Smart Operations

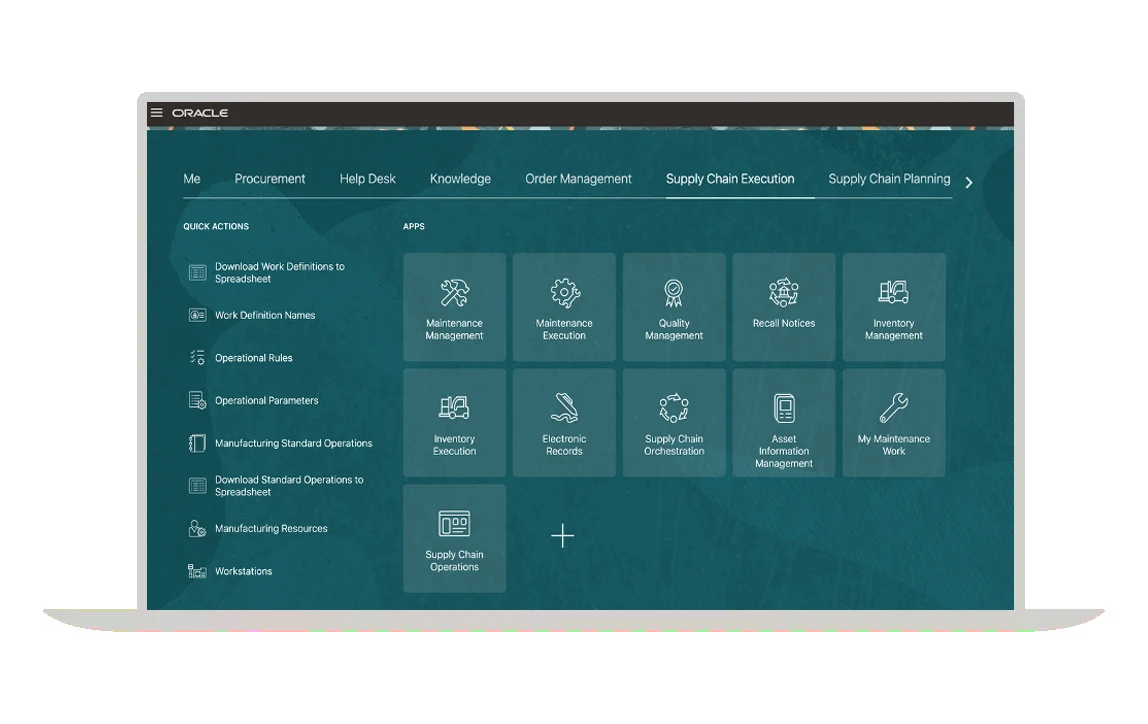

Smart Operations seamlessly connects the enterprise with the factory floor, automating end-to-end processes from inventory to manufacturing, maintenance, and quality.

Drive Smart Operations with AI

Drive Smart Operations with AI

Discover how AI in Oracle Fusion Supply Chain Execution can help optimize operations and facilitate the disruption-free factory.

