- Revision History

- Overview

- Pre-Update and Post-Update Tasks

- Optional Uptake of New Features (Opt In)

- Feature Summary

- Supply Chain Orchestration

- Quality Management

- Manufacturing

-

- SCM Common Components

- Manufacturing

-

- Define a Minimum Transfer Quantity When Modeling Overlapping Operations or Work Orders

- Automatically Assign Item Structure Components to Work Definition Operations

- Report Ad hoc Outputs During Work Order Execution in Discrete Manufacturing

- Create Manufacturing Work Order and Transaction Reports with a UDI Using OTBI

- Redwood Experience

-

Update 24B

Revision History

This document will continue to evolve as existing sections change and new information is added. All updates appear in the following table:

| Date | Module | Feature | Notes |

|---|---|---|---|

| 24 MAY 2024 | SCM Common Components | Extend SCM Redwood Application Pages Using Visual Builder Studio | Updated document. Revised feature description and key resources. |

| 26 MAR 2024 | Manufacturing | Define a Minimum Transfer Quantity When Modeling Overlapping Operations or Work Orders | Updated document. Updated key resources. |

| 14 MAR 2024 | Manufacturing | Search for, Create, and Edit Work Definition Names Using the Redwood User Experience | Updated document. Added a link to a demo. |

| 14 MAR 2024 | Manufacturing |

Search for, Create, and Edit a Standard Item Work Definition Using the Redwood User Experience | Updated document. Added a link to a demo. |

| 14 MAR 2024 | Manufacturing |

Search for, Create, and Edit Work Areas Using the Redwood User Experience | Updated document. Added a link to a demo. |

| 14 MAR 2024 | Manufacturing |

Define a Minimum Transfer Quantity When Modeling Overlapping Operations or Work Orders | Updated document. Added a link to a demo. |

| 14 MAR 2024 | Manufacturing |

Automatically Assign Item Structure Components to Work Definition Operations | Updated document. Added a link to a demo. |

| 14 MAR 2024 | Manufacturing |

Report Ad hoc Outputs During Work Order Execution in Discrete Manufacturing | Updated document. Added a link to a demo. |

| 11 MAR 2024 | SCM Common Components | Extend SCM Redwood Application Pages Using Visual Builder Studio | Updated document. Revised feature description. |

| 01 MAR 2024 | Created initial document. |

Overview

HAVE AN IDEA?

HAVE AN IDEA?

We’re here and we’re listening. If you have a suggestion on how to make our cloud services even better then go ahead and tell us. There are several ways to submit your ideas, for example, through the Ideas Lab on Oracle Customer Connect. Wherever you see this icon after the feature name it means we delivered one of your ideas.

GIVE US FEEDBACK

We welcome your comments and suggestions to improve the content. Please send us your feedback at oracle_fusion_applications_help_ww_grp@oracle.com.

DISCLAIMER

The information contained in this document may include statements about Oracle’s product development plans. Many factors can materially affect Oracle’s product development plans and the nature and timing of future product releases. Accordingly, this Information is provided to you solely for information only, is not a commitment to deliver any material, code, or functionality, and should not be relied upon in making purchasing decisions. The development, release, and timing of any features or functionality described remains at the sole discretion of Oracle.

This information may not be incorporated into any contractual agreement with Oracle or its subsidiaries or affiliates. Oracle specifically disclaims any liability with respect to this information. Refer to the Legal Notices and Terms of Use for further information.

Pre-Update and Post-Update Tasks

Depending on the features you're using in your Cloud applications, you may be required to perform certain steps immediately before or after your quarterly update. For details of these pre-update and post-update steps and the product areas that are affected, refer to Oracle Fusion Cloud SCM: Performing Your Quarterly Update (doc ID 2337485.1) on My Oracle Support.

Optional Uptake of New Features (Opt In)

Oracle Cloud Applications delivers new updates every quarter. This means every three months you'll receive new functionality to help you efficiently and effectively manage your business. Some features are delivered Enabled meaning they are immediately available to end users. Other features are delivered Disabled meaning you have to take action to make available. Features delivered Disabled can be activated for end users by stepping through the following instructions using the following privileges:

- Review Applications Offering (ASM_REVIEW_APPLICATIONS_OFFERINGS_PRIV)

- Configure Oracle Fusion Applications Offering (ASM_CONFIGURE_OFFERING_PRIV)

Here’s how you opt in to new features:

- Click Navigator > My Enterprise > New Features.

- On the Features Overview page, select your offering to review new features specific to it. Or, you can leave the default selection All Enabled Offerings to review new features for all offerings.

- On the New Features tab, review the new features and check the opt-in status of the feature in the Enabled column. If a feature has already been enabled, you will see a check mark. Otherwise, you will see an icon to enable the feature.

- Click the icon in the Enabled column and complete the steps to enable the feature.

In some cases, you might want to opt in to a feature that's not listed in the New Features work area. Here's how to opt in:

- Click Navigator > My Enterprise > Offerings.

- On the Offerings page, select your offering, and then click Opt In Features.

- On the Opt In page, click the Edit Features (pencil) icon for the offering, or for the functional area that includes your feature.

- On the Edit Features page, complete the steps to enable the feature.

For more information and detailed instructions on opting in to new features for your offering, see Configure Offerings.

Opt In Expiration

Occasionally, features delivered Disabled via Opt In may be enabled automatically in a future update. This is known as an Opt In Expiration. If your cloud service has any Opt In Expirations you will see a related tab in this document. Click on that tab to see when the feature was originally delivered Disabled, and when the Opt In will expire, potentially automatically enabling the feature. You can also click here to see features with Opt In Expirations across all Oracle Cloud Applications.

Feature Summary

Column Definitions:

Features Delivered Enabled

Report = New or modified, Oracle-delivered, ready to run reports.

UI or Process-Based: Small Scale = These UI or process-based features are typically comprised of minor field, validation, or program changes. Therefore, the potential impact to users is minimal.

UI or Process-Based: Larger Scale* = These UI or process-based features have more complex designs. Therefore, the potential impact to users is higher.

Features Delivered Disabled = Action is needed BEFORE these features can be used by END USERS. These features are delivered disabled and you choose if and when to enable them. For example, a) new or expanded BI subject areas need to first be incorporated into reports, b) Integration is required to utilize new web services, or c) features must be assigned to user roles before they can be accessed.

Supply Chain Orchestration

Supply Chain Orchestration

Use Redesigned Pages to View Supply Requests

Use redesigned pages to view supply requests and their details on your desktop, tablet, or mobile device. You can now use the supply request reference, supply order, supply document, or item to search for your supply requests. Create and save your own default searches. Filter search results according to the supply's requested date, requested delivery date, request status, and so on. View recommended actions that you need to take to remove exceptions. View the supply documents that Oracle Supply Chain Orchestration created for each request. View details about request lines and take actions.

To use this feature, go to the Supply Orchestration work area, click Tasks > Supply Requests, then search for your supply request.

Improve your efficiency when you search for and view supply requests.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management

Tips And Considerations

Use these attributes to search for your supply requests:

- Supply Request Reference

- Supply Order

- Supply Document

- Item

Use these attributes to filter your search results:

- Supply Requested Date

- Requested Delivery Date

- Supply Status

- Supply Type

- Business Flow

Do more:

- View details about the supply documents for each supply request.

- Create and save your own search. Make that search your default search.

- Drill into into the supply request to get details about the supply request and any exception messages that might exist.

- If a supply request is in exception, then you can view a recommended action to fix it.

- Do various actions on each supply request.

Key Resources

- See Using Supply Chain Orchestration and Supply Chain Orchestration on Oracle Help Center.

Access Requirements

You have a couple of options for giving people access to this feature, depending on whether you're assigning them predefined job roles or your own configured job roles.

- Users who are assigned any of these predefined job roles can access this feature:

- Supply Chain Operations Manager (ORA_DOS_SUPPLY_CHAIN_OPERATIONS_MANAGER_JOB)

- Users who are assigned a configured job role that contains these privileges can access this feature:

- Process Supply Order Interface (DOS_PROCESS_SUPPLY_ORDER_INTERFACE_PRIV)

- View Supply Orders (DOS_VIEW_SUPPLY_ORDERS_PRIV)

- Manage Supply Request Exceptions (DOS_MANAGE_SUPPLY_REQUEST_EXCEPTIONS_PRIV)

- View Supply Order Exceptions and Status (DOS_VIEW_SUPPLY_ORDER_EXCEPTIONS_AND_STATUS_PRIV)

If you're maintaining your own job roles, no new privileges were introduced to support this feature.

