Oracle Manufacturing

Is your manufacturing application improving your production efficiency and quality while reducing costs? Oracle Fusion Cloud Manufacturing helps you streamline your global, mixed-mode manufacturing to maximize operational performance, with an intelligent, connected, and automated Smart Operations solution powered by artificial intelligence.

Watch our on-demand webinar for an overview of Oracle Smart Operations. See how an AI-driven approach can help boost efficiency across manufacturing, maintenance, and inventory management.

Adopt manufacturing practices with AI-powered applications and prebuilt analytics to help increase business agility, operational efficiency, and sustainability.

Explore Oracle Cloud Manufacturing

Discrete manufacturing

Master Data management

Visually define your production process. Streamline your entire production cycle and manage operations more efficiently.

Lean work execution

Leverage best-in-class capability for efficient shop floor execution. Digitally transform your factory.

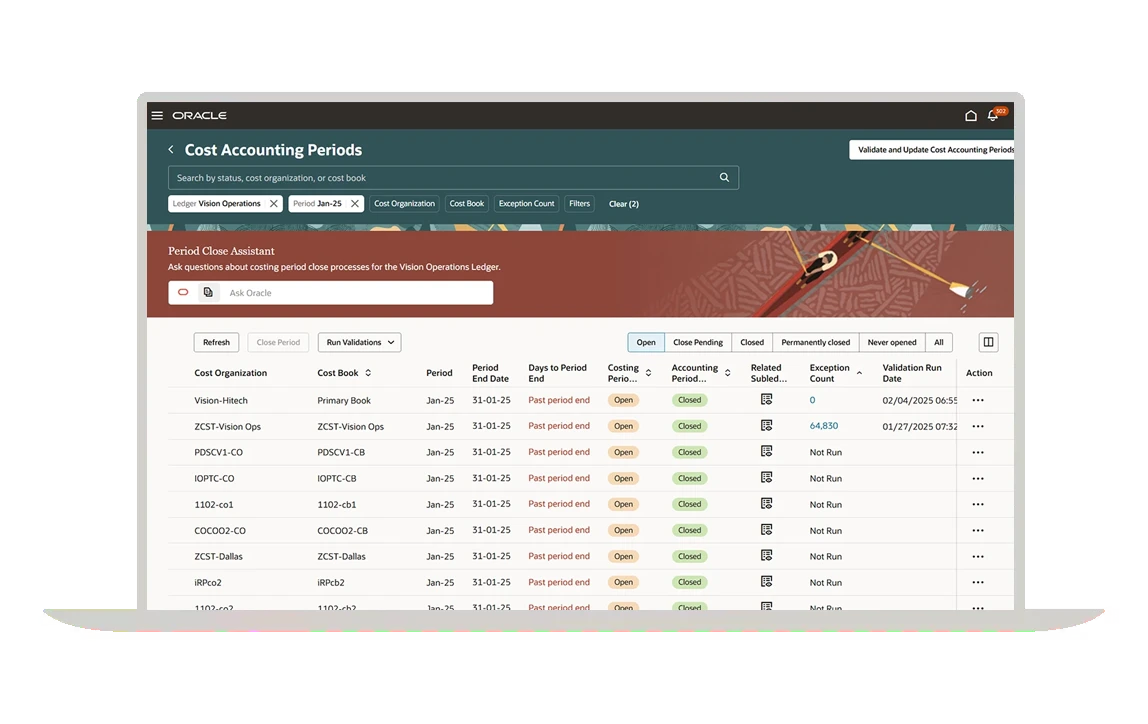

Cost management

Effectively monitor manufacturing costs and variances by plant and determine root causes for cost variances.