5 Reasons Why Advanced Inventory Is Right for Your Warehouse

5 Reasons Why Advanced Inventory Is Right for Your Warehouse

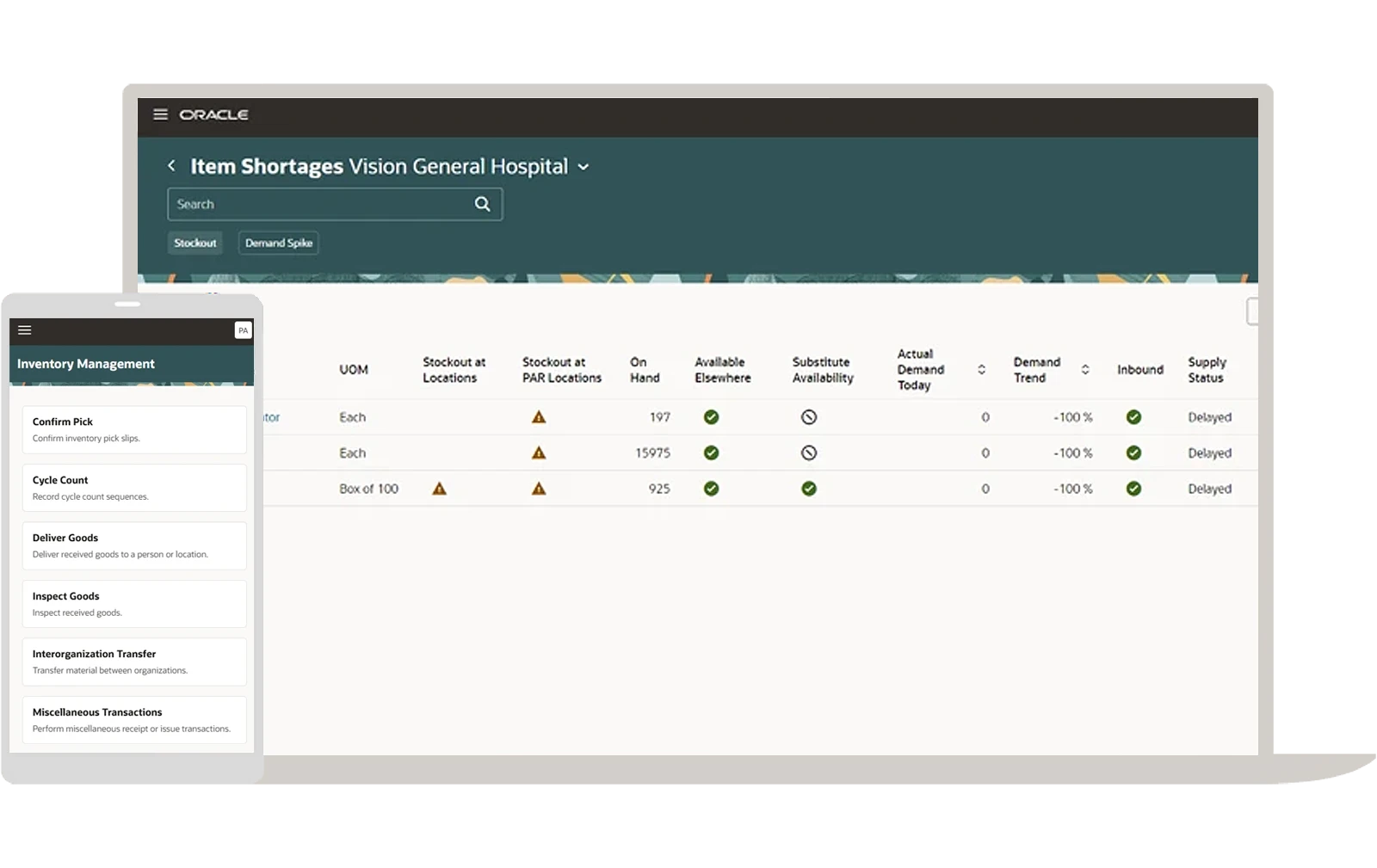

Oracle Fusion Cloud Advanced Inventory extends the capabilities of Oracle Inventory Management to support mid-tier, low-complexity warehousing operations

