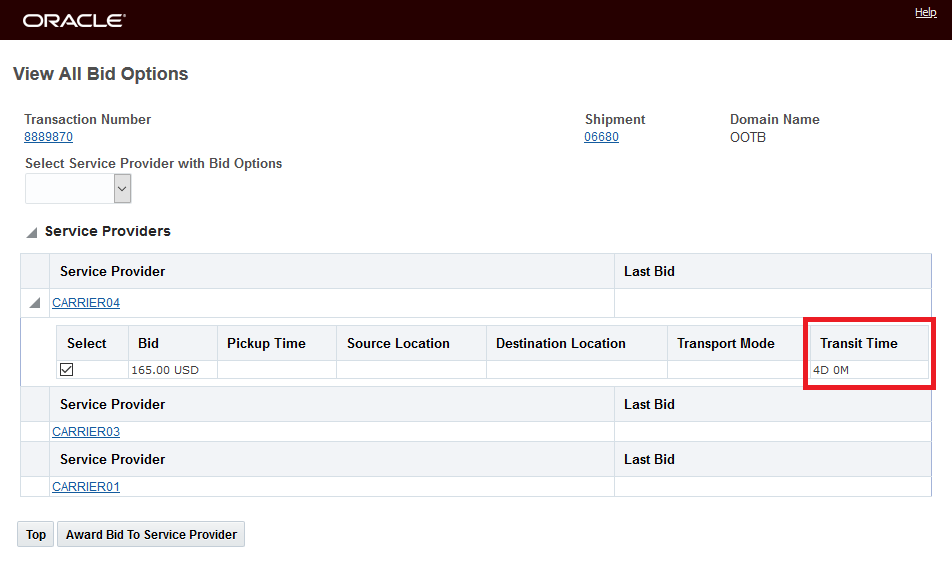

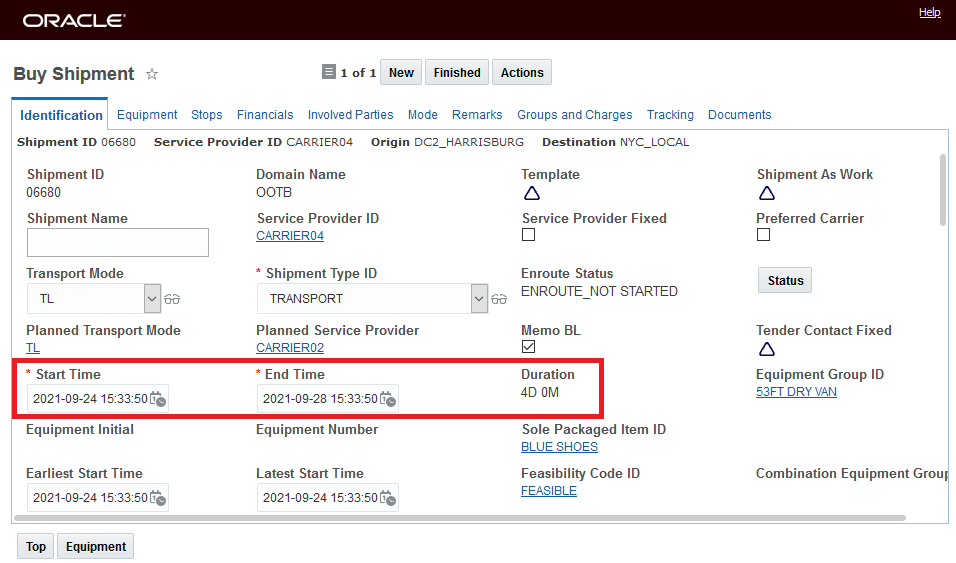

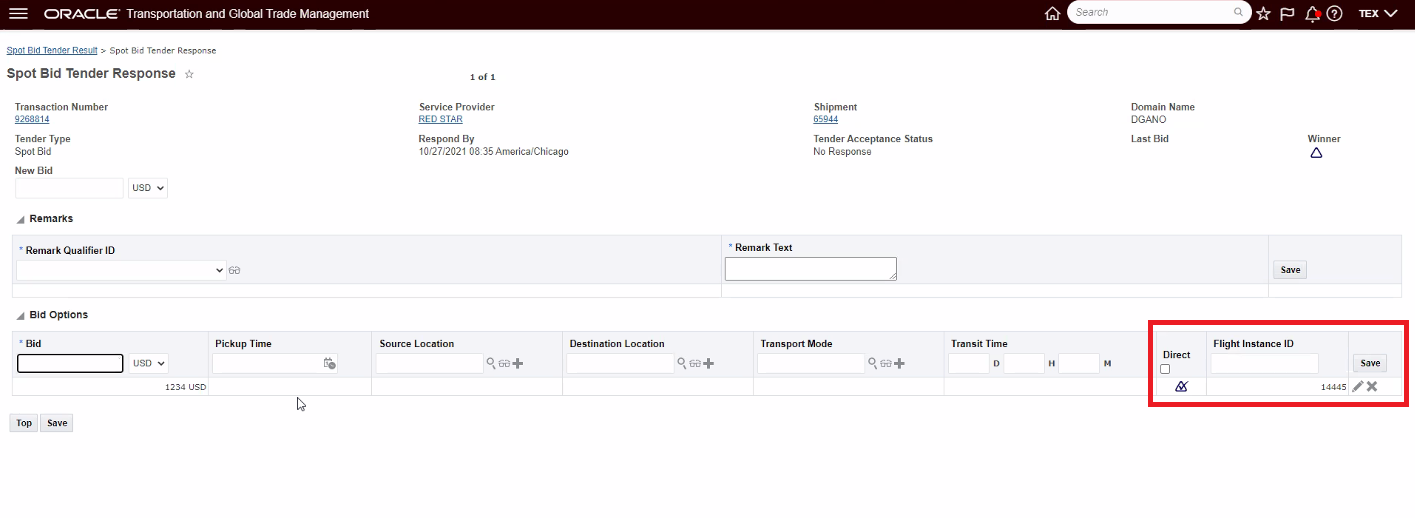

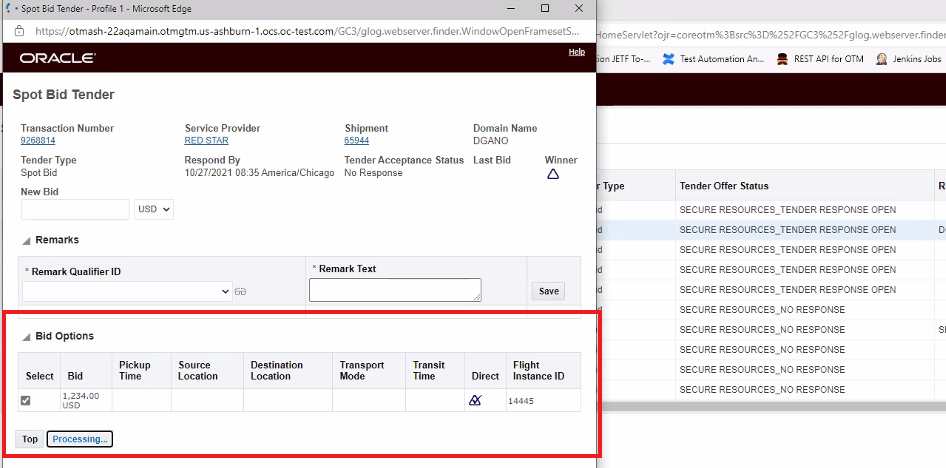

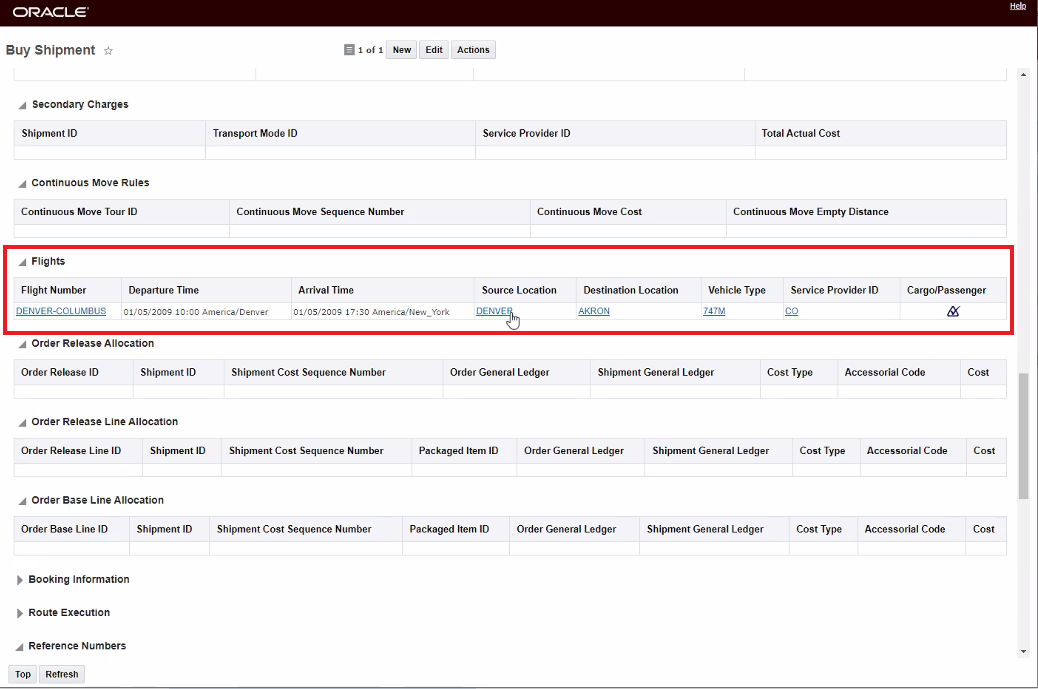

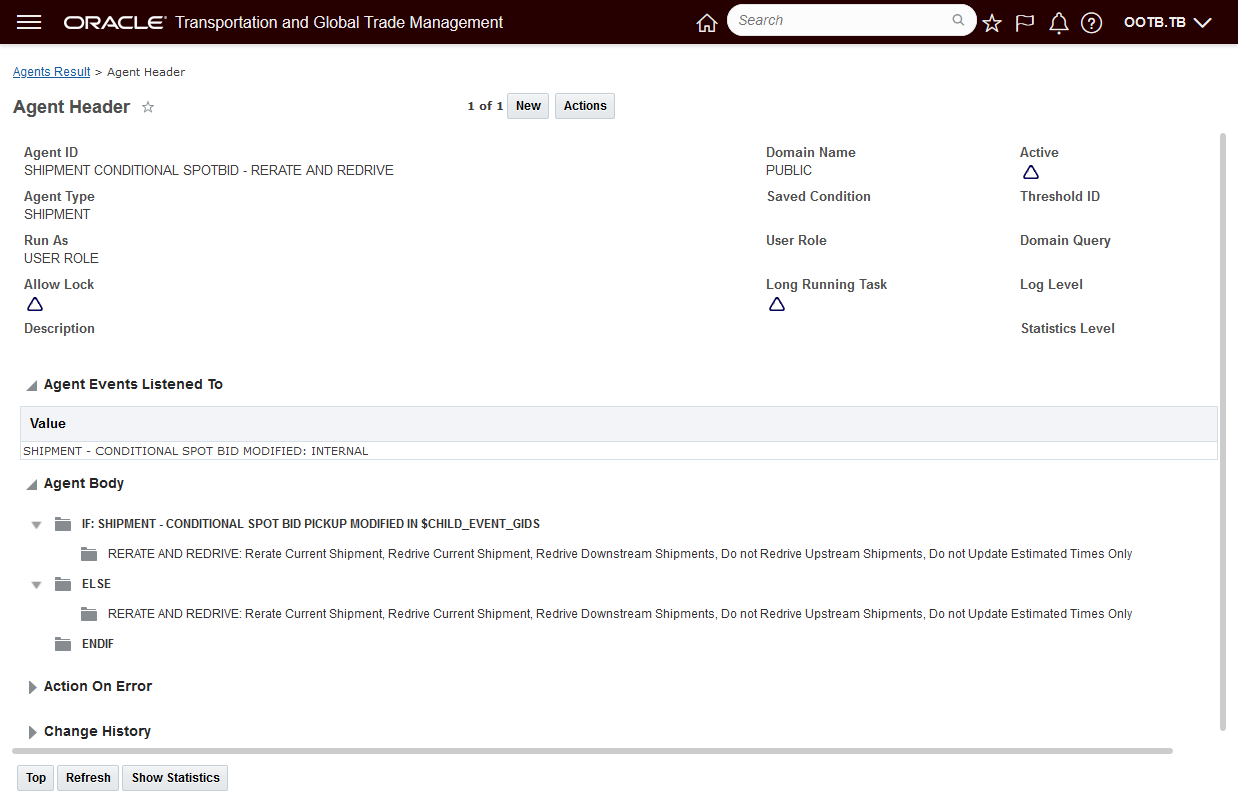

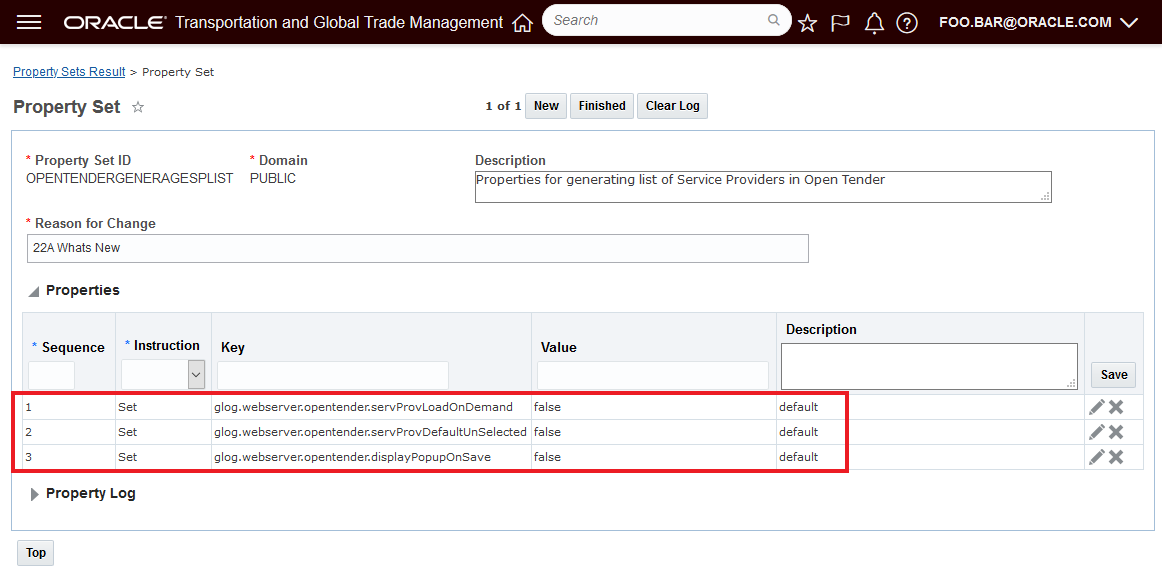

Spot Bid Tender - Optional Bids

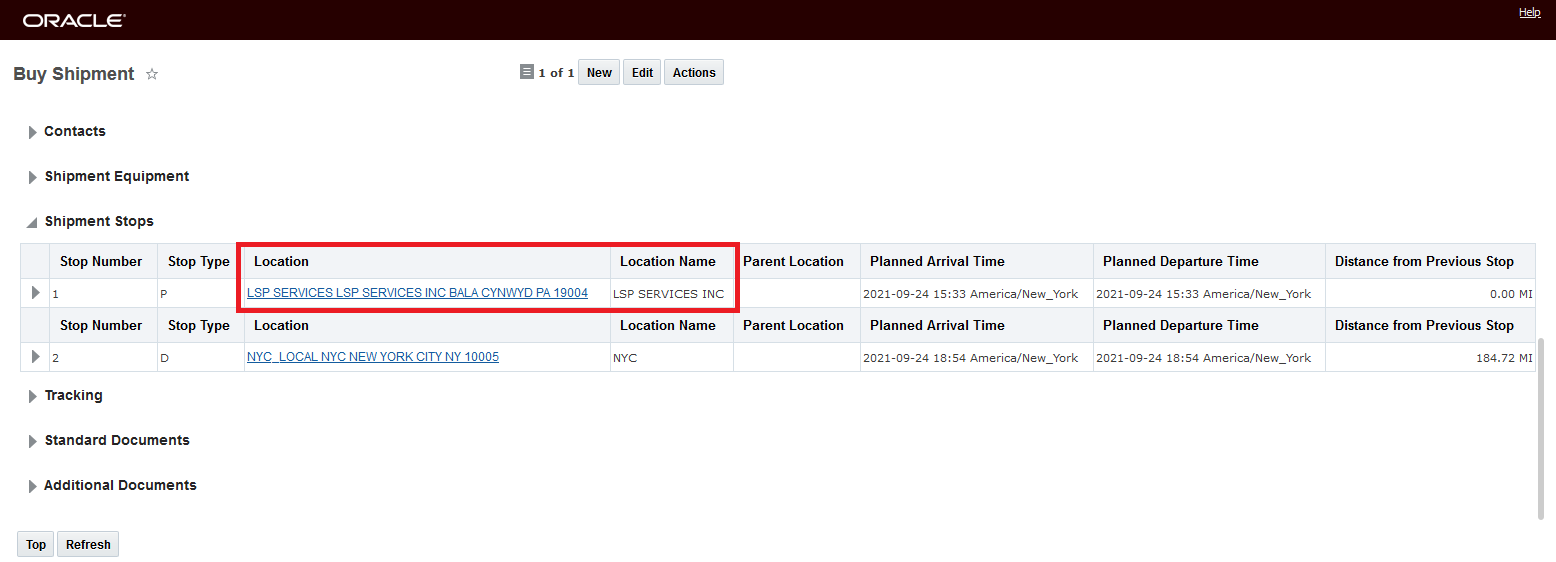

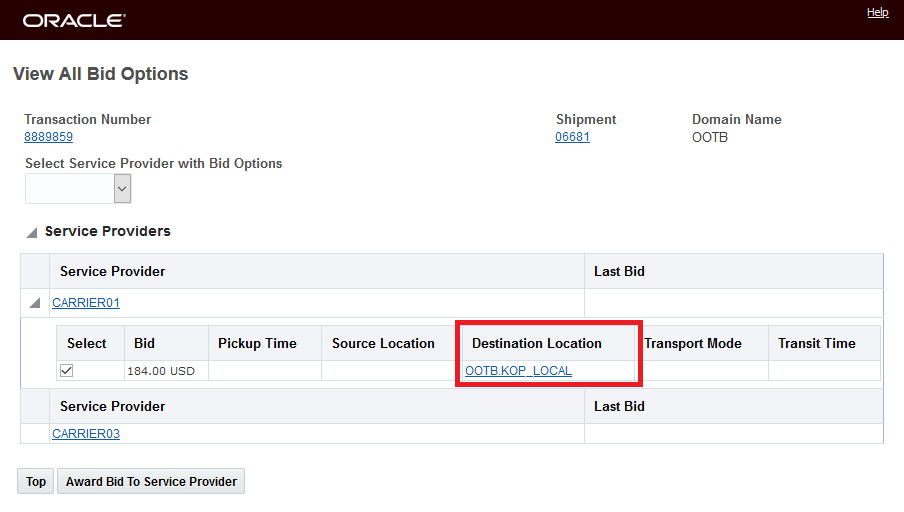

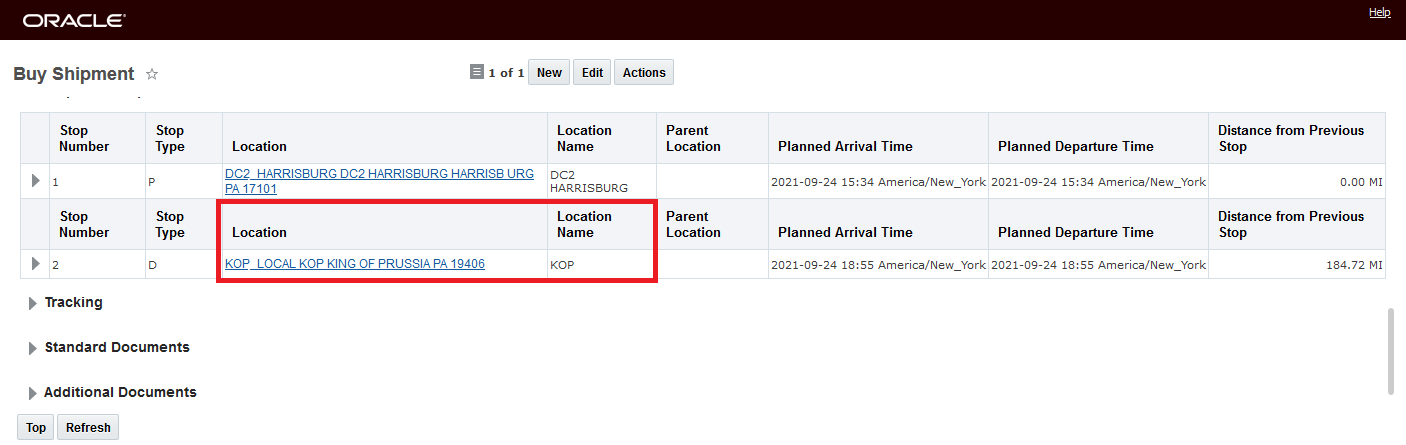

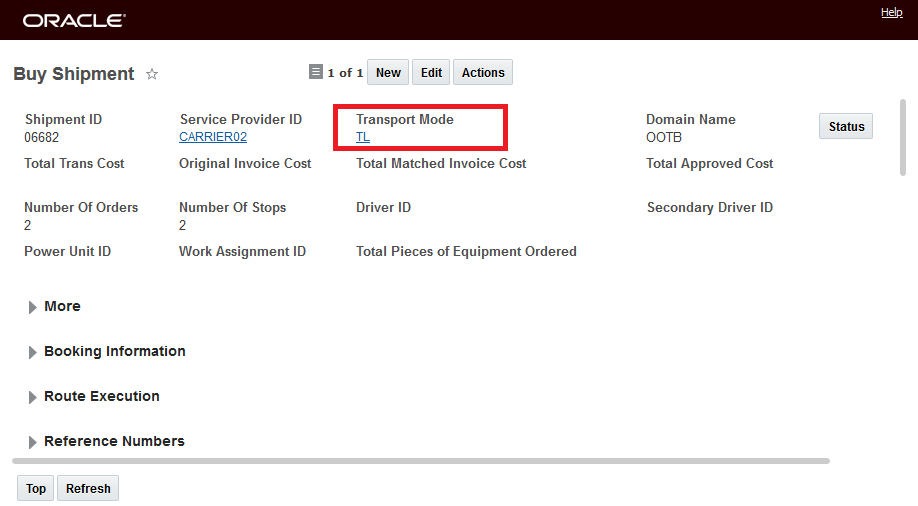

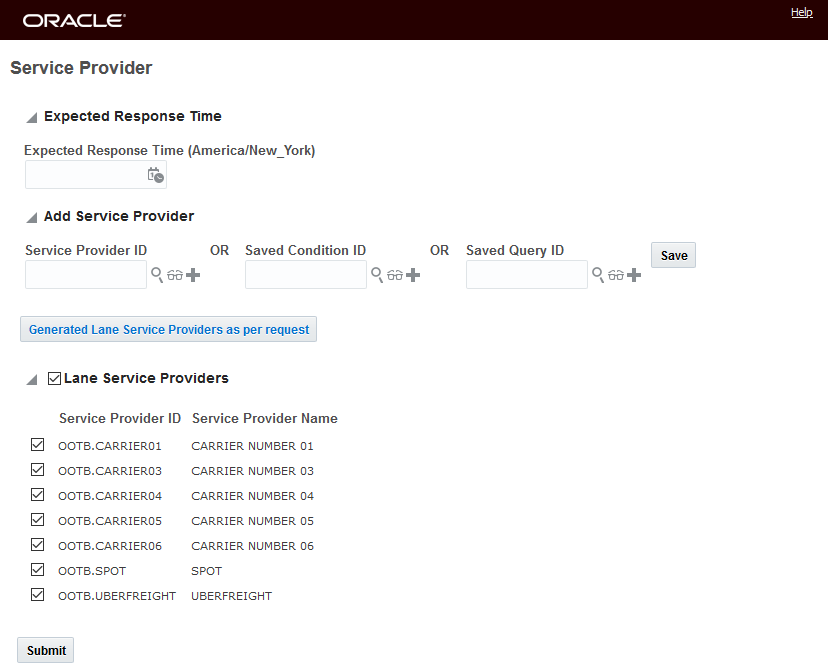

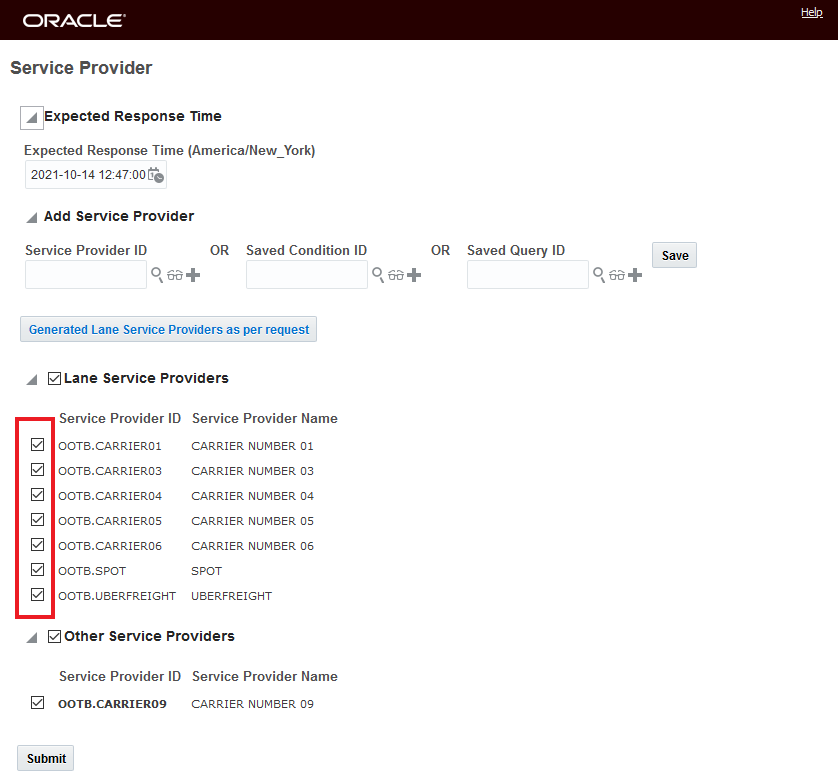

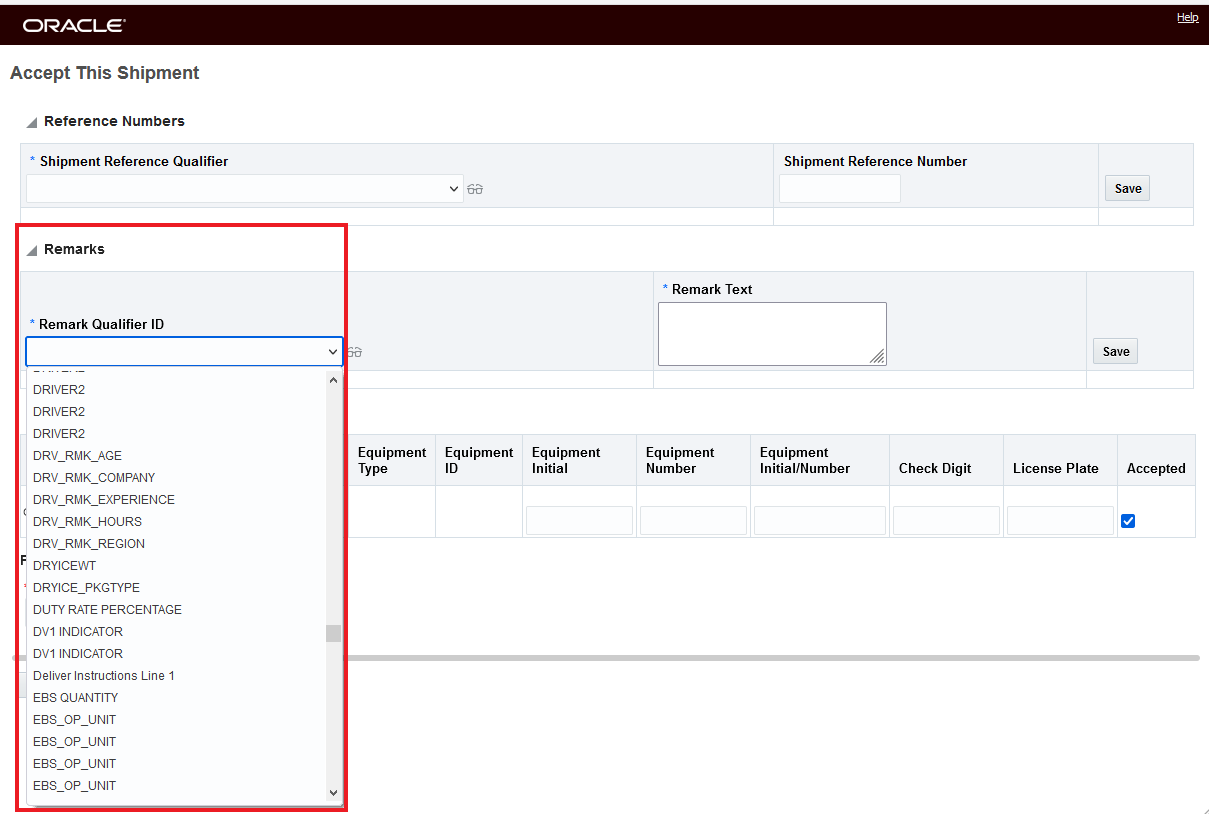

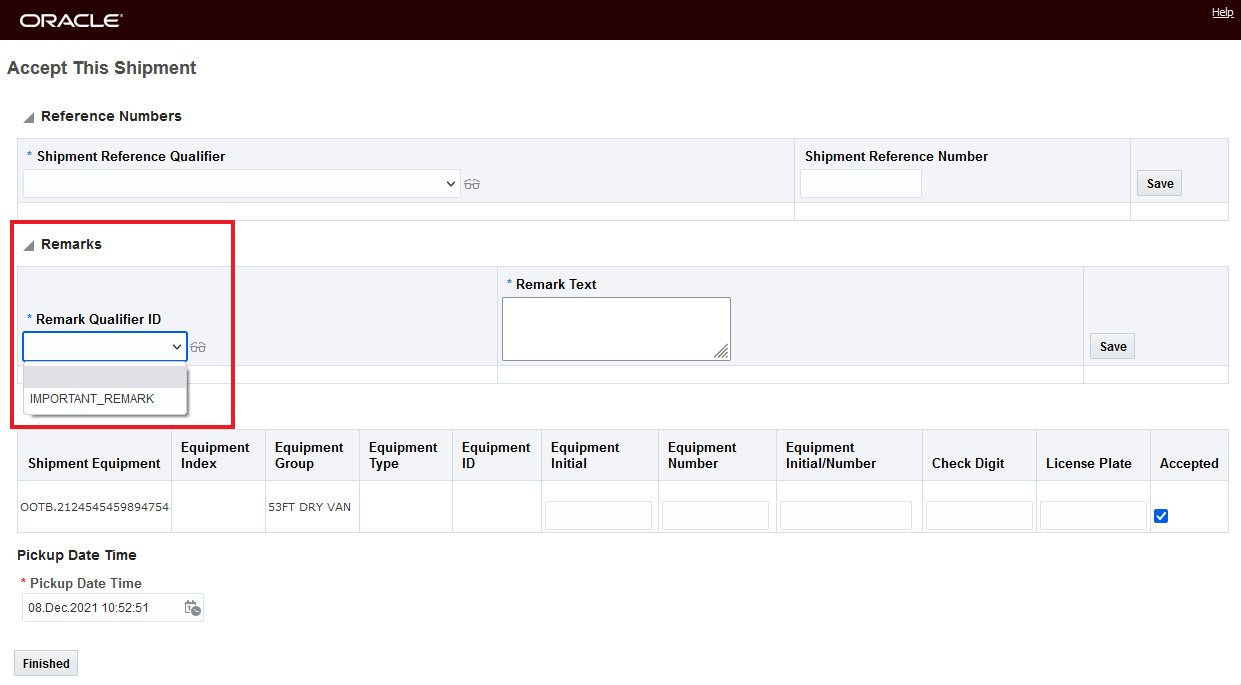

This feature allows you to extend your spot bid process to include receiving optional bids from your Service Providers. Optional bid conditions supported include supporting bids for different Pickup Date(s), Source Location(s), Destination Location(s), Mode(s), and Transit Time(s). In addition, for air freight related spot bids, this feature provides the ability to for the Service Provider to specify the proposed