Quality Management

Quality Management

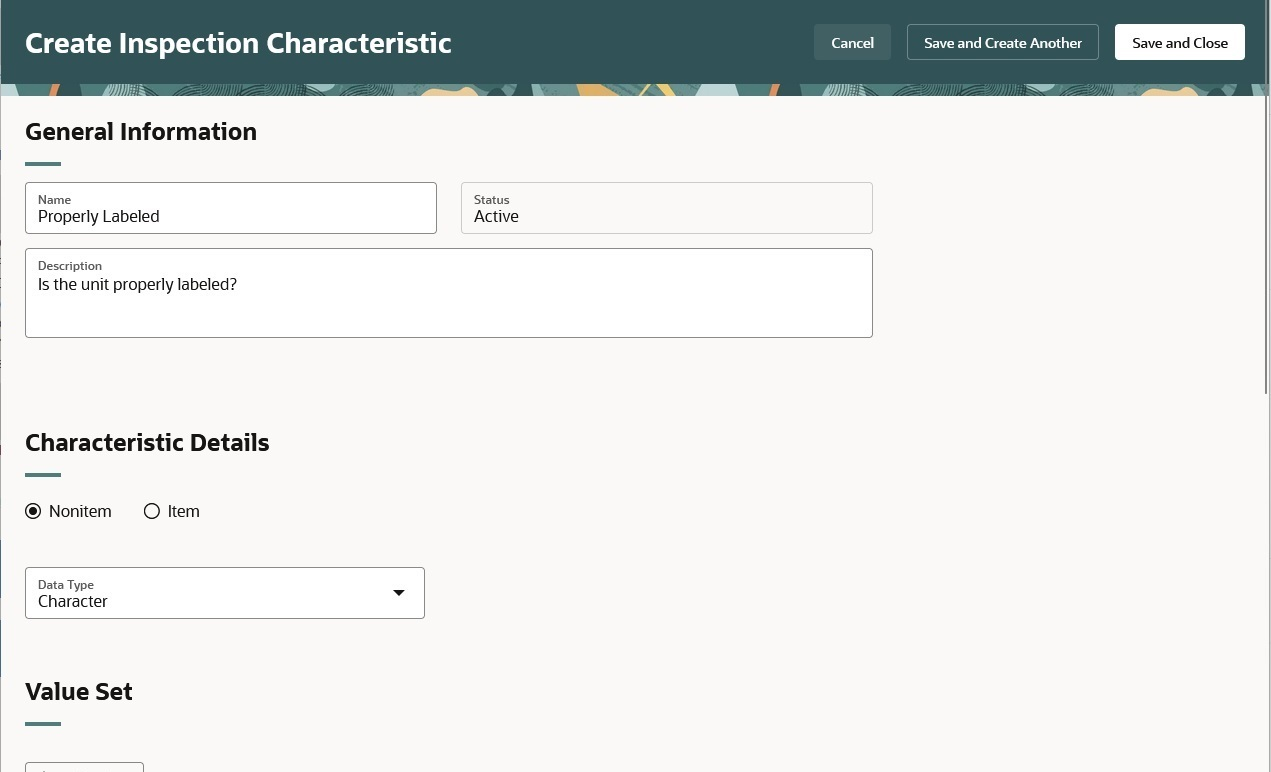

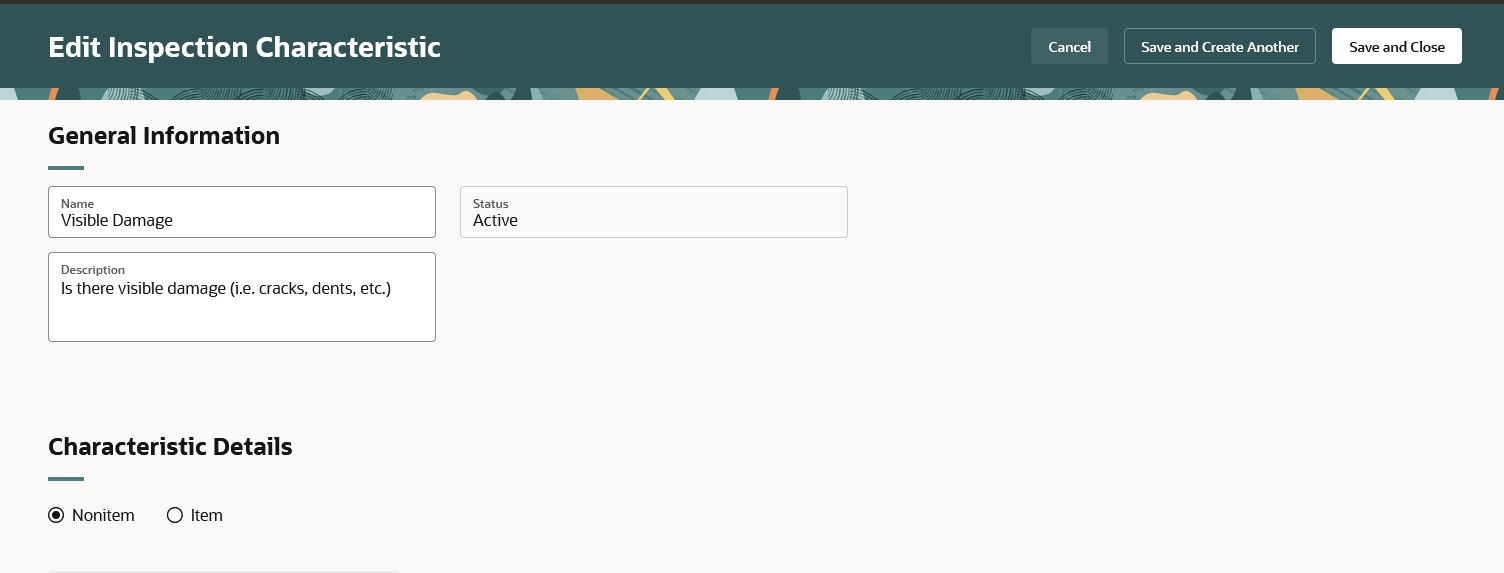

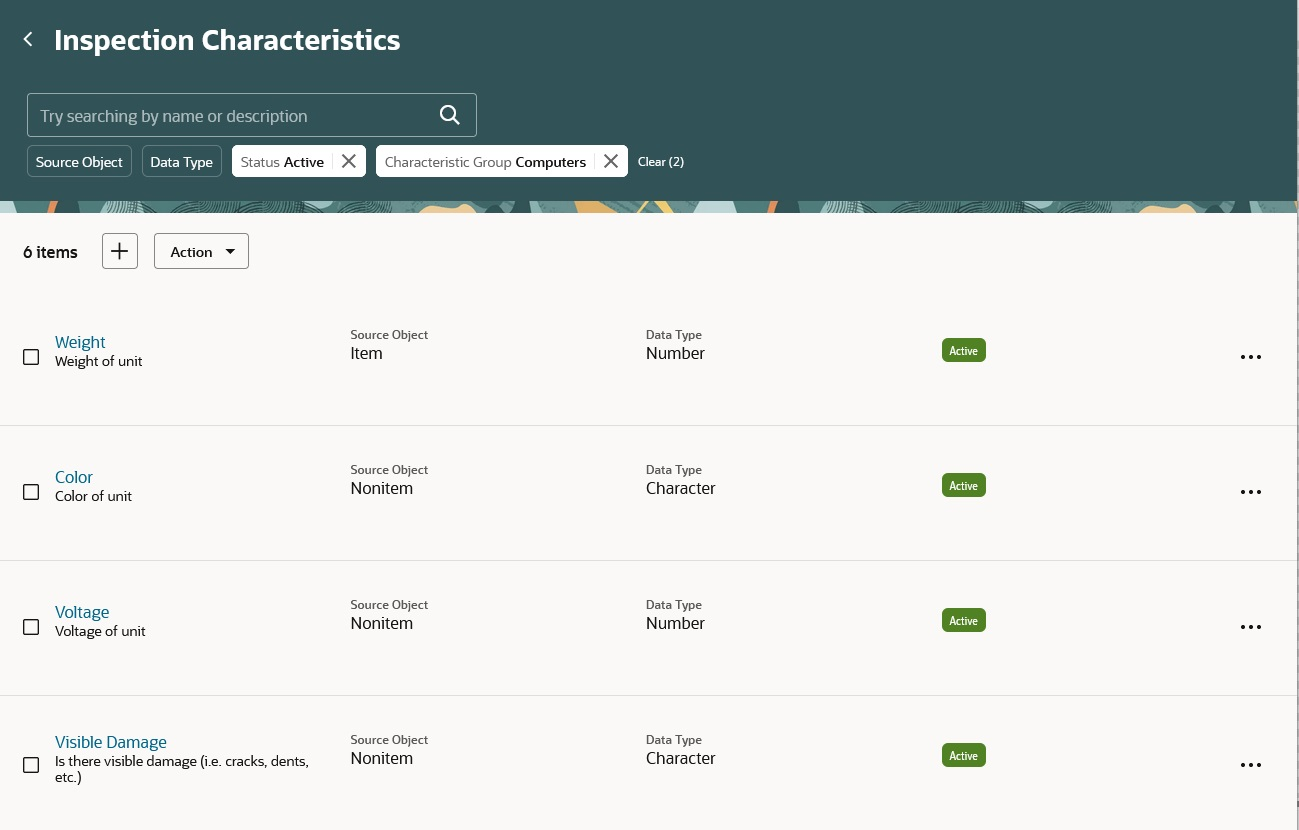

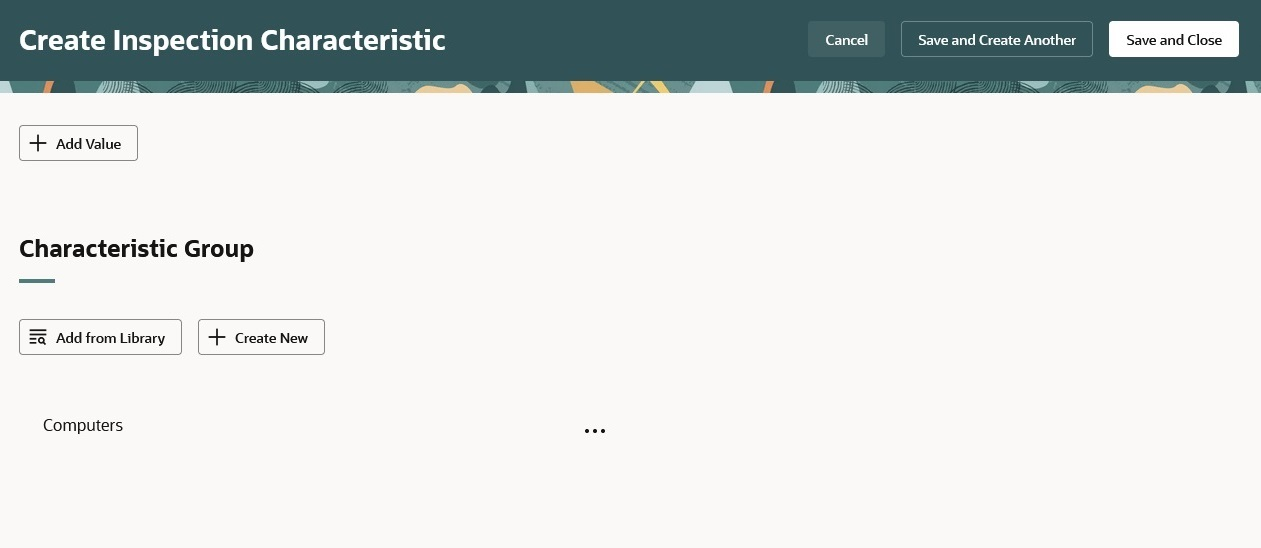

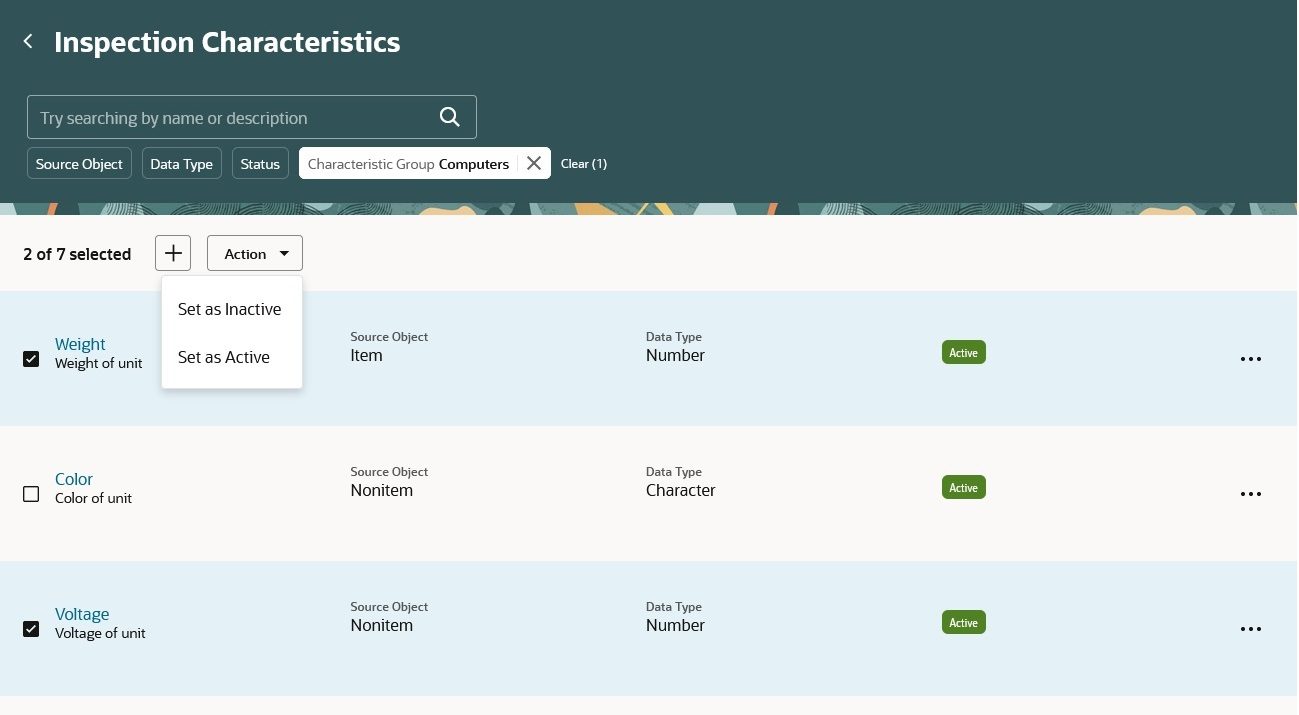

Manage Inspection Characteristics in Redwood Pages

Inspection characteristics represent the attributes used in an inspection plan and inspection results to determine conformance to specification requirements. Inspection characteristics can be associated with a characteristic group for the ease of adding them to an inspection plan or inspection results.

You can now experience the Inspection Characteristics related pages in Redwood, Oracle’s next-generation user experience. Redwood brings state-of-the-art, consumer-grade user experiences across devices to the sophisticated enterprise scenarios that Oracle enables.

This enhanced user experience on your redesigned Redwood pages has been enabled for:

- Create inspection characteristic

- Edit inspection characteristic

- Manage inspection characteristics

- Create characteristic groups and associate them with characteristics

This update lets you accomplish more work quickly, with the following improvement

- Ability to activate or inactivate multiple characteristic at once from the manage inspection characteristic page

- More efficient and consistent user experience

- Enhanced search capabilities

Steps to Enable

Follow these steps to enable or disable this feature:

- In the Setup and Maintenance work area, search for and select the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_QA_CHARACTERISTIC_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value is N.

- Y = enables the feature

- N = disables the feature

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

You'll have the option to enable or disable this feature for 3 quarterly updates. After that, this feature will be enabled by default.

Tips And Considerations

- Business Rules have been implemented for all pages

- Guided Journeys have been implemented for all pages

Key Resources

Access Requirements

Access to this feature is through the following privileges:

- Edit Characteristics

- View Characteristics

Selected Quality Issue and Action Management Bug Fixes in This Update

This update includes some bug fixes that can change the way Oracle Quality Issue and Action Management works. This isn't a full list of all the bug fixes in this update. This list includes the bug fixes that can cause a noticeable change in application behavior.