Smart Operations featured products

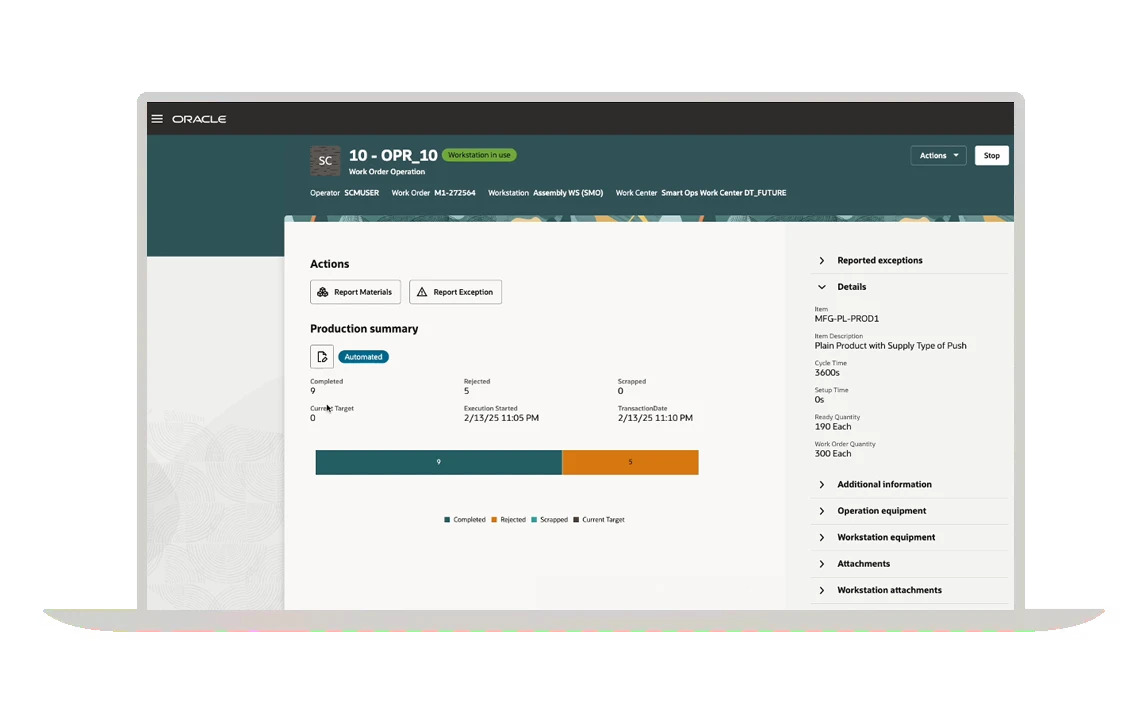

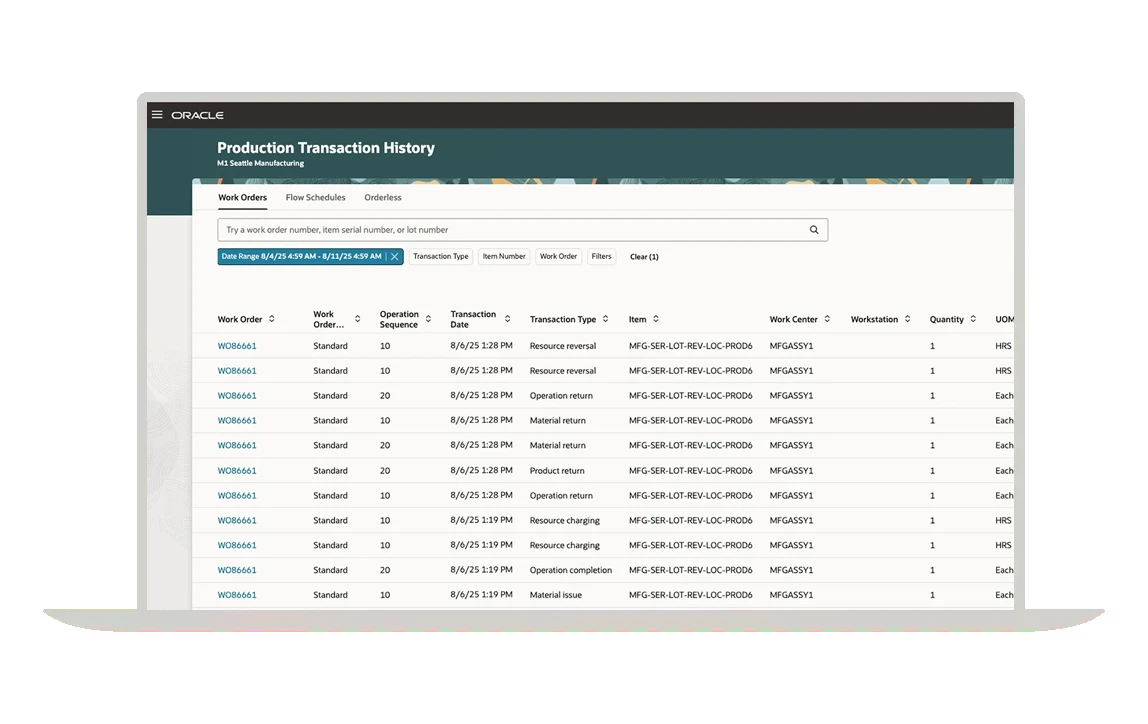

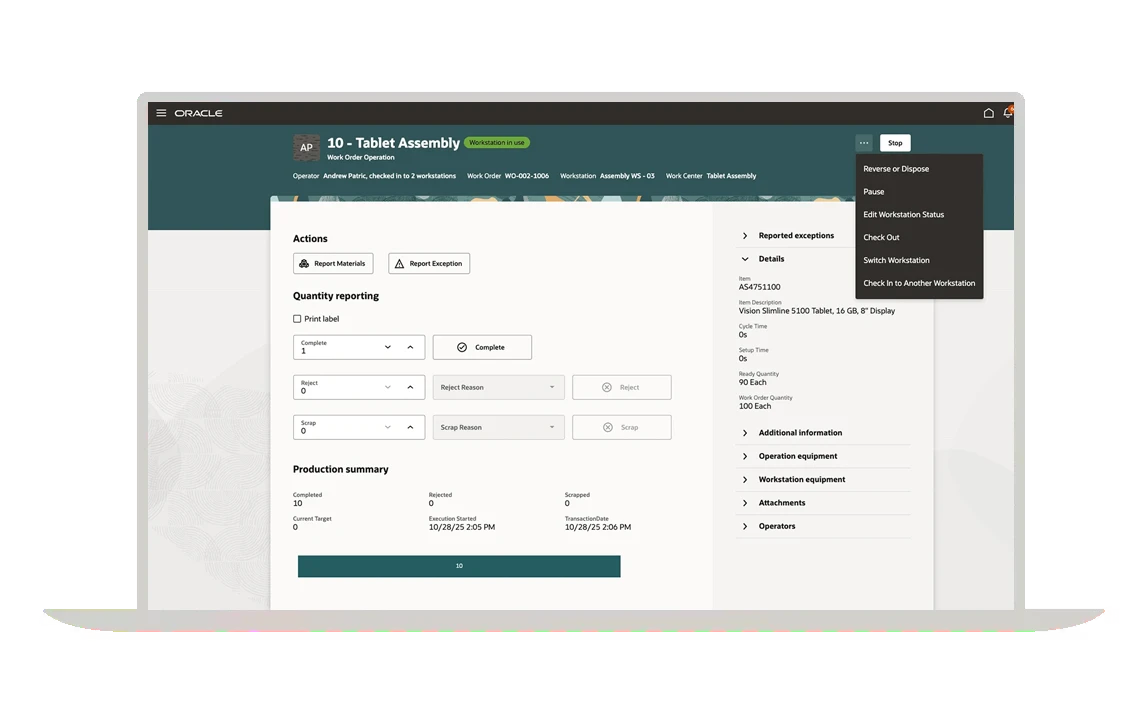

Oracle Fusion Cloud Manufacturing

Streamline your global, mixed-mode manufacturing to make anything, anywhere, with an intelligent, optimized, and integrated solution powered by IoT and AI.