Flight Instance ID and indicate if the flight is a Direct flight. All of the proposed optional bids, with their condition(s), are available for you to review and compare within the Spot Bid Tender screen.

The Optional Spot Bid Tender includes the following additions:

For the planner, the Spot Bid Tender UI now includes a new Has Bid Options column to indicate the Spot Bids that contain one or more Bid Option(s).

Spot Bid Tender - Has Bid Options Indicator Column

For your Service Providers, a new Spot Bid Tender manager has been provided to allow the Service Providers to manage all of their Spot Bid Tender responses. The new Spot Bid Tender manager provides the Service Provider with the ability to include both bids for the base shipment (Service Provider bids without any optional conditions) and optional bids as part of their spot bid tender response.

Service Provider Spring Board - New Manager Spot Bid Tender

To simplify the UI and the workflow for responding to Spot Bids, the new Spot Bid Tender manager has been designed specifically for the Service Provider to manage all of their Spot Bid Tender responses.

Spot Bid Tender - Finder

The finder result for the Spot Bid Tender is below.

Spot Bid Tender - Finder Result

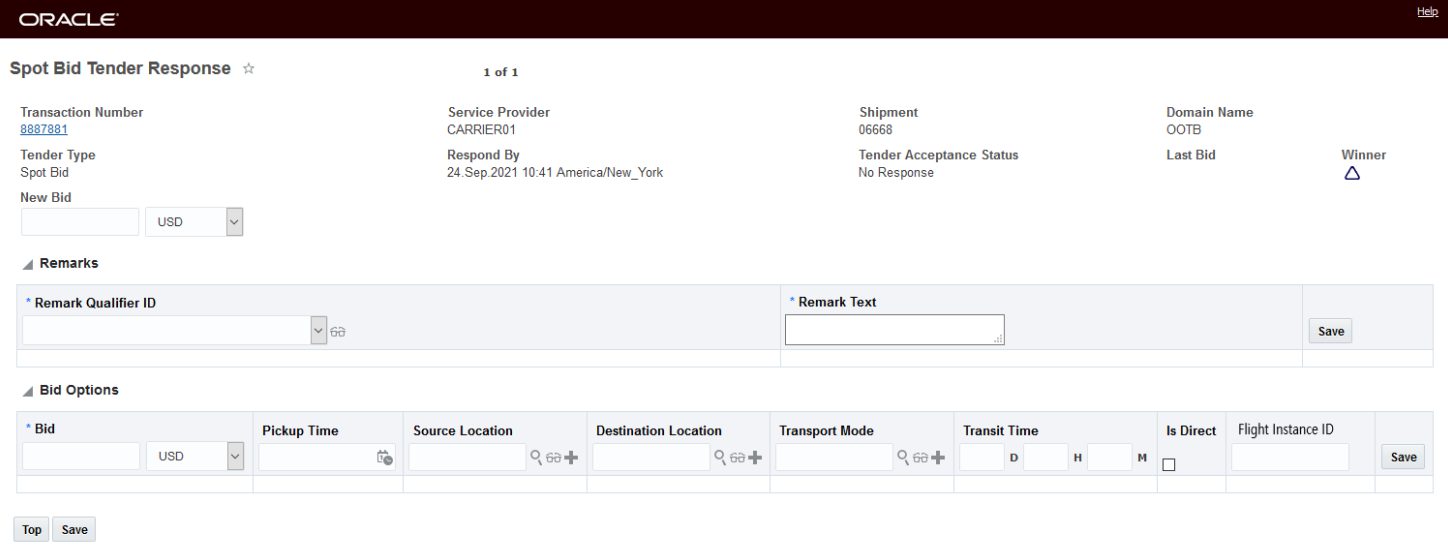

The new Spot Bid Tender Response UI (below), provides a Bids Options grid where your Service Providers can enter their Optional Bids. Note the grid supports the option for entering multiple optional bids - so the optional bids may involve one or more conditions. For example, a service provider could have one Bid Option for a different pickup date and another Bid Option for the same pickup date and a longer transit time.

Spot Bid Tender Response Screen

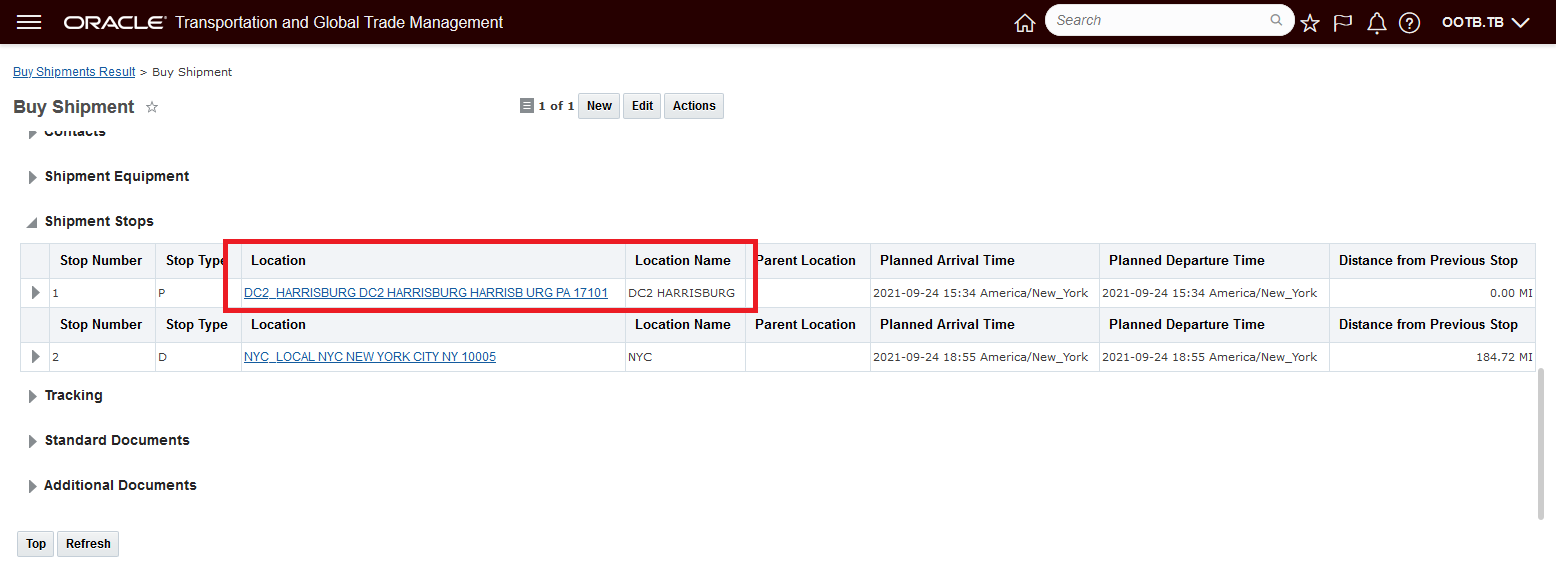

In the scenario below, the shipment 06668 will be sent out for spot bids to five service providers. Three of the Service Providers will provide Bid Options - some with and some without a bid for the base shipment, one service provider will provide just a bid for the base shipment (with no Optional Bids) and one Service provider will provide no bids at all.