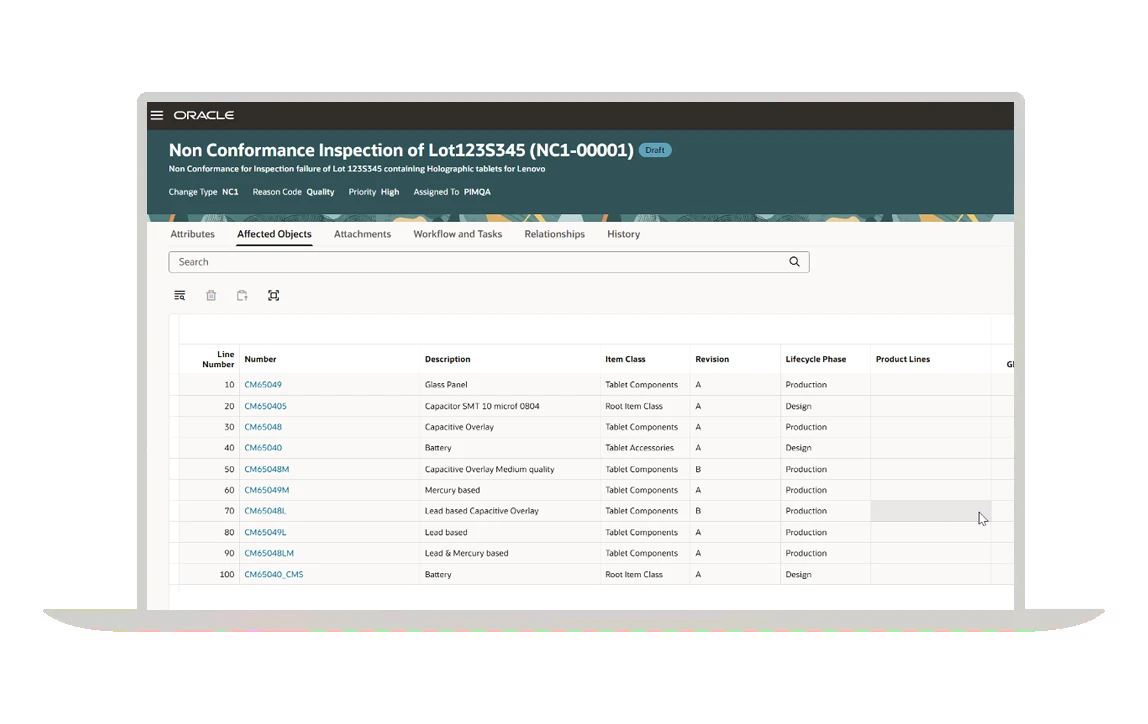

Closed-loop enterprise quality

Capture and analyze quality data. Predict potential issues and take corrective actions throughout the manufacturing lifecycle.

Genealogy and compliance

Capture genealogy for track and trace of lot and serialized products to maintain compliance with local regulations.

Configured products

Manufacture customer-configured products with complete integration from order-to-cash.

Process manufacturing

Recipe management

Streamline your production process. Visually define recipes to make a batch with co-products and by-products.

Batch execution

Digitally transform your factory. Leverage Oracle’s best-in-class capabilities to complete batch with co-products and by-products.

Cost management

Effectively monitor batch manufacturing costs and variances by plant and determine the root causes for cost variances.

Closed-loop quality

Capture and analyze quality data. Predict potential issues and take corrective action throughout the manufacturing lifecycle.

Genealogy

Capture genealogy for track and trace of lot and serialized products to maintain compliance with local regulations.

Compliance

Comply with regulations by capturing electronic records and signatures at the critical points for good manufacturing practices (GMPs).

Mixed-mode manufacturing

Production execution flexibility

Execute production based on make-to-stock, make- to- order, configure-to-order, engineer-to-order, or make-to-project.

Differentiate by work method

Determine the ideal method for each stage of production such as using process for bulk processing and discrete for packaging.

Consistent processes

Share the same dispatch list, production-reporting, and quality inspections for a consistent shop floor experience.

Cost management

Effectively monitor manufacturing costs and variances by plant and determine the root causes for cost variances.

Closed-loop quality

Capture and analyze quality data. Predict potential issues and take corrective actions throughout the manufacturing lifecycle.

Genealogy and compliance

Capture genealogy for track-and-trace of lot and serialized products to maintain compliance with local regulations.

Production scheduling

Create high-quality, executable schedules

Use real-time resource availability and work orders to create feasible schedules that take the latest material, capacity, and calendar constraints into account. Increase factory throughput and reduce work in process inventory, waste, and expedites.

Optimize changeovers to minimize downtime

Increase throughput and asset utilization by grouping work orders based on your industry attributes, minimizing changeovers and idle time.

Resolve shop floor bottlenecks

Schedule work order operations with your desired attribute sequence to maximize the efficiency of your production lines. Visualize how work order operations are allocated to resources and reduce bottlenecks by offloading to alternate resources.

Simulate the impact of schedule changes

Easily inspect schedules and analyze production issues in a visual Gantt chart. Make drag-and-drop adjustments and edit dispatch lists as necessary. Run quick, in-line simulations and what-ifs to resolve issues.

Minimize the effect of unplanned downtime

Run and repair schedules dynamically to deal with unexpected machine outages, labor shortages, material delays, and changes in order priorities. Release adjusted schedules as needed during the day for instant shop floor execution.

Proactively monitor your shop floor

Evaluate how your factory is scheduled at a glance, with interactive analytics that reveal insights about changeover time, resource utilization, and late orders.

Project-driven supply chain

Serve multiple projects

Segment your supply chain operations to serve multiple projects from a common set of resources in a plant.

Execute by project

Manage order management, procurement, material, manufacturing, and service by a specific project.

Cost by project

Ensure the right material, resources, and costs are allocated to the right project.

Differentiate by customer

Manufacture and purchase products including deal-specific R&D or services.

Project-based billing

Capture project expenditures in Oracle Project Portfolio Management and bill based on project contract rules.

Contract manufacturing

Flexible production

Outsource one or multiple work order operations, an assembly, or a sub-assembly based on your plant’s internal and external capacity.

Supplier collaboration

Streamline contract manufacturing processes by using the supplier portal. Collaborate with suppliers using industry standard protocol.

Consign material

Buy material and consign it to your contract manufacturer, without losing visibility to your financial liability.

Multi-tier visibility

Plan, execute, and view status across all internal and external manufacturing sites, allowing you to control quality and cost.

Orchestrated processes

Orchestrate the movement of goods and the financial transactions to buy and sell the materials and the build service.

Genealogy, quality, and compliance

Capture genealogy for track-and-trace and manage data quality to maintain your compliance with regulations.