Automatic Promotion of Quality Actions Doesn't Work

Prior to this update, quality actions weren't automatically closed even when the workflow was set to automatically promote the status from Approval to Closed, because duplicate approvers were being added to the approval step. This issue is now fixed.

Oracle reference: 35778053

Steps to Enable

You don't need to do anything to enable this feature.

Manufacturing

SCM Common Components

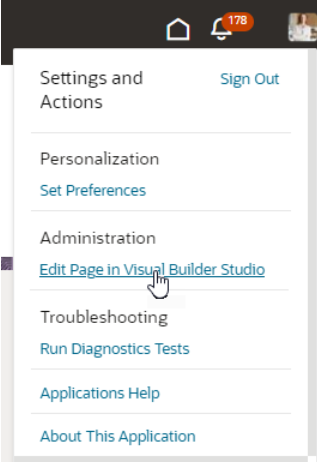

Extend SCM Redwood Application Pages Using Visual Builder Studio

Tailor a seamless experience for the users in your enterprise using Oracle Visual Builder Studio. You can use business rules in Visual Builder Studio’s Express mode to:

- Make the fields and regions on a page required or optional.

- Make the fields and regions on a page read-only or editable.

- Show or hide fields and regions depending on specific criteria.

- Configure Redwood pages to best meet your specific business needs. For example, you can control which actions are visible on the Receipt Deliveries page, or you can set the default date range that's available on the PAR Counts Overview page.

The types of changes you can make to a page depend on the page you're modifying.

NOTE: In this update, business rules aren't yet supported on all SCM Redwood pages.

To determine whether you can extend a specific page using Visual Builder Studio, go to the page and open the Setting and Actions menu. Look for the Edit Page In Visual Builder Studio task:

Settings and Actions Menu

If you don’t see the Edit Page in Visual Builder Studio task, then you can’t use Visual Builder Studio to edit the page, either because you're not assigned the necessary privilege to edit pages in VB Studio, or because the page can't currently be edited in VB Studio.

When you open a page in Visual Builder Studio, use only the Express mode to extend the page. Advanced mode isn’t supported. If Express mode isn't available when you open the page in VB Studio, then you can't extend the page in VB Studio. You can find the Express mode in the Visual Builder Studio header region:

Header Region in Visual Builder Studio

See Extending Oracle Cloud Applications in Visual Builder Studio Express Mode for details about how to extend your application pages in Express mode.

Steps to Enable

Leverage the Visual Builder Studio to expose your applications. To learn more about extending your application using Visual Builder, visit Oracle Help Center > your apps service area of interest > Books > Configuration and Extension.

Before you can start working with Visual Builder Studio, a systems administrator must complete some initial setup. For instructions, see Set Up VB Studio to Extend Oracle Cloud Applications.

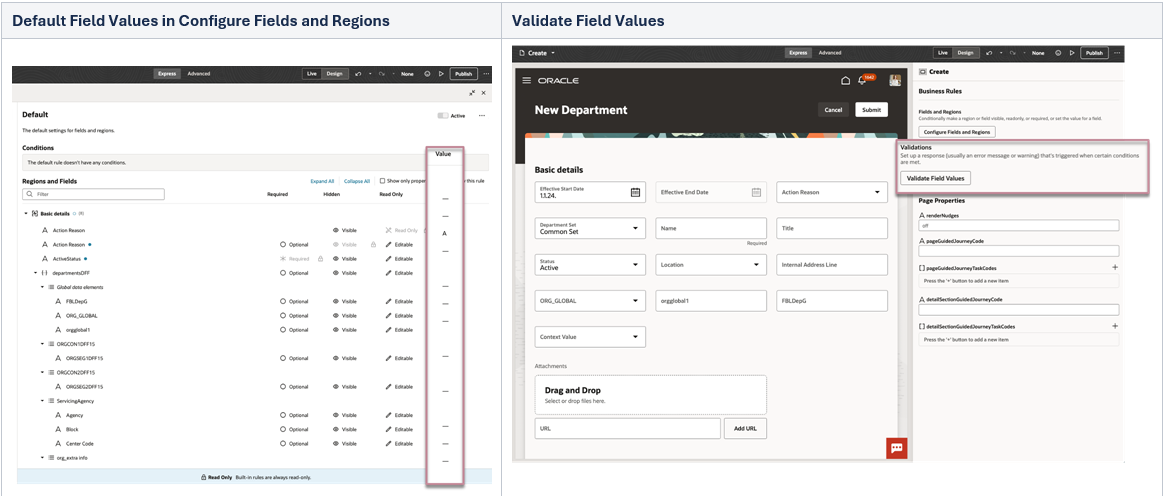

Tips And Considerations

Keep the Pages list closed while you work in Visual Builder Studio Express mode. Closing the list gives you a cleaner view of the page you’re extending.

In Visual Builder Studio Express mode, you might see capabilities that support defaulting and validation of field values. The features aren't supported in SCM Redwood pages in update 24B. You'll be able to use defaulting and validation for selected SCM Redwood pages in future updates.

Default Field Values and Validate Field Values in VB Studio Express Mode

Key Resources

To start extending your application pages in Visual Builder Studio, follow the instructions to access Visual Builder Studio. As you’re working, you can find additional information in these resources:

- Extend Oracle Cloud Applications in Visual Builder Express Mode

- Oracle Fusion Cloud HCM and SCM: Extending Redwood Applications for HCM and SCM Using Visual Builder Studio

Access Requirements

To extend application pages using Visual Builder Studio, you must be assigned a configured job role that contains this privilege:

-

Administer Sandbox (FND_ADMINISTER_SANDBOX_PRIV)

This privilege was available prior to this update.

Manufacturing

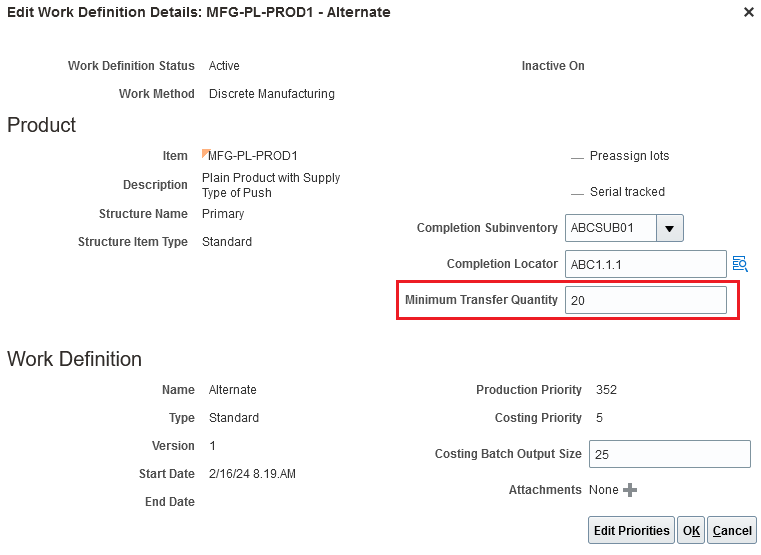

Define a Minimum Transfer Quantity When Modeling Overlapping Operations or Work Orders

Today, production scheduling assumes all units of the the prior operation in a work order must be completed before the next operation can be scheduled to begin. This may result in longer than necessary operation durations and lead times.

In certain industries, manufacturers leverage a common strategy for reducing the lead time for an operation by overlapping the time when an operation starts before the previous operation completes. They identify a minimum quantity to transfer between operations based on the capacity of their production line or bottleneck resource to avoid gaps in scheduling.

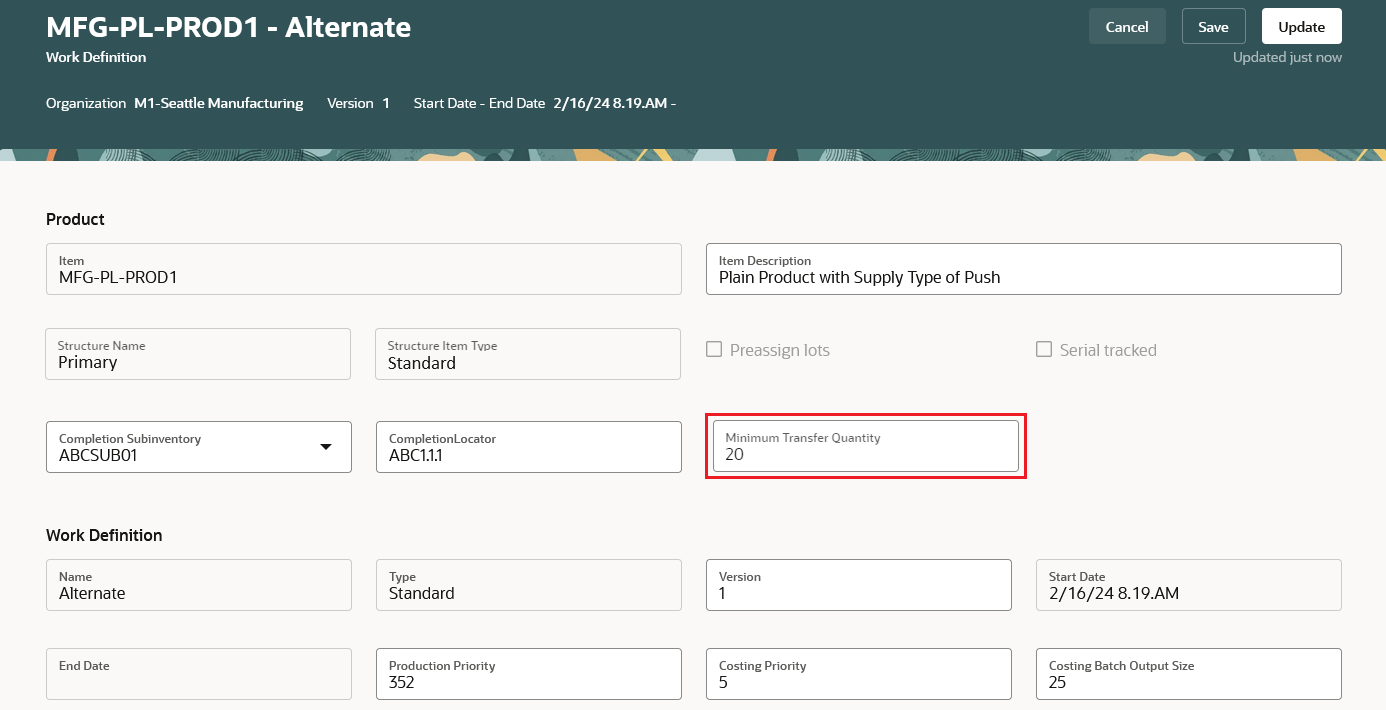

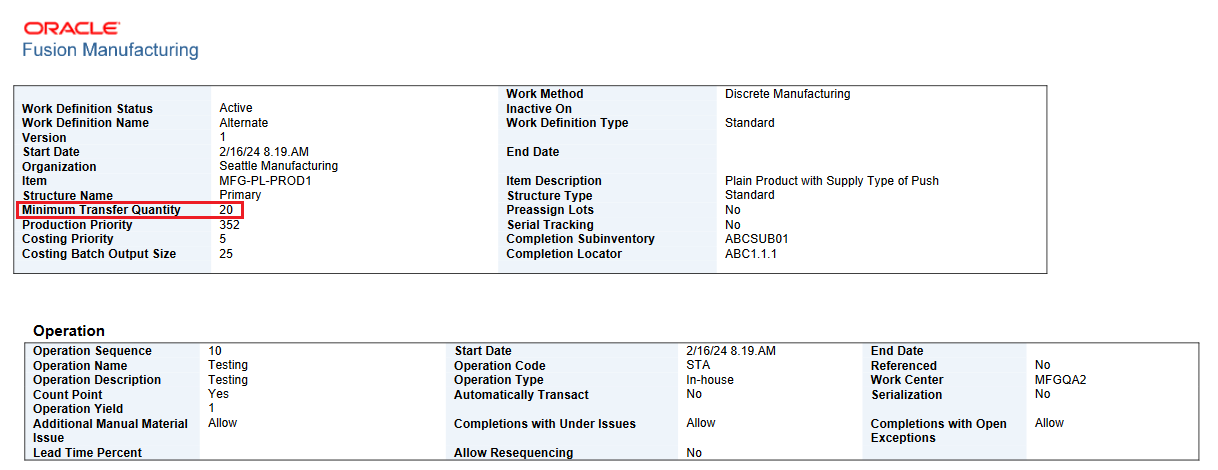

Now you can optionally define a minimum transfer quantity for an item to model overlapping, sequential operations or work orders. In the Edit Work Definition page, you can specify the minimum transfer quantity in the same unit of measure as the primary product, which is identified in the work definition header. When a work order is created using a work definition, the minimum transfer quantity is applied across all operations.