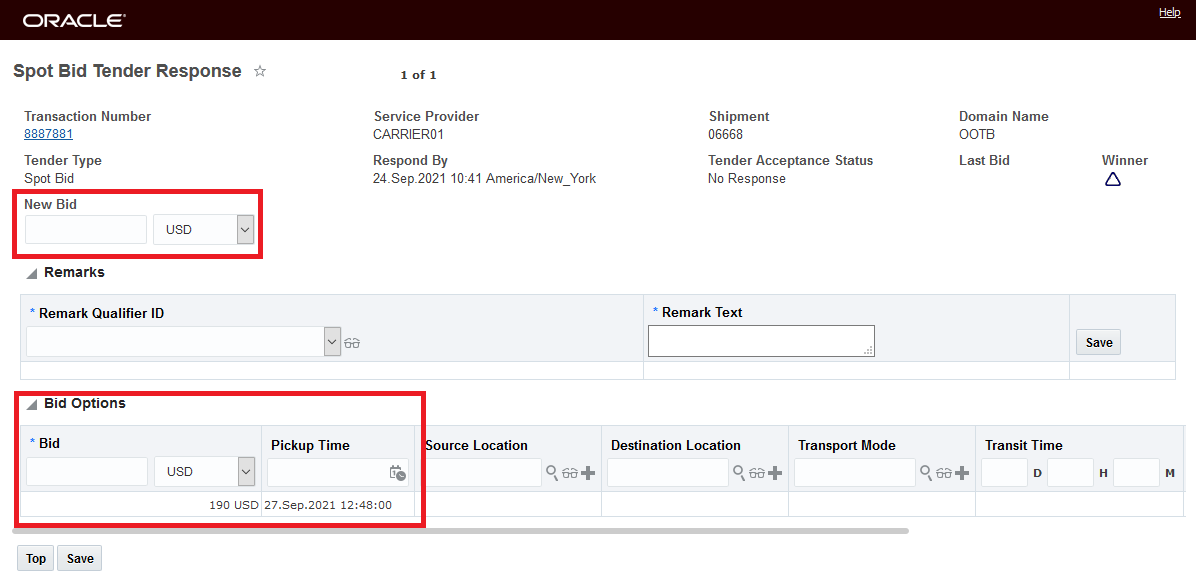

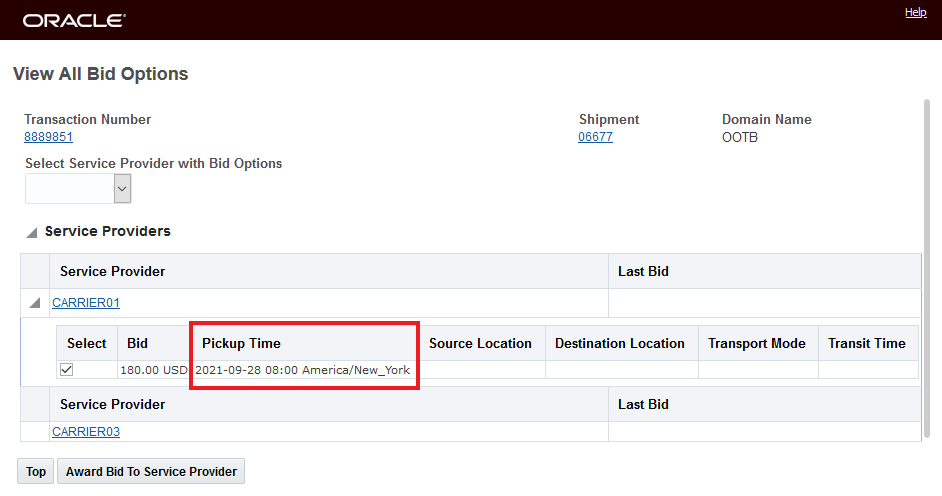

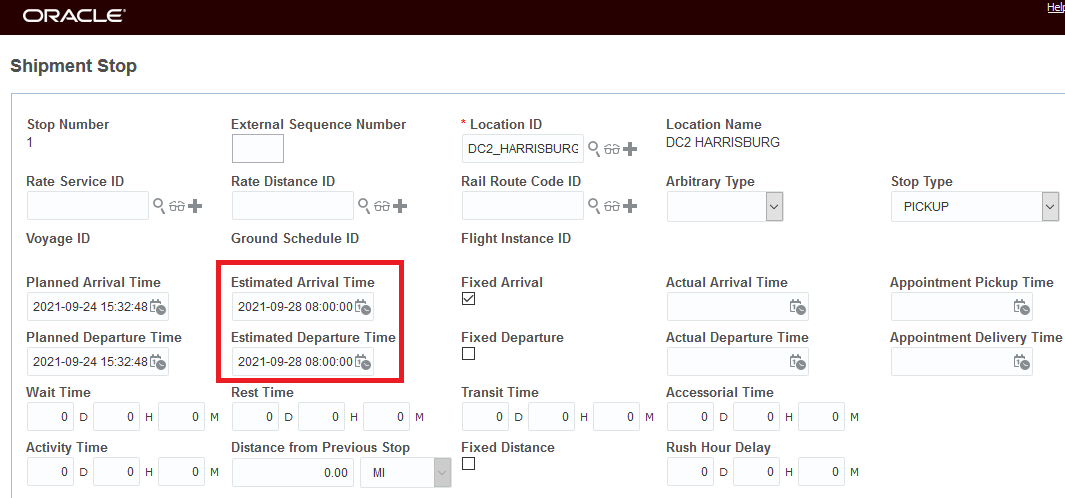

In the Spot Bid Tender Response below, Carrier01 does not provide a bid for the base shipment, but does enter one Optional Bid of 190.00 USD that is dependent on accepting the proposed pickup date on the 27th of September at 12:48.

Carrier01 Optional Bid Only - Different Pickup Date

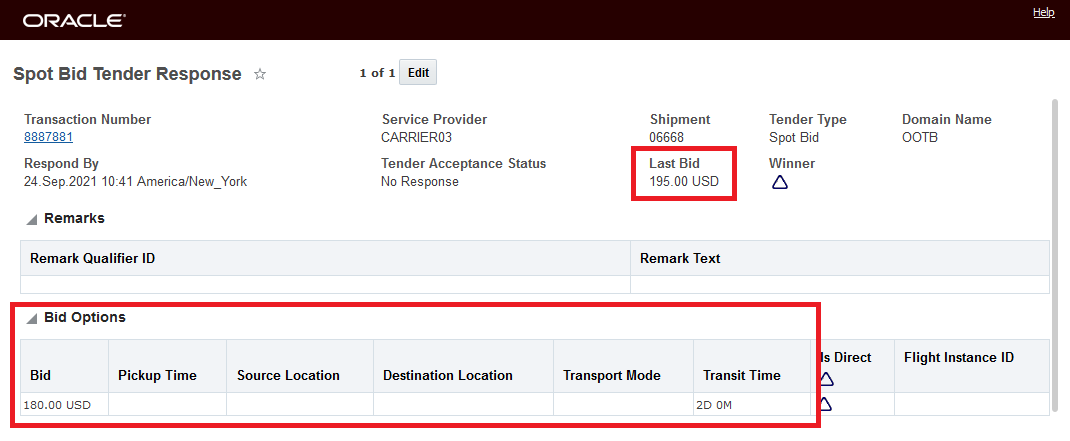

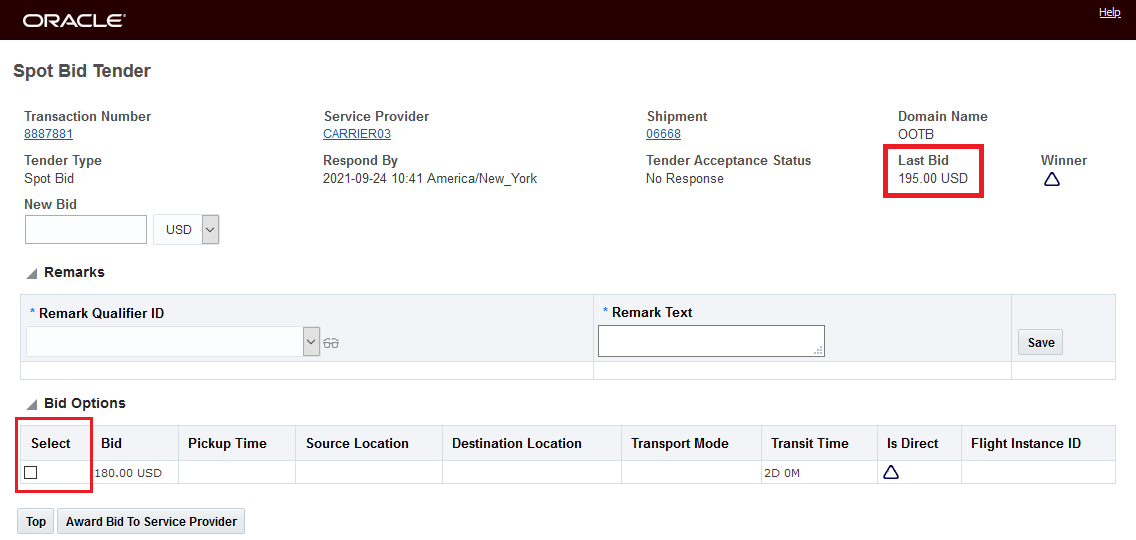

In the Spot Bid Tender Response below, Carrier03 offers both a bid for the base shipment (195.00 USD) as well as an Optional Bid of 180.00 USD that is dependent on accepting the proposed 2 day transit time.

Carrier03 Base Bid and Optional Bid for 2 Day Transit

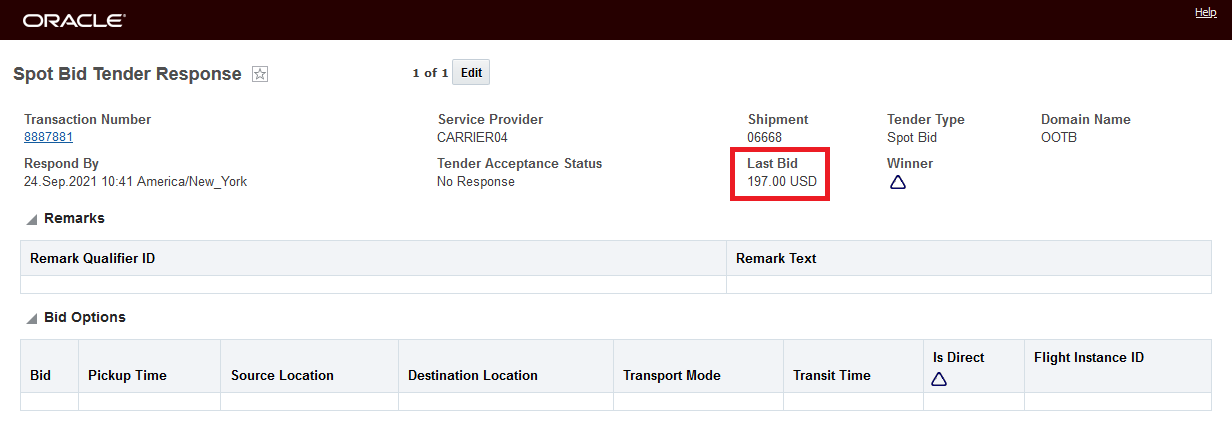

In the Spot Bid Tender Response below, Carrier04 only offers a bid for the base shipment (197.00 USD) and does not offer any Optional Bids.

Carrier04 Base Shipment Bid Only

Carrier05 does not provide a bid.