Smart Operations for manufacturing

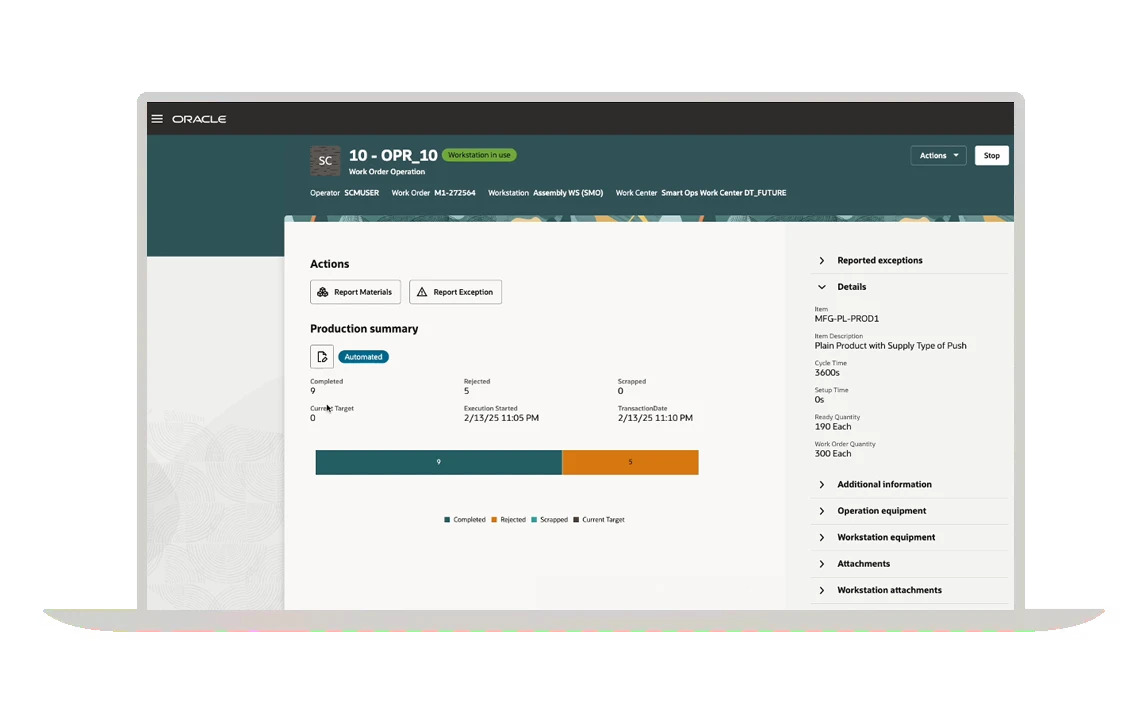

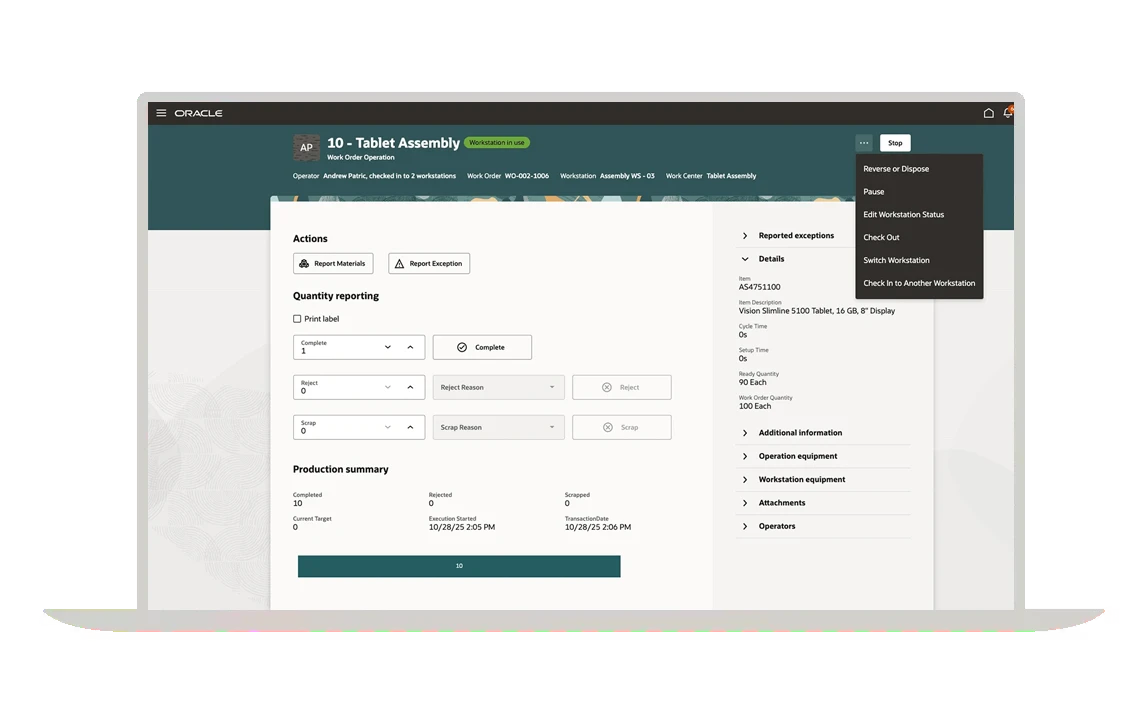

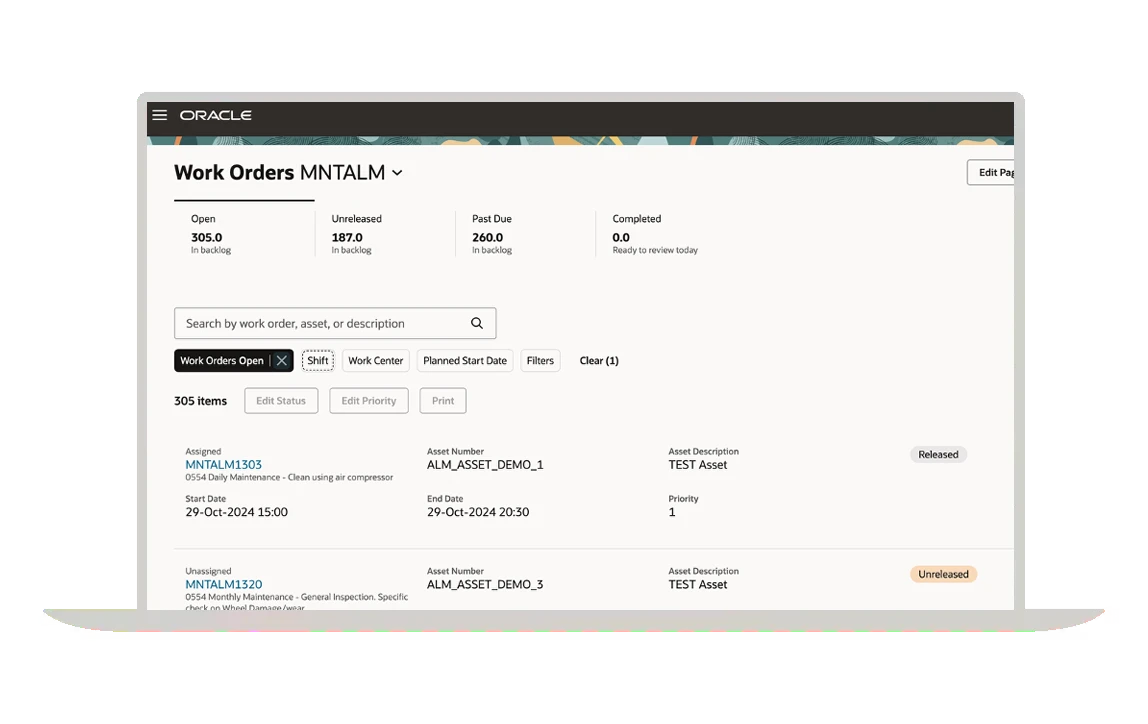

Operator workbench

Empower operators via a digital, frictionless experience, including guided step-by-step instructions and all the information