Minimum Transfer Quantity in Work Definition

Minimum Transfer Quantity in Work Definition Using Redwood User Experience

Minimum Transfer Quantity in Work Definition Report

File-Based Data Import (FBDI) changes:

You can specify minimum transfer quantity when creating a work definition using file-based data import. A new column called Minimum Transfer Quantity has been added to Work Definition Headers sheet. Its an optional attribute available in discrete and process work definition templates.

ADFdi changes:

You can manage the Minimum Transfer Quantity attribute using the ADFdi (Application Development Framework desktop integration) spreadsheet.

REST API changes:

You can manage the Minimum Transfer Quantity attribute for the work definition using a REST service, specify minimum transfer quantity during create and update actions in the work definition POST request.

OTBI changes:

You can use minimum transfer quantity in the OTBI (Oracle Transactional Business Intelligence) reports. The Minimum Transfer Quantity attribute is included the Work Definition dimension for the following Manufacturing Subject Areas

- Work Order Performance Real Time

- Material Usage Real Time

- Resource Usage Real Time

- Actual Production Real Time

By specifying a minimum transfer quantity for a work definition, you can enable more accurate modeling of factory operations and more effective scheduling with compressed manufacturing lead times. As a result, operational efficiency is increased and overall equipment effectiveness is maximized.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 24D

Tips And Considerations

- You can define a minimum transfer quantity for all work definition types and work order types in Manufacturing. It doesn't apply to supplier operations.

- You can't define additional relationships between the start and completion of operations at this time, except for sequential operations.

- You can't define a minimum transfer quantity for a standard operation.

- Minimum transfer quantity isn't considered by the unconstrained work order scheduler and lead time calculations for an item at this time.

- In update 24B, the Plan and Schedule Supplies Respecting Minimum Transfer Quantity Between Operations feature in Oracle Fusion Production Scheduling is on controlled availability and is available only to customers who were provided a promotion code to access it. To inquire about a promotion code for this feature, contact your Oracle account representative.

- You can integrate work definitions having the minimum transfer quantity defined with an external planning or scheduling application.

Key Resources

- Watch the Define a Minimum Transfer Quantity When Modeling Overlapping Operations or Work Orders Demo.

- Oracle Fusion Cloud Supply Planning Update 24B What's New - Plan and Schedule Supplies Respecting Minimum Transfer Quantity Between Operations.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Manage Work Definitions (WIS_MANAGE_WORK_DEFINITIONS_PRIV)

The privilege was available prior to this update.

Automatically Assign Item Structure Components to Work Definition Operations

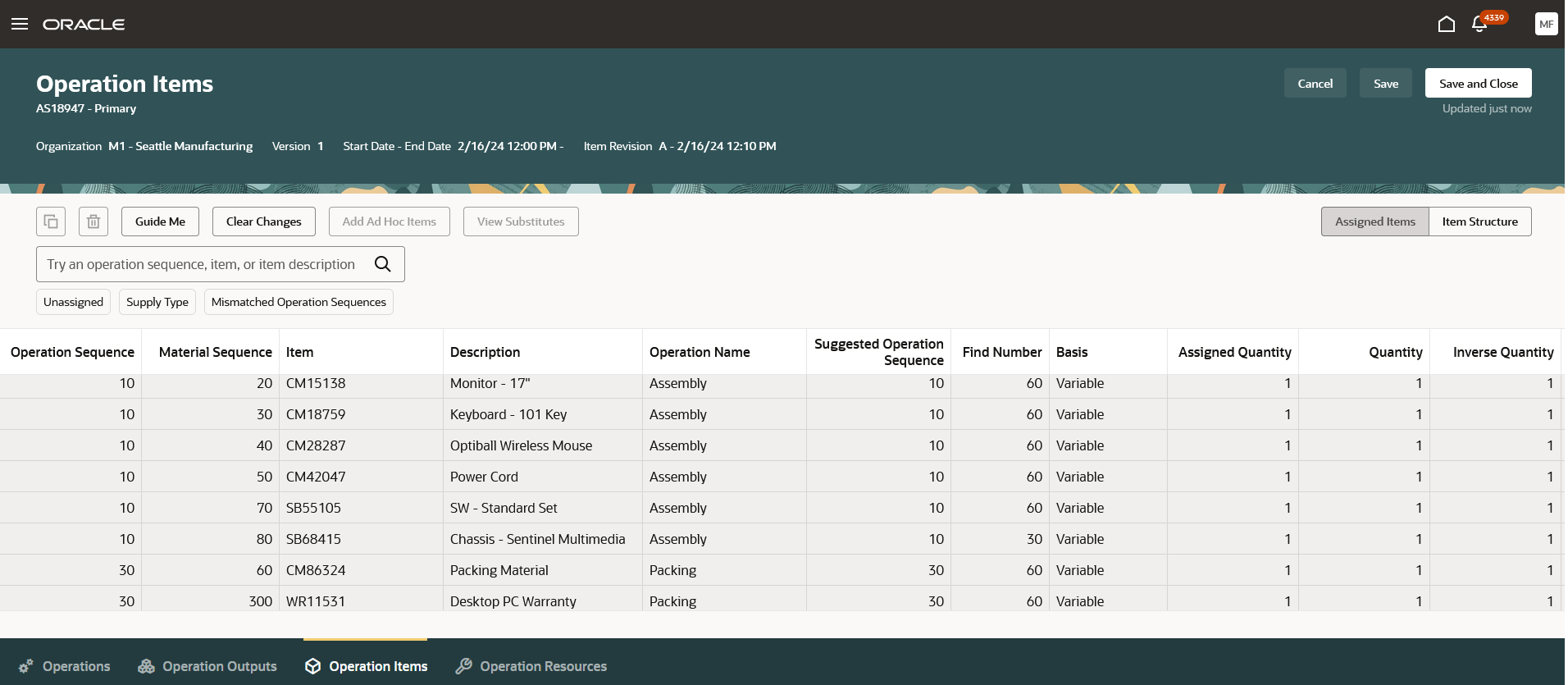

Today coordinating item structure changes to work definitions requires a multistep process of reviewing and approving changes to implement. Specifically, the assignment of components to operations needs to be finalized before the work definition can be used for production, supply planning, and cost planning. In the item structure, the suggested operation sequence records a design engineer's suggestion for the operation sequence of components in a manufacturing work definition.

Using the Redwood user experience, you can now create or copy a discrete or process manufacturing work definition for a standard item with its components automatically assigned to operations based on the suggested operation sequence in the item structure. In addition, you can run the Process Item Changes to Work Definitions scheduled process to support the following scenarios:

- Automatically assign an added structure component to the corresponding manufacturing work definitions in the existing and Redwood user experiences.

- Receive a notification of an updated, suggested operation sequence for review and possible actions such as versioning, update, or correction.

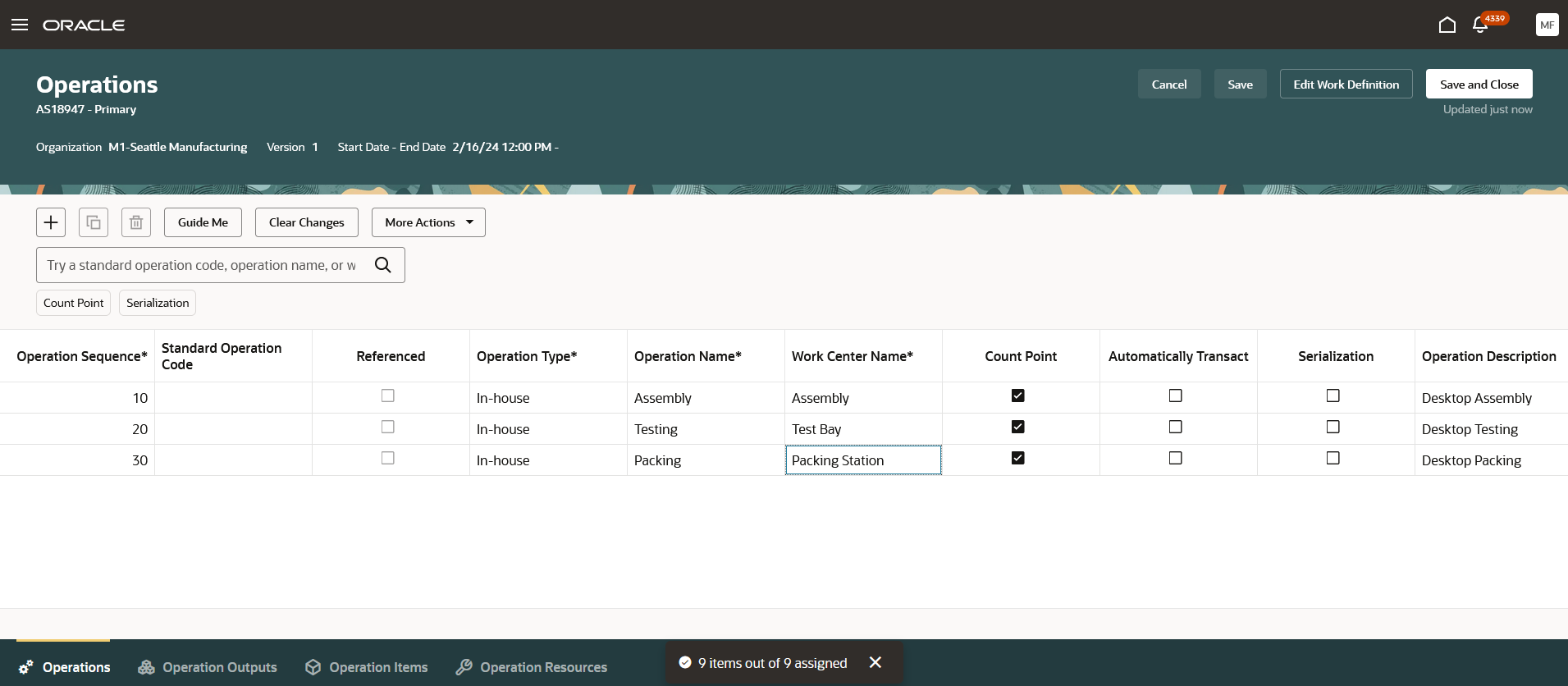

Automatic Assignment of Item Structure Components While Creating a Work Definition