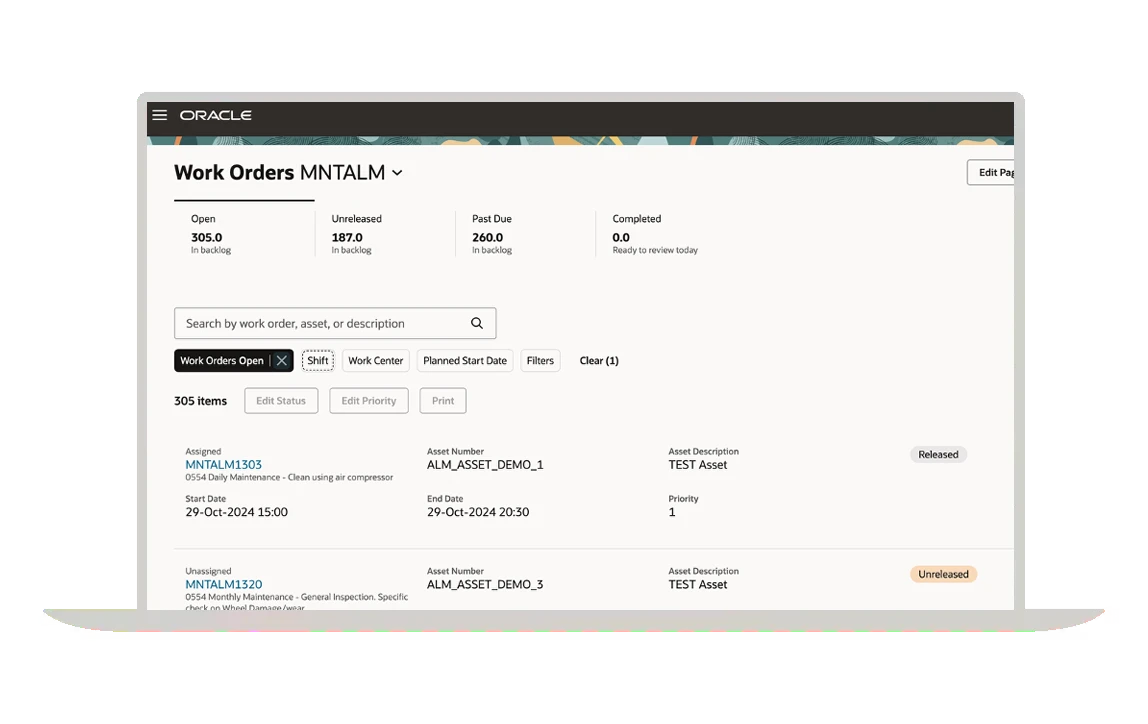

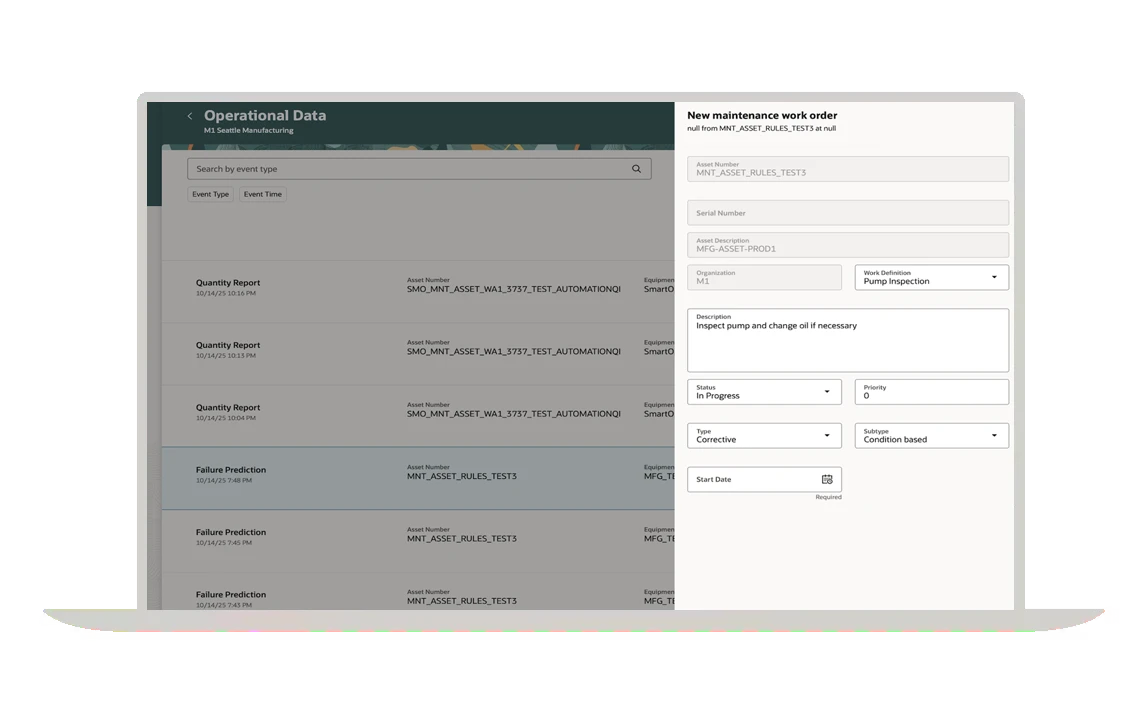

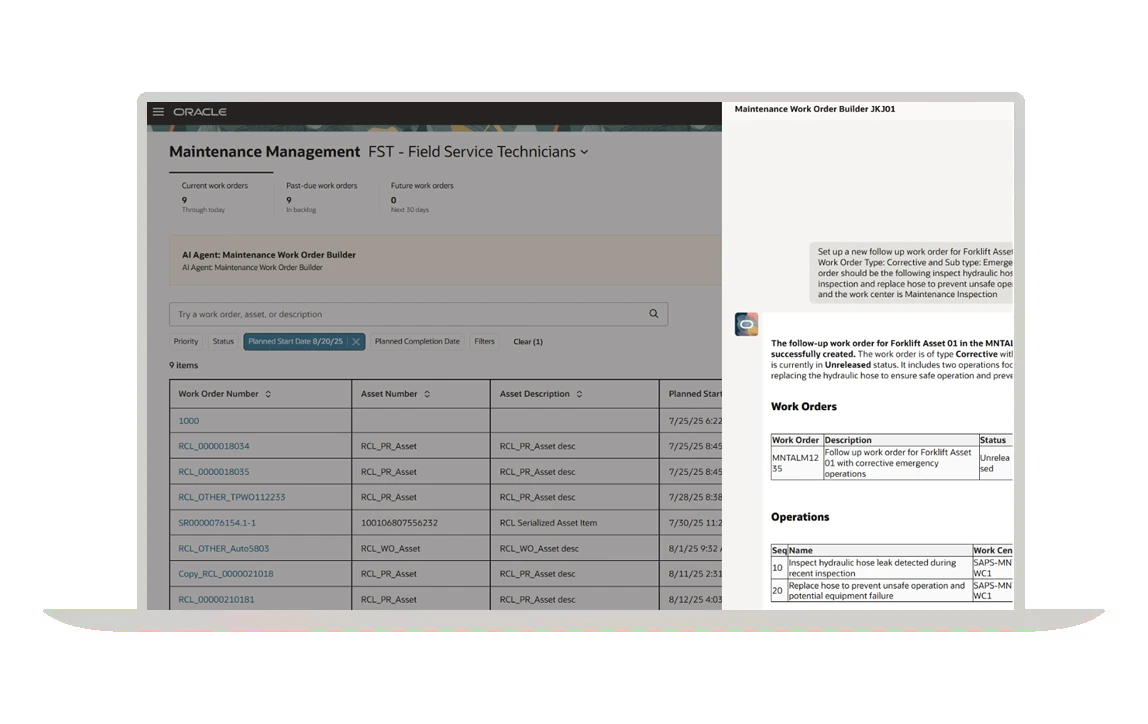

Oracle Fusion Cloud Maintenance

Transform your maintenance processes with an integrated and intelligent enterprise asset management system that’s written for the cloud and designed for the Internet of Things environment. Use Industry 4.0 capabilities and predictive analytics to predict asset failure, estimate reliable lifespan, and trigger prescriptive workflows to take preemptive action.