they need to complete their manufacturing tasks.

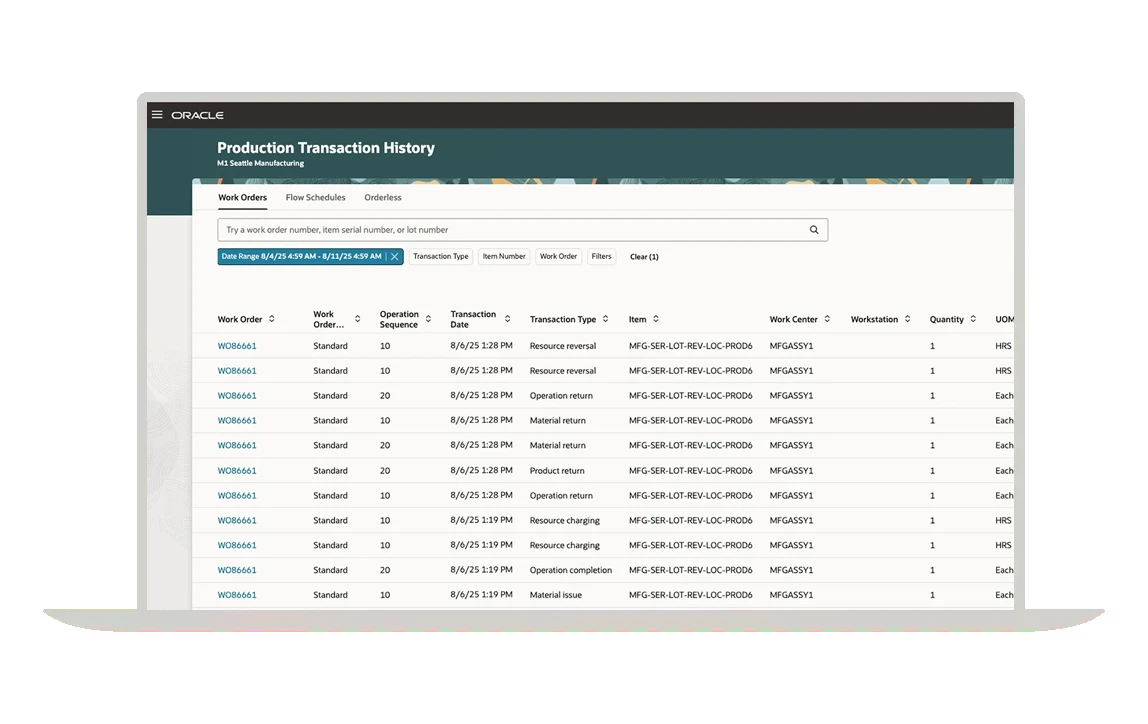

Production supervisor workbench

Equip supervisors with real-time visibility so they can monitor shift performance and make data-driven decisions to resolve issues that interfere with operational performance.