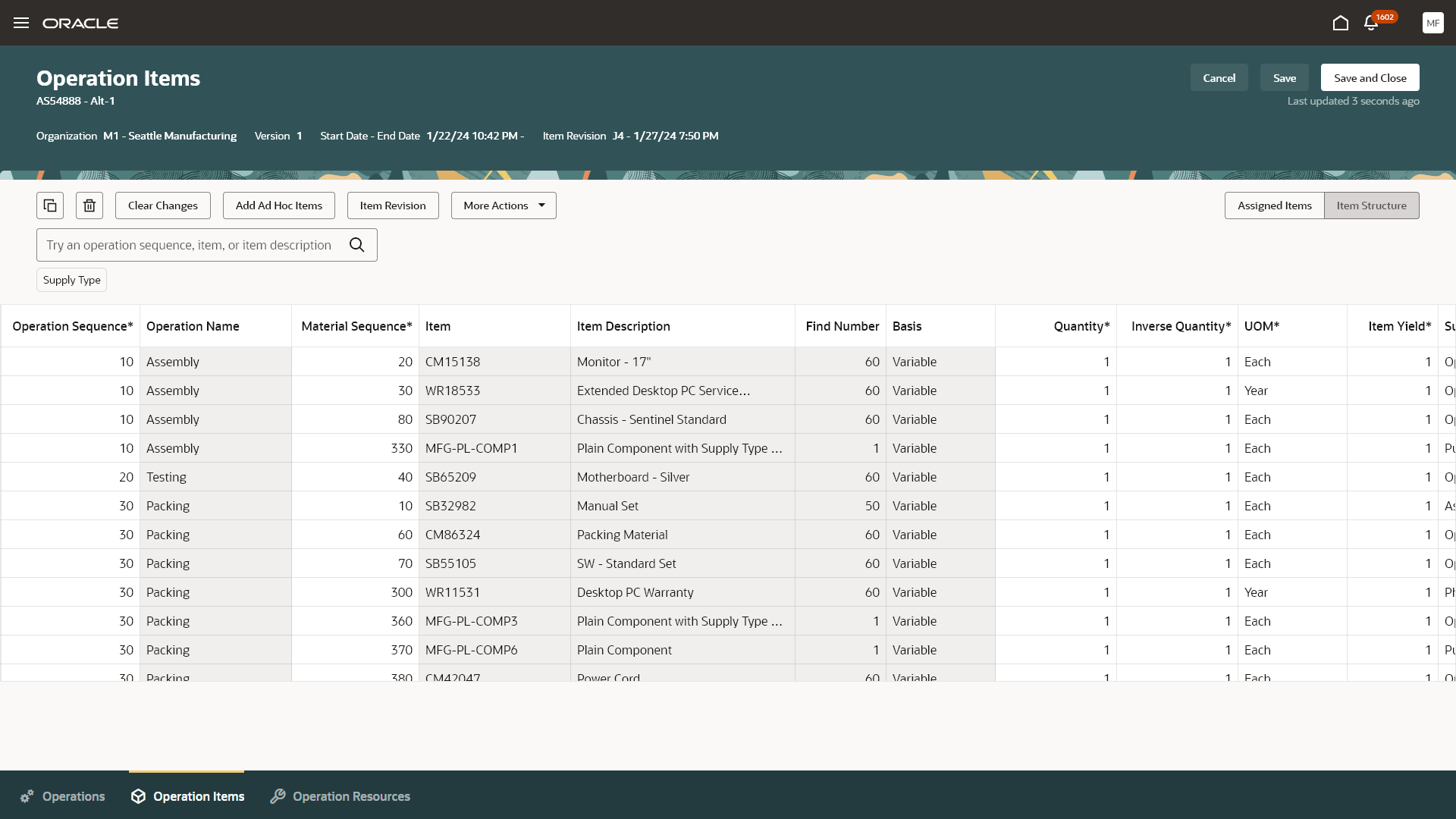

The Operation Items page displays the item structure components that are automatically assigned to work operations based on the suggested operation sequence defined in the item structure. The Assigned Items view in the Operation Items page displays the item structure components automatically assigned to work order operations, The Item Structure view in the Operation Items page displays the suggested operation sequence that's used as a basis to automatically assign item structure components. It also provides a means to identify mismatched operations and manually assign the components to the intended operation sequence.

Assigned Items View in the Operation Items Page

Item Structure View in the Operation Items Page

The automatic operation assignment of item structure components to work definition operations enables better synchronization in the design-to-manufacturing digital thread without manual intervention.

Steps to Enable

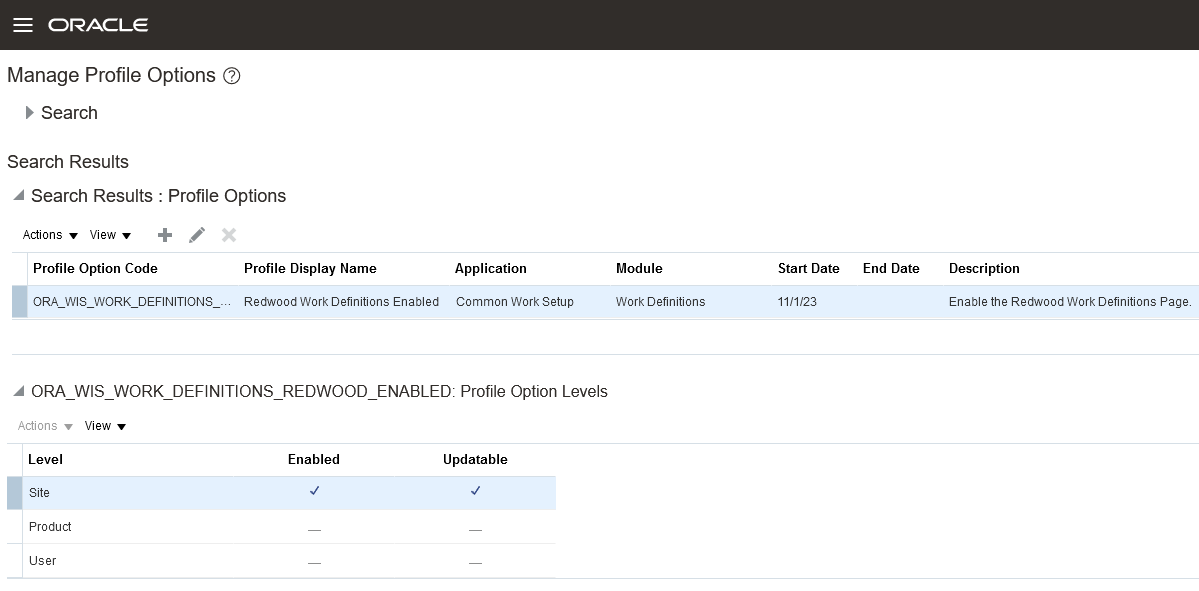

Follow these steps to enable or disable this feature:

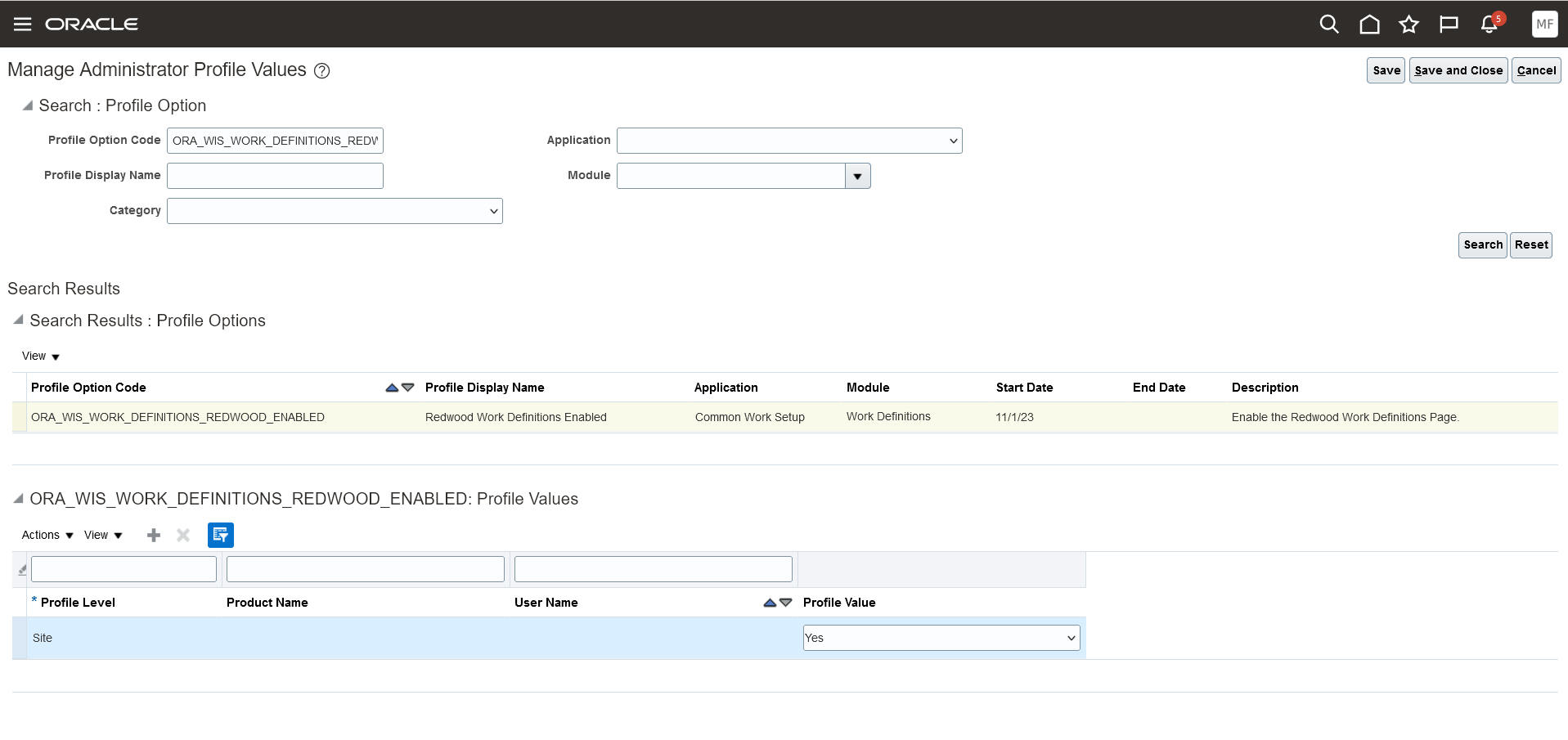

- In the Setup and Maintenance work area, search for and select the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_WIS_WORK_DEFINITION_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is N.

- Y = enables the feature

- N = disables the feature

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

You'll have the option to enable or disable this feature from 24B update.

Profile Option for Accessing Work Definitions Using Redwood Experience

Tips And Considerations

- You can leave the suggested operation sequence blank for an item structure component to disable the automatic assignment to a work definition operation.

- A best practice is to include a manufacturing engineer in the Change Order approval process to coordinate changes to the suggested operation sequence for item structure components.

- It's recommended to use a unique combination of suggested operation sequence and find number to distinguish duplicate component instances in an item structure. The alternative approach of splitting the item structure component quantity across multiple operations in the work definition doesn't support the following:

- Automatic synchronization of item structure changes to impacted work definitions through a scheduled process

- Automatic assignment of item structure components to work definition operations based on the suggested operation sequence

For more information, refer to the 24A features in Oracle Fusion Product Lifecycle Management and Oracle Fusion Manufacturing, respectively:

- You can't view the substitutes for item structure components that are automatically assigned to work definition operations at this time.

- You can't automatically assign item structure components when creating or copying manufacturing work definitions for standard items in the following scenarios:

- The existing work definition user interface

- Application Development Framework Desktop Integration (ADFdi)

- File Based Data Import (FBDI)

- REST API

- Electronic records and electronic signatures are enabled

- You can't automatically synchronize subsequent changes to the suggested operation sequence for item structure components to the impacted work definitions. It's a one-time automatic operation assignment when creating a manufacturing work definition or adding an item structure component. Instead, you will receive a notification for review and action.

Key Resources

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can use this feature:

- View Work Definitions (WIS_VIEW_WORK_DEFINITIONS_PRIV)

- Manage Work Definitions (WIS_MANAGE_WORK_DEFINITIONS_PRIV)

These privileges were available prior to this update.