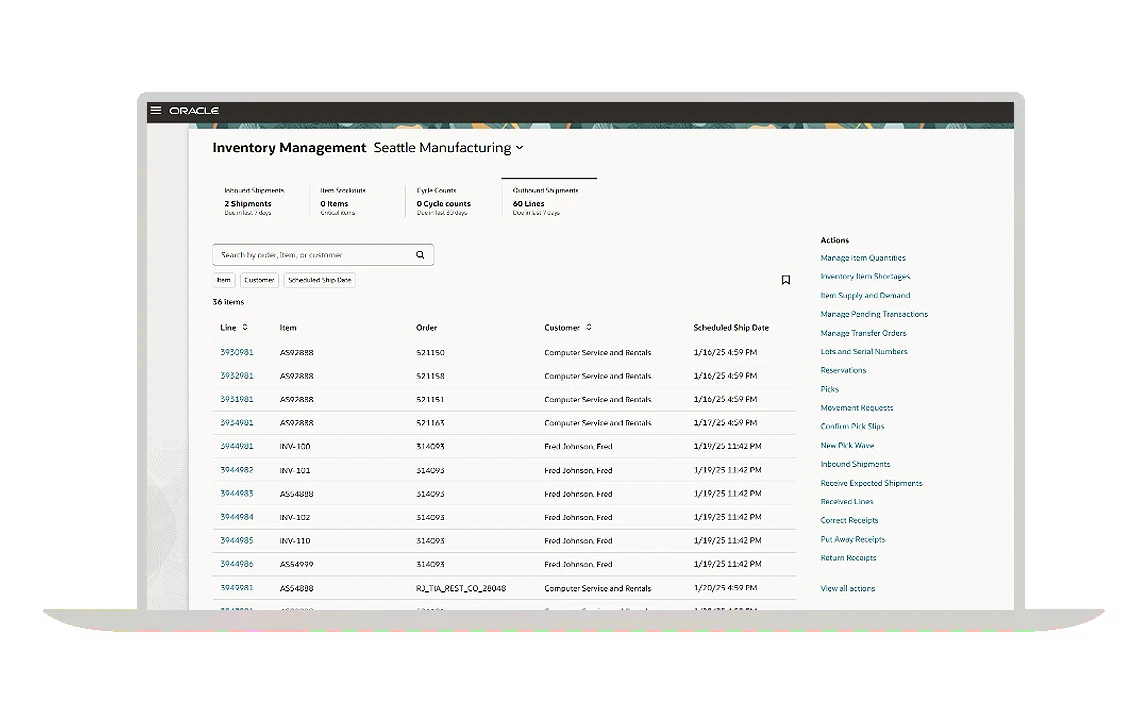

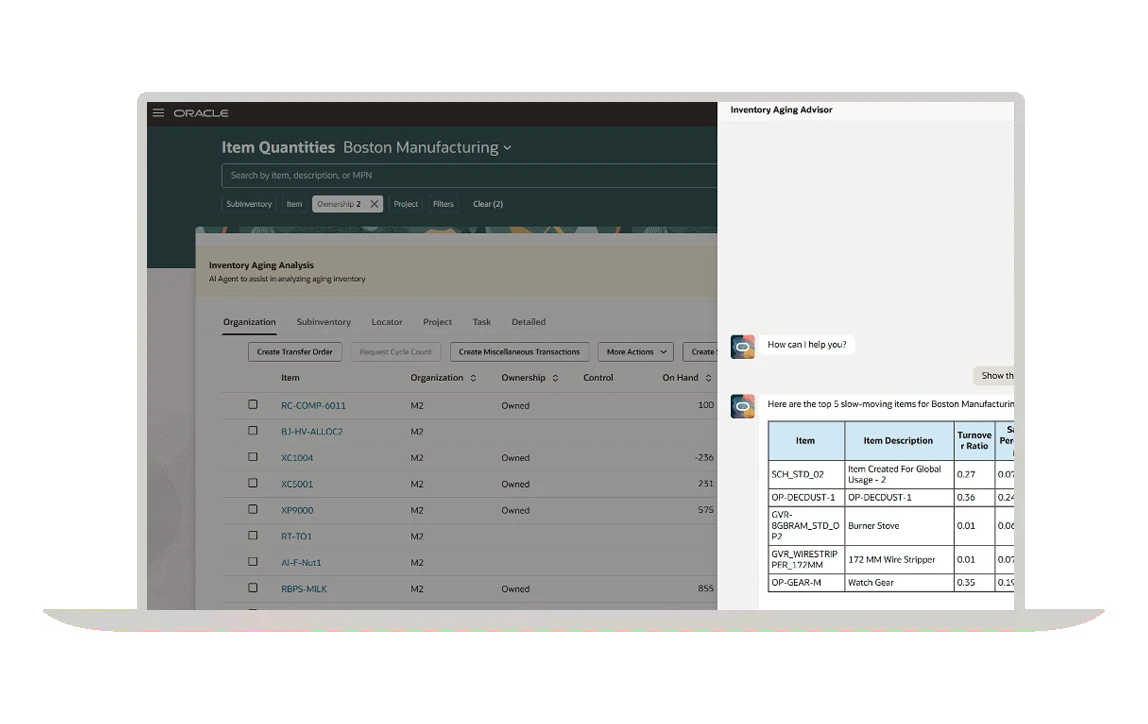

Oracle Fusion Cloud Inventory Management

Gain full visibility into and control of the flow of goods across your company and global supply networks to improve customer satisfaction, decrease costs, and optimize service levels and working capital investment.

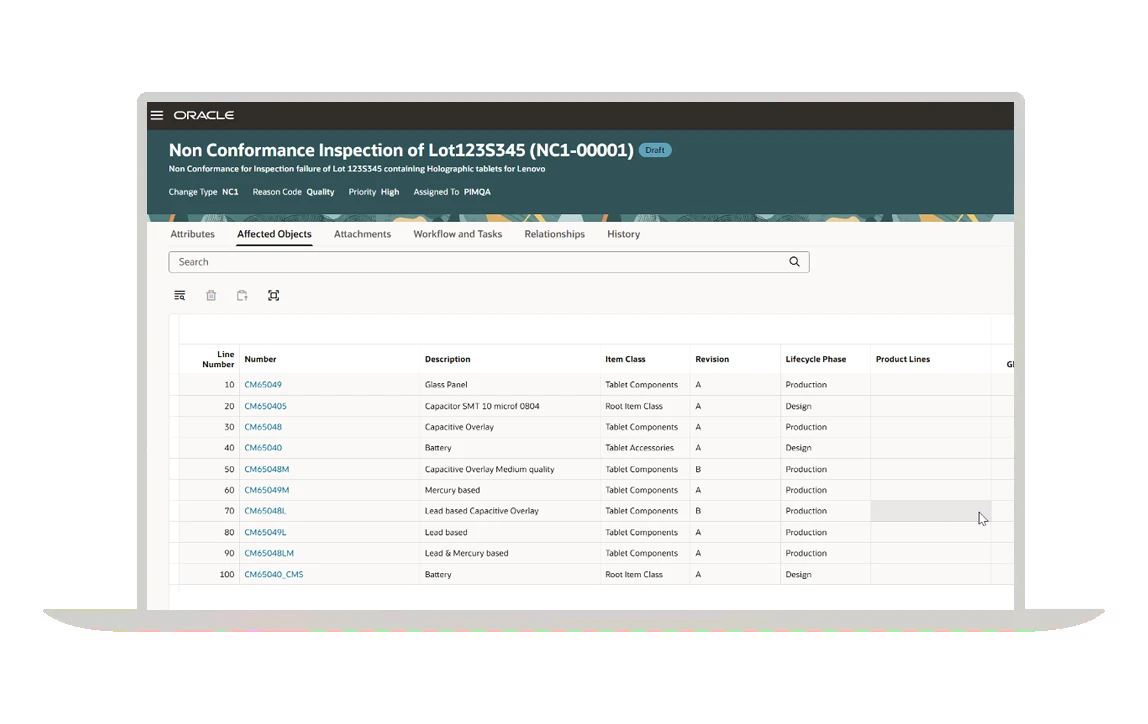

Oracle Fusion Cloud Quality Management

Drive closed-loop quality processes through design, procurement, inventory, manufacturing, and field service to ensure rapid detection and resolution of quality events. Make faster, more informed decisions and reduce risk with a predictive and connected 360-degree view of product quality across product lifecycle and supply chain processes.