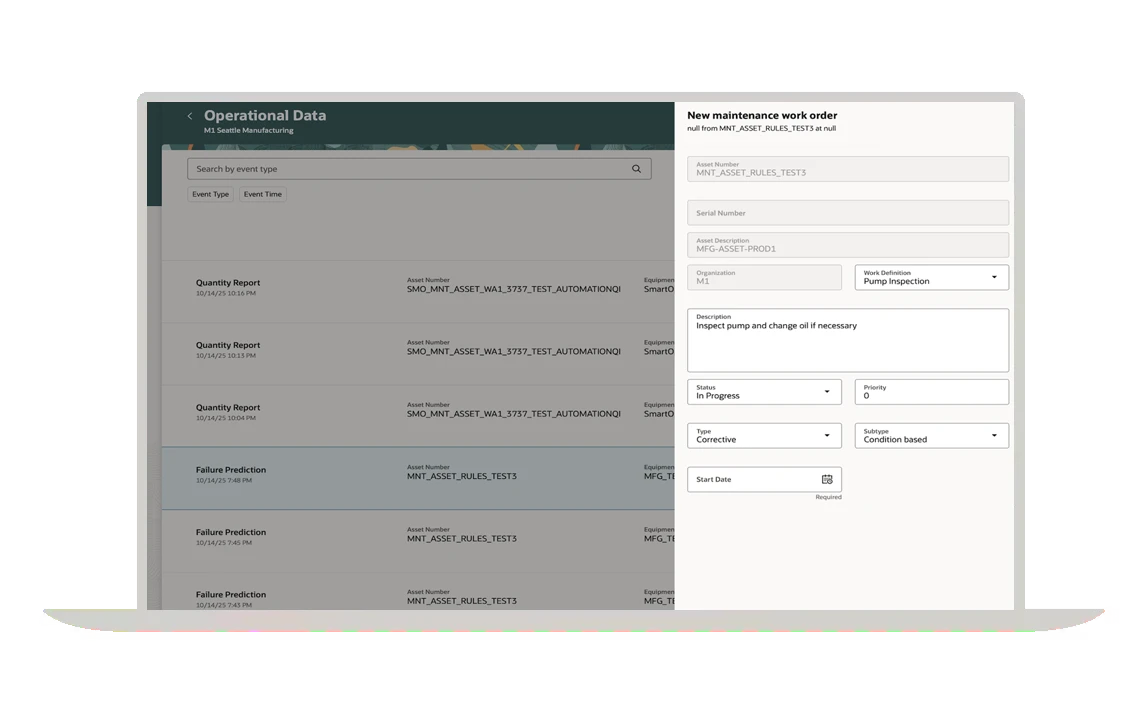

Connected equipment

Automate business processes based on rule-driven machine events from connected equipment. Contextualize real-time operational data with business data and digital technologies to drive execution decisions and processes.