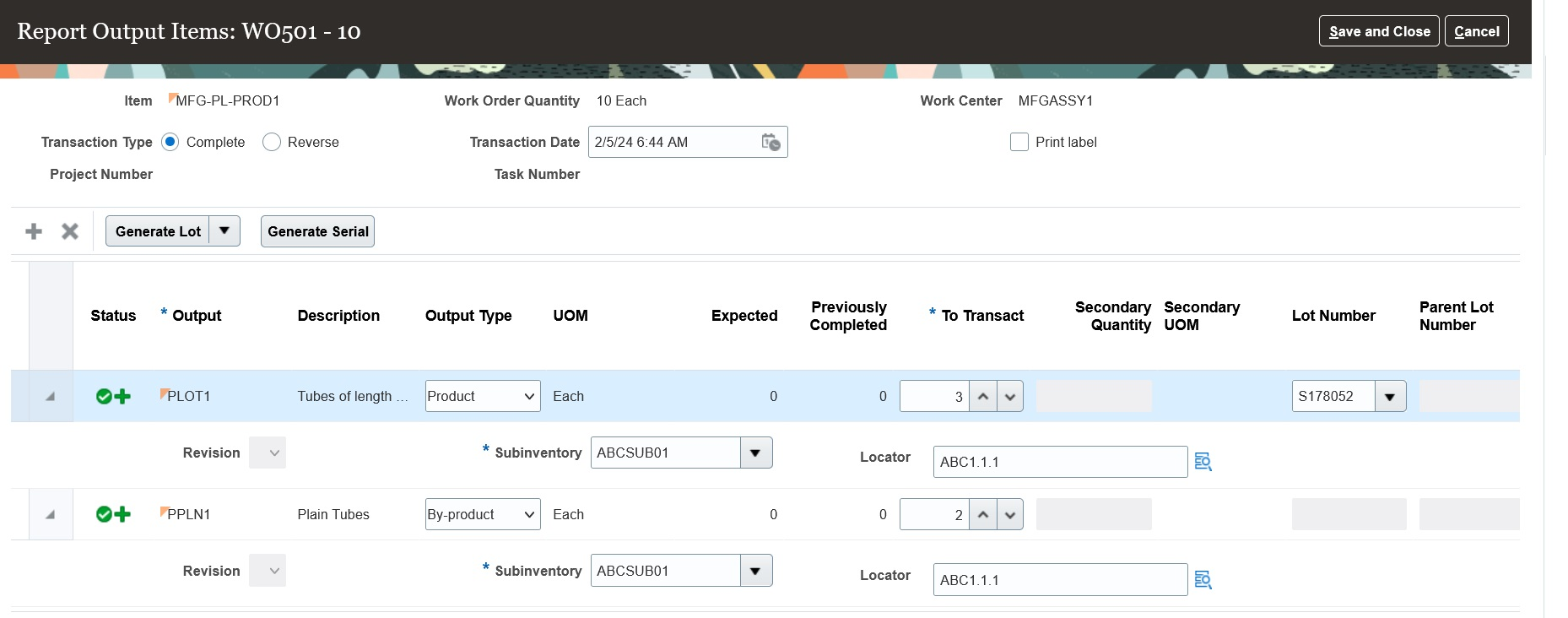

Report Ad hoc Outputs During Work Order Execution in Discrete Manufacturing

Discrete manufacturing processes sometimes involve production of more than one output at the end of an operation. For example, cutting multiple sheets of metal from a larger sheet, or capturing a by-product while making the main product which can be sold as a separate item. The completion of primary product and reporting of rejected quantity or disposal of scrap was allowed. However, for scenarios involving multiple outputs, these additional outputs need to be reported into inventory as supply, as reusable material for subsequent work orders or recoverable scrap sold as a separate item.

With this new update, you can now report additional co-products and by-products as ad hoc outputs during the execution of an operation, for standard, discrete manufacturing work orders. An ad hoc output can be reported as an output completion transaction into a specified completion subinventory from the Review Dispatch List page. You can use the output reverse transaction to correct the output completion transaction. This capability is also available through File-Based Data Import (FBDI), ADFdi data import correction, and REST web service. The ad hoc output completions will use a fixed cost that is set up in the Manage Standard Costs page. The primary product is reported along with the operation completion transaction at the last operation.

Reporting Ad Hoc Output at a Discrete Work Order Operation

File-Based Data Import (FBDI) Changes:

The FBDI Discrete Manufacturing Work Order Material Transactions Import, WorkOrderMaterialTransactionTemplate.xlsm, has been enhanced to enable reporting of ad hoc outputs in count point in-house operations for standard work orders. The Transaction Type Code column in Material Transaction Header worksheet will show two new values PRODUCT_COMPLETION and PRODUCT_RETURN for reporting output completions and output returns. Use the latest FBDI template after the 24B update.

You can reverse the reported outputs to correct any errors. The transactions reported through FBDI that failed validations can be corrected and resubmitted through ADFdi.

REST API Changes:

You can now report outputs for standard discrete manufacturing work order operations using the Work Order Material Transactions REST API.

Discrete manufacturers will achieve accurate recovery and valuation of scrap or any unplanned outputs, leading to maximum value realization from items produced.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 24D

Tips And Considerations

- Ad hoc negative component quantities can't be reported as outputs. For more information about negative material transactions, refer to the 23C feature Remove a Component During Discrete Manufacturing Work Execution.

- Ad hoc outputs are generally unplanned outputs and aren't considered in supply planning.

- Outputs can be optionally enabled as lot or serial-controlled to support product genealogy.

Key Resources

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Report Material Transactions (WIP_REPORT_MATERIAL_TRANSACTIONS_PRIV)

This privilege was available prior to this update.

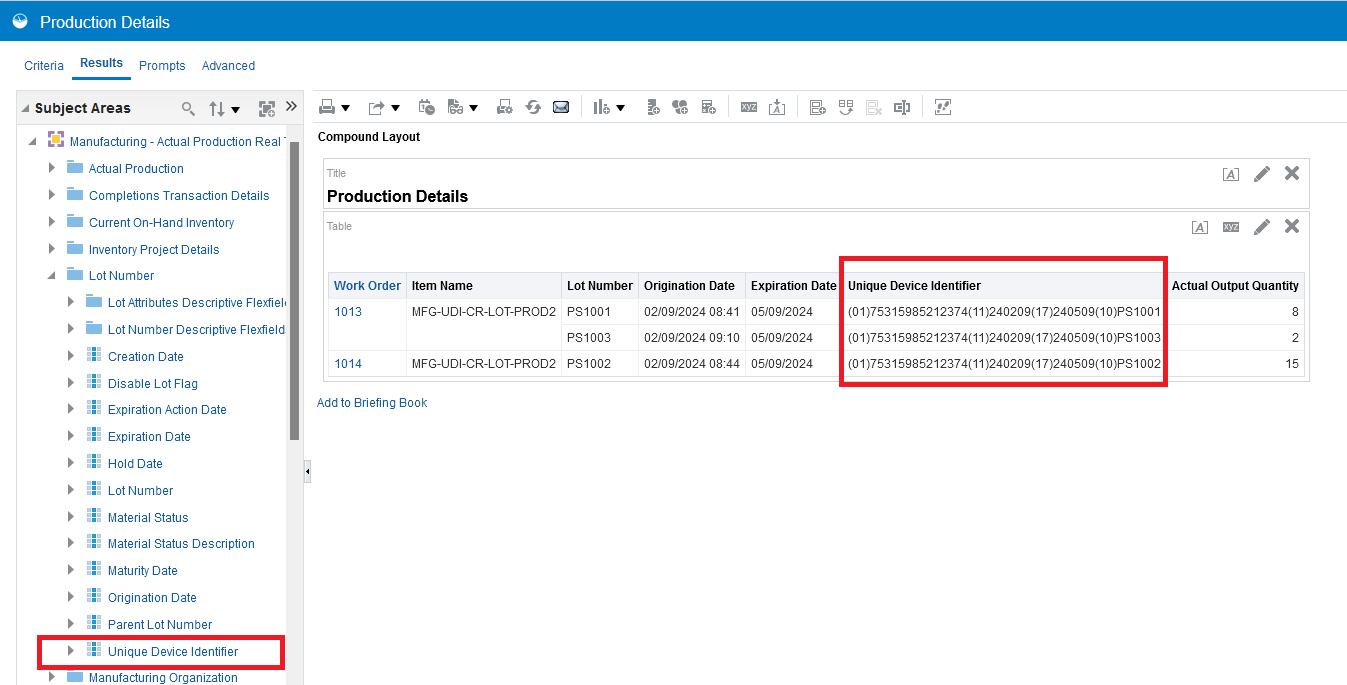

Create Manufacturing Work Order and Transaction Reports with a UDI Using OTBI

Oracle Transactional Business Intelligence (OTBI) lets you create reports using real-time transactional data from Oracle Fusion Cloud Manufacturing to analyze work orders and view transaction history. In this update, you can view the Unique Device Identifier (UDI) of a manufactured medical device that's assigned to or transacted in a work order (at product completion) by adding this new column to your manufacturing reports in OTBI. The UDI is a series of numeric or alphanumeric characters that's assigned to uniquely identify a medical device.

The Unique Device Identifier attribute has been included in both the Lot Number and Serial Number dimensions of the Manufacturing - Actual Production Real Time subject area to help you analyze production reported in manufacturing work orders.

Unique Device Identifier Attribute in the Manufacturing - Actual Production Real Time Subject Area

- Enhanced Traceability: The ability to view the UDI in manufacturing reports significantly improves product traceability. This is crucial in the medical device industry for tracking the lifecycle of a product from production to end user.

- Compliance with Regulations: By incorporating UDI in the reports, businesses can ensure compliance with global regulatory requirements, which often mandates the use of UDIs for medical devices.

- Decision Support: Access to detailed transactional data, including UDI, supports better decision-making by providing a holistic view of the manufacturing process and product lifecycle.

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

- More information about UDI is available in the 24A feature - Generate a Unique Device Identifier for Lot and Serial-Controlled Manufactured Products

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Manufacturing Execution Analysis Duty (FBI_MFG_EXECUTION_ANALYSIS_DUTY)

- BI Author Role (BIAuthor)

These privileges were available prior to this update.

Redwood Experience

These features were built in Redwood, Oracle’s next-generation user experience. Redwood brings state-of-the-art, consumer-grade user experiences across devices to the sophisticated enterprise scenarios that Oracle enables.

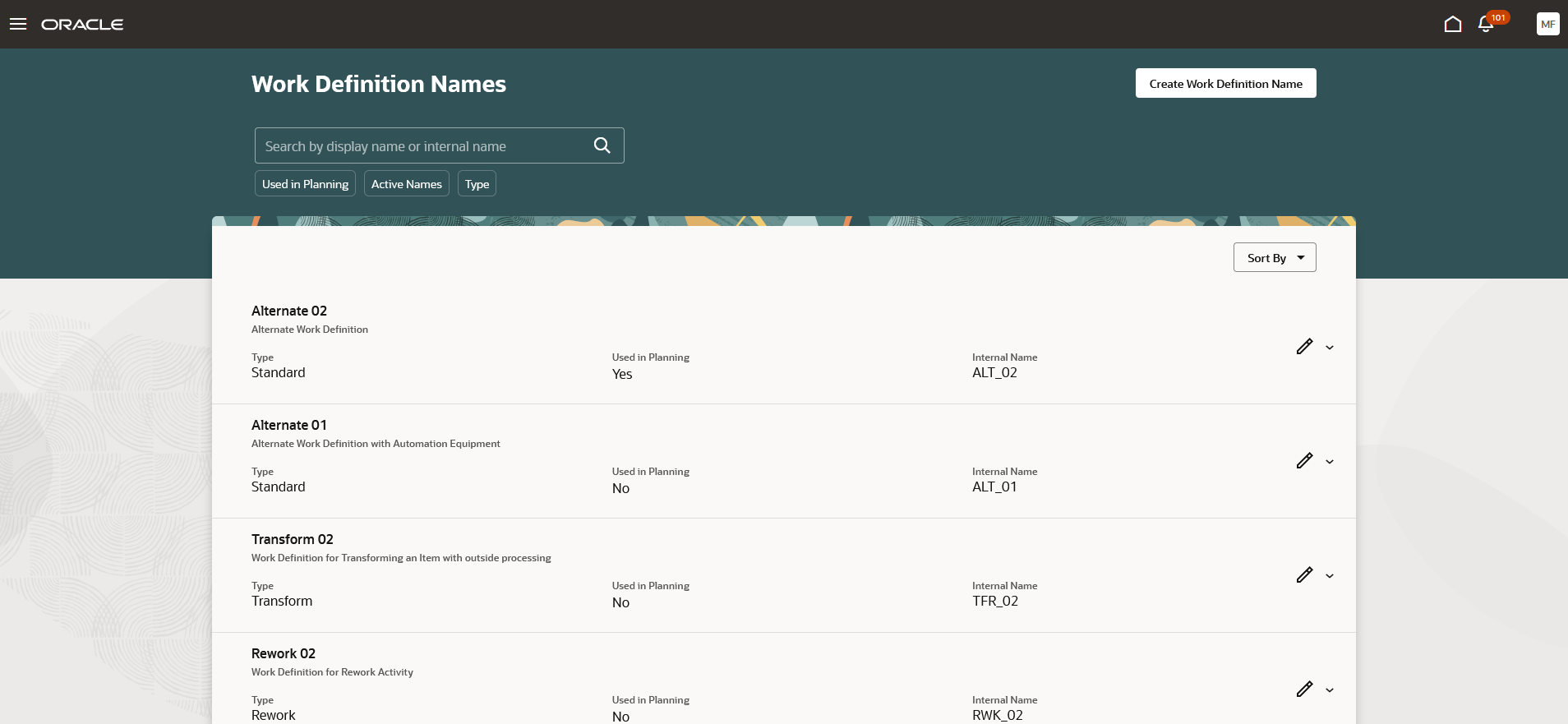

Search for, Create, and Edit Work Definition Names Using the Redwood User Experience

Work definition names identify the different ways of manufacturing an item, such as primary, alternate, transform, and rework. As part of the end-to-end flow for managing manufacturing work definitions, you can now search for, create, and edit a work definition name using a Redwood page.