Smart Operations key benefits

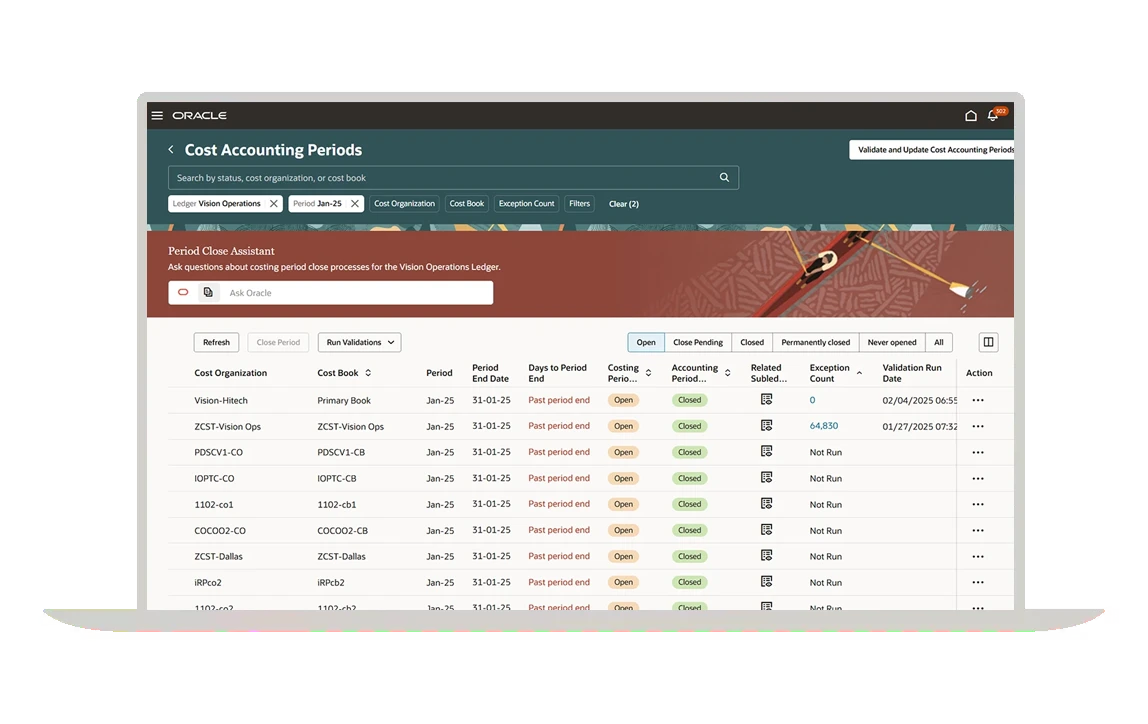

Improve visibility into costs, efficiency, and quality across factories

Use powerful solutions for collecting operational data in real time, gleaning insights from the data, communicating rapidly, and making holistic and collaborative decisions.

Monitor production performance and predict maintenance failure

Monitor factory efficiency to detect any unusual production behavior using predictive analytics on multiple sources of data. Provide a machine-monitoring platform to detect and predict unusual equipment behaviors and recommend the next best action to fix anticipated failures.

Make better, faster decisions with AI

Leverage machine learning to identify hidden root causes for quality, yield, and other operational issues. Use deeper insights with your experts to make faster decisions and eliminate bottlenecks in production.

Monitor quality and apply best practices training

Use quality monitoring all along the production cycle to detect quality deviations and generate predictive alerts. Run an immediate root cause analysis to identify the sources of a quality issue. Set up best practices training using real data from past quality issues.

Product Tour—Oracle Fusion Supply Chain Execution

Transform operations with Oracle Fusion Supply Chain Execution

Learn about the revolution that's changing manufacturing.

Get started with Smart Operations

Smart Operations demo

Take a walkthrough with one of our experts.

Supply Chain and Manufacturing tours

Explore the suite on your own.

Contact SCM sales

Talk to a team member about Oracle Cloud Manufacturing.

Smart Operations Explained

Smart Operations Explained