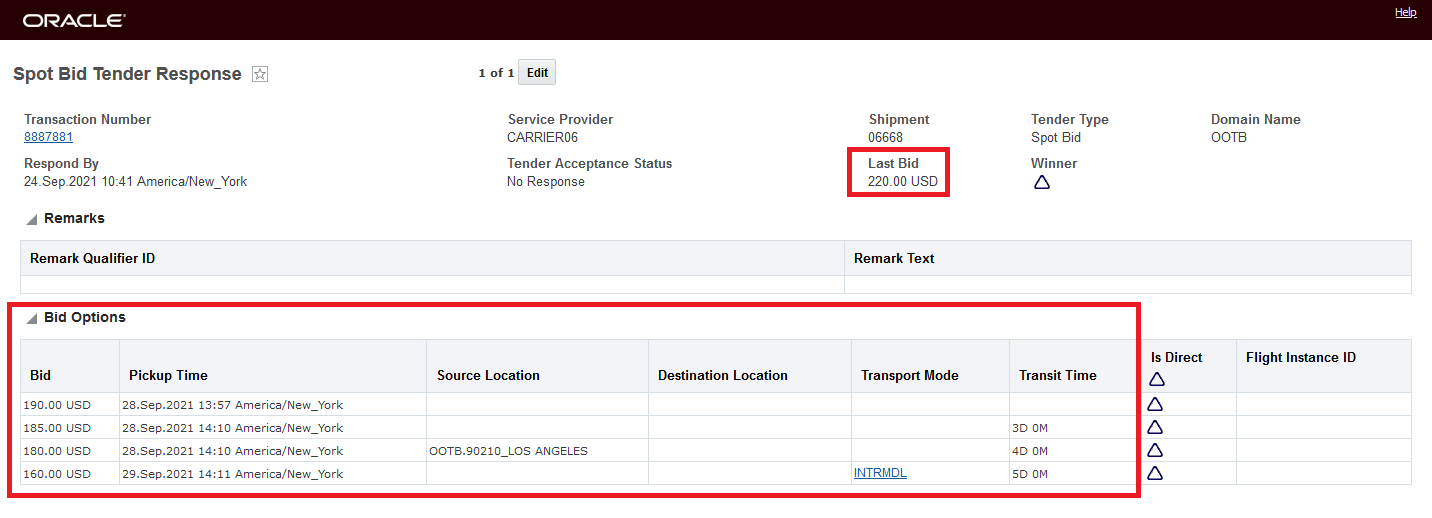

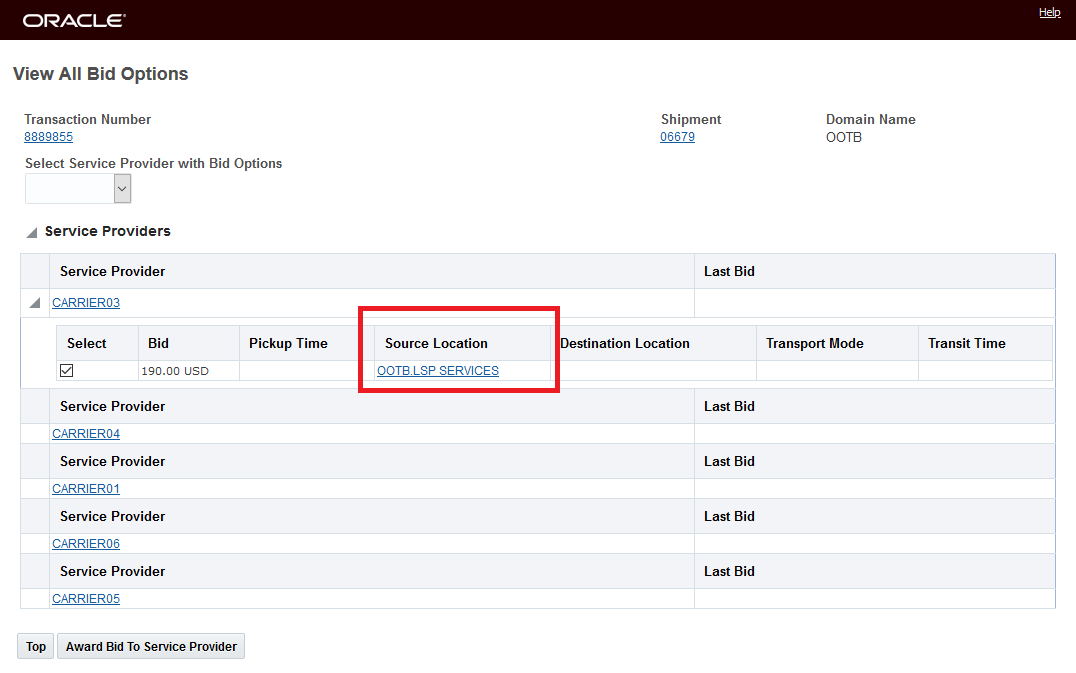

In the Spot Bid Tender Response below, Carrier06 provides a bid for the base shipment and then provides four different Optional Bids, all dependent on different conditions.

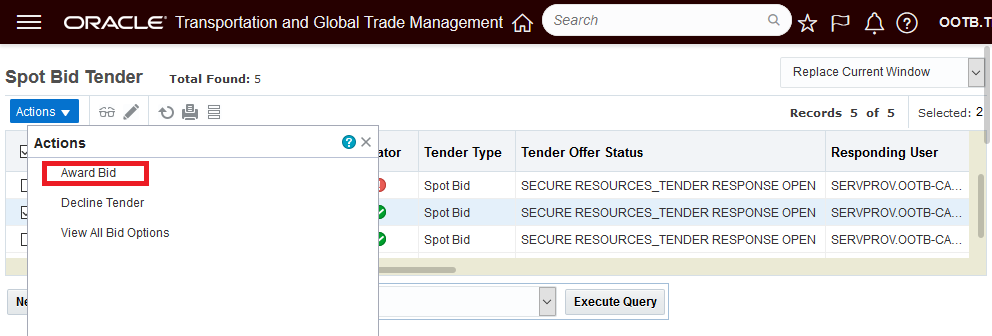

The Planner View to the variety of Spot Bid Responses entered above provides a quick summary into the responses received. The Bid Amount column shows you the service providers who have offered bids for the base shipment, and the Has Bid Options identifies the Service Providers (Carrier01, Carrier03, and Carrier06) who have provided Optional Bids.