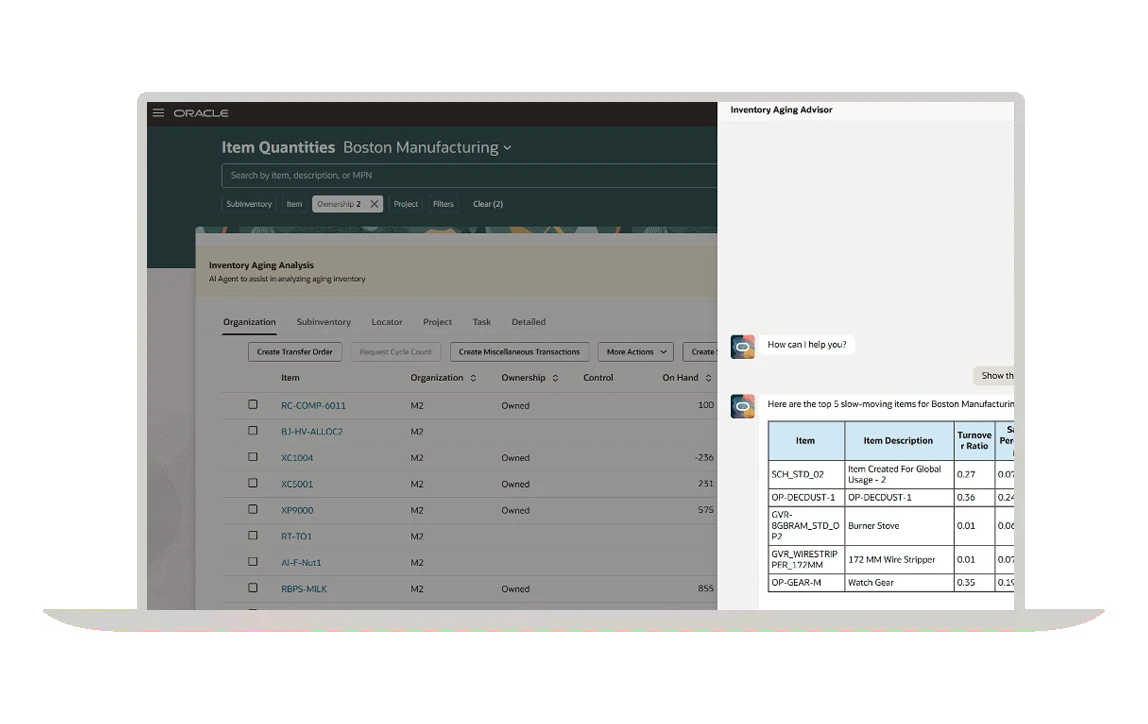

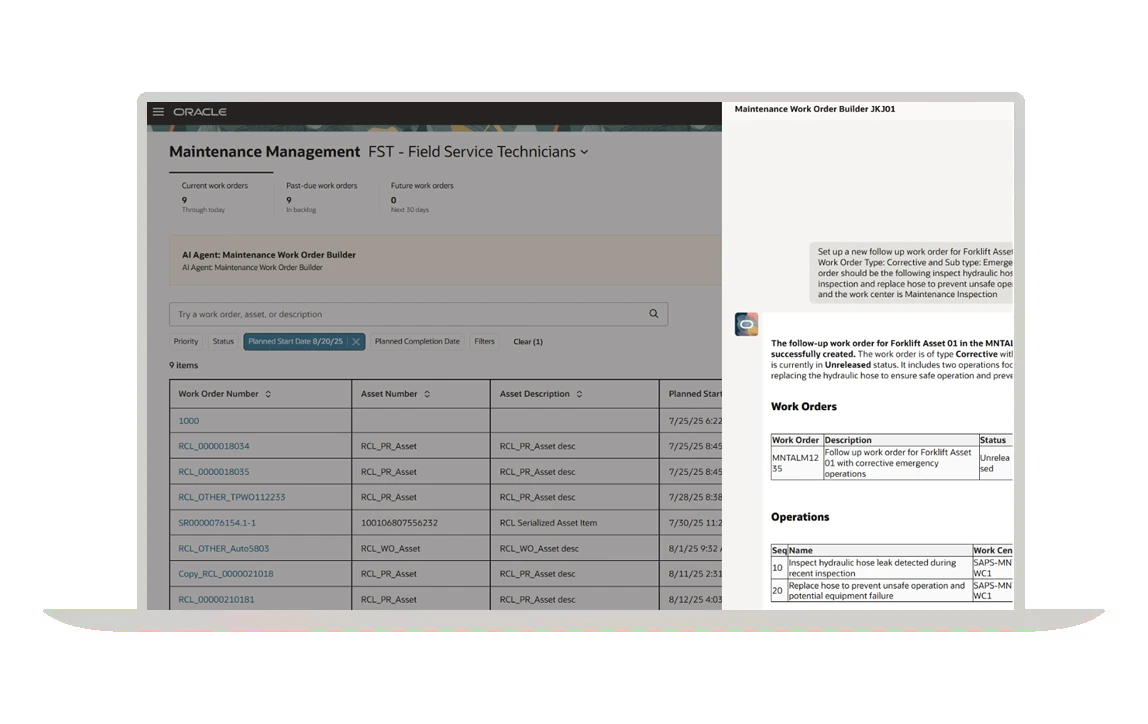

AI-powered platform

Use AI to generate operator shift notes and production shift reports and summaries to reduce the time spent on non–value-added activities.

Oracle a Leader in the IDC MarketScape for Order Orchestration and Fulfillment for Manufacturing

Oracle a Leader in the IDC MarketScape for Order Orchestration and Fulfillment for Manufacturing

The choice of Order Management solutions is clear. See what analysts are saying about Oracle Fusion Cloud Order Management now.

Precision Group improves operational efficiencies with Oracle Cloud Manufacturing

