Maintenance cost management

Maintenance cost tracking

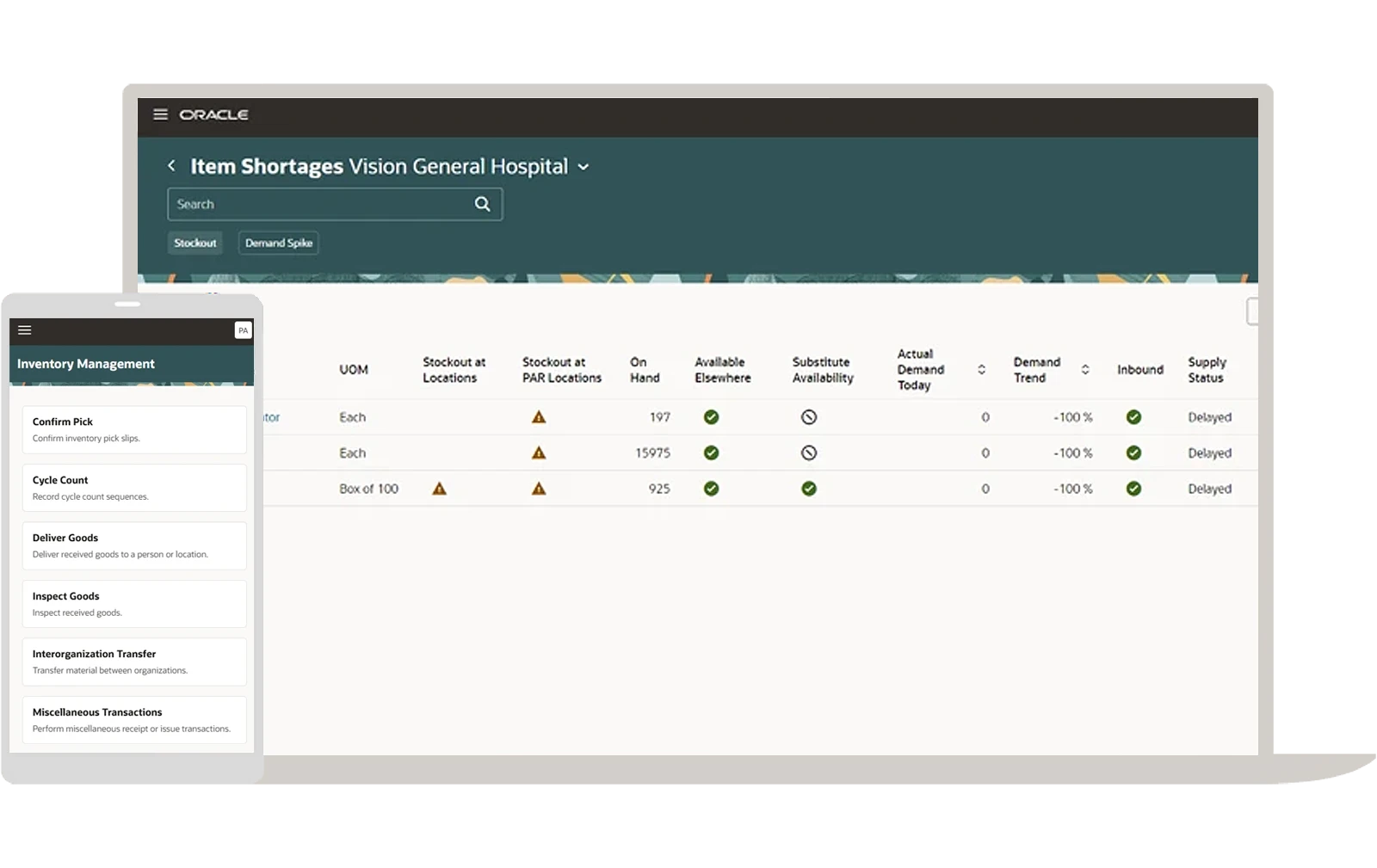

Monitor and manage costs at a granular level, adjusting details by item. Track actual costs for high-value spare parts while applying average costs for less critical items.