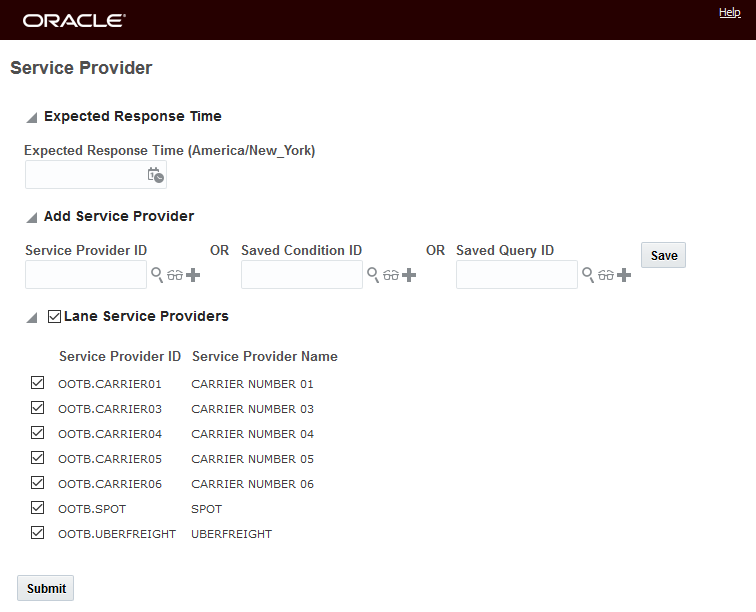

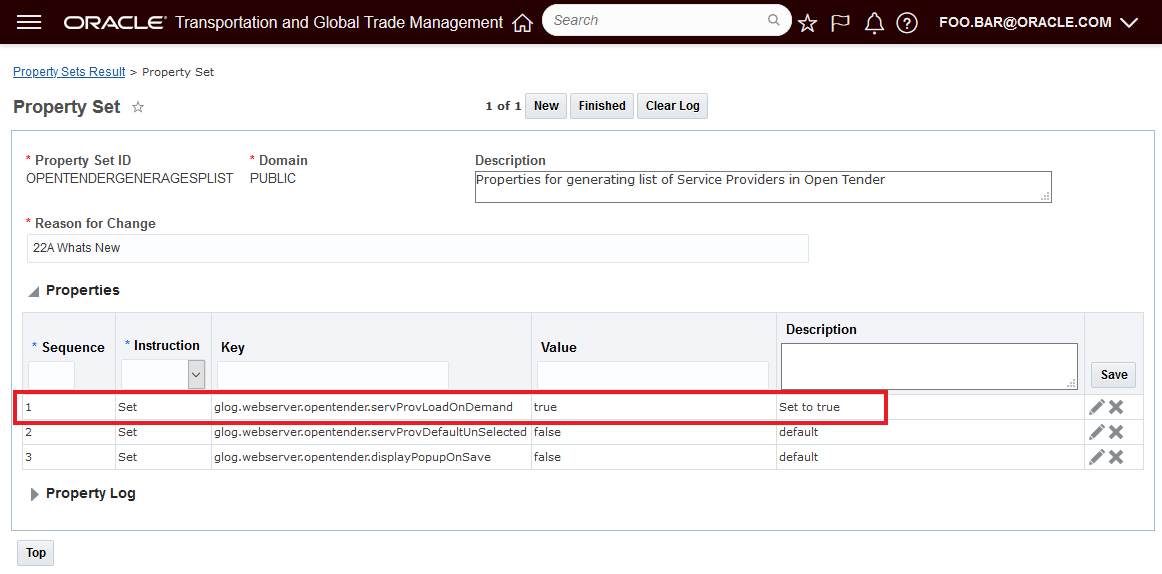

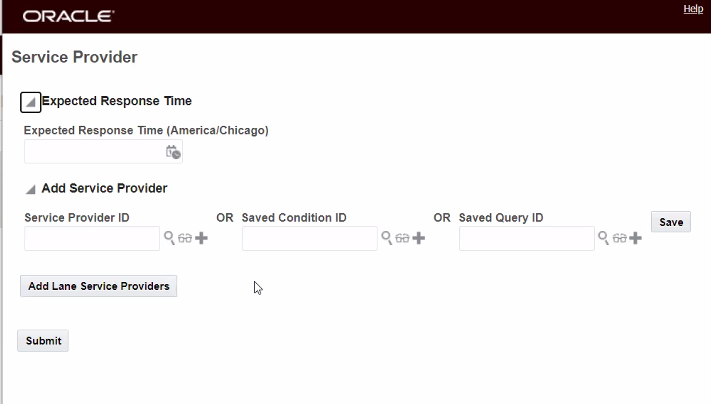

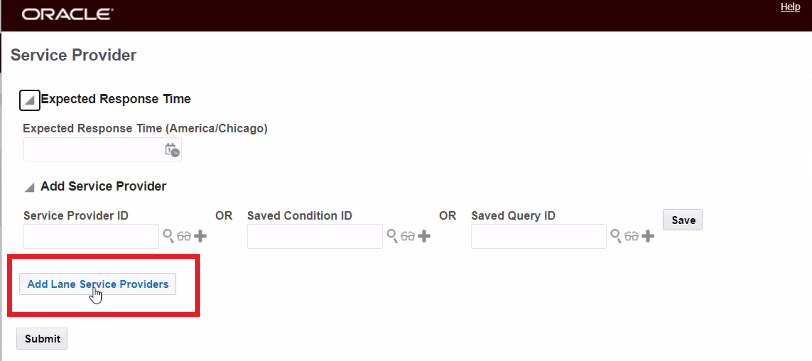

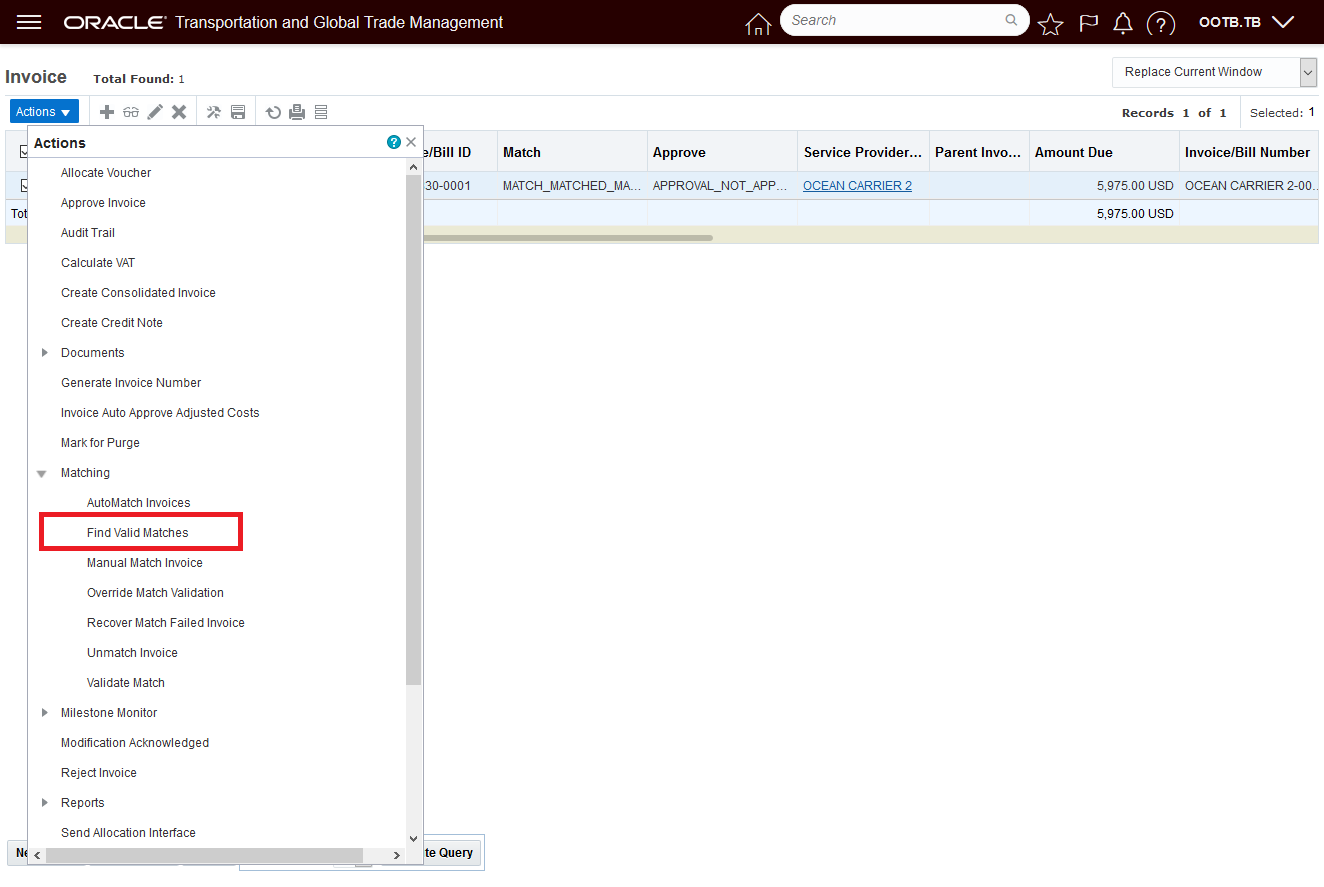

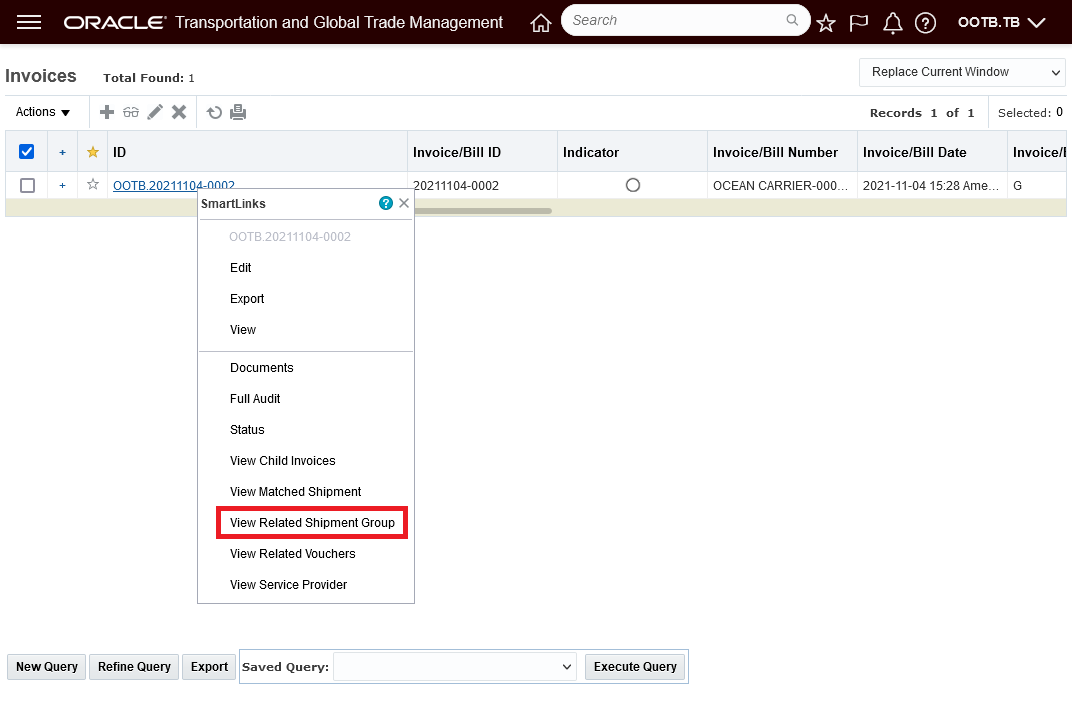

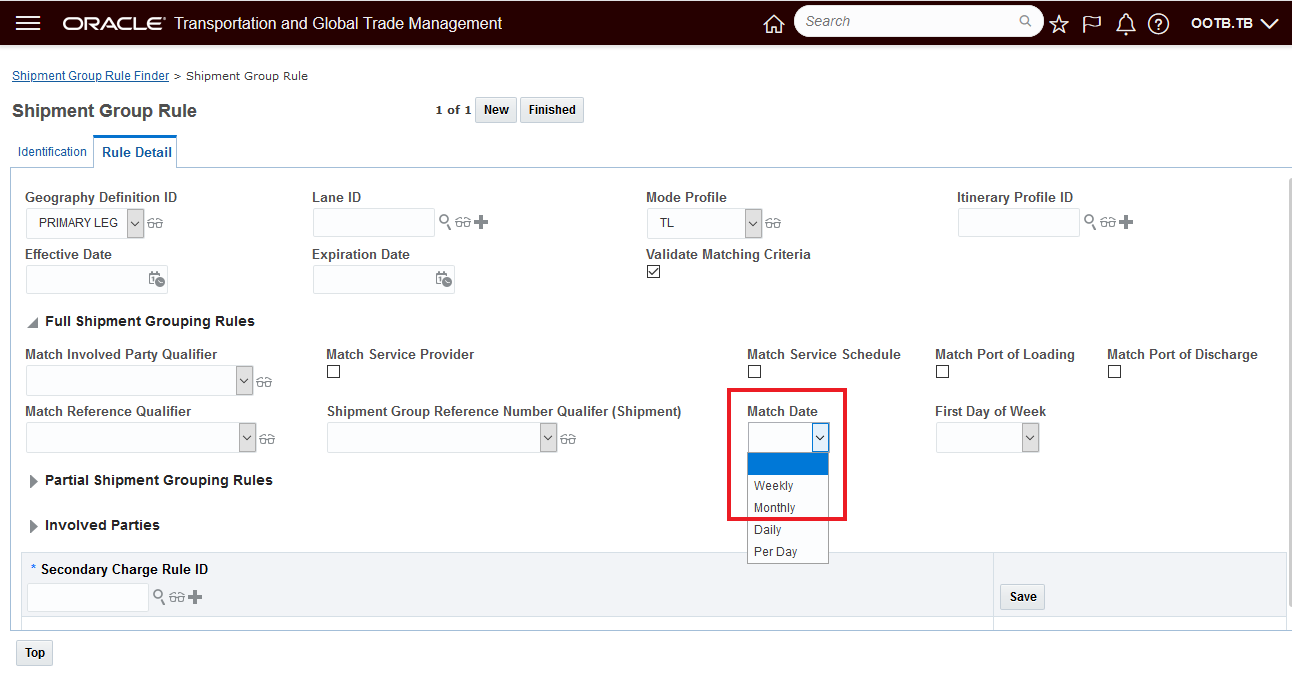