- Faster search and filter work definition names – Use keywords and filters to quickly find a work definition name to review and edit

- Quickly create a work definition name – Enter the work definition name information on a single page

- Efficiently edit a work definition name – Update a work definition name or add the end date

The Manage Work Definition Names task now launches in the Redwood user experience. The Search page displays the work definition names. Here you can search by display name or internal name of a work definition name and filter to see active work definition names. You can use the Create Work Definition Name button to create a new work definition name. You can edit an existing work definition name by using the overflow actions menu.

Search and Filter Page for Work Definition Names

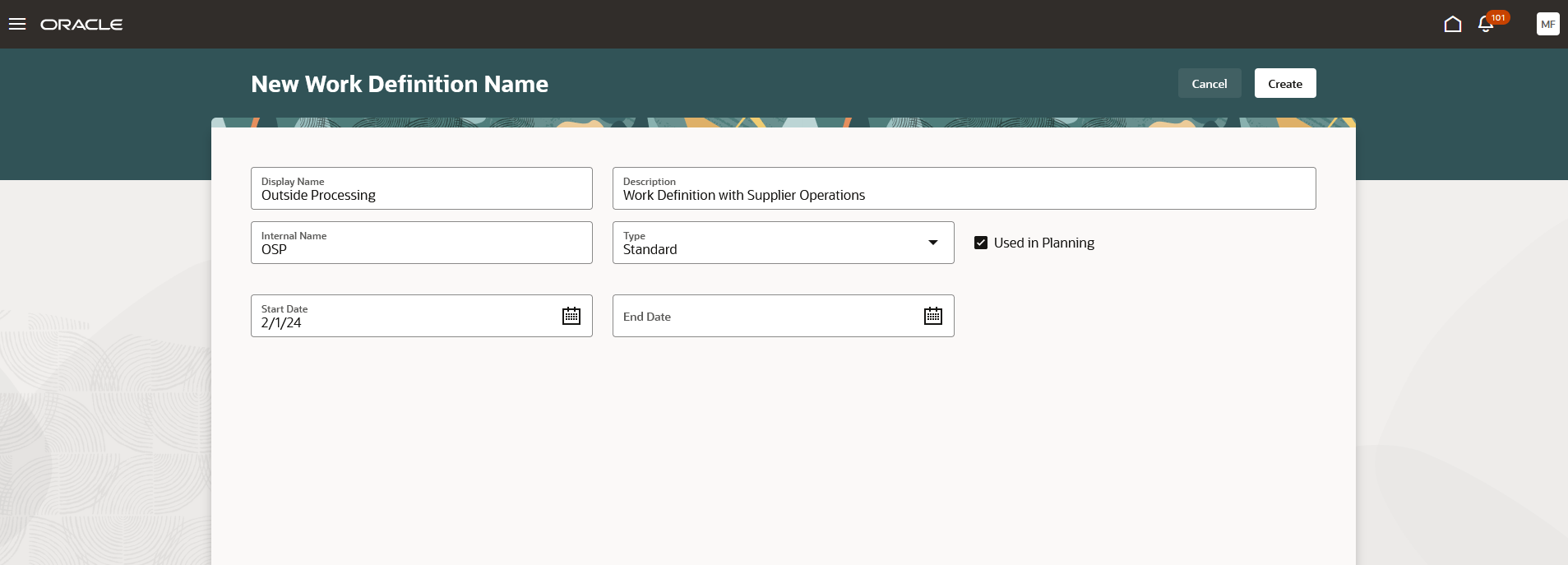

Create Work Definition Name Page

Using a Redwood page, the definition and maintenance of work definition names become streamlined tasks with a modern, responsive layout.

Steps to Enable

Follow these steps to enable or disable this feature:

- In the Setup and Maintenance work area, search for the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_WIS_WORK_DEFINITION_NAMES_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is Y.

- Y = enables the feature

- N = disables the feature

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

You'll have the option to enable or disable this feature from 24B update.

Profile Option for Accessing Work Definition Names in Redwood Experience

Tips And Considerations

- The Redwood user experience is enabled by default for searching, creating, and editing work definition names based on the Redwood Work Definition Names Enabled profile option.

- You can continue to use the Work Definition Names REST API to query for work definition names. You can't use this REST API to create or edit work definition names at this time.

Key Resources

- Watch the Search for, Create, and Edit Work Definition Names Using the Redwood User Experience Demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges to manage work definitions can access this feature:

- View Work Definitions privilege: WIS_VIEW_WORK_DEFINITIONS_PRIV

- Manage Work Definitions privilege: WIS_MANAGE_WORK_DEFINITIONS_PRIV

These privileges were available prior to this update.

Search for, Create, and Edit a Standard Item Work Definition Using the Redwood User Experience

Prior to this update, the Work Definition pages focused on visualizing the data relationships within a work definition, displaying a limited view of the dataset and utilizing mouse-driven navigation and techniques like drag and drop, or expand and collapse. However, for work definitions with extensive data, particularly in their item structures, manufacturing engineers prefer spreadsheet interfaces for quick editing and better information density.

Now, you can efficiently create and update a work definition for a standard item in discrete and process manufacturing using the Redwood user experience.

- Faster search and filter work definitions – Use keywords and filters to quickly find an item's work definition to review and manage

- Efficiently manage work definitions – Take actions like copy, delete, deactivate, and reactivate on a work definition. Manage versions and edit priorities in change management scenarios.

- Create a work definition for a standard item in fewer steps – Enter the product information with an optional reference to its item structure and default a placeholder operation as a starting point.

- Edit work definition's operations, operation outputs, operation items, and operation resources using a grid experience:

- Provides spreadsheet-like interfaces and allows to enter, access, or edit large volumes of data with high efficiency.

- Navigate through the data relationships in a work definition using tabs and grids

- Add, copy, or delete rows in the grid

- Search for specific data in the grid to narrow down the dataset

- Enter data using keyboard shortcuts or mouse-driven interactions including cut, copy, paste, and autofill

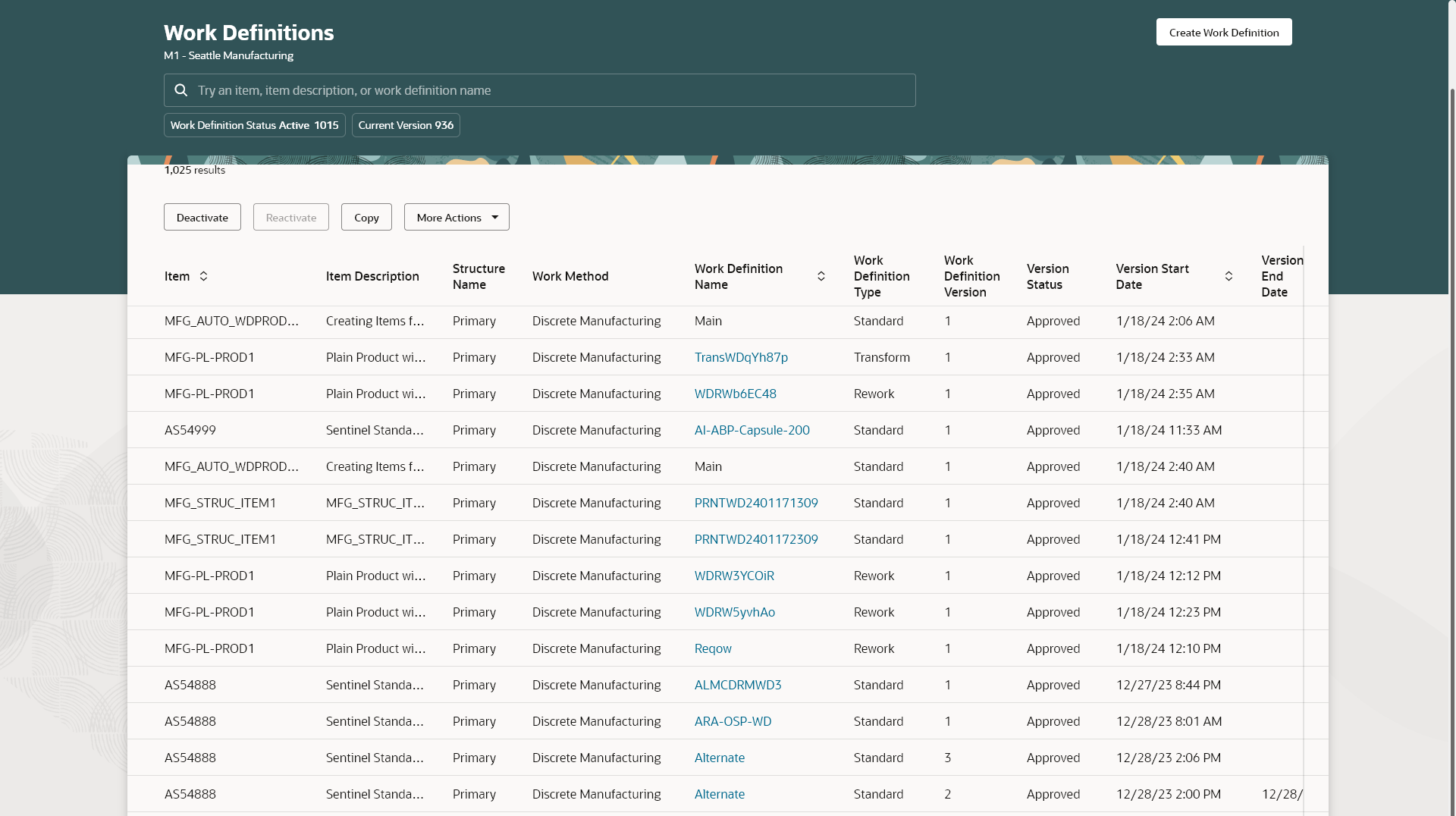

Manage Work Definitions Page

During Work Definition creation, the placeholder operation gets added and it can be overwritten or deleted as you add operations in the Operations page. You can enable guided journeys in Work Definition user experiences and users can see a Guide Me button in the task. You can provide resources and guidance such as instructions, videos, and best practices and so on to help user to perform the task.

Work Definition Operations with Guide Me Button Enabled

You can toggle between the Assigned Items and Item Structure views in the Operation Items page to review the already assigned and unassigned items.

Work Definition Operation Items on the Assigned Items View

Using the Redwood user experience, you can significantly reduce the time to launch a new or updated work definition through user productivity gains, such as easier readability, editing in a tabular format, and faster user interface performance for searching, sorting, and saving.

Steps to Enable

Follow these steps to enable or disable this feature:

1. Enable the Profile

- In the Setup and Maintenance work area, search for and select the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_WIS_WORK_DEFINITIONS_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is N.

- Y = enables the feature

- N = disables the feature

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

You'll have the option to enable or disable this feature from 24B update.

Profile Option for Accessing Work Definition Using Redwood User Experience

2. The Manage Work Definitions page in the Redwood user experience is based on an elastic index. Run the following scheduled processes, when the work definitions are created using Import Work Definition Scheduled Process or using REST API to populate the details in the Manage Work Definitions page in the Redwood user experience.

(Navigation: Tools > Scheduled Processes > Schedule New Process)

- Scheduled process 'ESS job to create index definition and perform initial ingest to OSCS' should be run one time initially. Input parameter Index name should be set as fa-scm-wis-work-definitions.

- Scheduled process 'ESS job to run Bulk ingest to OSCS' should be run periodically with input parameter Program Name as MFG_WD_BULK_INGEST.

Tips And Considerations

- The Redwood user experience can be enabled by default for searching, creating, and editing work definitions when using the Manage Work Definitions task in the Work Definition work area. This default is based on the Redwood Work Definitions Enabled profile option.

- You can continue to use the existing work definition REST services, then view or edit a work definition using a Redwood page based on the user privileges.