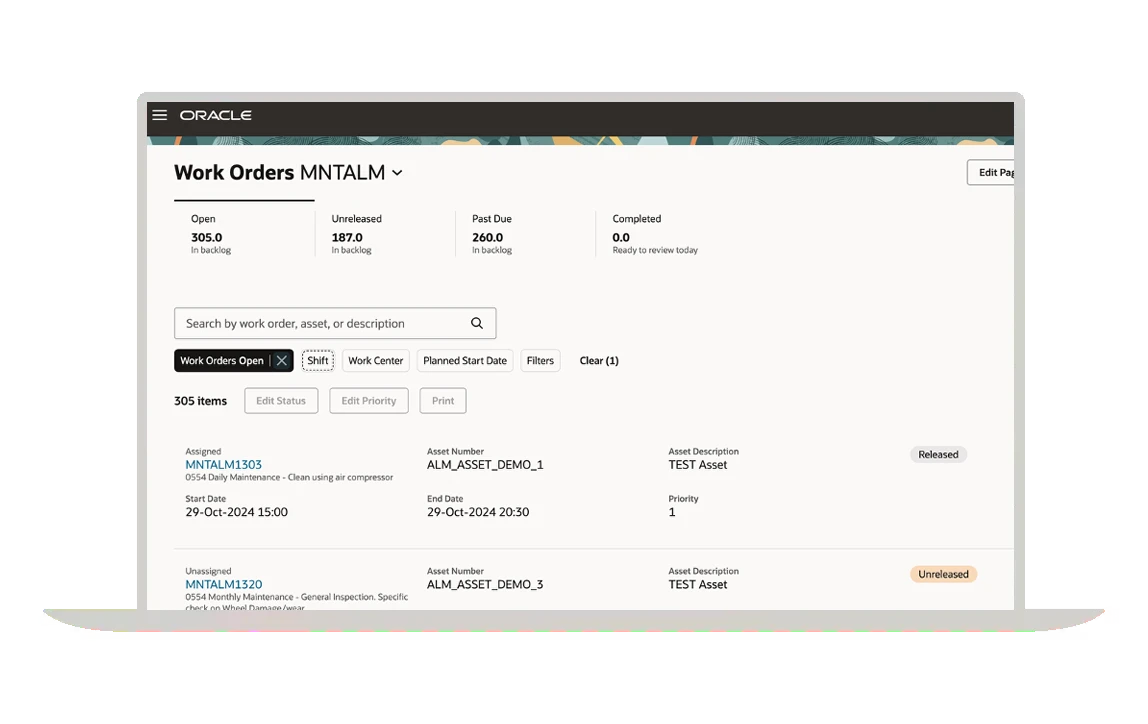

Work cost monitoring

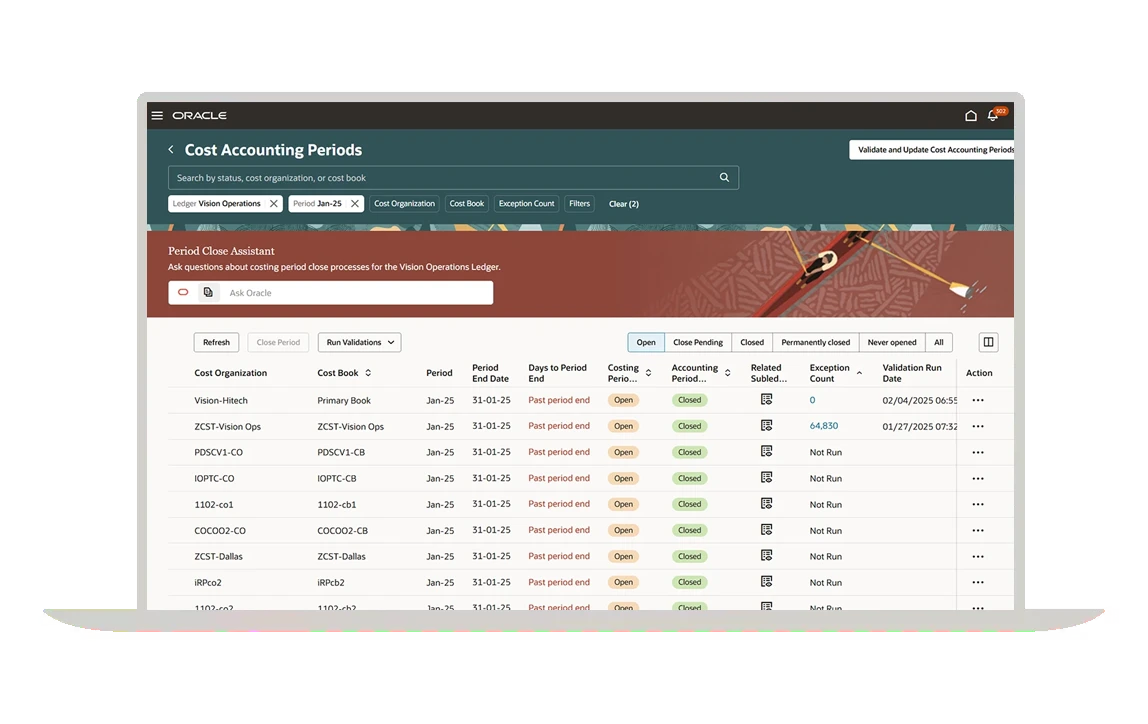

Monitor material, labor, and other costs throughout the entire lifecycle of the work order. The work order cost accounting integration helps ensure cost accounting distributions are created quickly and accurately.

Multiple cost methods and representations

Use one or more costing methods—standard, actual, average, periodic average, and multiple representations of cost with cost books. This approach enables more flexible, and tailored cost tracking, allowing organizations to optimize budgeting, forecasting, and financial analysis across various costing methods and accounting standards.

Insight-driven decisions

Analyze costs by asset, work order, or type of work, and get the insight you need to control material and resource costs. Determine a repair versus replace strategy by analyzing work order charges and overall asset costs. Track item costs at any desired level of granularity (for example, serial, lot, and so on), and track true costs using landed costing.