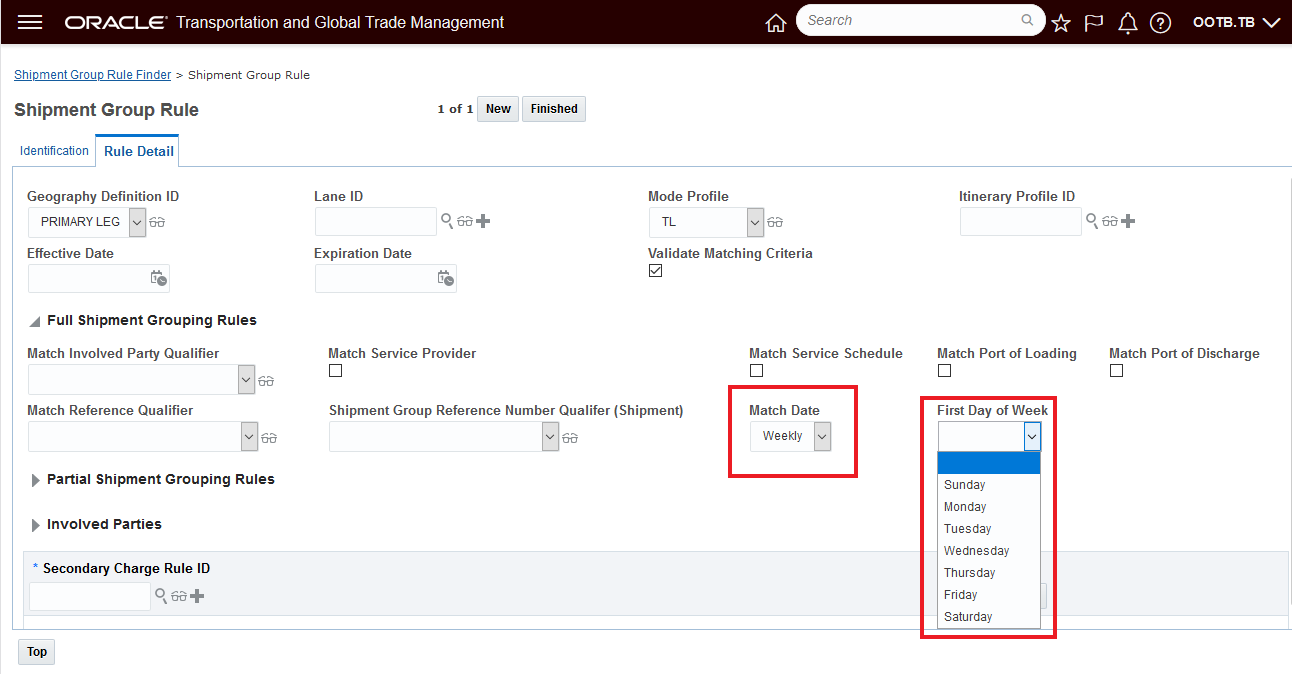

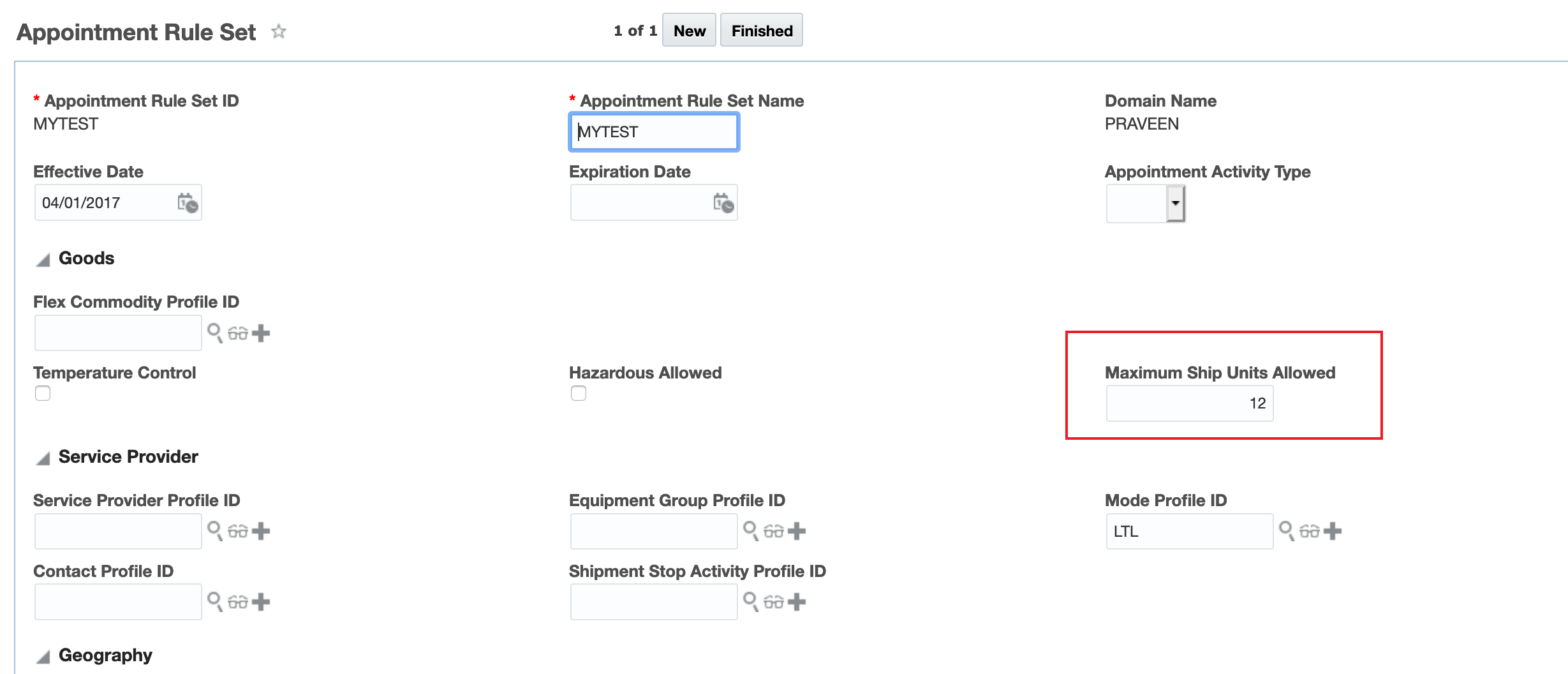

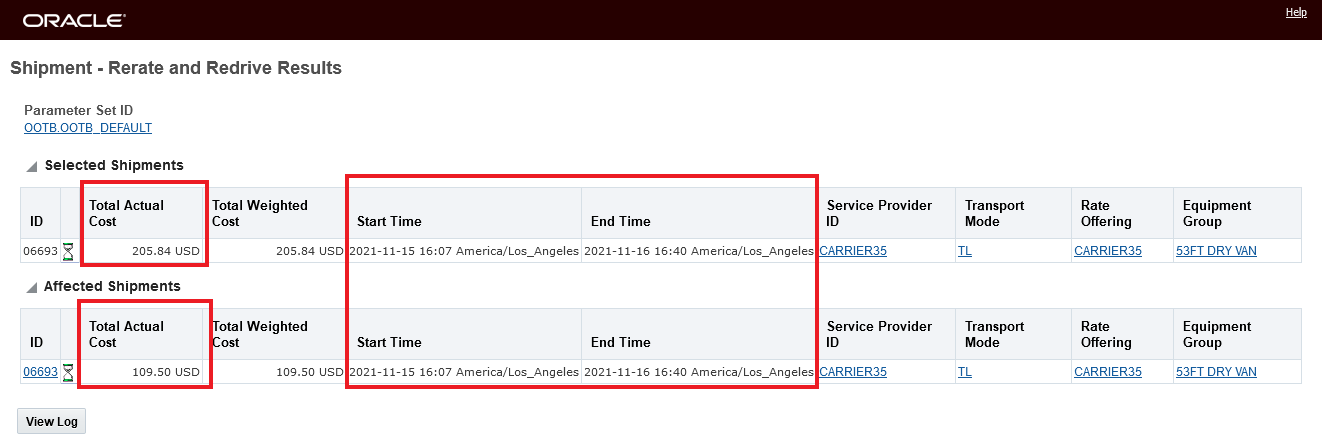

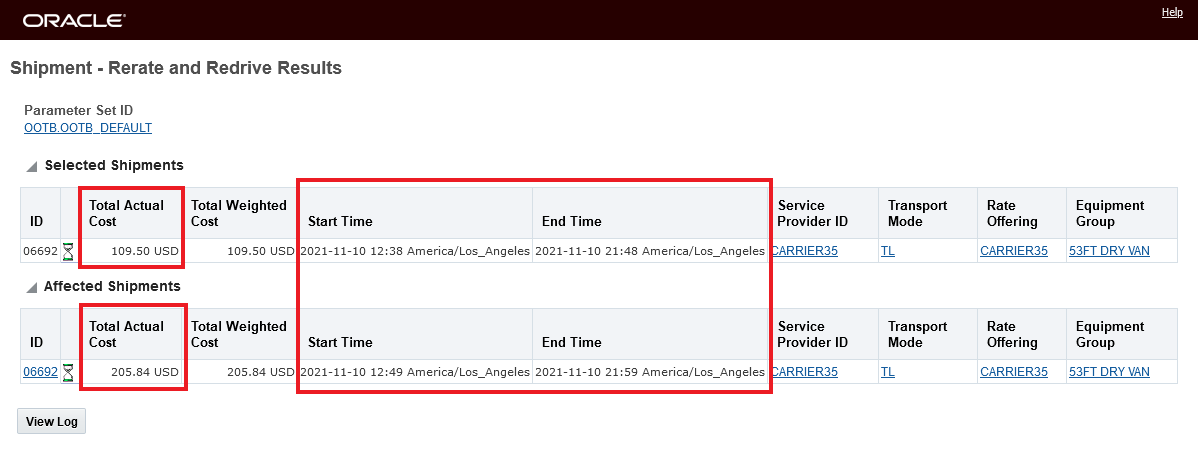

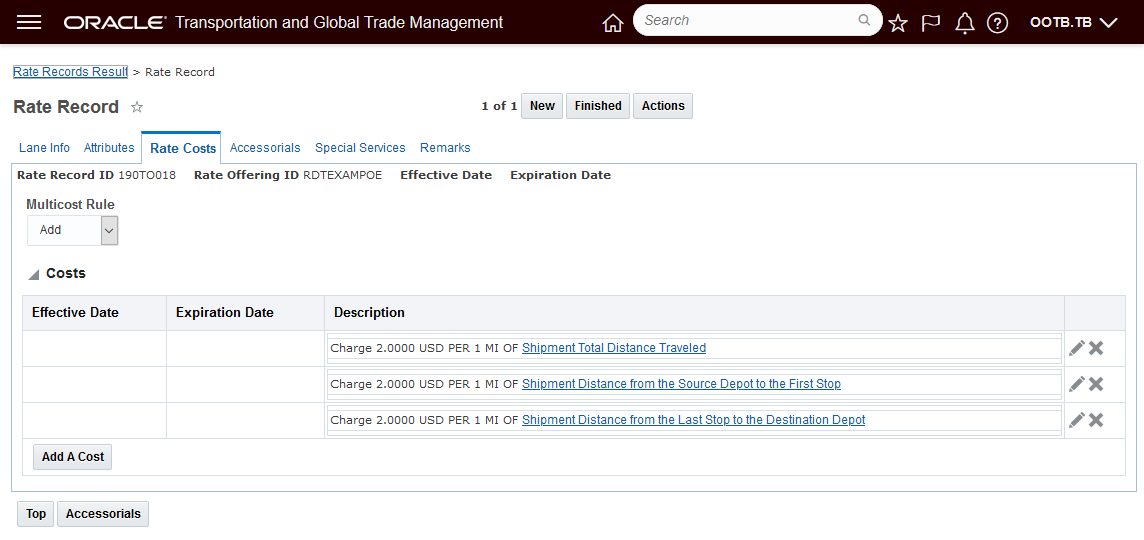

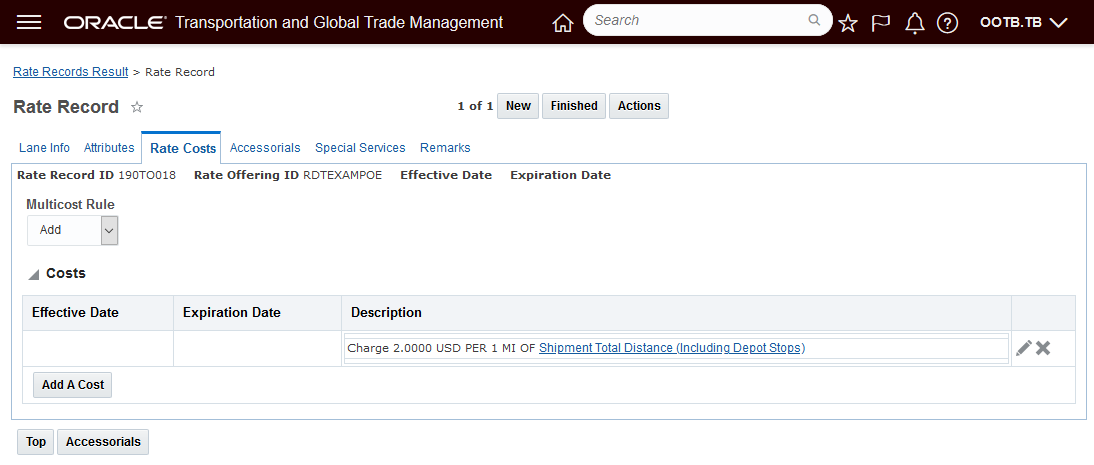

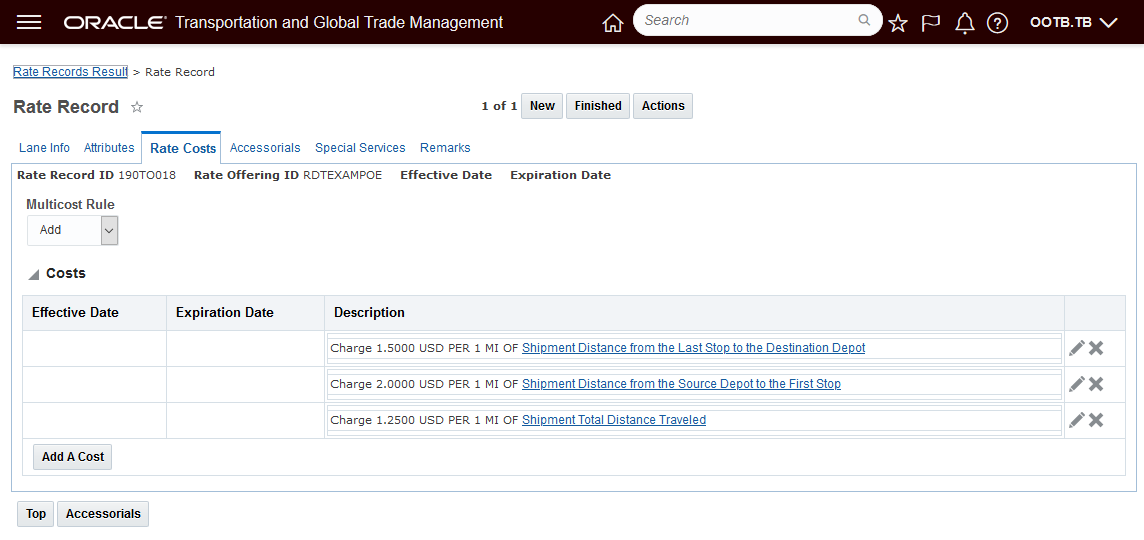

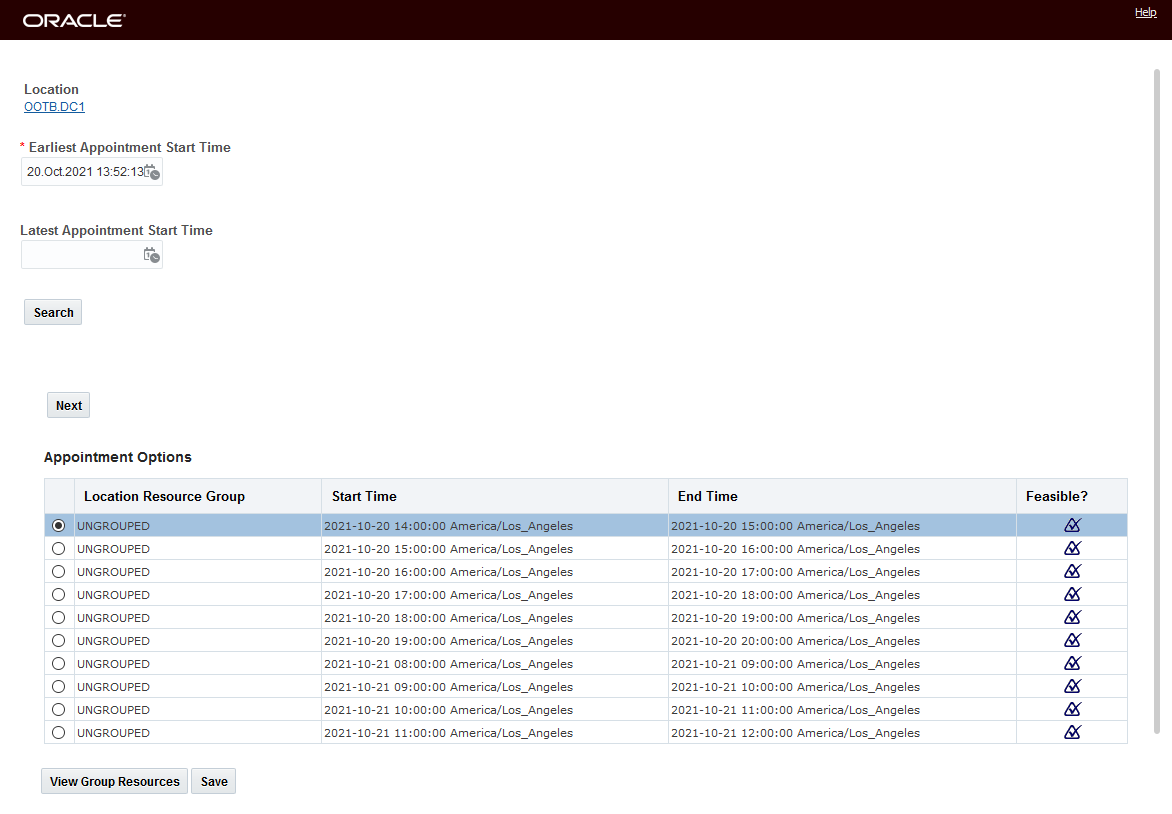