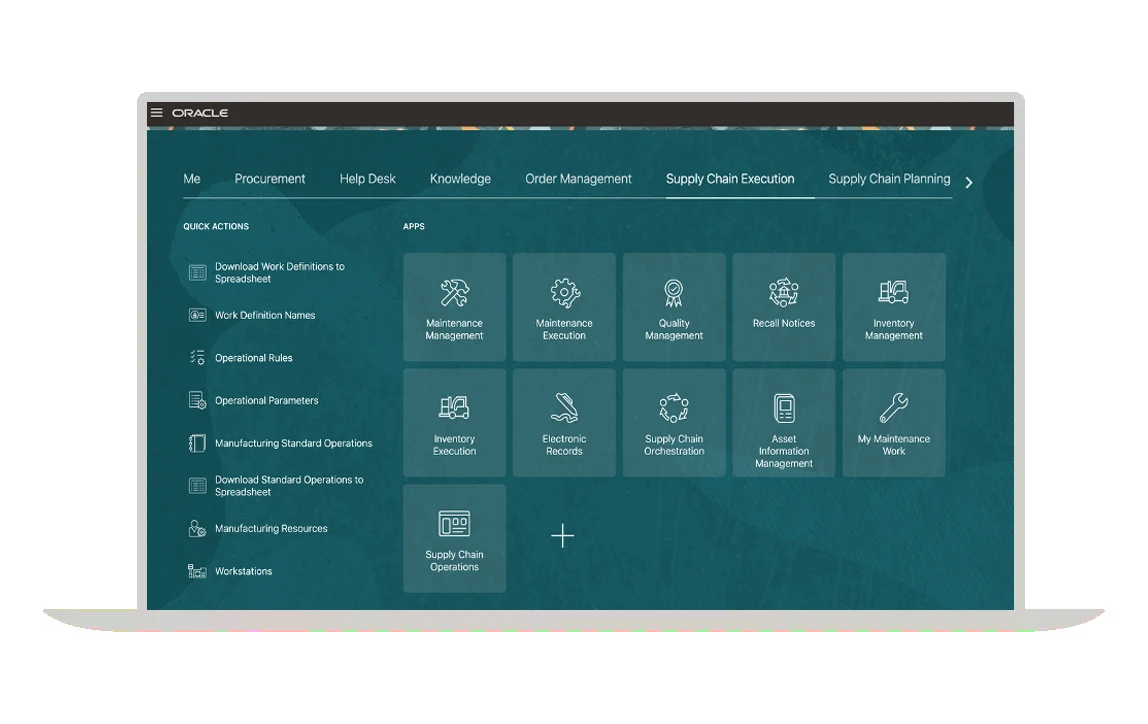

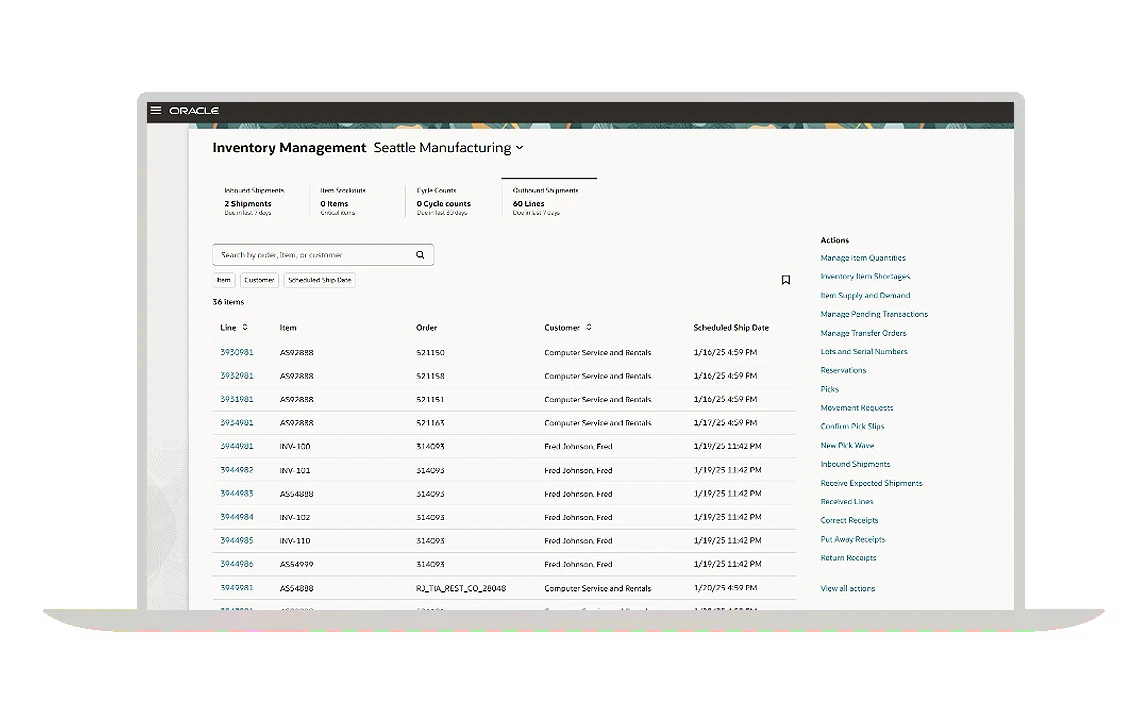

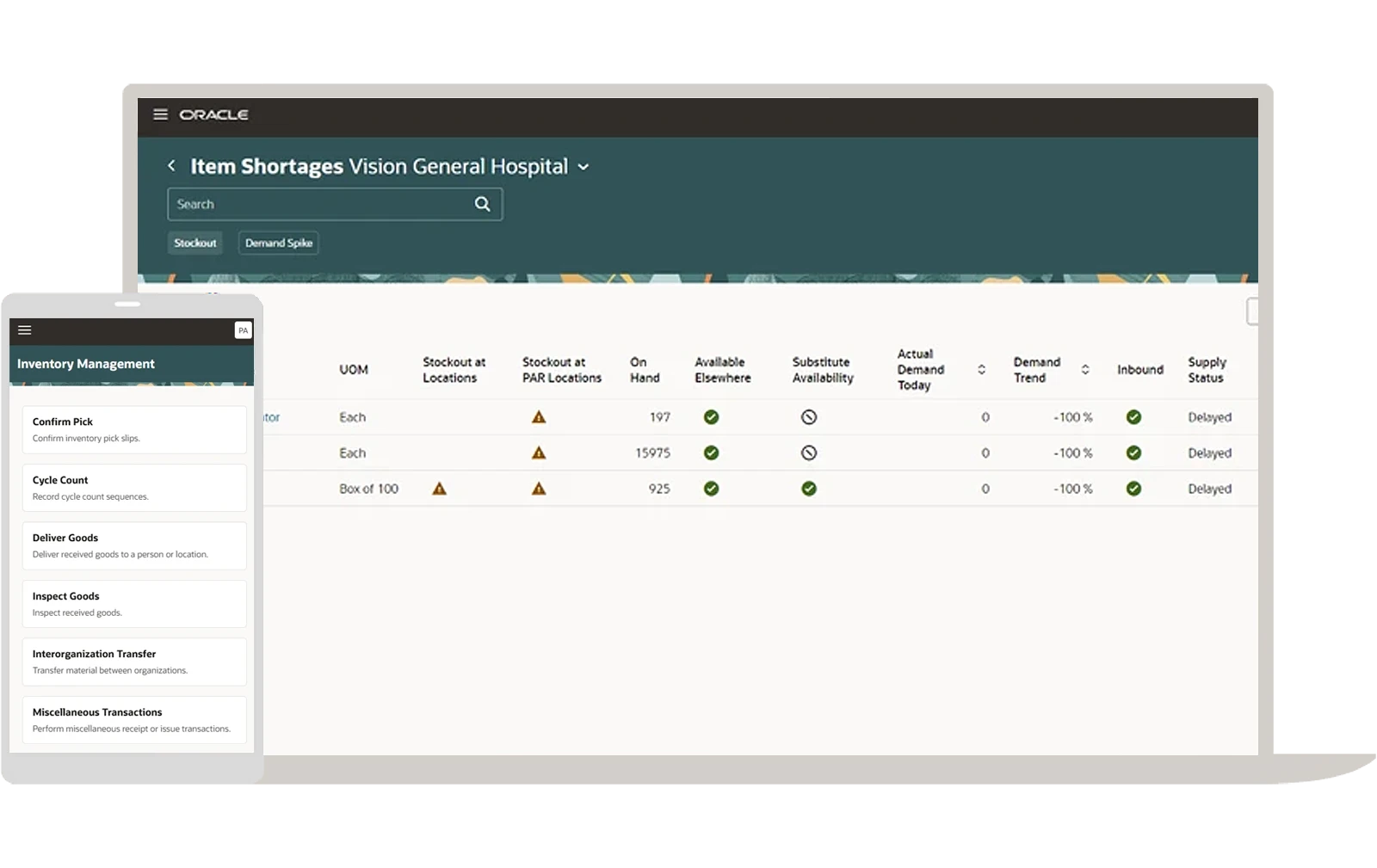

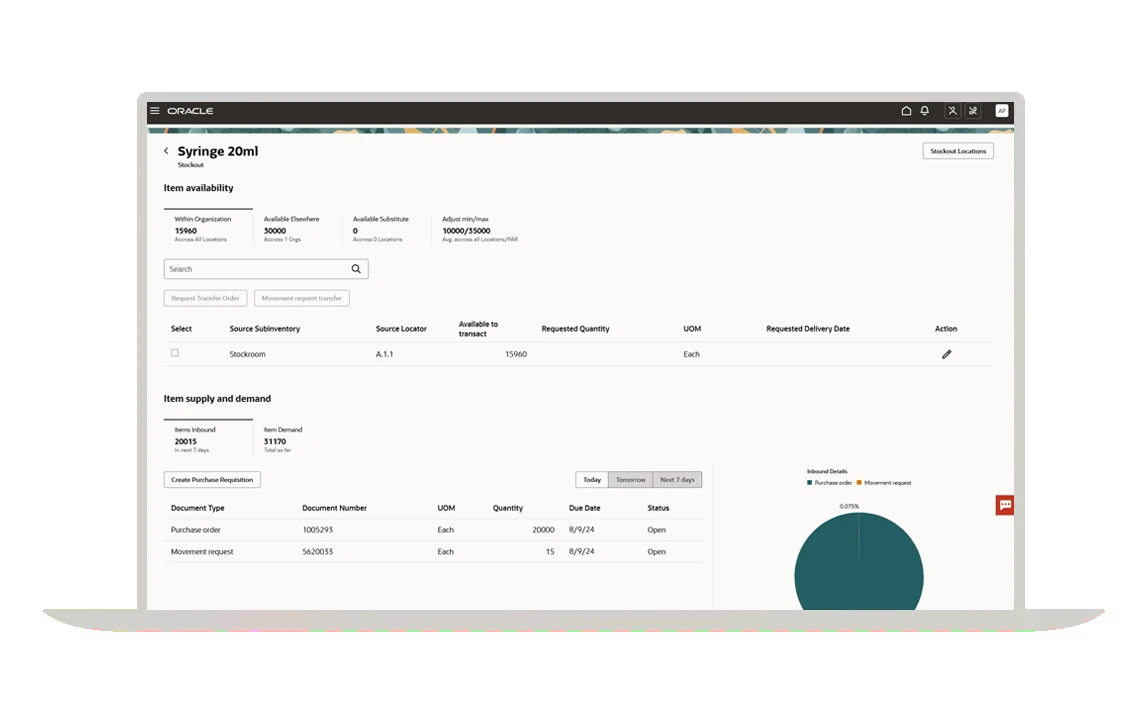

Product Tour—Oracle Fusion Supply Chain Execution

Transform operations with Oracle Fusion Supply Chain Execution

Oracle Manufacturing use cases

Maximize productivity and efficiency

Improve shop floor performance with real-time, actionable insights from AI and predictive analytics. Increase business agility with by automating manufacturing processes.

Improve collaboration across the value chain

Leverage one seamlessly integrated solution and extend processes, visibility, analytics, and execution into contract manufacturers and suppliers.

Improve product quality

Connect items to inspections to define quality attributes, quickly identify defects, solve problems in an auditable manner and implement corrective and preventative actions.

Reduce costs and improve ROI

Streamline and effectively manage your extended supply chain to reduce costs, improve on-time delivery, and make smarter decisions.

Resources

What’s new

Learn what’s new in the latest release of Oracle Cloud Manufacturing.

Readiness training demos and videos

Get an in-depth look at best practices and update capabilities.

Join a community of your peers

Cloud Customer Connect is Oracle's premier online cloud community. With more than 200,000 members, it's designed to promote peer-to-peer collaboration and sharing of best practices, product updates, and feedback.

Develop your Cloud SCM skills

Oracle University provides you with free training and certification you can rely on to ensure your organization’s success, all delivered in your choice of formats.

Related products

Product Lifecycle Management

Accelerate product innovation, development, and commercialization

Maintenance

Drive efficient maintenance with a tightly integrated solution

Get started with smart factory solutions

Smart factory demo

Take a walkthrough with one of our experts.

Smart Manufacturing solution tour

Explore the suite on your own.

Contact SCM sales

Talk to a team member about Oracle Cloud Manufacturing.