- You can also enable automatic assignment of item structure components to work definition operations based on the suggested operation sequence in the item structure at the time of creating a work definition or later adding a component in the item structure. Subsequent updates to the suggested operation sequence in the item structure aren't automated to existing work definitions. Refer to the Automatically Assign Item Structure Components to Work Definition Operations feature for more information.

- You can't search for, create, or update manufacturing work definitions for Assemble To Order model items using the Redwood user experience at this time.

- You can't navigate to the Redwood user experience when selecting the link for impacted work definitions in the item structure change notification at this time.

- You can't use the quick action or the Recently Updated Work Definitions link to navigate to the Redwood user experience for a work definition at this time.

- You can't generate an electronic record and sign off a work definition with electronic signature using the Redwood user experience at this time.

- You can't restrict the data security access to work definitions using the Redwood user experience at this time.

Key Resources

- Watch the Search for, Create, and Edit a Standard Item Work Definition Using the Redwood User Experience

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges and codes can access this feature:

Manufacturing Privileges :

- Manage Work Definitions (WIS_MANAGE_WORK_DEFINITIONS_PRIV)

- View Work Definitions (WIS_VIEW_WORK_DEFINITIONS_PRIV)

- Get Work Definitions by Service (WIS_GET_WORK_DEFINITIONS_SERVICE_PRIV)

- Manage Work Definitions by Service (WIS_MANAGE_WORK_DEFINITIONS_SERVICE_PRIV)

- Get Manufacturing Plant Set Up Data by Service (WIS_GET_MFG_PLANT_SETUP_SERVICE_PRIV)

- Get Standard Operations by Service (WIS_GET_STANDARD_OPERATIONS_SERVICE_PRIV)

Other than Manufacturing Privileges :

- View Subinventory and Locator List of Values by Web Service (INV_VIEW_SUBINVENTORY_LOCATOR_LOV_WEB_SERVICE)

- View Inventory Organizations List of Values by Web Service (RCS_VIEW_INV_ORG_LOV_WEB_SERVICE_PRIV)

- View Units Of Measure List of Values by Web Service (RCS_VIEW_UNITS_OF_MEASURE_LOV_WEB_SERVICE_PRIV)

- Get Item Rest (EGP_GET_ITEM_REST)

- Create Item Structure (EGP_CREATE_ITEM_STRUCTURE_PRIV)

- Use REST Service - Talent Model Profiles Read Only (HRT_REST_SERVICE_ACCESS_TALENT_MODEL_PROFILES_RO_PRIV)

- View Qualification Profiles (MNT_VIEW_QUALIFICATION_PROFILES_PRIV)

- View Supplier List of Values Using REST Service (POZ_VIEW_SUPPLIER_LOV_REST_SERVICE_PRIV)

- Manage Subinventory and Locator (INV_MANAGE_SUBINVENTORY_AND_LOCATOR_PRIV)

- View Unit Of Measure Conversion List of Values by Web Service (RCS_VIEW_UNITS_OF_MEASURE_CONVERSION_LOV_WEB_SERVICE_PRIV)

Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These privileges were available prior to this update.

Search for, Create, and Edit Work Areas Using the Redwood User Experience

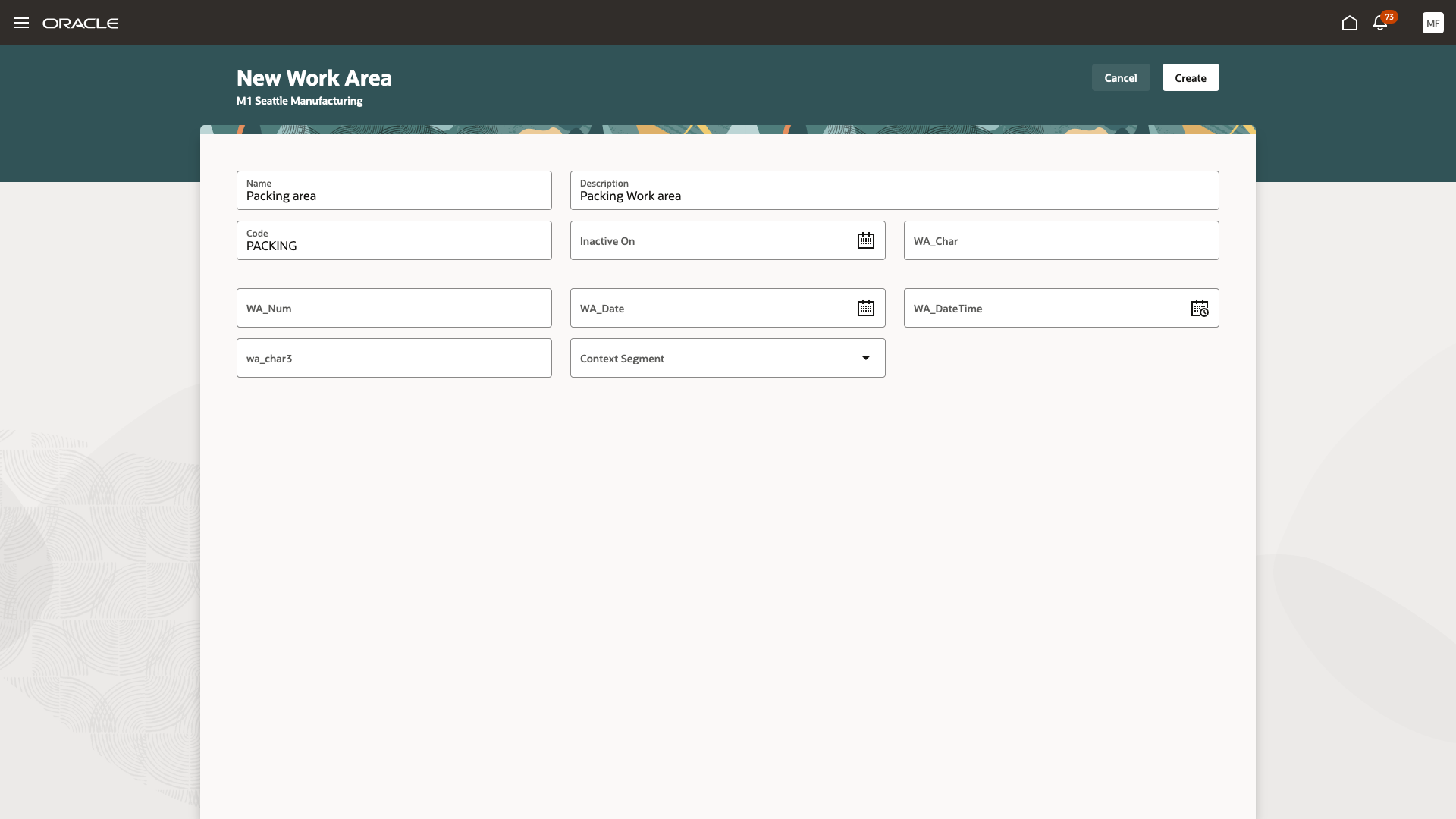

Work areas model specific regions in the manufacturing plant, where you perform work for manufacturing or maintenance activities. Now you can create and edit work areas in a manufacturing plant using a redwood page.

- Faster search and filter work area – Use keywords and filters to quickly find a work area to review and edit

- Quickly create a work area – Enter the work area information on a single page

- Efficiently edit a work area – Update a work area

The Manage Work Areas task now launches with Redwood user experience. The page displays the work areas for a given organization. Here you can search by work area name or code and filter to see active work areas. You can use the Create Work Area button to create a new work area. You can edit an existing work area by using the overflow actions menu.

Search and Filter Page for Work Areas Using Redwood User Experience

Create Work Areas Using Redwood User Experience

Using a Redwood page, the definition and maintenance of work areas become streamlined tasks with a modern, responsive layout.

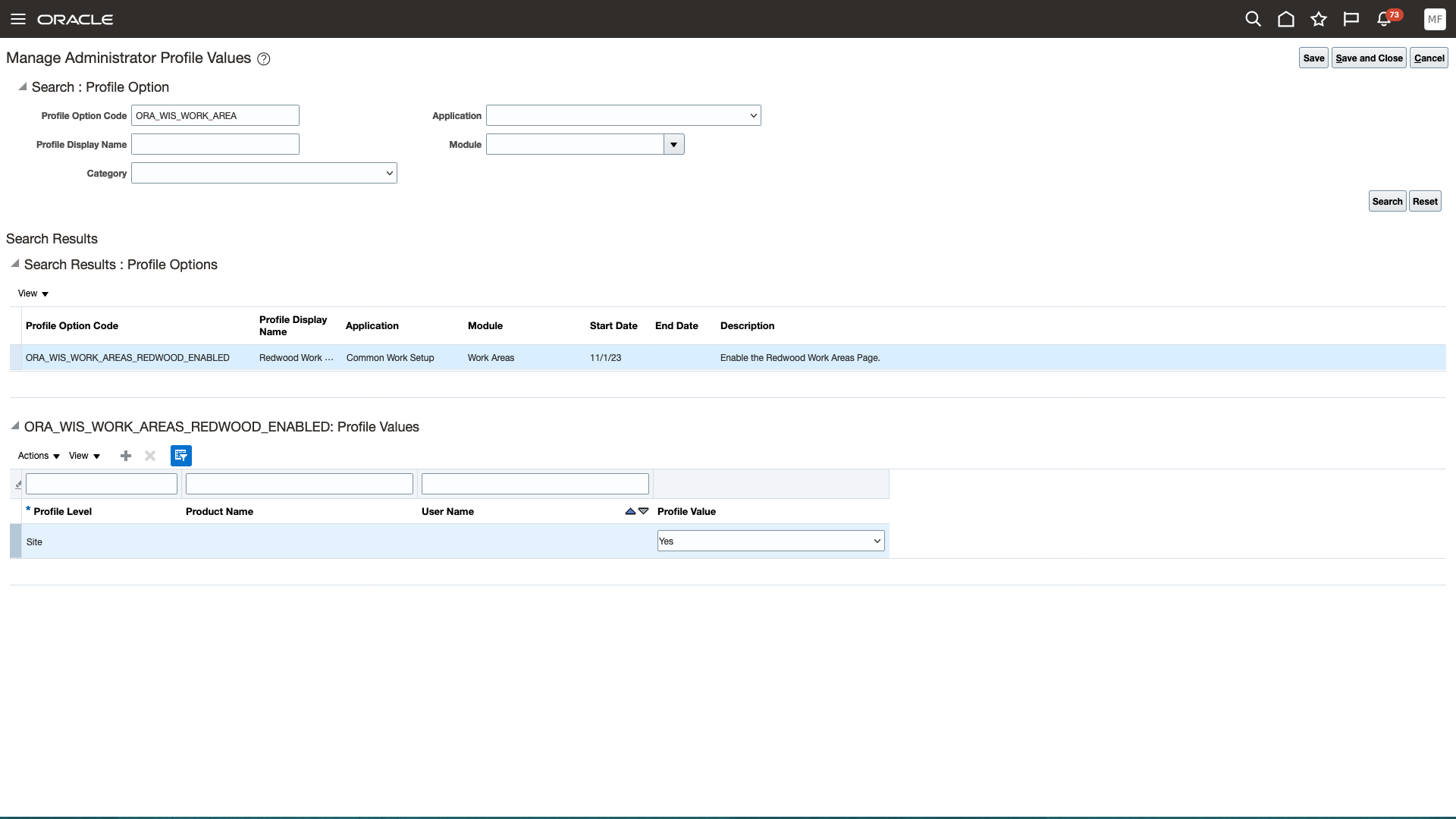

Steps to Enable

Follow these steps to enable or disable this feature:

- In the Setup and Maintenance work area, search for and select the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_WIS_WORK_AREAS_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is Y.

- Y = enables the feature

- N = disables the feature

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

You'll have the option to enable or disable this feature from 24B update.

Profile Option for Accessing Work Areas Using Redwood User Experience

Tips And Considerations

- The Redwood user experience is enabled by default for searching, creating, and editing work areas when using the Manage Work Areas task in the Work Definition work area based on the Redwood Work Areas Enabled profile option.

- You can't access the redwood page when using the Manage Work Areas task via the Setup and Maintenance area.

Key Resources

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can use this feature:

- View Work Areas (WIS_VIEW_WORK_AREAS_PRIV)

- Manage Work Areas (WIS_MANAGE_WORK_AREAS_PRIV)

These privileges were available prior to this update.