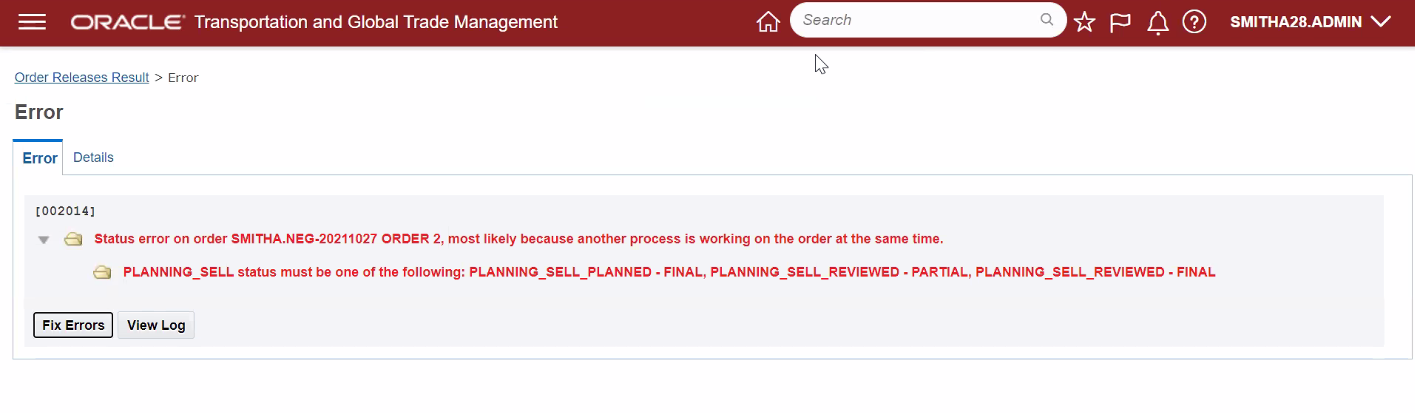

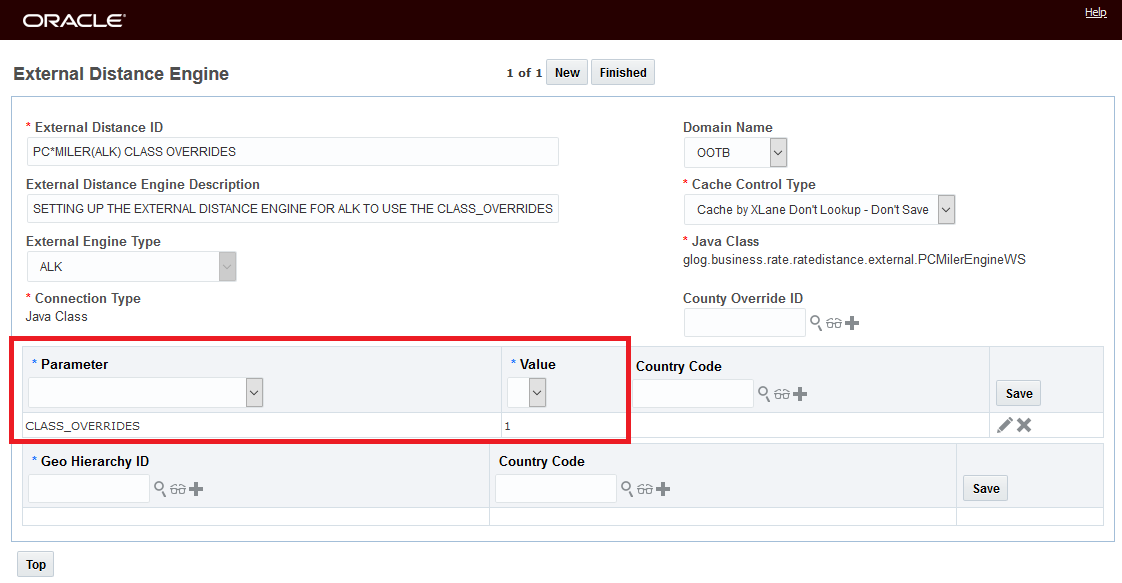

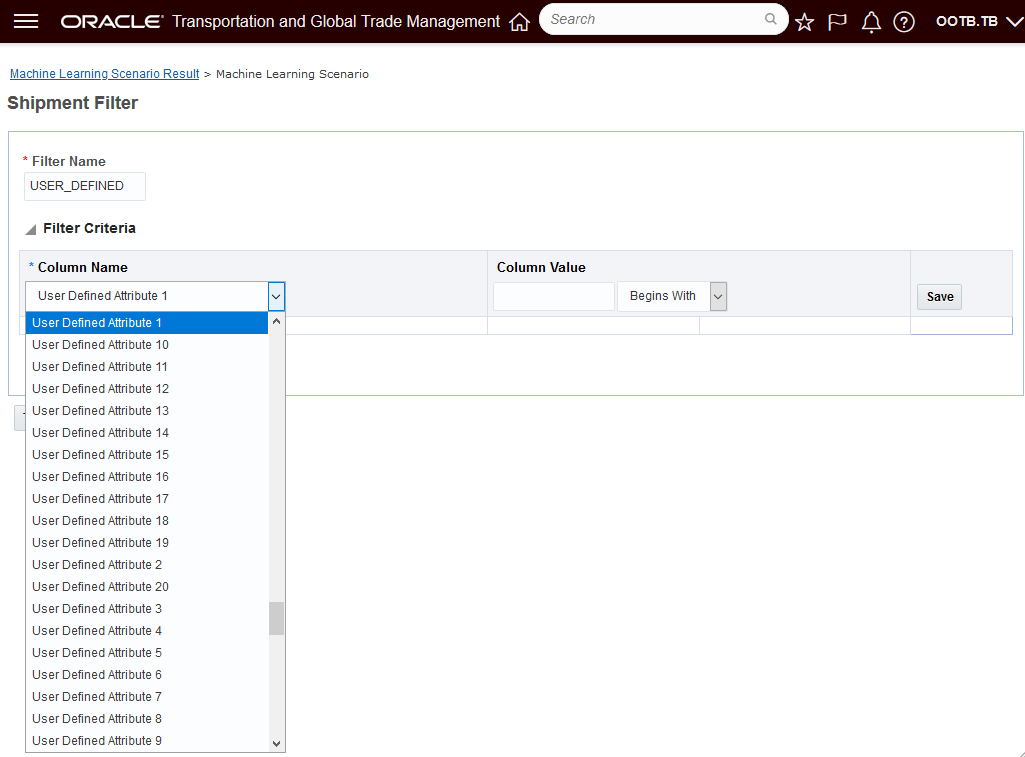

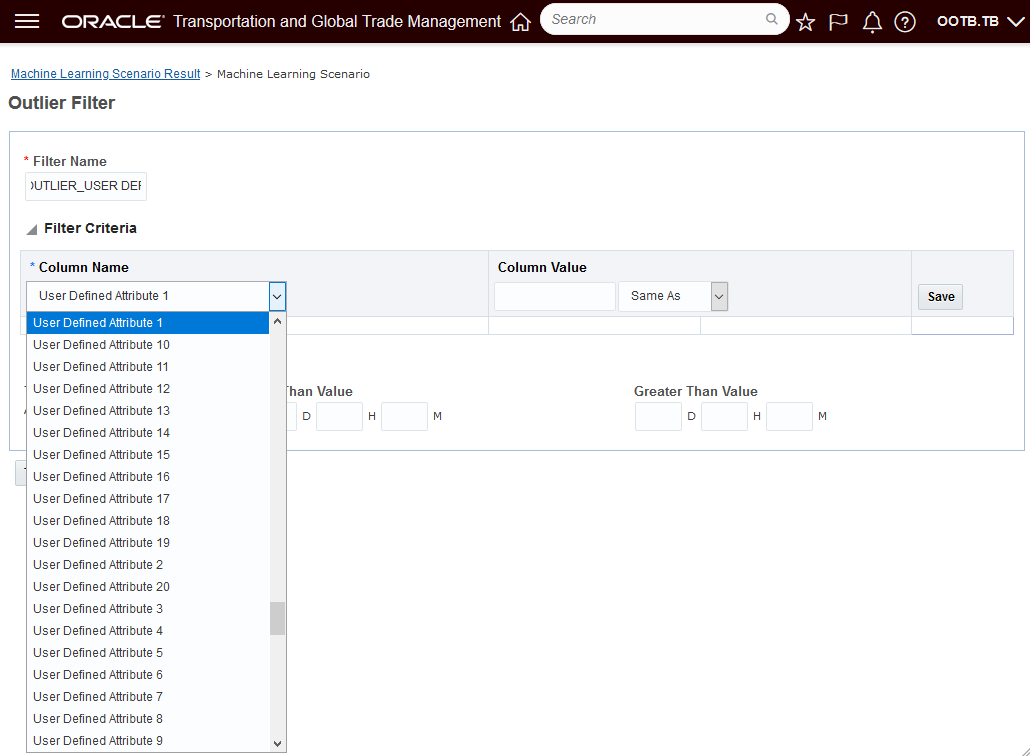

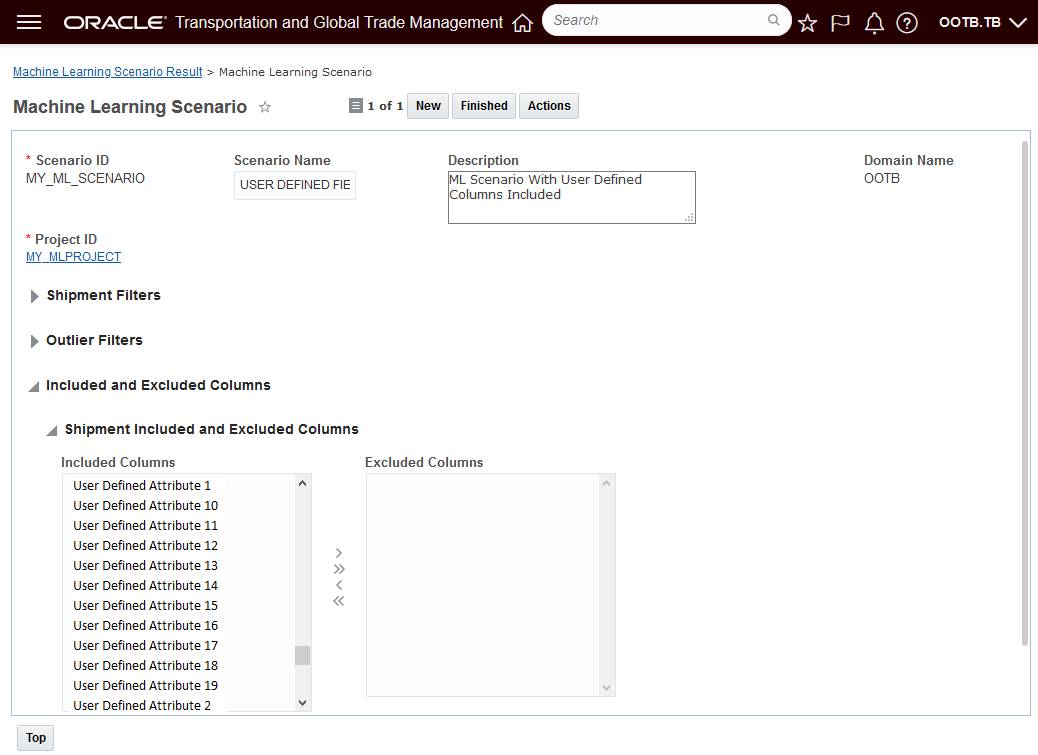

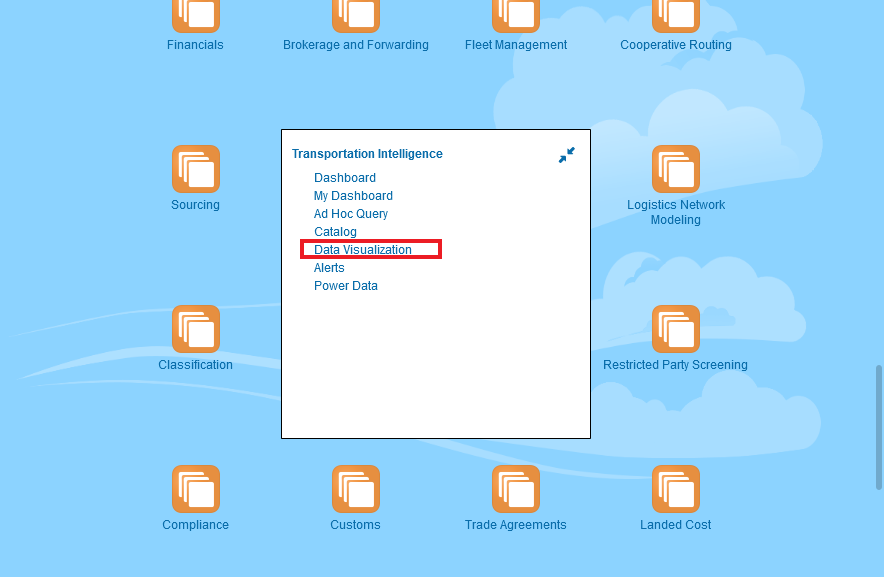

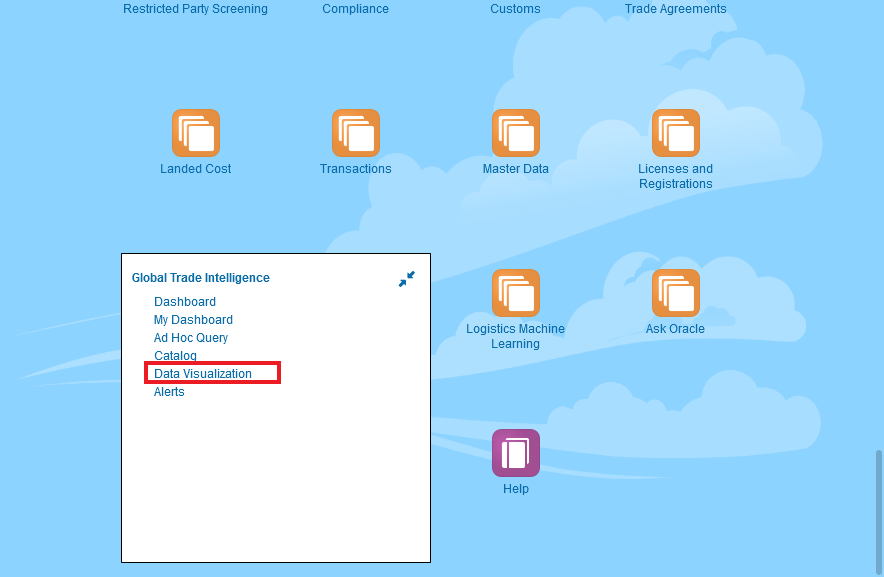

Spot Bid Tender View